Maretron® N2KView®

Vessel Monitoring and Control Software for NMEA 2000® Networks

User’s Manual

Revision 6.3.0

Copyright © 2021 Carling Technologies, Inc.

60 Johnson Ave.

Plainville, CT 06062 USA

All Rights Reserved

Maretron Manual Part #: M001401

Revision History

|

Rev. |

Description |

|

1.0 |

Original document. |

|

2.2 |

New release corresponding to Version 2.2 of N2Kview |

|

2.3 |

New release corresponding to Version 2.3 of N2Kview |

|

2.4 |

New release corresponding to Version 2.4 of N2KView |

|

2.5 |

New release corresponding to Version 2.5 of N2Kview |

|

2.6 |

New release corresponding to Version 2.6 of N2Kview |

|

3.0 |

New release corresponding to Version 3.0 of N2Kview |

|

3.2 |

New release corresponding to Version 3.2 of N2Kview |

|

3.4 |

New release corresponding to Version 3.4 of N2Kview |

|

3.5 |

New release corresponding to Version 3.5 of N2Kview |

|

3.6 |

New release corresponding to Version 3.6 of N2Kview |

|

3.6.1 |

Update for version 3.6.1 of N2KView |

|

3.6.2 |

Update for version 3.6.2 of N2KView |

|

3.6.3 |

Update for version 3.6.3 of N2KView |

|

4.0.0 |

Update for version 4.0.0 of N2KView |

|

5.0.0 |

Update for version 5.0.0 of N2KView |

|

5.0.6 |

Update for version 5.0.6 of N2KView |

|

5.0.15 |

Update for version 5.0.15 of N2KView |

|

5.1.0 |

Update for version 5.1.0 of N2KView |

|

6.0.0 |

Update for version 6.0.0 of N2KView |

|

6.0.12 |

Update for version 6.0.12 of N2KView |

|

6.0.14 |

Update for version 6.0.14 of N2KView |

|

6.3.0 |

Update for version 6.3.0 of N2KView |

Table of Contents

6.1 Install IPG100 or USB100 if applicable

6.2 Get the N2KView Install Program

6.3.1 Accept the License Agreement

6.3.3 Continue with the Installation

8.1 Data Security and Encryption

8.2 Using Maretron’s Cloud Server

9.1.5 Favorite Screens and Parameter Display

9.1.6 Protecting the System Configuration

9.3.1 Changing Between User-Defined screens

9.3.3 Switching Between Day and Night Mode

9.3.4 Switching Between Windowed and Full-Screen Configurations

9.4 Commands & Settings Dialog

9.4.8 Power Management Sub-Menu

9.5.2 Active Button Gray (4x1)

9.5.4 Active Button Gray (2x1)

9.5.5 Active Button Invisible (1x1)

9.5.6 Air Conditioning / Heating

9.5.10 Bar Graph Vertical (1x2)

9.5.12 Circuit Breaker / Rocker Switch (2x1)

9.5.13 Rocker Switch Left/Right (6x1)

9.5.19 Digital Invisible (2x1)

9.5.33 Line Graph / Depth Graph / Indicator Graph

9.6.5 Air Conditioning / Heating

9.6.7 BNWAS (Bridge Navigation Watch Alarm System)

9.6.11 Electrical Distribution

9.6.23 NMEA 2000 – N2KView Connection

9.6.36 Transmission (Twin Disk)

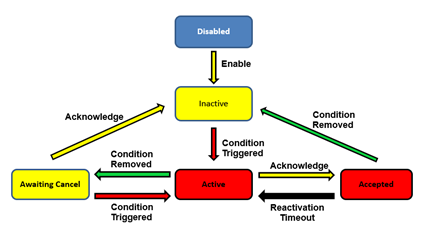

10.2.4 Vessel Alert Operating Modes

10.2.6 Available Alert Classes

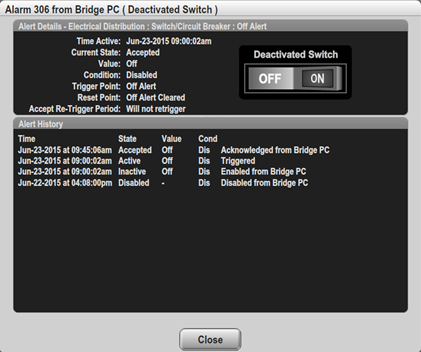

10.3.4 Alert Log for all Alerts

10.4.8 Alerts for each Parameter

10.4.17 Electrical Distribution

10.4.28 NMEA 2000 – N2KView Connection

10.4.39 Transmission (Twin Disk)

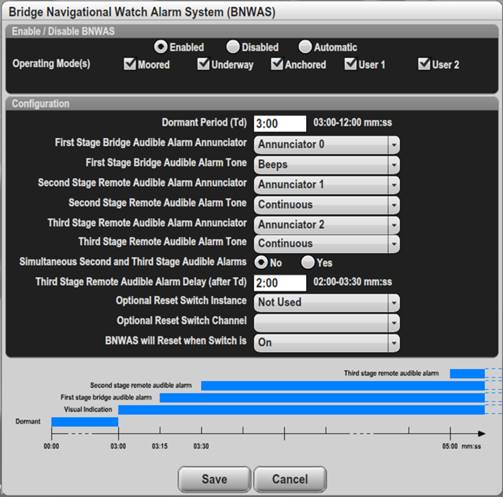

11 BNWAS (Bridge Navigation Watch Alarm System

11.1.1 Enabled / Disabled / Automatic Control

11.1.3 Visual Indication Stage

11.1.4 First Stage Bridge Audible Alarm

11.1.5 Second Stage Remote Audible Alarm

11.1.6 Third Stage Remote Audible Alarm

11.1.7 Optional Reset Switch Instance

11.1.8 Optional Reset Switch Channel

11.1.9 BNWAS will Reset when the Switch is

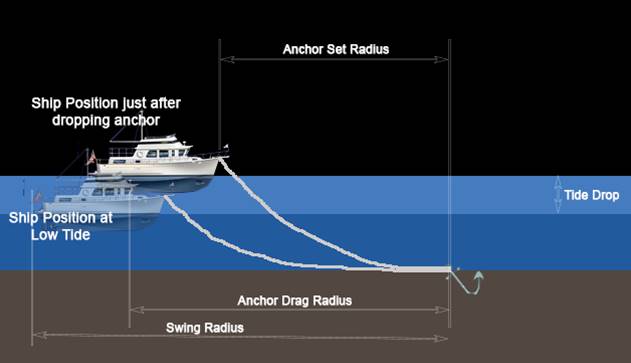

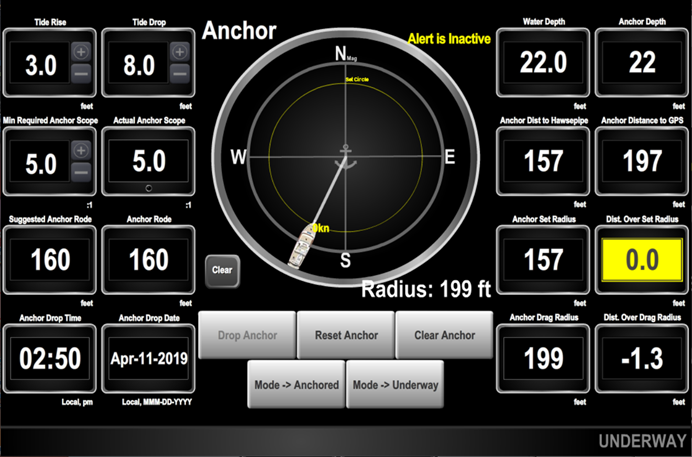

13.1 Glossary of Terms used in Anchoring

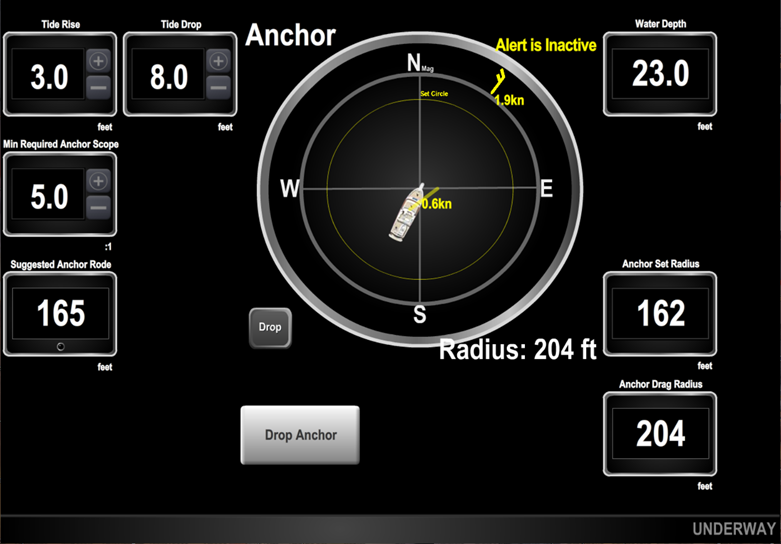

13.2 How is N2KView going to help you anchor

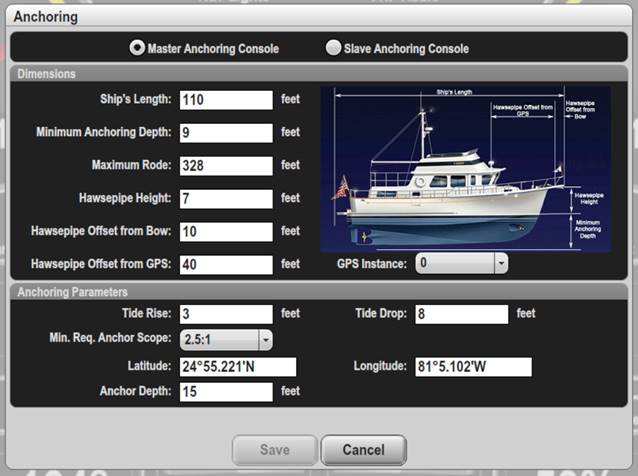

13.3 Configuring N2KView Anchoring.

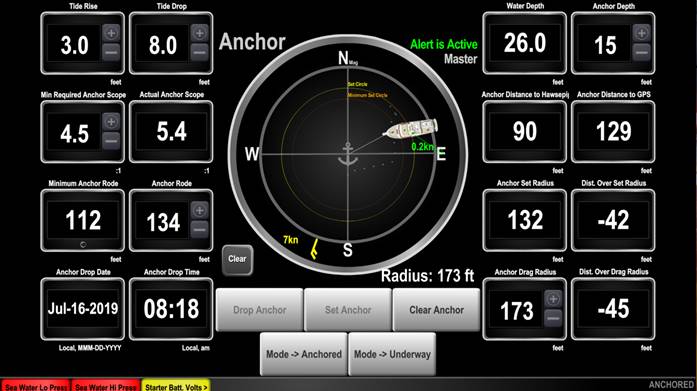

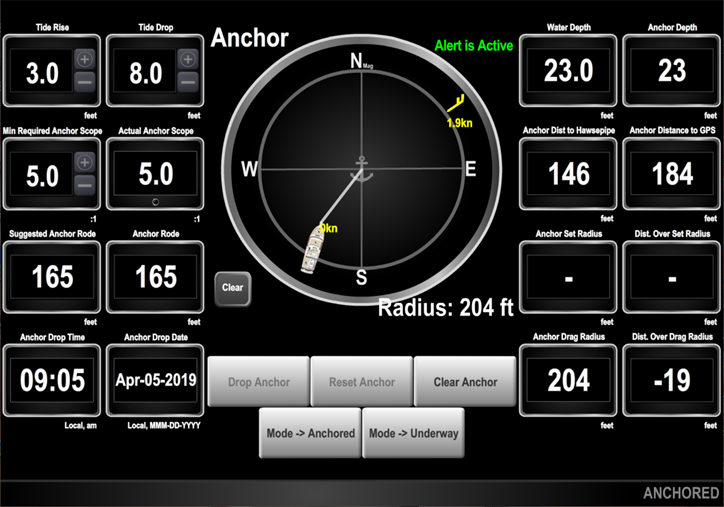

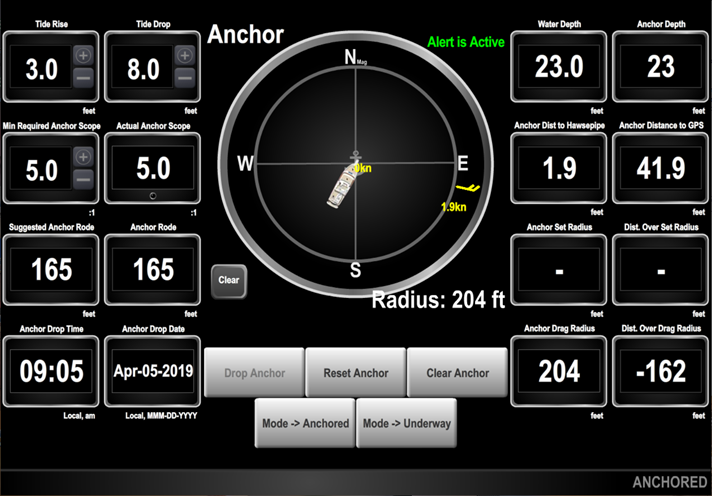

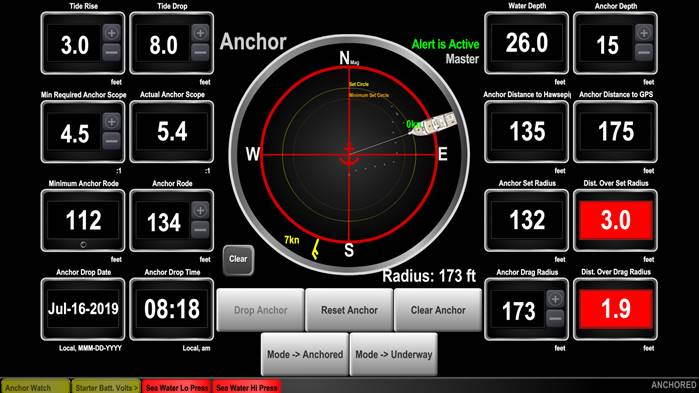

13.7 Dragging you anchor while Setting

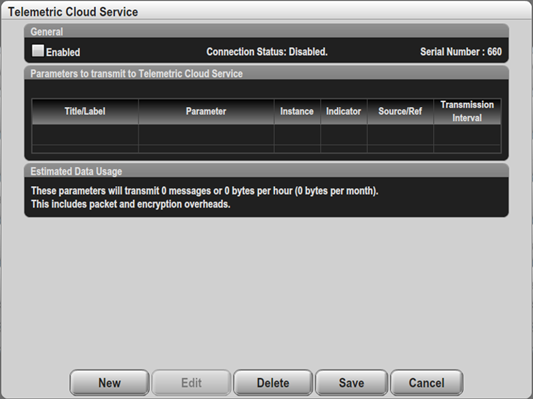

15 Send data to the Telemetric Cloud Service

15.1.1 Maretron Real Time Cloud Service

15.1.2 Maretron Telemetric Cloud Service

15.2 Telemetric Cloud Service Dialog

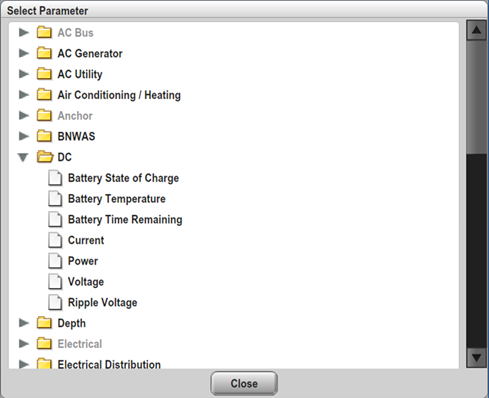

15.2.2 Selecting Parameters to be Transmitted

15.2.4 Maximum amount of data that can be transmitted

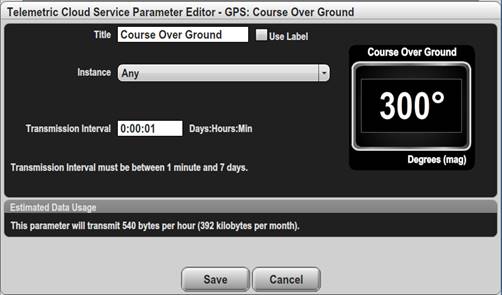

15.3 Telemetric Cloud Service Parameter Editor

15.3.7 Also Transmit on Change

16.2 Building the N2KView Mobile Screens

16.2.1 Other Configuration Data

16.3 Send the Configuration to the IPG100

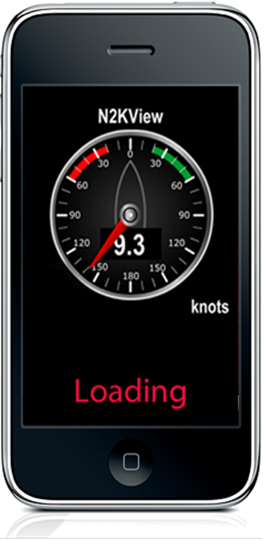

16.4 Starting N2KView® on the iPhone

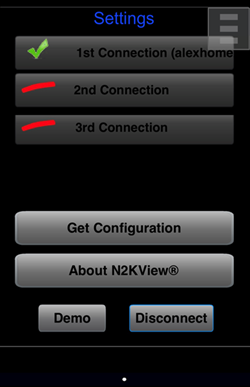

16.5.3 Cloud Connection Method

16.6 Download the Configuration File

19 Maretron Software License Agreement

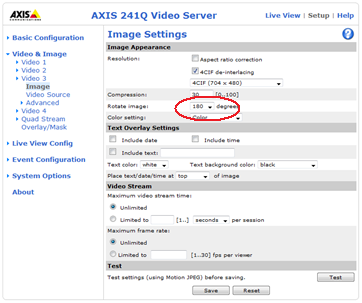

20 Example of Setting up the AXIS Quad Video Server 241Q

20.1 Install the AXIS Camera Manager

Table of Figures

Figure 1 – N2KView Installation License Agreement Page

Figure 2 – Additional N2KView Installation Tasks.

