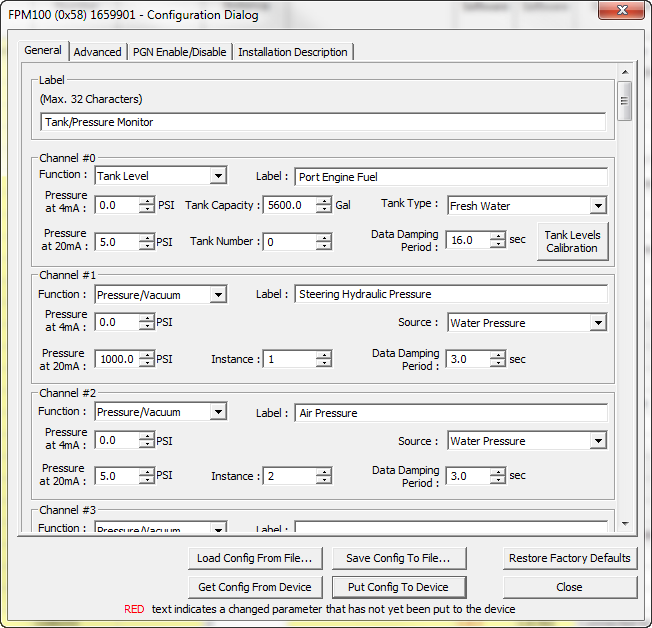

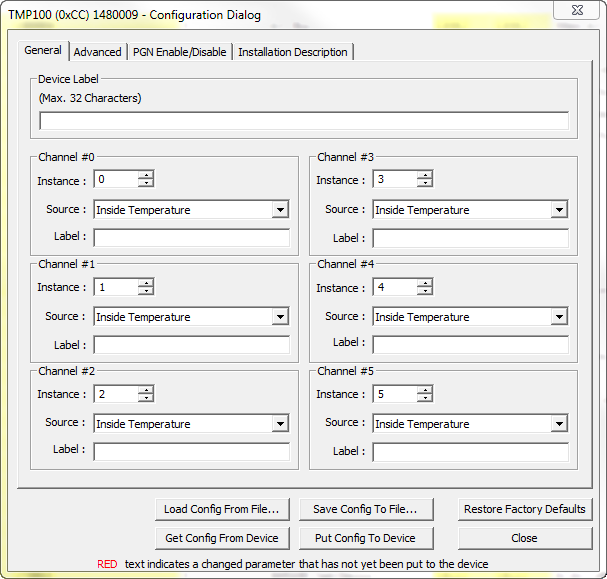

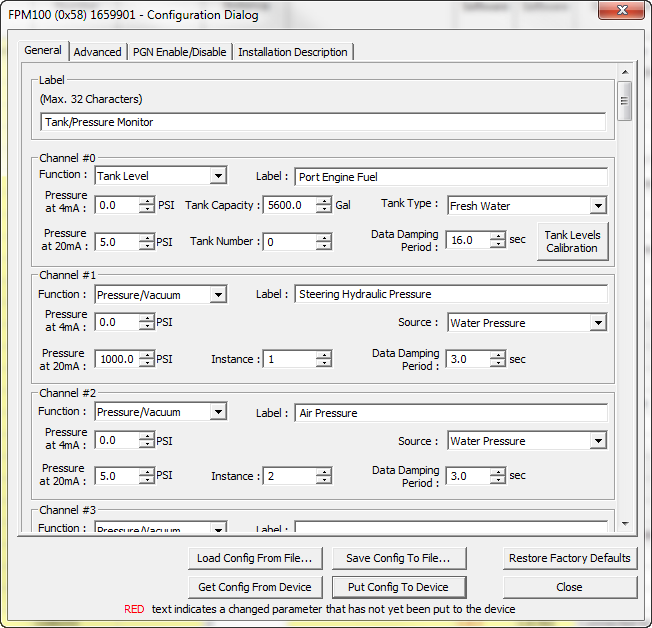