Figure 3 – Maretron N2KView Installation Wizard Completion Page

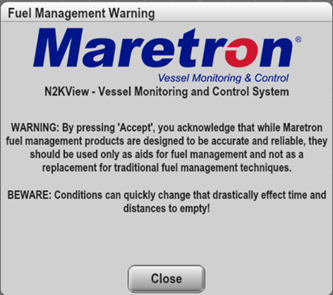

Figure 4 – N2KView Startup Disclaimer Screen

Figure 5 – N2KView Window with Tabs Displayed

Figure 6 – NMEA 2000® Connection Dialog

Figure 7 – Setting Instance Number

Figure 8 – N2KView Opening Dialog

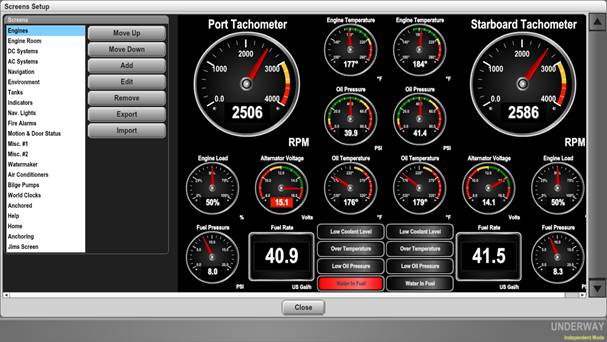

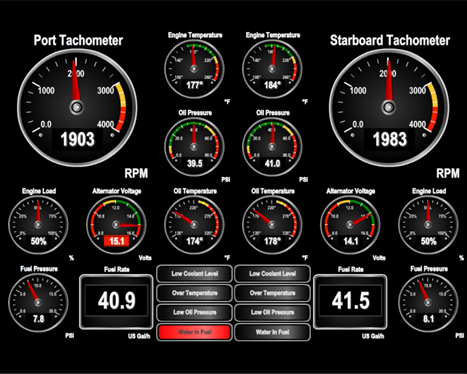

Figure 9 – Typical N2KView Screen

Figure 10 – N2KView Commands & Settings Dialog.

Figure 12 – Clean Screen Dialog

Figure 13 – Configuration Sub-Menu

Figure 14 – General Configuration Dialog

Figure 15 – Load Configuration dialog

Figure 16 –TSM/MBB Load Configuration Dialog

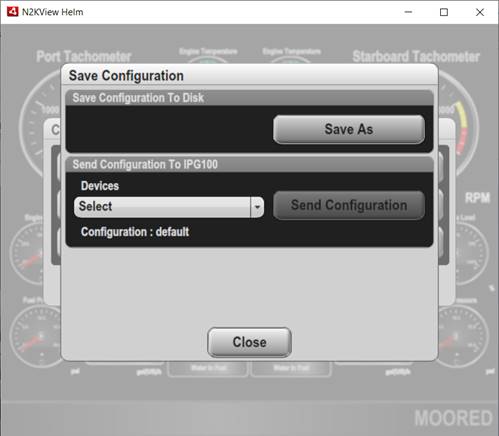

Figure 17 – Save Configuration Dialog

Figure 18 – TSM/MBB Save Configuration Dialog

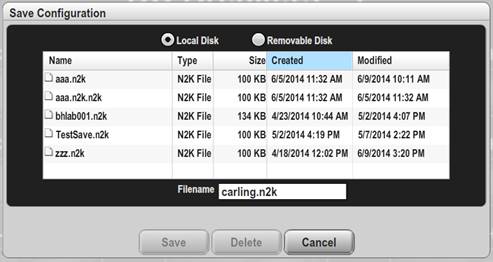

Figure 20 – Connections Settings Dialog

Figure 21 – Breaker Lockout Dialog

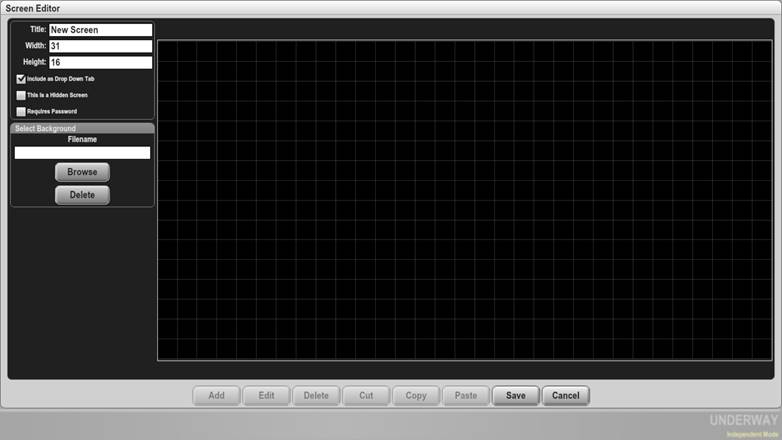

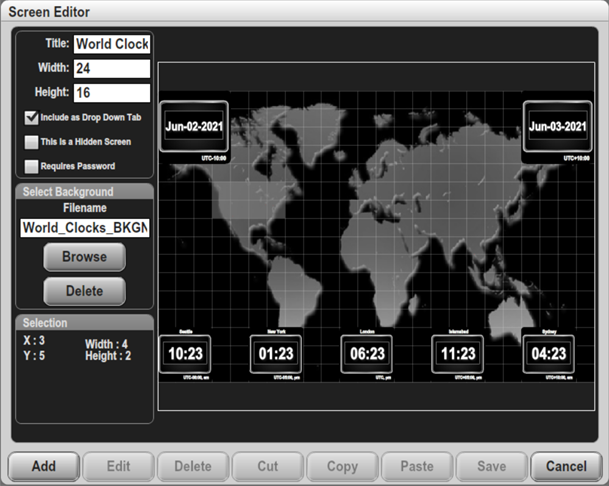

Figure 22 – Screens Setup Screen

Figure 24 – Selected Component in Screens Setup Mode

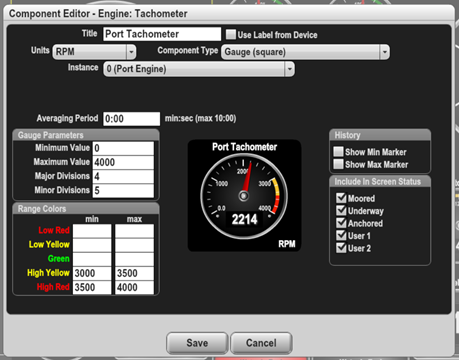

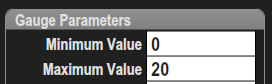

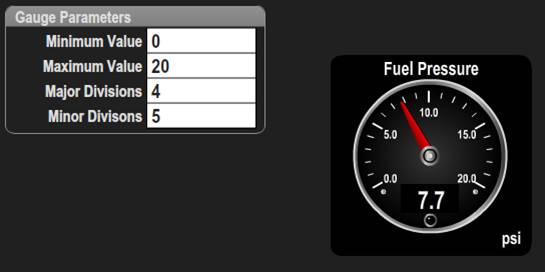

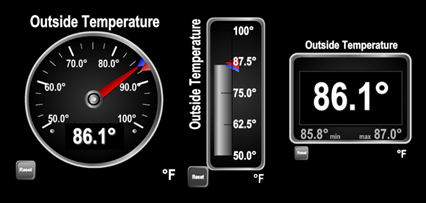

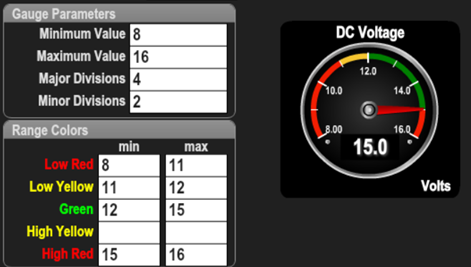

Figure 26 – Example of setting Divisions and Ranges

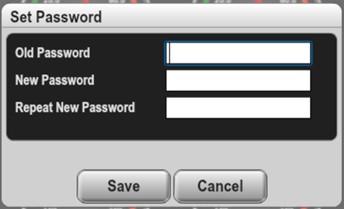

Figure 27 – Set Password Dialog

Figure 28 – Units Setup Dialog

Figure 29 – Active Button (4x1) Example

Figure 30 – Active Button Gray (4x1) Component Example

Figure 31 – Active Button (2x1) ComponentExample

Figure 32 – Active Button Gray (1x1) Component Example

Figure 33 – Active Button Invisible (1x1) Component Example

Figure 34 – Air Conditioner Component Example

Figure 35 – Q-Logic Air Conditioner Component with Aux Heat

Figure 36 – Analog Clock Component Example

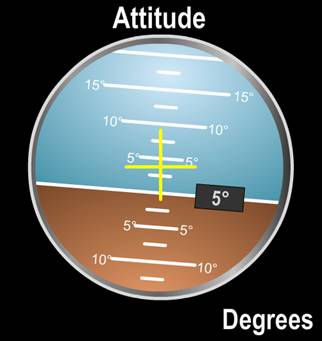

Figure 38 – Attitude Indicator Example

Figure 39 – Bar Graph Component Example

Figure 40 – Bar Graph Example with Min Max Marks

Figure 41 – Borderless Bar Component Example

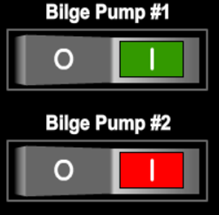

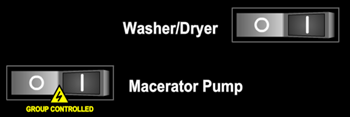

Figure 42 – Rocker Switch Component Examples

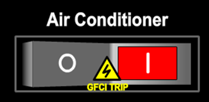

Figure 44 – GFCI Tripped Breaker

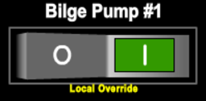

Figure 45 – Breaker with Local Override

Figure 46 – Breaker under Timer Control

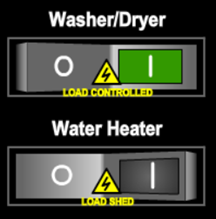

Figure 47 – Locked Rocker Switch

Figure 49 – Group Controlled Rocker Switch

Figure 50 – Alert Controlled Rocker Switch

Figure 51 – Load Controlled Rocker Switch

Figure 52 – Rocker Switch (6x1) Component Example.

Figure 53 – Vertical Switch Component Examples

Figure 54 – Digital Component Examples

Figure 55 – Digital (4x3) Component Example

Figure 56 – Digital (3x2) Component Example

Figure 57 – Digital (2x1) Component Example

Figure 58 – Digital Invisible (2x1) Component Example

Figure 59 – All Digital Components

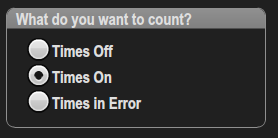

Figure 60 – Digital Counter Component Example

Figure 61 – Dimmer (2 Button) Component Example

Figure 62 – Dimmer (3 Button) Component Example

Figure 63 – Ice Maker Component Example

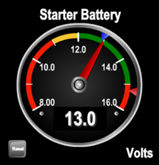

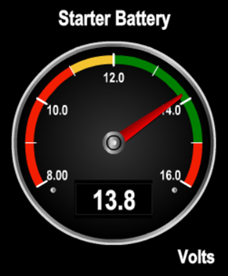

Figure 64 – Gauge Component Example

Figure 65 – Gauge with Min Max Markers

Figure 66 – Gauge (5x6) Component Example

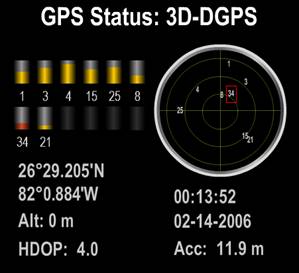

Figure 67 – GPS Status Component Example

Figure 68 – Head Up Rose Component Example

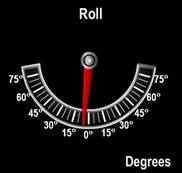

Figure 69 – Inclinometer Component Example

Figure 70 – Inclinometer with Min Max Marks

Figure 71 – Indicator (4x1) Component Example

Figure 72 – Indicator (2x1) Component Example

Figure 73 – Indicator (1x1) Component Example

Figure 74 – Indicator Beam Examples

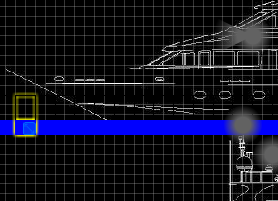

Figure 75 – User Defined Screen with Indicator Beams

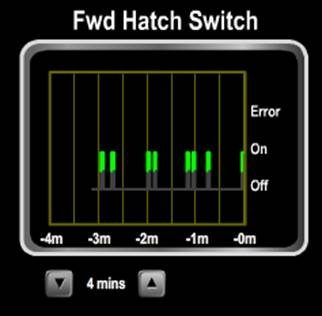

Figure 76 – Line Graph Component Example

Figure 77 – Depth Graph Component Example

Figure 78 – Indicator Graph Example

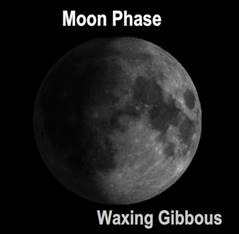

Figure 79 – Moon Phase Component Example

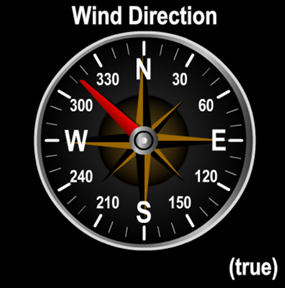

Figure 80 – North Up Rose Component Example

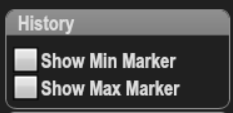

Figure 81 – North Up Rose with History Markers

Figure 82 – Backlit Pushbutton (1x1) Component Examples

Figure 83 – Backlit Pushbutton (2x1) Component Examples

Figure 84 – Metallic Pushbutton (1x1) Component Examples

Figure 85 – Metallic Pushbutton (2x1) Component Examples

Figure 86 – Pushbutton (4x1) Component Examples

Figure 87 – Invisible Push Button (1x1) Component Example

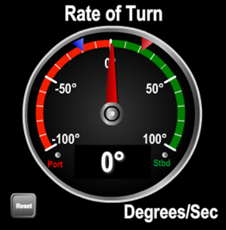

Figure 88 – Rate of Turn Component Example

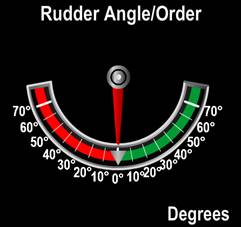

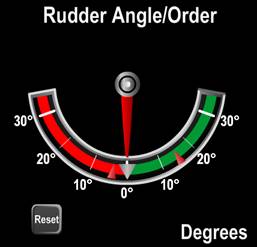

Figure 89 – Rudder Angle Component Example

Figure 90 – Rudder Angle with Min Max Marks

Figure 91 – Example Screen with Screen Status Components

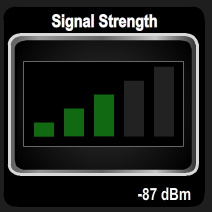

Figure 92 – Signal Strength Component Example

Figure 93 – Status Bar (28x1) Component Examples

Figure 94 – Status Bar (12x1) Component Examples

Figure 95 – Status Bar (8x1) Component Examples

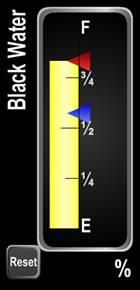

Figure 96 – Tank Component Example

Figure 97 – Tank Component Example with Min Max Marks

Figure 98 – Text Component Example

Figure 99 – Multi-line Text Component Example

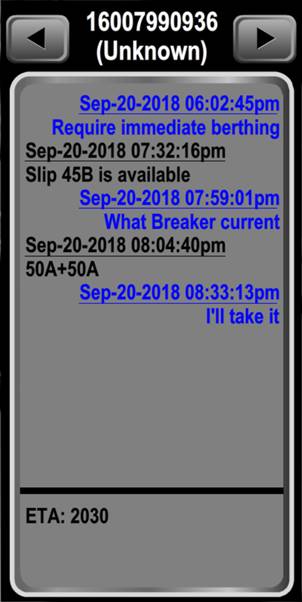

Figure 100 – Text Message (SMS) Component Example

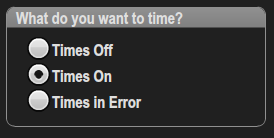

Figure 101 –Timer Component Example

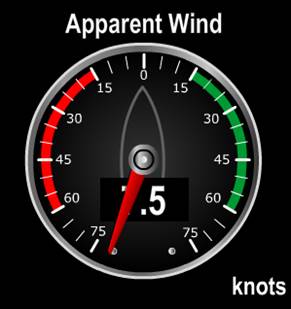

Figure 102 – Wind Angle Component Example

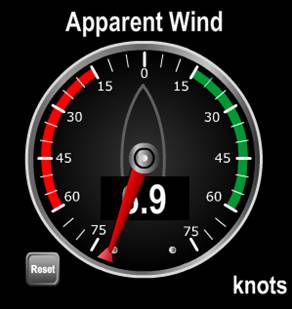

Figure 103 – Wind Angle Component with Min Max Marks

Figure 104 – Wind Close Angle Component Example

Figure 105 – Close Angle Component with Min Max Marks

Figure 106 – Video Component Examples

Figure 107 – 3:4 Video (No Border)Component Examples

Figure 108 – 4:3 Video (No Border) Component Examples

Figure 109 – 16:9 Video (No Border) Component Examples44

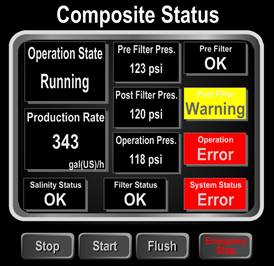

Figure 110 – Watermaker Component Example

Figure 111 – Watermaker with request for Confirmation

Figure 112 – Fuel Management Warning Screen

Figure 114 – Over Full Alert Status Bar

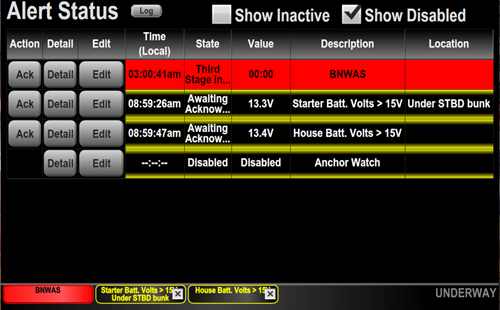

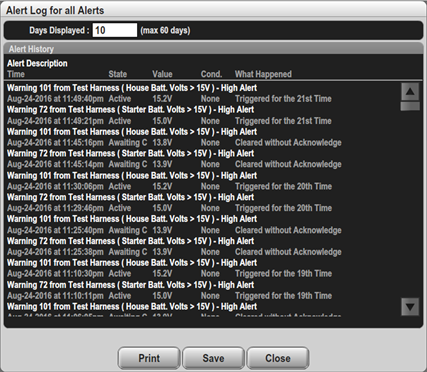

Figure 116 – Alert Status Screen

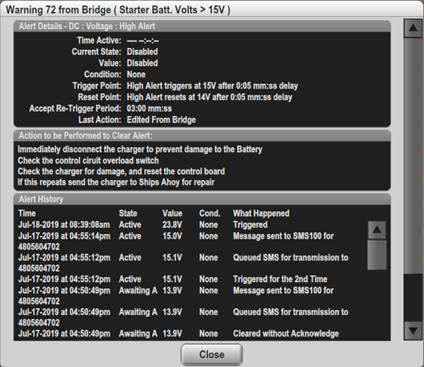

Figure 117 – Alert Detail Dialog

Figure 118 – Alert Table Editor

Figure 119 – Alert Table Editor

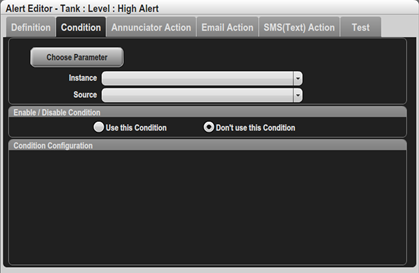

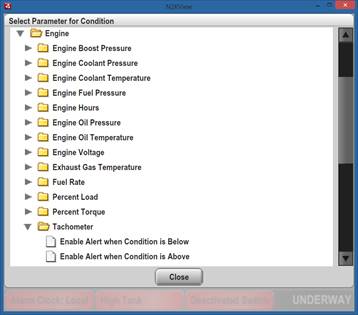

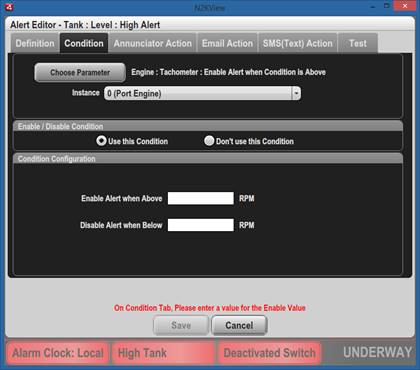

Figure 120 – Alert Editor Example

Figure 121 – Alert Editor – Definition Section

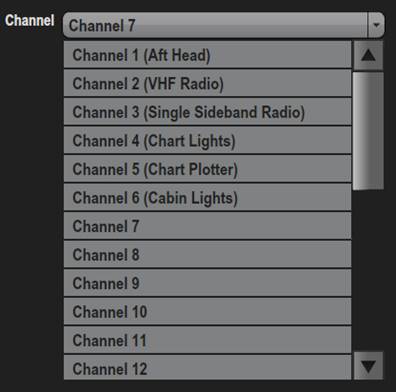

Figure 122 – Channel Drop Down List

Figure 123 – Instance Drop Down List

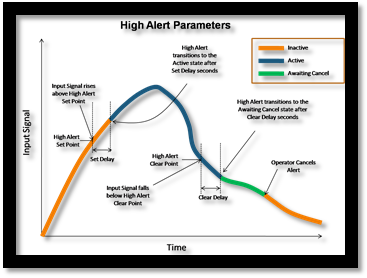

Figure 124 – High Alert Parameters

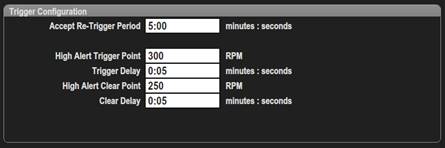

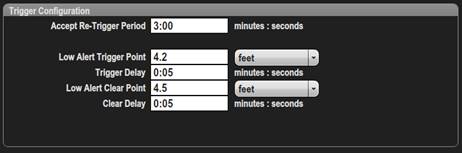

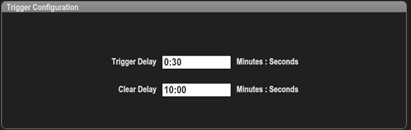

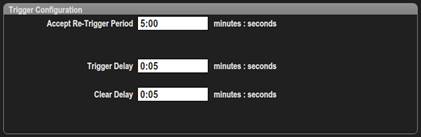

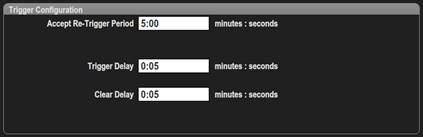

Figure 125 – Trigger Configuration – High Alert

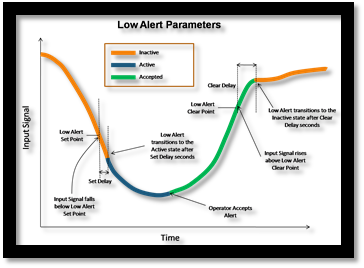

Figure 126 – Low Alert Parameters

Figure 127 – Trigger Configuration – Low Alert

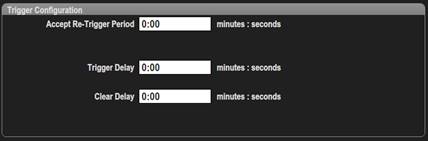

Figure 128 – Trigger Configuration – Data Unavailable Alert

Figure 129 – Trigger Configuration – On Alert

Figure 130 – Trigger Configuration – Off Alert

Figure 131 – Trigger Configuration – Entry On Alert

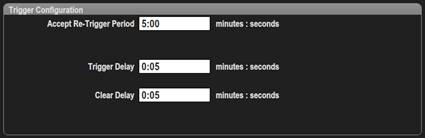

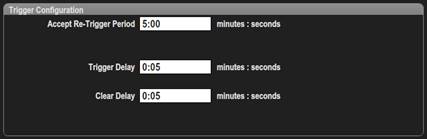

Figure 132 – Trigger Configuration Editor – Tripped Alert

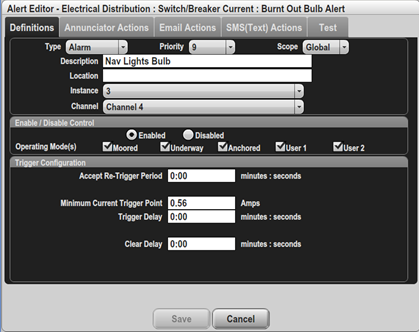

Figure 133 –Configuration – Burnt Out Bulb Alert

Figure 134 – Trigger Configuration Editor – Server Disconnected Alert

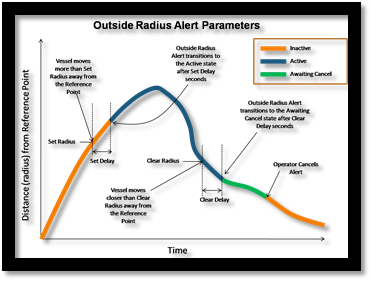

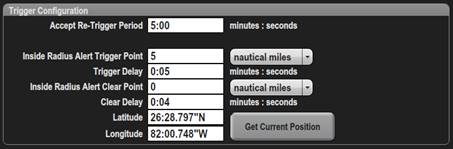

Figure 135 – Outside Radius Alert Parameters

Figure 136 – Trigger Configuration – Outside Radius Alert

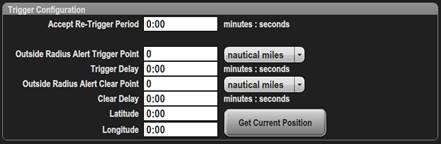

Figure 137 – Trigger Configuration – Anchor Watch Alert

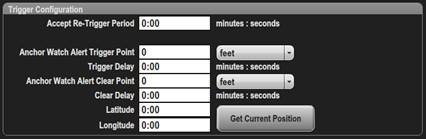

Figure 138 – Trigger Configuration – Inside Radius Alert

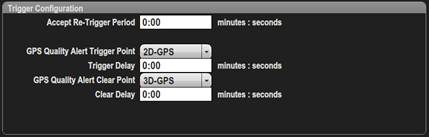

Figure 139 – Trigger Configuration – GPS Quality Alert

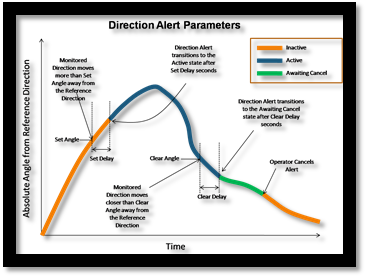

Figure 140 – Direction Alert Parameters

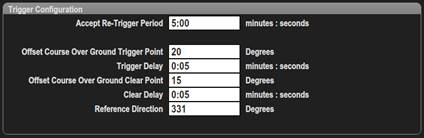

Figure 141 – Trigger Configuration – Direction Alert

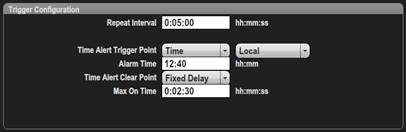

Figure 142 – Alert Editor – Time Alert

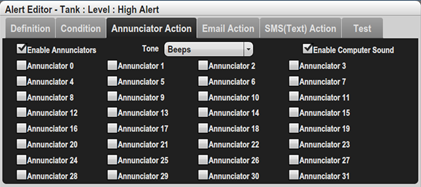

Figure 143 – Alert Editor– Annunciator Actions

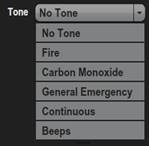

Figure 144 – Annunciator Tone Selection

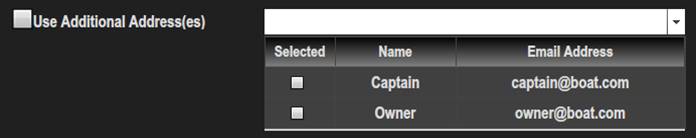

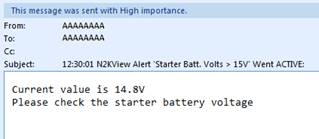

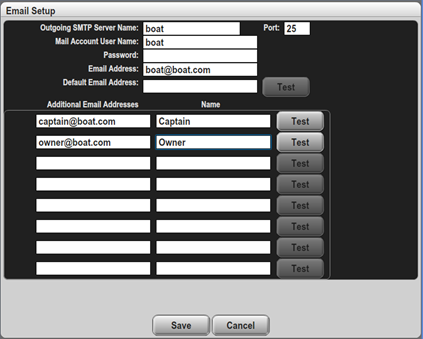

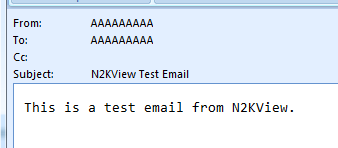

Figure 145 – Alert Actions Dialog – Email Actions Tab

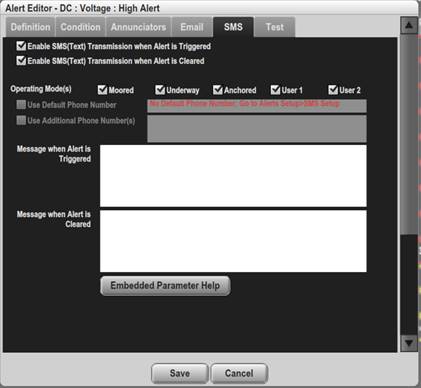

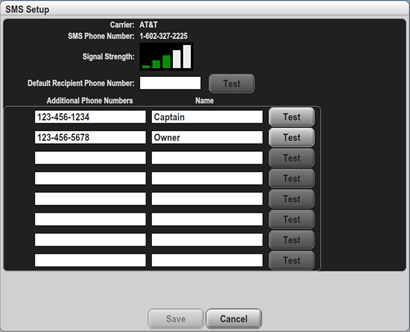

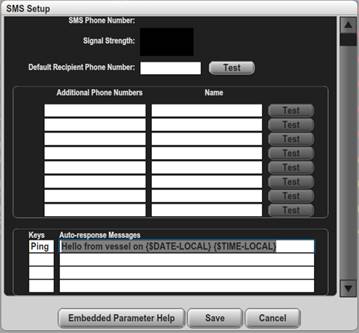

Figure 146 – Alert Editor– SMS (Text) Actions Tab

Figure 147 – Alert Editor– Switch Actions Tab

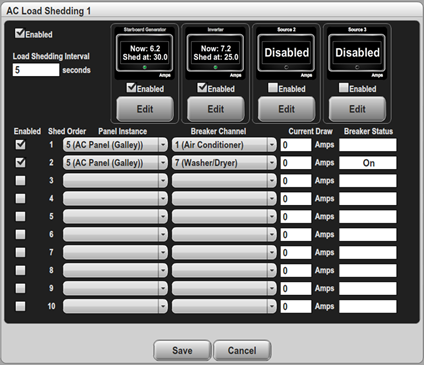

Figure 148 – AC Load Shedding Dialog

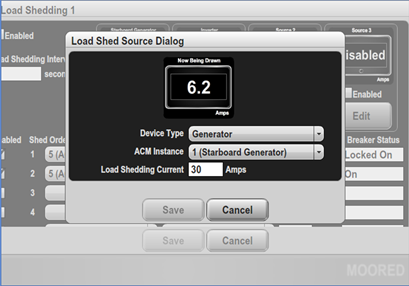

Figure 149 – Load Shed Source Dialog

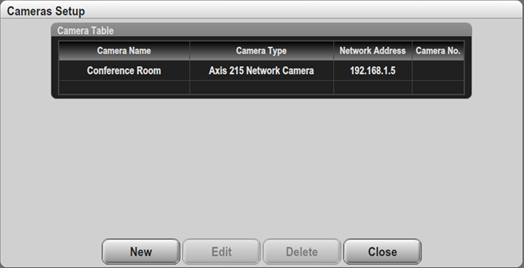

Figure 150 – Camera Setup Dialog

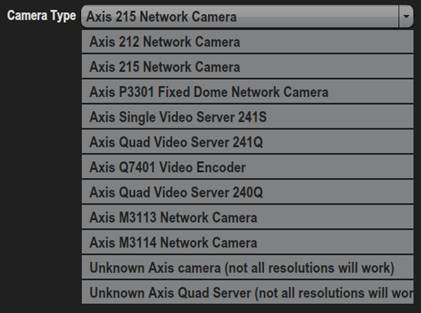

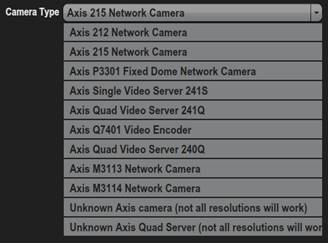

Figure 151 – Camera Type Drop Down List

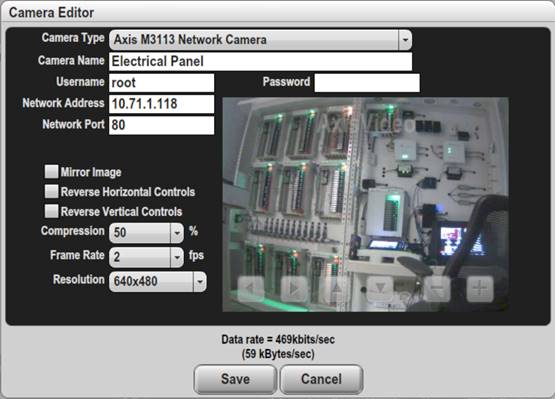

Figure 152 – Camera Editor Example with Axis M3113 Camera

1 Introduction

Thank you for purchasing the Maretron N2KView Vessel Monitoring and Control System. N2KView® is a comprehensive vessel monitoring and control software that goes beyond simple monitoring. With N2KView® you get additional functionality including alerts, video, control, and fuel management. The alerts functionality allows you to setup as many warnings and alarms as you need so you can be forewarned of potential problems. With alerts, you can relax knowing that the system is watching for smoke, CO, high bilge water, or anything else you deem important. N2KView® video capability allows you to add cameras as part of the monitoring system - for example a camera in the engine room - or the cameras can be used as part of the security system. The control functionality gives you the ability to manage your electrical system; for example, you can turn lights or pumps on or off directly from N2KView® and even tell if the lights or pumps are burned out and not working. Lastly, the fuel management function uses information from the fuel flow monitor, tank monitors, and GPS to provide advanced information like distance and time to empty as well as fuel rate and fuel economy..

N2KView® software can run on your vessel's computer (PC) with a USB License Key or on standalone products like Maretron's TSM810C display or the Maretron Black Box (MBB300C) vessel monitoring computer.

If you want to run N2KView® software on your vessel’s computer, you will need either a Maretron USB100 or an IPG100, which are necessary to get sensor information from the NMEA 2000® network to the computer.

There is also a mobile version of N2KView® which runs on iPhone or iPad, or an Android device and connects to the NMEA 2000 network through the IPG100.

See section 8.1 for more details and examples of how to configure N2KView and N2KServer.

2 Software Version

This manual corresponds to N2KView Version 6.3.0 and N2KServer Version 3.6.

This manual is applicable to versions of N2KView running on the following platforms

· PC

· Macs

· Maretron MBB300C

· Maretron TSM800

· Maretron TSM800C

· Maretron TSM810C

· Maretron TSM1330

· Maretron TSM1330C

· Apple iPhone

· Apple iPad

· Android 3.2 phones and tablets including Nook Color, Nook Tablet and Kindle Fire.

3 Software Editions

Beginning with Version 4.0.0, N2KView is offered as a single user complete package will full functionality of all the previous modules.

In version 4.0.0, the following functionality was added

· Bridge Navigation Watch Alarm System (BNWAS) This is not available on the Mobile versions.

· Differential Temperature Monitoring

· SMS Signal Strength Component.

· The Connections Dialog has been re-worked to allow you to enter the Serial number of the IPG100 connecting you with the NMEA 2000 bus

In version 5.0.0, the following major changes were made

· Complete rework of the User Interface to support touch screens

· Screen Selection components allow you to add a control to any screen that, when pressed, will jump you to a screen of your choice.

· 2x1 Indicator components allow multiple lines of text

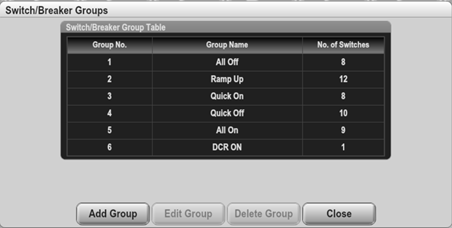

· Breaker/Switch groups

· Alert Detail shows alert history

In version 5.0.4, the following features were added

· Conditional Alerts

· New Parameters for Anchor Distance and Position

· Breakers are shown in the Alert Detail Dialog for Remote Breaker Tripped Alerts

In version 5.1.0, the following features were added

· Sending of parameter data to the Maretron Telemetric Cloud Service.

· Global log of Alert history events

In version 5.1.6, the following features were added

· Multi-line Text Components

· Filtering of Alerts in Alerts Setup dialog

· New Digital Control with colored background

In version 5.1.7, the following features were added

· Alert Vessel Mode table

In version 5.1.8, the following features were added

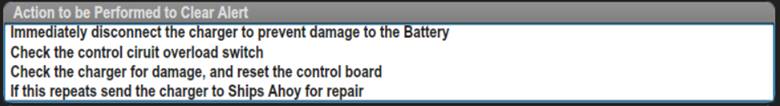

· Added an Action Text Field to Alerts.

In version 6.0.0, the following features were added

· The ability to display the screen of a MBB300C remotely as a web page.

In version 6.0.5, the following features were added

· The BNWAS function was extended to allow resetting through an external input.

In version 6.0.10, the following features were added

· The ability to send and receive free format text messages through a SMS100, including embedded parameter values.

· Controls can be created on top of video controls.

In version 6.0.12, the following features were added

· A new comprehensive anchoring package to assist with all phases of Anchoring.

· Reception of video from Axis cameras with password protection.

In version 6.0.14, the following features were added

· Support for Axis Cameras with new resolutions.

· Support for direct transfer of Configurations between all implementations of N2KView and also to the IPG100.

· An Active Button to switch between Day Mode and Night Mode.

· The ability to specify the instance number.

· Added support for new AC Phase PGNs.

· Allow Alert Emails and SMSs to be transmitted only in certain Vessel Modes.

In version 6.3.0, the following features were added

· Support for DC Chargers, Xantrex Converters, Thrusters,

· New parameters for Total DC Current, Set and Drift, Shaft Seal Temperature, Vessel Speed Components

· Momentary OFF Buttons. The momentary button control has been removed; there is now a single button control that can be set to Toggle, Momentary ON, or Momentary OFF.

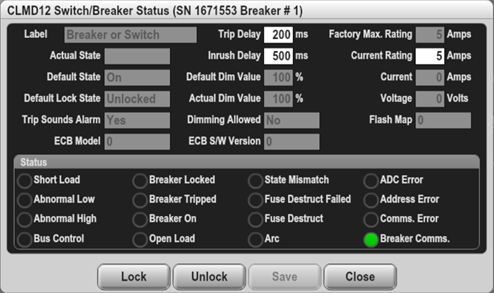

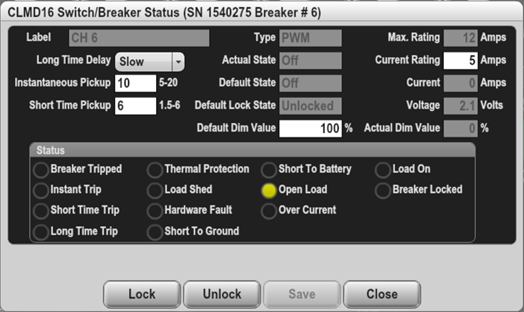

· Lock and Unlock buttons have been added to the AC and DC Breaker Status dialog, and the dialog can be opened by a long click on the name of the switch controls.

· New Alert type for Door Entry Alert (for security functionality)

· Switch Actions on Alerts.

· The embedded parameter list used in emails, SMSs, and Textual displays has been extended.

· New Control Types of Digital2x1, Digital3x2, Digital4x3,Gauge4x5, Status Bars and Switch 6x1 to allow for more dense screen layouts.

· Screen Status controls to allow a summary of conditions on one screen to be seen on another.

· Improved navigation between screens using Back, Home, and Vessel Modes

· Improved layout editing using key presses to line up components.

· Password protection of a screen.

·

4 Prerequisites

4.1 N2KView

The following requirements must be met in order to successfully run N2KView on a PC or Mac.

· License – this is supplied on a USB Dongle.

o If running on a PC, connecting to the NMEA 2000 network through a USB100, the USB Dongle must be plugged into the PC.

o If running on a PC, connecting to the NMEA 2000 network through an IPG100, the USB Dongle may be plugged into the PC or the IPG100.

o If running on a Mac the connection to the NMEA 2000 network must be made through an IPG100 and the USB Dongle must be plugged into the IPG100.

· Operating System:

o Windows XP Home Edition/Professional, or Microsoft Vista (32 or 64 bit) or Windows 7 through 10 (32 or 64 bit).

§ N2KView runs under the Adobe Integrated Runtime (AIR). From version 6.3.0 the AIR runtime will be bundled with N2KView.

§ Please contact Maretron Support at (866) 550-9100 if you have any questions.

o N2KView will also run under MacOS. Users should follow the following instructions to install N2KView manually …

§ Install AIR (Adobe Integrated Runtime)

![]() Go to https://airsdk.harman.com/runtime,

and press this button to start the download.

Go to https://airsdk.harman.com/runtime,

and press this button to start the download.

§ Install N2KView

Go to the following URL. http://www.maretron.com/products/N2KView.php to download and install.

After installation the AIR update process will take care of future updates.

· CPU: Minimum Pentium® 4 or Equivalent, Recommended Pentium® 4, 3.0 GHz

· Memory: Minimum 1GB RAM, Recommended 2 GB RAM on Windows XP and 2GB RAM on Windows Vista.

· Hard Drive Space: 4 GB

· Video Card: Minimum 128 MB memory, Recommended 256 MB. N2KView is a graphics intensive program which will allow more complex screen layouts with high power graphics engines.

· Network Connection: 10BASE-T or 100BASE-TX, or 802.11a/b/g, or 3G. With the TSM800C, TSM1330C or MBB300C, the network connection is only required for software updates and to connect with IP cameras

· Display: Minimum 1024x768 Resolution, 32-Bit Color Video

· Multiple Monitor Support: Dedicated Video Cards with Minimum 64 MB memory per monitor

· Touch Screen or Mouse with Windows Compatible Driver

· Keyboard (for assigning user-defined titles to components, entering passwords and connection information)

4.2 N2KServer

N2KServer is required on a PC when interfacing to the NMEA 2000 network through a USB100. The following requirements must be met in order to successfully run N2KServer on a PC:

· Operating System: Windows XP Home Edition/Professional, Microsoft Vista (32 or 64 bit), Windows 7 through 10 (32 or 64 bit)

· CPU: Minimum Pentium® 4 or Equivalent, Recommended Pentium® 4, 3.0 GHz

· Memory: Minimum 512 MB RAM, Recommended 1 GB RAM

· Hard Drive Space: 40 MB

· Video Card: Minimum 128 MB memory, Recommended 256 MB

· USB Ports: Two 1.1 or 2.0 compatible ports

· Network Connection: 10BASE-T or 100BASE-TX, or 802.11a/b/g

· A NMEA 2000 gateway. Currently, compatible gateways include the following:

o Maretron USB100 with firmware revision 1.7.1 or greater (contact Maretron for any necessary firmware updates) with a Maretron USB100 Windows driver dated 8/3/2007, version 1.0.0.0, or a more recent revision. This version of the driver is installed by default by the Maretron N2KServer Setup Wizard, but you may need to manually update the USB100 driver using the Windows Device Manager in order to use the updated driver if you are using a NMEA 2000 gateway you installed previously to installing N2KServer. N2KServer can operate with earlier versions of USB100 drivers, but will not automatically recover when NMEA 2000 power is lost or when the USB gateway is unplugged from the computer and then plugged in again.

o Maretron IPG100 with firmware revision 4.0.1 or greater. This is a bridge between the NMEA 2000 network and Ethernet. N2KServer runs on the IPG100, so there is no requirement to run it on the PC if the USB License Key is plugged in to the IPG100.

· Mouse

· Keyboard

5 N2KView System Features

- Provides monitoring of a wide variety of NMEA 2000 data (see section 9.6 for a complete list of available data types):

· AC Bus Parameters (Average and Phase specific)

· AC Generator Parameters (Average and Phase specific)

· AC Utility Parameters (Average and Phase specific)

· AC Phase Parameters

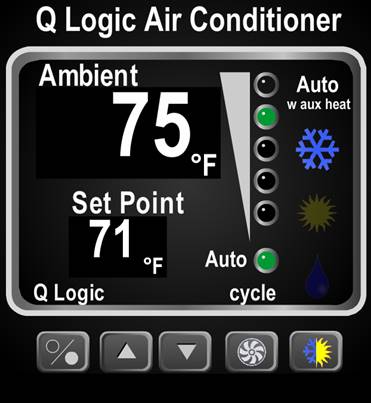

· Air Conditioners (requires a compatible Air Conditioner)

· Anchoring with Anchor Watch Alert

· Bridge Navigation Watchkeeper Alarm System (BNWAS)

· DC

· Depth

· Electrical Distribution (to control Breakers requires a compatible breaker)

· Engine

· Engine Warning

· Environment

· Fuel Management

· GPS

· Heading

· Humidity

· Ice Makers (requires a compatible Ice Maker)

· Indicators

· Navigation

· Pressure / Vacuum

· Rudder

· Speed/Distance

· Switch (to control Switches requires a compatible breaker)

· Tank

· Temperature and Differential Temperature

· Text

· Time/Date

· Transmission

· Transmission Warning

· Vessel

· Video

· Watermakers (requires a compatible Watermaker)

· Wind

- Provides ability to control compatible NMEA 2000 switches and circuit breakers.

- Client/Server architecture allows monitoring from anywhere in the world with an internet connection. If a direct connection to the boat is not possible, then Maretron’s Cloud Service may be used to make the connection.

- Alerts N2KView provides the ability to monitor a wide variety of NMEA 2000 data for values going outside predetermined values, to add gating conditions under which the alert will be enabled, and to perform one or more of the following actions when an alert value goes out of bounds and the gating condition is met

· Display the alert on any or all N2KView Screens connected to an N2KView Server on the NMEA 2000 network. This includes N2KView stations connected remotely through an Internet connection.

· Sound one or more Annunciators connected to the NMEA 2000 network.

· Sound the PC Speaker on local and/or remote Alerts.

· Email alert details to one or more email addresses, including cell phones.

· Text (SMS) alert details to one or more cell phones.

- SSL Encryption with password protection for security against eavesdropping.

- Password protected configuration files

- Password protected server login

- Gauge components with programmable warning and fault ranges, and optional tracking on minimum / maximum values.

- Digital components with programmable warning and fault ranges

- Unlimited number of user-defined screens

· User graphics and pictures may be added to any screen as a background

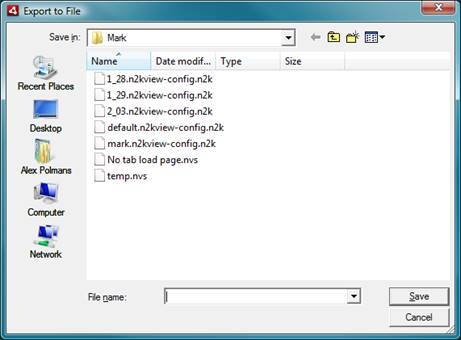

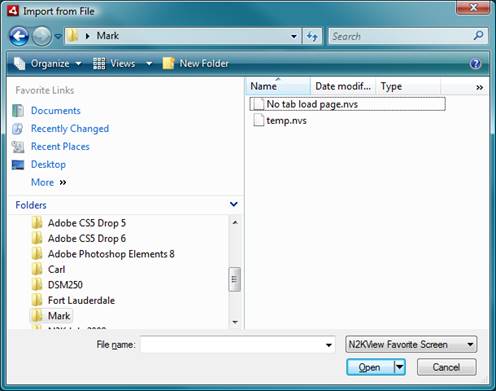

Individual screen layouts may be imported and exported to other copies of N2KView.

- Easy transfer of configurations between N2KView installations on PCs, IPG100, MBB300C and TSM810C

6 Quick Install

This section will help you install the software on a PC for the first time and get it running as quickly as possible with basic settings.

The following options are possible, all require a license.

PC and USB100: The PC version of N2KView may connect to the NMEA 2000® network through a USB100 connected to a USB port on the same PC. This requires a license key plugged into another USB port on the same PC.

PC and IPG100: The PC version of N2KView may connect to the NMEA 2000® network through an IPG100. The IPG100 may be on the same network (a LAN connection), on a different network through a gateway (a WAN connection) or through the Maretron Cloud (a cloud connection). This requires a license key plugged either into the PC running N2KView, or into the IPG100.

Mac and IPG100: The Mac version of N2KView may connect to the NMEA 2000 network through an IPG100 only. The IPG100 may be on the same network (a LAN connection), on a different network through a gateway (a WAN connection) or through the Maretron Cloud (a cloud connection). This requires a license key plugged into the IPG100.

TSM/MBB with NMEA 2000 connection: The TSM800C, TSM810C, TSM1330C, MBB200C and MBB300C have a pre-licensed copy of N2KView built-in and just require connecting to the NMEA 2000® network. No key is required.

TSM/MBB with IPG100: The TSM800, TSM1330 and MBB100 have N2KView pre-installed and must be connected to an IPG100 through Ethernet. This requires a license key must plugged into the IPG100.

6.1 Install IPG100 or USB100 if applicable

Please refer to the Maretron IPG100 User’s Manual or the Maretron USB100 User’s Manual.

6.2 Get the N2KView Install Program

From the blue Maretron USB Drive.

a. Insert the blue Maretron USB Drive into your computer. Double click on the menu.html file to display the USB Drive’s web page.

b. Click on the Install PC Software button

c. Click on the N2KView button to start the installer.

From the Maretron website.

a. Go to the following URL. http://www.maretron.com/products/N2KView.php to download and install.

b. Click on the link for the PC installer to download the installer to your computer.

c. Run the installer after it has downloaded

6.3 Install N2KView

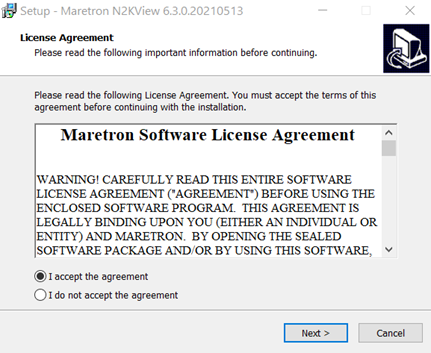

The “License Agreement” screen will be shown next. Please read the license agreement carefully. If you agree with the terms of the license agreement, please select “I accept the agreement” and then click “Next >“ to continue the installation. If you select “I do not accept the agreement”, the installer will terminate without installing the software.

6.3.1 Accept the License Agreement

Figure 1 – N2KView Installation License Agreement Page

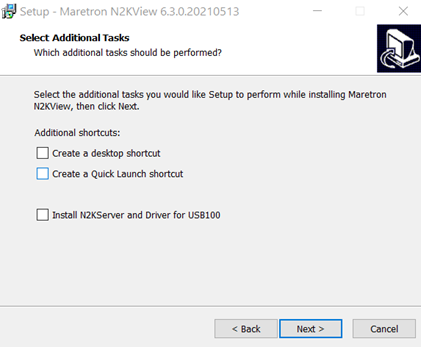

6.3.2 Select Additional Tasks

Figure 2 – Additional N2KView Installation Tasks

If the USB100 is being used as the NMEA 2000® bridge, then N2KServer and USB Drivers need to be installed. Please check the box. If the IPG100 is being used as the bridge, the box does not need to be checked.

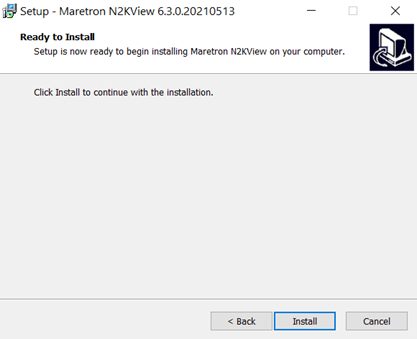

6.3.3 Continue with the Installation

Press Install.

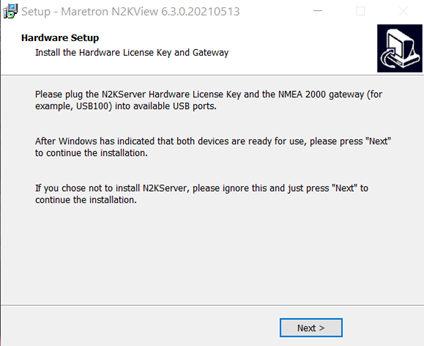

6.3.4 Hardware Setup

This screen can be ignored if you chose to not install N2KServer.

Press Next> to continue.

6.3.5 Finish

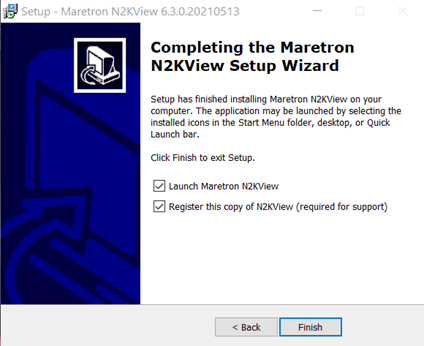

Figure 3 – Maretron N2KView Installation Wizard Completion Page

After pressing Finish, you will be given the opportunity to register your software and start using N2KView. Please make sure to register your software in order to qualify for technical assistance.

The installation is now complete. To run the N2KView software, click on the N2KView icon in the Start Menu, desktop, or Quick Launch bar. When N2KView starts you will be given the option to:

1. Enter Demo Mode, which has simulated data and does not require a license.

2. Accept the terms of the license agreement and start monitoring live data. This will require a license and a gateway to the NMEA 2000® network.

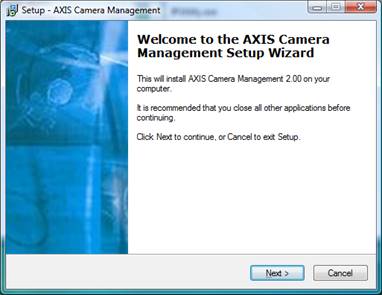

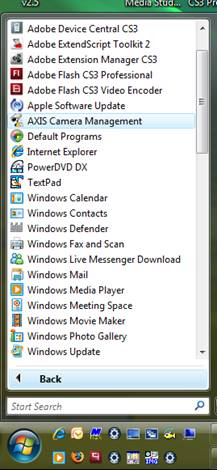

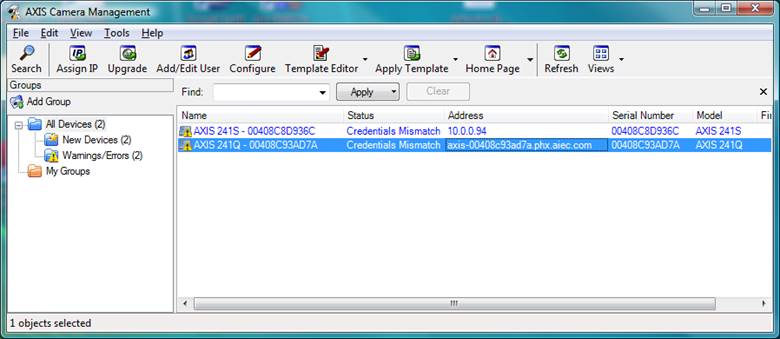

6.4 Installing Cameras

N2KView is designed to display data from IP cameras produced by AXIS Communications. The cameras are connected to the computer running N2KView via Ethernet. While all Axis cameras with the VAPIX streaming protocol are supported, the following cameras have been thoroughly tested by Maretron.

- Axis 212 PTZ Network Camera. This is a wall-mounted camera with software pan Tilt and Zoom.

- Axis 215 PTZ Network Camera. This is a sophisticated camera with hardware Pan Tilt and Zoom. It requires a 12V power supply which is supplied with the camera.

- Axis P3301 Fixed Dome Network Camera

- Axis Single Video Server 241S

- Axis Quad Video Server 241Q

- Axis Q7401 Video Encoder

- Axis Quad Video Server 240Q

- Axis M3113 Network Camera

- Axis M3114 Network Camera

- Axis M3343 Network Camera

- Axis M5525 PTZ Network Camera

- Unknown Axis Camera - If any other Axis Network Camera is used, N2KView will not know which picture sizes are valid for the camera, and you will need to enter the value manually.

- Unknown Axis Quad Server - If any other Axis Video Server is used, N2KView will not know which picture sizes are valid for the server, and you will need to enter the value manually.

The video servers allow the connection of analog cameras to the video server using co-axial cable, which then serves the video to N2KView via Ethernet. The cameras require a separate 12V power supply.

In addition, the Hatteland Seahawk range of cameras are also supported.

Connection of IP cameras requires knowledge of computer networks to allocate an address to the cameras. The camera is identified by N2KView by this address (see 8.5 for more information). In simple networks, this address (the IP address) can be permanently set inside the camera; in more complex networks a server can dynamically allocate the IP address to the camera, and the camera addressed though its name. The software and installation manual supplied by Axis Communications must be used to set up the camera’s address.

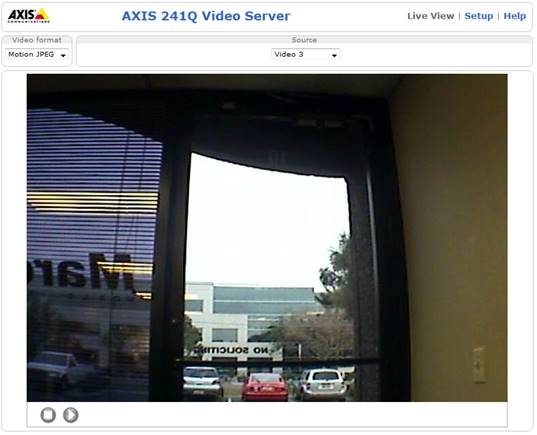

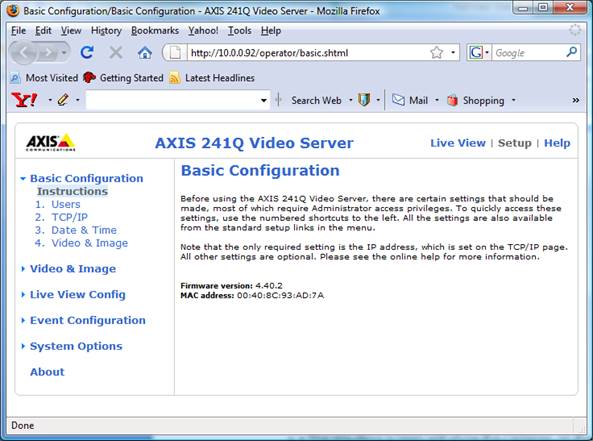

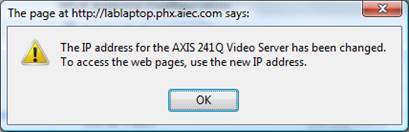

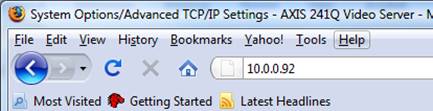

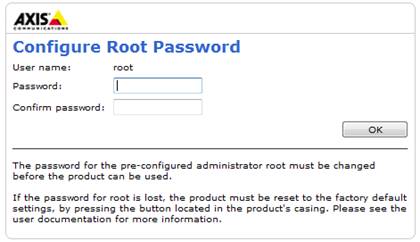

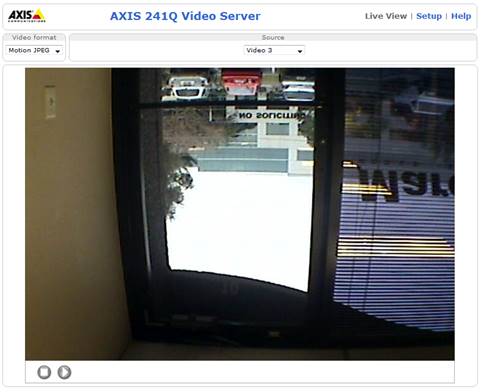

Section 19 gives a step-by-step example of setting up the Axis Quad Video Server 241Q.

6.5 Run N2KView

Note: Before running N2KView in Live Mode, please make sure you are connected to a USB100 on the same computer or on a Maretron IPG100 whose IP address is accessible from this computer. The MBB300C, TSM800C, TSM810C, and TSM1330C products have a built-in IPG100 and require connecting directly to the NMEA 2000® bus.

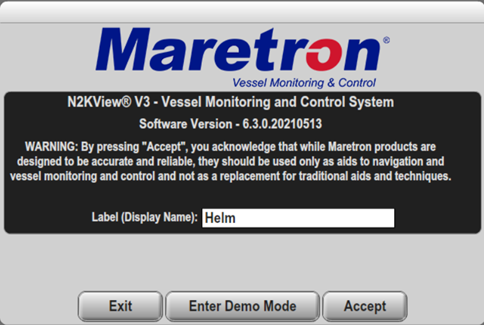

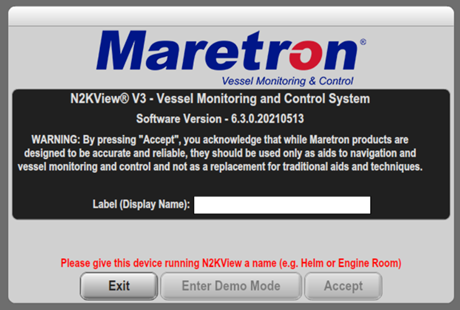

N2KView will start up with the following disclaimer screen.

Figure 4 – N2KView Startup Disclaimer Screen

Please enter a Label (Display Name) that uniquely identifies the device on which N2KView is running. This name will be used in the Alerts Module to identify to you which of your devices generated an Alert, and which device was used to acknowledge the alerts. The name may be changed from the Configuration Dialog.

You are required to press Accept with the left mouse button and thereby acknowledge this warning message before N2KView will run in Live Mode. Clicking Accept with the right mouse button will force N2KView to the top left of the screen.

Alternatively, you may Enter Demo Mode. In Demo Mode, you will not be able to view live data; instead simulated data will be provided to stimulate the controls. You will be able to create Configurations and transfer them to an IPG100 or other copies of N2KView in this mode. Clicking Enter Demo Mode with the right mouse button will force N2KView to the top left of the screen.

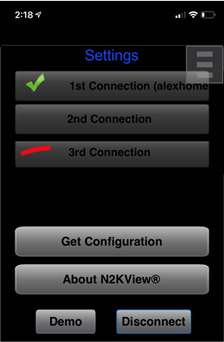

The first time you run N2KView in Live Mode, you must select the device through which the connection to the NMEA 2000® bus will be made. This is not required in the devices that connect directly to the NMEA 2000® network (i.e. MBB300C, TSM800C, TSM810C and TSM1330C)

This is done through the following steps:

a. Click (or touch) anywhere inside the N2KView screen to display the screen tabs.

Figure 5 – N2KView Window with Tabs Displayed

b. Click on the Commands & Settings tab (on the right of the screen) to display the buttons to access the Settings dialogs

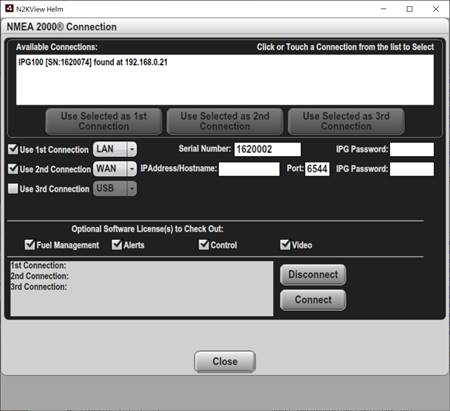

c. Click on the Configuration button to display the Configuration sub-menu.

d. Click on the “NMEA 2000® Connection” button to display the NMEA 2000® Connection dialog.

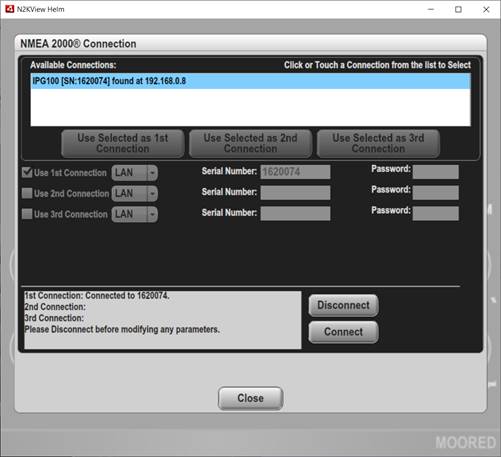

Figure 6 – NMEA 2000® Connection Dialog

e. Ensure that N2KView is not connected to a Server by pressing the “Disconnect” button. While N2KView is connected you are not able to edit fields.

In this section of the manual, we will only use the 1st Connection. The other lines provide alternative ways to connect so that you do need to change the configuration each time to leave the boat and move (for example) from a LAN connection to a Cloud connection.

f. If you are running on a PC connected to a USB100, you will see the line “PC [USB Key:nn] found on local PC” in the list of Available Connections at the top of the dialog. Click on the line in the list, and then press the Use Selected as 1st Connection button.

This will populate the 1st Connection for a USB connection.

g. If you are running on a PC or Mac and you have an IPG100 running on the same Ethernet network as the PC or Mac, then you will see the line “IPG100 [SN:nnnnnnn] found at nn.nn.nn.nn” in the list of Available Connections at the top of the Dialog. Click on the line in the list and press the Use Selected as 1st Connection button.

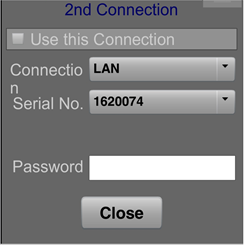

This will populate the 1st Connection for a LAN connection as shown below. The Serial Number will be entered into the line; if you entered a password in the IPG100, enter the same password in the Password box.

![]()

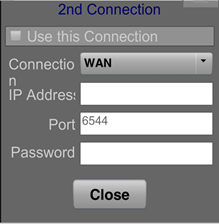

h. If you are running on a PC or Mac and you have an IPG100 running on a different Ethernet network as the PC or Mac, this cannot be detected by N2KView. You will need to enter the IP Address or Hostname of the gateway where you have established port forwarding to the IPG100. Check the Use 1st Connection box, select WAN from the list of methods and then enter the IP Address/Hostname and the Port of the global port. This is the most difficult way to connect N2KView and the IPG100, and should only be attempted by IT professionals

This will populate the 1st Connection for a LAN connection as shown below. The Serial Number will be entered into the line; if you entered a password in the IPG100, enter the same password in the Password box.

An example of this is shown below:

![]()

In the “Password:” text box, enter the same password that you entered in the IPG100.

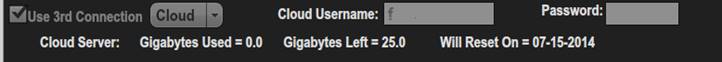

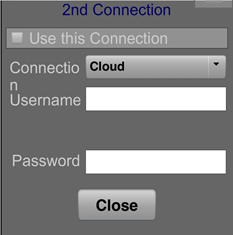

i. If you are running on a PC or Mac and you are connecting to the IPG100 through the Maretron Cloud Services, check the Use 1st Connection box, select Cloud from the list of methods and then enter your Cloud Username and the Password from your IPG100. Maretron Cloud Services solves all the complex problems of accessing your boat remotely, and is the preferred method of making such connections.

![]()

j. If you are connecting to an older version you may be asked to request which of the optional modules for N2KView you wish to use; select the appropriate licenses that must be checked out from the server.

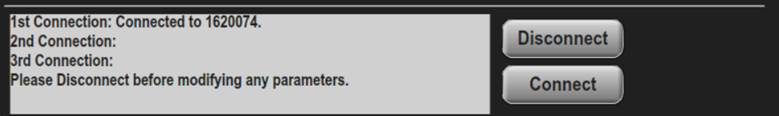

k. Click “Connect”. The Connection State part of the window will blink “Connecting…” for a few seconds. It will then either display “Connected” if the connection was successfully made, or display a message indicating that the connection was not made and suggesting further action to take.

It will also show details about the connection made.

If the connection is not made, please check the following:

1. Make sure the “Server Password” entered in N2KView matches the “Server Password” entered into the IPG100; the password in the IPG100 is set from a Maretron DSMxxx or N2KAnalyzer. (The USB100 has no password.)

2. If using the WAN mode, make sure the “IP Address/Hostname” of the IPG100 is reachable from PC running N2KView. (If this is a problem we suggest using Maretron Cloud Services, or contacting an Internet Technician to help set up your network with the correct port forwarding.)

3. If you are using Cloud Services, make sure that you have a Cloud Services account with Maretron, and that Maretron Cloud Services is enabled in the IPG100. Also check that your Cloud username is correct.

3. Make sure you have appropriate instruments on the NMEA 2000 network to provide the data you are trying to view on the N2KView screen.

4. Make sure that the instances that are being monitored correspond to the instances being transmitted. You can set the instance number of the component to “Any” to make sure that there is any data of that type on the bus.

7 Upgrading N2KView

As N2KView is released with new features on a regular basis, you will want to keep N2KView upgraded to the latest version.

7.1 Automatic Updates

If your PC running N2KView, TSM1330, TSM1330C, TSM800, TSM800C, TSM810C, MBB300C, or MBB100 has access to the Internet through the ship’s computer network, N2KView will check on each startup if a later version is available. If you are ready for an update, then you will asked if you want to update.

Follow the instructions given. On the TSM800, TSM1330 and MBB100, the system will restart about 6 minutes after the update is started. On the TSM800C, TSM810C, TSM1330C and MBB300C, you will be prompted at the end of the installation and the system will restart immediately.

Automatic updates may be disabled from the Configuration Dialog. (see 9.4.6.1).

7.2 Manual Updates

If you do not have access to the Internet, your copy of N2KView will need to be upgraded manually. You will need to load the upgrade files from the Maretron website onto a USB Flash Drive (on a computer that does have Internet access) and then insert the USB Flash Drive into the computer, TSM800, TSM800C, TSM810C, TSM1330, TSM1330C, MBB100, MBB200C or MBB300C while N2KView is running.

Visit the web page <http://www.maretron.com/products/N2KView.php> and click on the Downloads tab for the latest instructions on how to update N2KView manually on a PC or Mac.

Visit the web page <http://www.maretron.com/products/tsm800c.php> and click on the Updates tab for the latest instructions on how to update N2KView manually on a TSM800C.

Visit the web page <http://www.maretron.com/products/tsm810c.php> and click on the Updates tab for the latest instructions on how to update N2KView manually on a TSM810C.

Visit the web page <http://www.maretron.com/products/tsm1330c.php> and click on the Updates tab for the latest instructions on how to update N2KView manually on a TSM1330C.

Visit the web page <http://www.maretron.com/products/mbb300c.php> and click on the Updates tab for the latest instructions on how to update N2KView manually on a MBB300C.

Visit the web page <http://www.maretron.com/products/mbb100.php> and click on the Documentation tab for the latest instructions on how to update N2KView manually on a MBB100.

Visit the web page <http://www.maretron.com/products/mbb200c.php> and click on the Documentation tab for the latest instructions on how to update N2KView manually on a MBB200C.

Visit the web page <http://www.maretron.com/products/tsm800.php> and click on the Documentation tab for the latest instructions on how to update N2KView manually on a TSM800.

Visit the web page <http://www.maretron.com/products/tsm1330.php> and click on the Documentation tab for the latest instructions on how to update N2KView manually on a TSM1330.

8 General Concepts

8.1 Data Security and Encryption

Making your vessel’s data available over local networks or the internet presents multiple security concerns. First, it is desirable to keep anyone from viewing your vessel’s data without authorization. Second, and more important, it is imperative that no unauthorized persons be able to place data onto your vessel’s NMEA 2000 network.

The N2KView system protects your vessel’s data with multiple levels of protection.

First, any data that passes between the IPG100 and N2KView is protected using industry-standard SSL encryption. This encryption standard is widely used to protect financial information on the internet. Each communication session negotiates a random encryption key every time a connection is established. This makes the data secure over public and private Wi-Fi networks, as well as the internet.

Second, each N2KView station that wishes to connect to an IPG100 must authenticate itself by means of a server password. The server password is transmitted by the N2KView station to the N2KServer server over the encrypted communication link. The N2KServer compares the server password to the one it was programmed with. Only if the server password received from the station matches the server’s stored password is the station granted access to the NMEA 2000 network data.

8.2 Using Maretron’s Cloud Server

To use Maretron’s Cloud Server, these steps should be followed:

Establish the key number that will identify your vessel to the Real Time Cloud Server.

· If you have a N2KView license key plugged into the IPG100, the serial number of the license key will be the key number.

· If not, the serial number of the IPG100 will be license key.

Log in to https://rtcs.maretron.com and create an account for the Cloud Services. You will need to provide a name and password for your account, the key number that will be associated with your account, and decide on a level of data that you will require. The levels are

· 25 GByte per month – This will be suitable for most users who are not monitoring video remotely.

· 50 GByte per month – This will be suitable for users that have little remote video monitoring.

· 100 GByte per month – This should be suitable for users with high remote video requirements.

· You can sign up for a trial period of the first option at no cost to evaluate the service before committing.

Enable Cloud Services on the IPG100, using N2KAnalyzer . At this point the IPG100 will start trying to make a connection to the Cloud Server. Data from the NMEA 2000 bus will not be transmitted to the Cloud Server when no N2KView clients are connected, but there will be a small amount of data transmission to manage the link.

On the N2KView Client, select Cloud Services in the Connection Dialog, and enter the name you specified in the account. If the IPG100 is protected with a password (recommended), then this password must be entered in the Connections Dialog. Do not enter the password that you used to create your account.

Add controls and alerts to N2KView so that you can monitor your use of bandwidth.

8.3 NMEA 2000 Considerations

This section describes some requirements for the NMEA 2000 networks to be monitored with N2KView.

8.3.1 Instancing

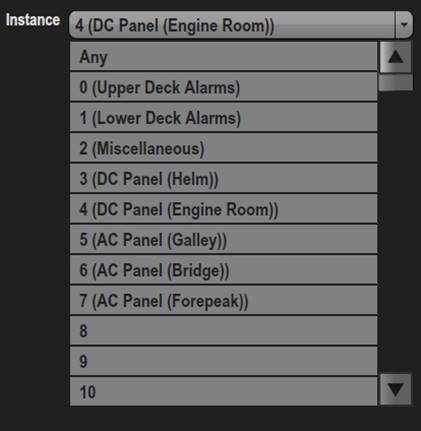

The one aspect of NMEA 2000 that you need to be aware of as a user of N2KView is the concept of instance numbers, or instancing. To enable parameters from different devices to be distinguished, an instance number is associated with the source of each parameter. This may be done as a Device Instance or a Data Instance, depending on the message format used to transport the data on the NMEA 2000 bus. The user does not need to know whether Device Instancing or Data Instancing is used to configure N2KView. When configuring each component on the display, the instance number associated with the source of the data should be known to ensure that the component is monitoring the correct instance of the parameter.

For example: when configuring a control to monitor the Port Engine RPM, the instance number should be set to 0; setting it to 1 would monitor the RPM of the Starboard Engine.

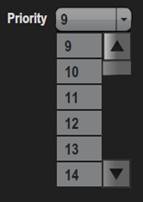

Figure 7 – Setting Instance Number

For simple configurations, where there is only one source of data, N2KView allows the Instance Number to be set to “Any”. If this is chosen, the component will lock on to the first matching parameter received on the NMEA 2000 bus, regardless of its Instance Number. If there are more than two matching parameters on the bus, this will lead to unpredictable behavior. If there is only one matching parameter, it is an easy way to set up the component without knowing what the real Instance Number is.

Instance Numbers can either be allocated to the Device as a whole (Device Instancing) or to individual data elements (Data Instancing).

8.3.1.1 Device Instancing

The device instance is an eight-bit value (ranging between 0 and 255) that every NMEA 2000 device transmits when it joins the bus and upon request thereafter. This becomes important when you have multiple devices that transmit the same data. It is possible, for example, to have two GPS antennas on a vessel, with one serving as a primary antenna and others serving as backups. If this is so, the NMEA 2000 standard requires that the two different antennas have two different device instances. If you are using a certified NMEA 2000 product, the NMEA 2000 standard requires that a user be able to set the device instance in each product. Consult the device documentation or contact your device manufacturer in order to determine how to set the instance into a particular device.

8.3.1.2 Data Instancing

Certain NMEA messages, such as those from batteries, tanks, engines, and transmissions, have data instances embedded in the messages. These data instances are used, if programmed, to relate data to specific data sources. Data instances are also required by the NMEA 2000 standard to be field-programmable, so please consult your device’s documentation for details on how to program this value.

In order to support “plug-and-play” operation, if N2KView receives the same data from multiple devices that have the same device instance programmed, it will “lock on” to the first unit it receives data from until either 1) it stops receiving data from the first unit, in which case it will switch to the second unit, or 2) it starts receiving data from another unit with higher Priority, in which case it will transmit the data from that unit.

8.3.2 Data Source Types

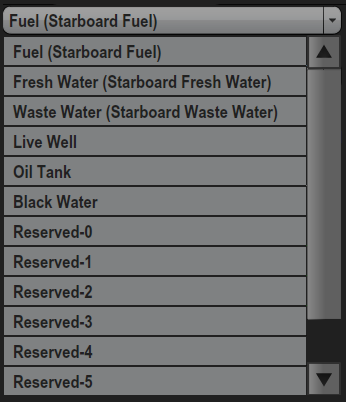

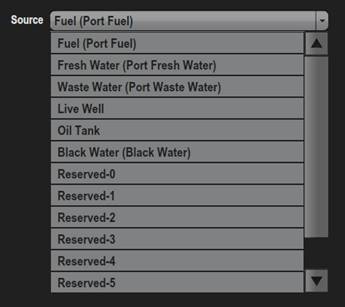

The NMEA 2000 standard provides for the transmission of data from similar devices, but for different sources. For example, the NMEA 2000 standard supports six different types of fluid tanks: Fuel, Oil, Live Well, Fresh Water, Waste Water, and Black Water. It further supports up to sixteen tanks of each of these types. It is the responsibility of the person installing the NMEA 2000 system to ensure that each tank level sender is programmed with the appropriate fluid type and tank instance.

8.3.3 Sensor Selection

Of course, one key to making the N2KView System work is making sure that your NMEA 2000 network has the proper sensors to provide the information you wish to monitor using N2KView. Section 9.6 on page 183 contains a listing of all of the data types that can be monitored using N2KView.

To see what Maretron sensors provide data for each of the listed data types, you may download the latest Maretron Capability Matrix from the Knowledge Base on the Maretron website.

<http://www.maretron.com/support/knowledgebase/phpkbv7/article.php?id=468>

9 N2KView

This section details the configuration and operation of N2KView.

9.1 General Concepts

9.1.1 Touch Screen Operation

N2KView was designed so that all functions in operational mode can be performed with either a mouse or a touch screen.

9.1.2 Keyboard Operation

A keyboard is suggested to configure N2KView. There are a number of fields that need to be entered with text. In normal operation, if a keyboard is connected, short cuts can be used to easily navigate from screen to screen.

In case there is no keyboard connected to the computer, a virtual keyboard will be displayed on the screen the first time there is a need to enter textual data. Pressing a key on a physical keyboard will remove the virtual keyboard from the display. If you are using a physical keyboard, and then unplug the physical keyboard, this action cannot be detected by the program and the virtual keyboard will not appear. The program needs to be restarted to enable the virtual keyboard again.

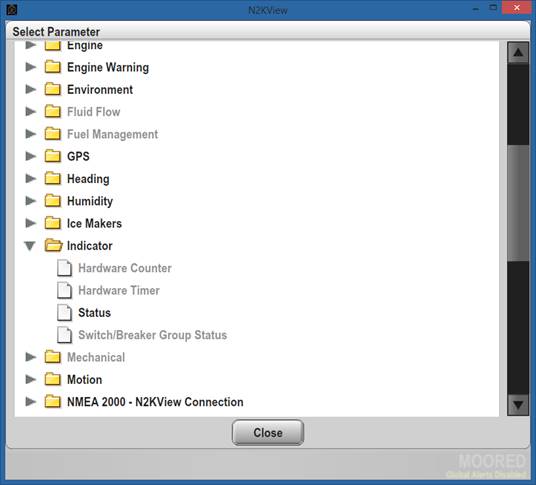

9.1.3 Parameters

The key concept of N2KView is the display of parameters. A parameter is a piece of information about some function of the vessel, such as engine speed or barometric pressure. In addition a particular instance of that data type will also need to specified, e.g. the speed of the Port Engine and possibly a source, e.g. Port Fuel Tank Level.

All of the available parameters that N2KView can display are listed in Section 9.6 on page 183. A device is required to be connected to the NMEA 2000 bus and producing the relevant data for it to be displayed.

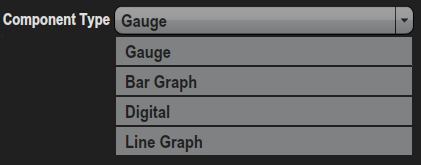

9.1.4 Components

Each parameter may be displayed on a User-defined Screen using a component. A component is a graphical display that is generally dedicated to the display of the value of a parameter. Examples of components include the digital display, a gauge, or a bar graph. A complete listing of available component types appears on page 124. If data is not available for a component, the component will display a dash (“-“), or two dashes (“‑ ‑“), and the indicators for gauge type components will be at the end stop (or peg). More complex components such as the compass will show a dimmed needle to indicate data not being available. Where secondary data is not available to perform a calculation to get the required parameter, every effort is made to inform the user what secondary data is missing. (e.g. If variation is not available to convert Magnetic Heading to True Heading the digital display will show “No VAR”.)

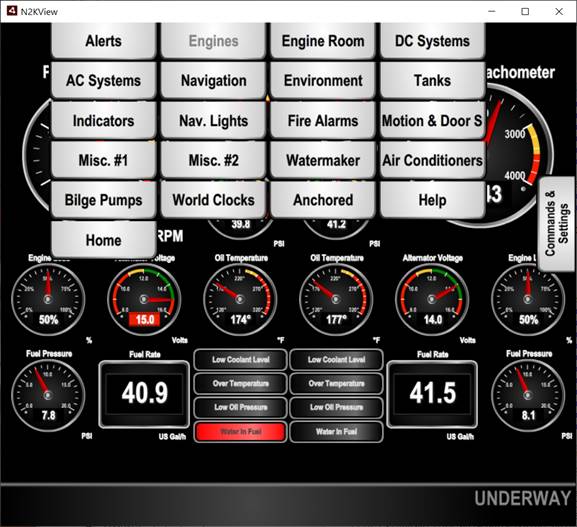

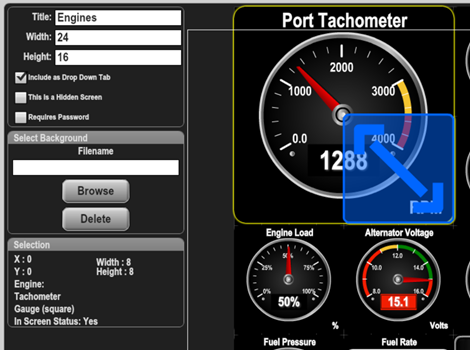

9.1.5 Favorite Screens and Parameter Display

N2KView employs the concept of user-defined screens. You can set up your own screens with your layout to display a group of components which generally will display related parameters, such as engine data, navigation data, tank levels, and so on. N2KView comes with the Alerts screen plus pre-defined favorite screens: Engines, DC Systems, AC Systems, Navigation, Environment, Tanks, and Miscellaneous. You may use the user-defined screens as provided, modify them, or delete them and create your own screens from scratch. There is no limit to the number of screens you can create.

Some (or all) of these screens can be set as favorite screens in the Screen Editor dialog, and can be selected directly from the drop down tabs that appear at the top of the screen when the screen is clicked or tapped. The default is that all screens are created as favorite screens.

The set of user defined screens, plus the configuration of the alerts and cameras is called the system configuration. The system configuration may be saved to disk, either as a backup or for transfer to another computer, or saved directly to the IPG100 , where it may be downloaded by another N2KView, or transferred directly to another copy of N2KView. The system configuration may also be saved to a USB Memory Stick and transferred to another computer.

9.1.6 Protecting the System Configuration

Once the configuration has been set up, it may be protected by a password, which prevents further authoring of the configuration by unauthorized users..

The authoring password is set in the Set Password Dialog (see section 9.4.5).

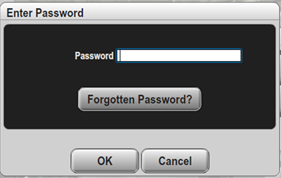

Any attempt to enter a dialog that has the potential to change the configuration will result in the following Enter Password dialog being displayed.

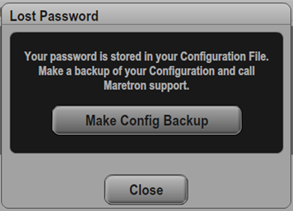

The password is encrypted and stored within the Configuration File itself. Should you forget the password, Maretron can help you retrieve it after sending a copy of your Configuration File to Maretron Support. Pressing the Forgotten Password? button will give instructions on how to get your configuration file.

9.1.7 Grid Layout Concepts

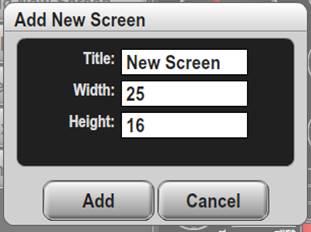

A user-defined screen in N2KView is laid out on a grid of squares. When you create a favorite screen, you determine the layout by setting the width and height in terms of the number of squares that will be displayed on the screen. When the screen is displayed it expands to fill the N2KView window as much as possible (or the entire computer screen if operating in full screen mode). You should choose a number of grids that is fairly small. When you create or move components, they snap to the grid intersections, so the fewer grids you have in your layout, the easier it is to place and align components. It is also important to choose a number of grids that matches the aspect ratio of the window in which you plan to run N2KView, in order to minimize blank space in the N2KView window. For example, if you are creating a favorite screen that is designed to run in full screen mode on a computer with a typical 4:3 aspect ratio, you may wish to make the favorite screen 40 grids wide by 30 grids high, so that the computer screen is completely filled when N2KView is operating in full-screen mode. However, you may wish to run N2KView simultaneously with a chart plotting program, letting the chart plotting program occupy the left half of the computer screen and letting N2KView occupy the right half of the computer screen. Choosing a favorite screen size of 20 grids wide and 30 grids high would allow you to completely fill this window with components. If you choose a favorite screen size and decide later that you wish you had chosen different height and width values, you can always change these at any time (see Section 9.4.9.5 for details).

If you have licensed the Alerts Module, the Alert Status bar will be created below the grid on all the screens, and will have a height equal to about ½ inch.

9.1.8 Hardware License Key

The licensing of the N2KView Vessel Monitoring and Control System is controlled by the use of a Hardware License Key, which is often referred to by the term “dongle”. This Hardware License Key may be installed in the PC running N2KView or in the IPG100. The software tests for the presence of the appropriate hardware license key before it begins operation. If the hardware license key is not detected, the software will not display live data. After the software starts running, it continually tests for the presence of the hardware license key.

If the license key is installed on the IPG100, the IPG100 will allocate them to the N2KView stations on a first come first served basis.

If the license key is installed on a PC, the PC may connect to the NMEA 2000 bus through a USB100. This is the recommended way of connecting PCs onboard, to reduce the possibilities of mal-functioning Ethernet devices or routers interfering with the vital operation of monitoring your vessel.

The TSM800C, TSM810C, TSM1330C, MBB200C and MBB300C do not require Hardware License Keys; the full license set is included with the hardware.

Currently N2KView licenses are all bundled together in the License Key. Older License Keys may only be licensed for part of the functionality.

9.2 Using N2KView

This section describes how to operate the N2KView program after it is installed.

9.2.1 First use

On running N2KView for the first time, you will be presented with the following dialog:

Label the device running this copy of N2KView by clicking in the white box, typing the name, and then press the Accept button. When generating and acknowledging alerts this label will help you identify the computer or mobile device originating the alert.

By pressing Accept, you are accepting the following agreement:

WARNING: By pressing “Accept”, you acknowledge that while Maretron products are designed to be accurate and reliable, they should be used only as aids to navigation and vessel monitoring and not as a replacement for traditional aids and techniques.

Pressing Enter Demo Mode will take you into demo mode with simulated data.

9.2.2 The Opening Screen

Subsequently, when you start N2KView, the program will display the same opening dialog and disclaimer message, and will show the name previously entered.

If you accept the warning, press the “Accept” button and the program will change into operational mode. If you do not accept the warning, press the “Exit” button and the program will terminate.

Figure 8 – N2KView Opening Dialog

Alternatively, pressing the Enter Demo Mode button will take you into a demo mode which showcases all the possible components with simulated data.

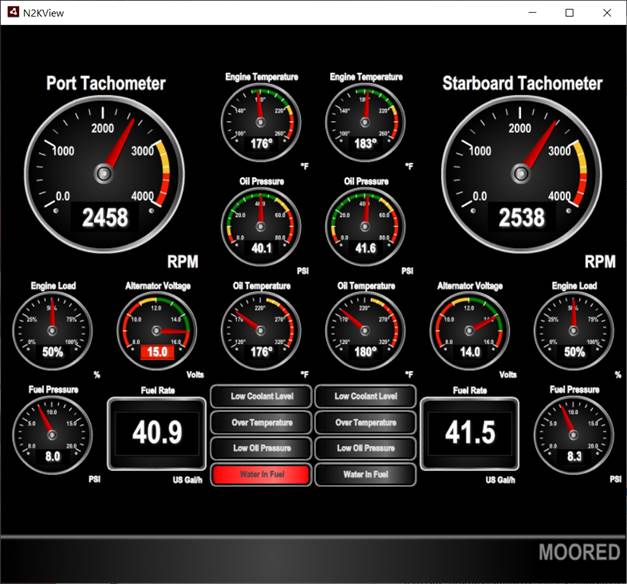

9.2.3 User-defined Screens

Once you have accepted the warning in the opening screen, it closes and a user-defined screen is displayed. A typical example of a such a screen is shown below.

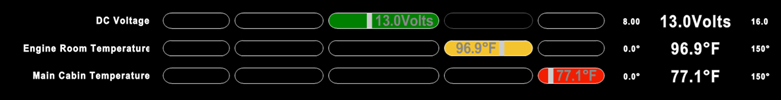

Figure 9 – Typical N2KView Screen

9.3 Operation

This section describes the activities that you may wish to perform with N2KView once it is fully configured and in operation.

N2KView will be configured with a number of User-defined Screens. These screens contain the controls that display the data received from the NMEA 2000 bus. Each screen may be customized with controls selected by the designer of the screen to suit the purpose of that screen.

The first screen is always the Alerts Screen and cannot be changed. The tab for the Alerts Screen will be semi-transparent if the Alerts feature is not licensed.

9.3.1 Changing Between User-Defined screens

Navigation between Screens has been reworked completely in N2KView 6.3.0. There are now a number of ways to set up your screens and navigate between them.

9.3.1.1 Favorite Screen Tabs

Along the top of the screen are tabs to allow you to access the favorite screens you have defined, as well as the Alerts Screen. Click on a screen tab to display the corresponding screen. The tab corresponding to the currently displayed screen is a shade darker than the other tabs.

![]() There

is one other tab on the right-side of the screen. This is not for screen

selection, and is used to navigate to the Commands & Settings Dialog. See

section 9.4.1.

There

is one other tab on the right-side of the screen. This is not for screen

selection, and is used to navigate to the Commands & Settings Dialog. See

section 9.4.1.

9.3.1.2 Keyboard

Use the left or right arrow key (ß or à ), or the page-up or page-down key to cycle between the different favorite screens.

Use the function keys.

- F1 – Go to a screen containing the word “help” in the title. The default configuration has such a page describing these shortcuts, or you can download the page from the Maretron website.

- F2 to F10 – Takes you to the nth favorite screen shown in the tabs

- Home – Go to a screen containing the word “home” in the title. If there is no such screen then the Alt Home function will be tried.

- Alt Home – Go to a screen containing the word “anchored” or “moored” or “underway”, depending on the Vessel Operating Mode.

- Backspace (or Alt ß) – go to the screen that you were previously viewing. You can go back 10 screens by repeating this.

- Alt à - undo the action of the backspace.

9.3.1.3 Screen Select Controls

Screen Select controls are placed by the designer of the screen to allow the user to jump directly to any user-defined screen (whether it has been marked as a favorite screen or not) by clicking on the control without needing the extra step of displaying the tabs. This can be very useful to minimize the number of tabs at the top of the screen by removing tabs to screens that are seldom used.

Screen Select controls may also have the Home, Vessel Mode, and backspace functions.

User-defined screens that are not favorite screens, cannot be accessed from the drop-down favorite screen tabs, or by using the left and right arrow keys. These are accessed only through the Screen Select controls, so one of your favorite screens must contain a Screen Select control to take you to that screen.

N2KView can be set to automatically cycle though your favorite screens from the General Configuration dialog. Screen changes occur every 10 seconds. If any user activity takes place, then the cycling is paused for 2 minutes.

9.3.2 Commands & Settings

In operational mode, press anywhere on the N2KView window to display the screen tabs. While the screen tabs along the top of the screen display your defined favorite screens, the tab on the right-hand edge of the screen allow access to the Commands & Settings Dialog. Section 9.4 describes the Commands & Settings Dialog and the functions they perform.

9.3.3 Switching Between Day and Night Mode

N2KView supports a Night Mode to enable viewing in dark conditions. In this mode, all colors are converted to muted red tones so that you can view the favorite screens without reducing your night vision. You may enter Night Mode by pressing the “Night Mode” button in the Commands & Settings Dialog. In Night Mode, this button changes to read “Day Mode”, which you may press to exit Night Mode and return to Day Mode.

You may also press “Alt” and the “N” key to toggle between day and night modes, or create an Active Button to toggle the mode.

9.3.4 Switching Between Windowed and Full-Screen Configurations

You may change the viewing mode of N2KView to take up the entire computer screen. Pressing the “F11” key will toggle N2KView between full-screen mode and windowed mode. In full-screen mode, you may wish to hide the Windows taskbar so that the N2KView window is the only visible element on the computer screen. You can do this by right-clicking on the Windows taskbar, selecting ‘Properties” from the pop-up menu, checking the “Auto-hide the taskbar” box on the “Taskbar” tab of the “Taskbar and Start Menu Properties” dialog box that displays, then clicking on the “OK” button. The Windows taskbar will then disappear from view but will reappear whenever you move the mouse to the bottom edge of the computer screen.

You may also enter Full Screen mode by pressing the “Enter Full Screen” button in the Commands & Settings Dialog. In Full Screen Mode, this button changes to “Exit Full Screen”, and now can be used to exit Full Screen mode.

Escape (ESC) will also transition from Full Screen Mode to Windowed Mode.

If the system was shut down in Full Screen mode, then it will start up again in Full Screen mode after the initial Warning message has been accepted.

The MBB300C and TSM810C will only operate in Full Screen Mode and have no ability to change out of this mode.

9.3.5 Minimizing N2KView

To minimize N2KView to the taskbar, switch N2KView into windowed mode if it not already there (see Section 9.3.4 for details), and then click on the minimize button (with a straight horizontal line in the bottom of the button), third from the right in the group of system buttons in the extreme upper right hand corner of the window, at the right edge of the Windows title bar.

N2KView running on the MBB300C and TSM810C may not be minimized.

9.3.6 Terminating N2KView

To terminate the N2KView program, click , on the Shutdown tab in the Commands & Settings Dialog.

If N2KView is in windowed mode, clicking on the “X” in the extreme upper right hand corner of the window, at the right edge of the Windows title bar, will also terminate N2KView.

You may also terminate N2KView using the “Alt-F4” or Ctrl-X key combination in full-screen mode, or in windowed mode when N2KView is the active window.

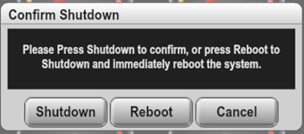

A confirmation pop-up will be displayed asking you to confirm the shutdown process. On the TSM810C and MBB300C you will also be given the option to shut down and restart the unit immediately.

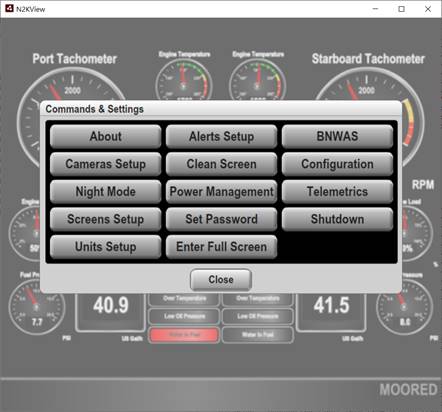

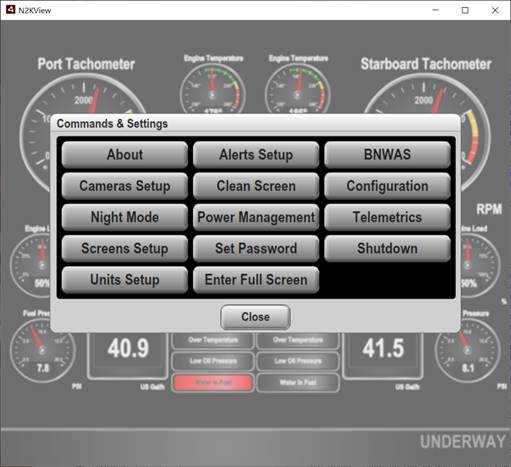

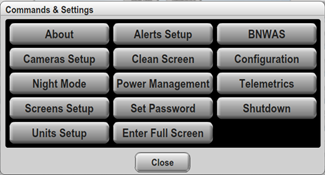

9.4 Commands & Settings Dialog

After you close the opening screen, the N2KView software enters normal operating mode. You may display the Commands & Settings Dialog at any time by pressing anywhere on the screen, and then clicking on the Commands & Settings tab on the right of the screen. The Commands & Settings Dialog appears in the center of the screen as shown below.

Figure 10 – N2KView Commands & Settings Dialog

If you are using an older licensing model and some modules have not been licensed, some buttons will grayed out. This indicated that these functions are not available.

This dialog may also vary slightly between the PC and MBB300C or TSM810C versions.

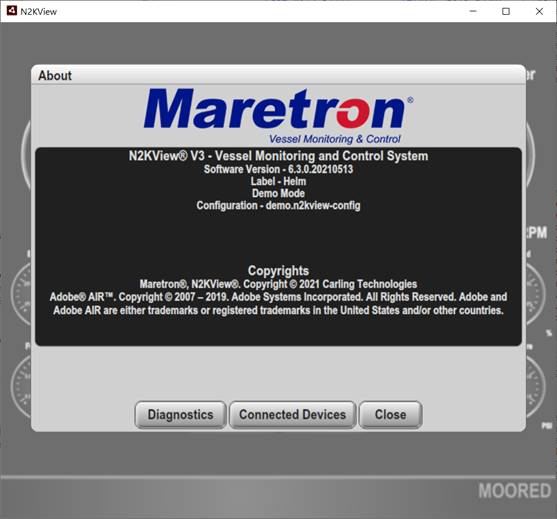

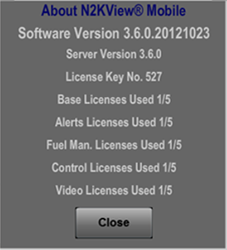

9.4.1 About Dialog

Pressing the “About” button will cause the “About” dialog to be displayed, which will display information about N2KView including

· The Software version number

· The label assigned to the unit by the user.

· The hardware license key number. For the MBB300C or TSM810C with direct NMEA 2000 connections, the Hardware License Key number is the serial number of the device.

· The name of the active configuration.

The Software Version Number and Hardware License Key number serial may be required in the event you need to contact Maretron for technical support.

Press the Close button to close the dialog box. A screenshot of the About Dialog is shown below.

Figure 11 – About Dialog

The logo in the display may vary with different installations.

If connected to an IPG100 with an old license structure, the About dialog may also display the quantity of licenses installed on the IPG100.

The Diagnostics button will enable you to display extra diagnostic information should Maretron support request it. This is the same screen that is displayed when the F12 button on the keyboard is pressed. (e.g. to trace email connection problems in section 10.4.6.1.7). If requested to send a diagnostic log to Maretron to aid in troubleshooting, use this dialog, plug in a USB drive if on the MBB300C or TSM810C, and press the Capture button to save the log file to the USB Drive.

Pressing the Connected Devices button will show the Connected Devices dialog.

9.4.1.1 Connected Devices Dialog

This dialog gives you a list of devices connected to the NMEA 2000® bus with the raw PGN data from each device. The contents of the dialog are a snapshot of the latest data received at the time of opening the dialog. It is not dynamically updated, although the dialog may be refreshed at any time by pressing the Refresh button.

9.4.2 Alert Setup

Alerts are such an important part of N2KView that they have a section on their own in this manual. See section 10.

9.4.3 BNWAS

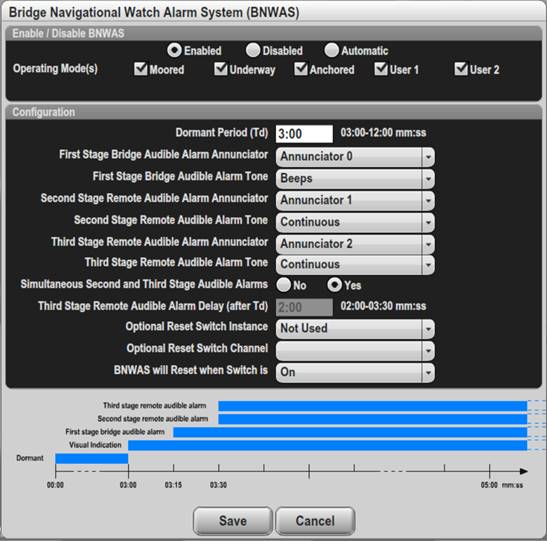

The Bridge Navigational Watch Alarm System (BNWAS) is described in section 11.

9.4.4 Cameras Setup

Setting up cameras is described in section 14.2.

9.4.5

Clean Screen

Figure 12 – Clean Screen Dialog

The Clean Screen Dialog disables all mouse and Touch Screen activity for 20 seconds so that a touch screen can be cleaned without triggering any undesired actions.

Pressing the Clean Screen button will disable all buttons and display a timer which counts down for 20 seconds.

When the timer reaches 0, the dialog is automatically closed.

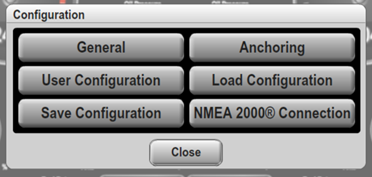

9.4.6 Configuration Sub-Menu

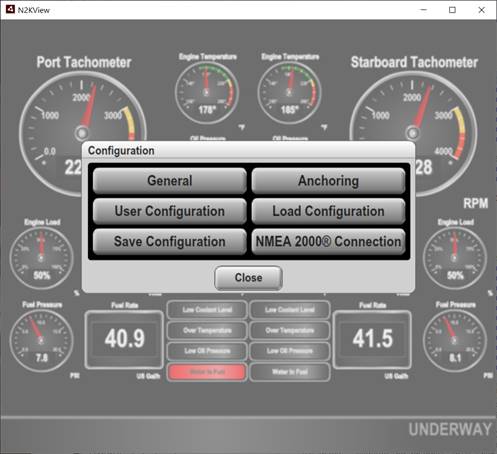

Pressing the Configuration button in the Commands & Settings dialog displays the Configuration sub-menu.

Figure 13 – Configuration Sub-Menu

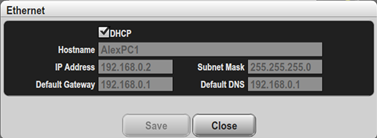

All the manipulation of the user defined screens is done from this dialog. If you are running on a MBB300C or TSM810C, the NMEA 2000® Connection button is not displayed, and is replaced with an Ethernet button.

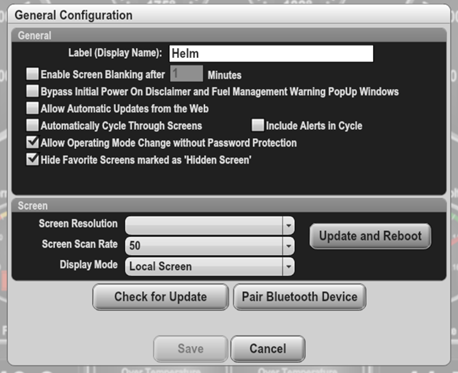

9.4.6.1 General Configuration Dialog

Pressing the “General” button causes the “General Configuration” dialog to be displayed. This window allows you to configure the parameters that are used in N2KView and if N2KView is running on the MBB300C or TSM810C it allows configuration of some system parameters.

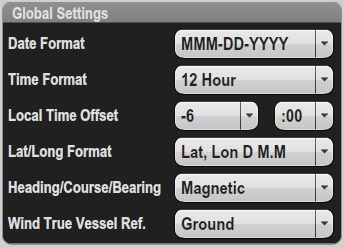

A screenshot of the “General Configuration” dialog is shown below. Not all fields will be shown on each hardware platform.

Figure 14 – General Configuration Dialog

9.4.6.1.1 Label (Display Name)

N2KView programs can be given a label so that an installation having multiple copies of N2KView can distinguish between them. This is important for the alert management, when the identity of the station that responds to an alert can be shown. The label is initially set by the user in the Initial Startup Warning dialog.

This is a text field into which the label of this copy of N2KView may be entered.

9.4.6.1.2 Enable Screen Blanking

This line is not visible on PC or Mac hardware platforms.

When selected, the screen will blank after the set amount of time. When unchecked, the screen will never blank. Touching the screen, or the generation of an alert will unblank the screen.

9.4.6.1.3 Bypass Initial Power On and Fuel Management Warning PopUp Windows

On startup, the normal operation is to display the disclaimer screen. If the computer is unattended and the power is cycled, N2KView will never get past this point and become operational. Checking this box will allow N2KView to bypass the Disclaimer Screen and start in normal mode without requiring operator input.

9.4.6.1.4 Allow Automatic Updates from Web

When checked (recommended) N2KView will query the Maretron website on each startup to see if a later version of N2KView is available. It also controls whether the Adobe Integrated Runtime (AIR) will check for and download updates automatically. This should be unchecked when data transfer rates are expensive, such as when using a satellite data link.

9.4.6.1.5 Automatically Cycle Through Screens

When checked N2KView will automatically cycle through the favorite screens, changing the display every 10 seconds. Screens that are not marked as favorite screens (i.e. not included in the drop down tabs) will be skipped. When any user interaction takes place, the cycling is paused for 2 minutes after the last user interaction so as to not interfere with the actions the user is taking.

9.4.6.1.6 Include Alerts in Cycle

When checked and the screens are cycling, the Alert Favorite Screen will be included in the cycle.

9.4.6.1.7 Allow Operating Mode Change without Password Protection

When the N2KView configuration is protected using a password, users will not be able to change the vessel operating mode without knowing the password. This may be too limiting, and can be overridden by checking this box.

9.4.6.1.8 Hide Favorite Screens marked as ‘Hidden Screen’

From version 5.0.15, it is possible to hide screens from users that do not have access to password. Using the Screen Editor dialog (9.4.9.2) mark each screen that should be hidden as a Hidden Screen, and then check this box.

To display these screens, only this box needs to be unchecked.

9.4.6.1.9 Screen Resolution

When this dialog is started on the MBB300C, N2KView queries the underlying operating system to determine what screen resolutions are available for the connected monitor. The resultant list of screen resolutions are displayed here and one may be selected by the user.

Changing the screen resolution requires that the box be rebooted with the new resolution. This is done by pressing the Update and Reboot button after selecting the new resolution.

9.4.6.1.10 Screen Scan Rate

This list allows the user to specify the required scan rate at which the monitor is to be configured. In most cases the highest scan rate can be set, but we have found one case where a specific lower value must be entered.

Changing the screen scan rate requires that the box be rebooted with the new scan rate. This is done by pressing the Update and Reboot button after selecting the new scan rate.

9.4.6.1.11 Display Mode

MBB300C only.

Changing the Display Mode to Remote HTML5 Access allows the N2KView Screen to be displayed on another display as a web page. The other display must be connected to the same Ethernet network as the MBB300C. This allows the MBB300C N2KView screen to be displayed, for example, on the Garmin 8400 series of MFDs. Having chosen to change the display mode, press the Update and Reboot button.

You may not simultaneously display on a screen connected to the MBB300C and a Remote HTML Screen.

9.4.6.1.12 Update and Reboot

Pressing this button will cause N2KView to exit, update the Screen Parameters on the computer, and then restart.

On restart, if the screen resolution was changed, the Disclaimer dialog will show a message requesting that the new screen resolution be accepted within 20 seconds. If this is not done, the box will be rebooted again with the old resolution / scan rate.

9.4.6.1.13 Check for Update

![]()

If connected to the Internet, N2KView will query the Maretron website and inform you if an Update is present. Normally this is checked on startup only, and then only if Allow Automatic Updates from the Web box is checked.

9.4.6.1.14 Calibrate Touch Screen (MBB300C)

![]()

The following Touch Screen Drivers have been pre-loaded onto the MBB300C.

· eGalax (USB)

These drivers have been tested on the NavPixel monitors

· Hampshire TSHARC (USB)

These drivers have been tested with the Hatteland HD Series monitors

· 3M Microtouch (USB & RS232)

These drivers have been tested with the Hatteland JH series monitors

These drivers have been tested with the Nauticomp Series II monitors

· ELO Intellitouch Drivers version 3.5.2 (USB)

· Penmount (RS232)

Touch Screen Drivers need to be calibrated to ensure that the position touches are accurately reported to the software. Pressing this button will cause N2KView to exit and start a separate program to calibrate the touch screen that you have connected. When the program is complete, N2KView will restart. In some cases the program can take a while (up to a minute) to start, so be patient.

Each driver has its own calibration program, and N2KView will examine the connected screen and choose the appropriate calibration program.

9.4.6.1.15 Save

The parameters in the General section of this dialog are stored in the configuration when the Save button is pressed. This button will be activated when any of these parameters are changed.

9.4.6.1.16 Cancel

Cancel allows you to exit the dialog without saving any of the parameters in the General section of the dialog.

9.4.6.2 User Configuration

If the same configuration is loaded on more than one terminal, each of these terminals will detect the same alert condition and generate an alert. This will result in multiple alerts being displayed on all the terminals for the same event. To prevent this, global alerts from this terminal may be disabled by the user by unchecking this box.

Local Alerts are not affected. Because they are not shared they will never result in duplicate alerts on one terminal.

This is typically used on a vessel with multiple displays to provide redundancy in alert generation. The full set of global alerts is loaded onto both displays, and then disabled on one display from this dialog. If the display with active global alerts was to be switched off, the only action needed to restore the alert monitoring capability will be to enable the alerts on the backup display.

To alert the user that no terminals are set to generate Global Alerts, the message “Global Alerts Disabled” will be displayed in the Alert Status bar (10.3.1).

This message will not be displayed if at least one terminal on the network has the “Enable Global Alerts from this Terminal” box checked.

9.4.6.2.1 Enable the Generation of Global Alerts from this Terminal

When unchecked, global alerts will not be generated from this terminal.

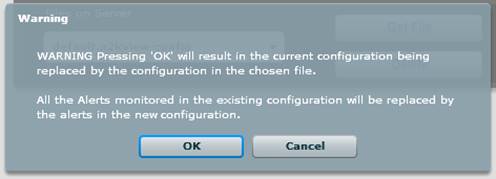

9.4.6.3 Load Configuration

Pressing the Load button brings up the Load Configuration dialog.

The Load Configuration Dialog is the way to change the currently running configuration. This can be helpful from shore station that is monitoring multiple vessels, or where different people on the same vessel prefer different screen layouts.

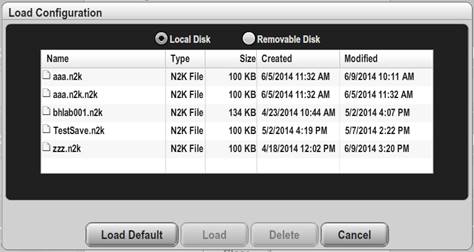

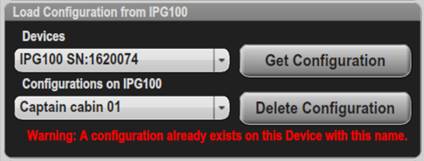

A screenshot of the Load Configuration dialog is shown below.

Figure 15 – Load Configuration dialog

There are three options to load a configuration.

9.4.6.3.1 Load the Default Configuration

9.4.6.3.2 Load Configuration from Disk

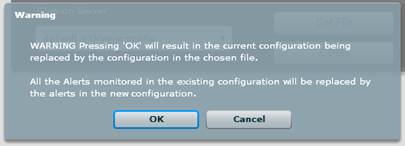

Pressing the Load Default button will load the default configuration as the new configuration. This will show a wide sample of available component types, and can be used as a reference for new designs.

Pressing the Get Configuration button in the this section will open a browser on the local computer. The user then finds the required configuration and selects the file. If the drive on which the configuration is stored is removable (e.g. a USB drive) then the configuration with all its background files will be copied onto the local disk of the computer so that it will be accessible after the removable disk is removed.

A warning dialog will be displayed, requiring the user to OK replacing the configuration.

9.4.6.3.2.1 PC or Mac

On a PC or Mac, the standard browser is opened.

9.4.6.3.2.2 TSM or MBB

On the TSM800C, TSM810C, TSM1330C, MBB300C pressing the Get Configuration button brings up the following Load Configuration dialog.

A screenshot of the Load Configuration dialog is shown below.

Figure 16 –TSM/MBB Load Configuration Dialog

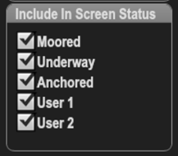

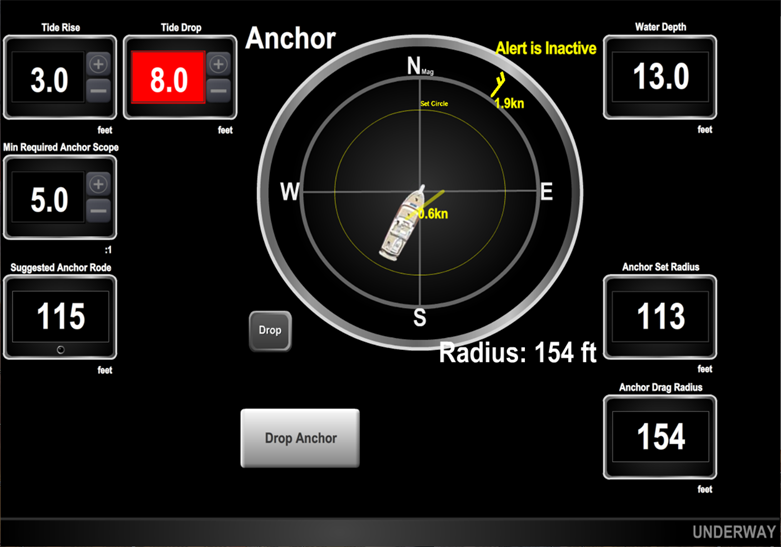

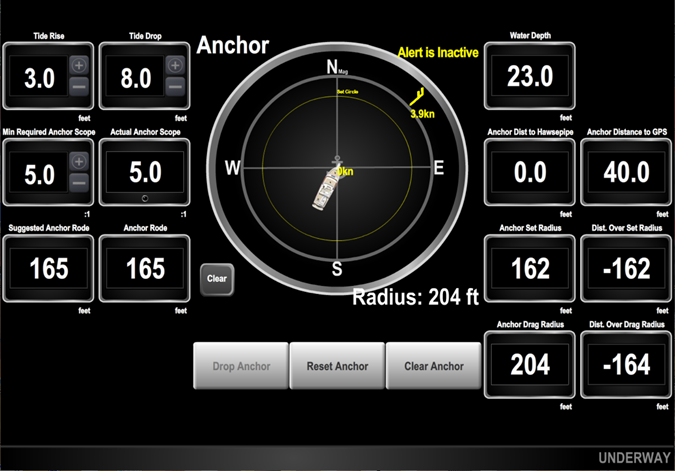

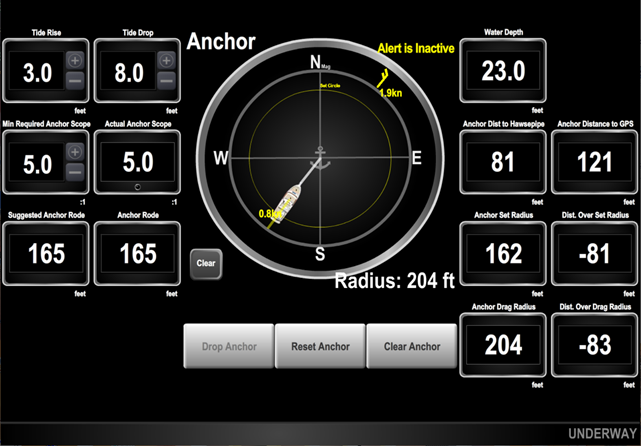

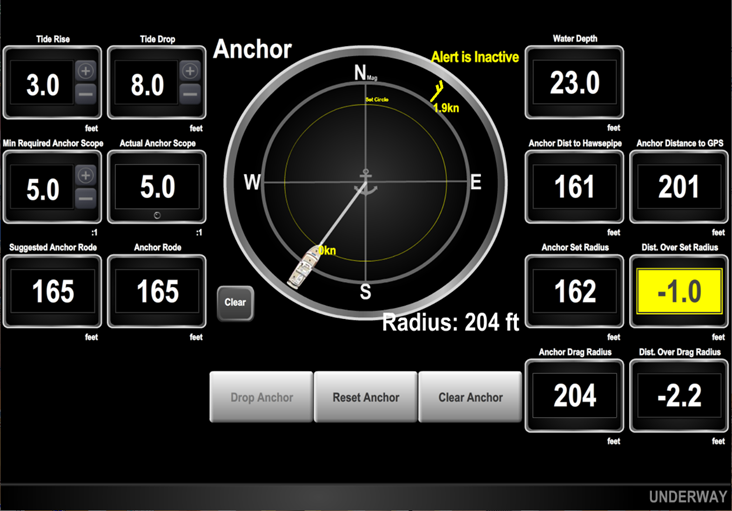

9.4.6.3.2.2.1 Local Disk / Removable Disk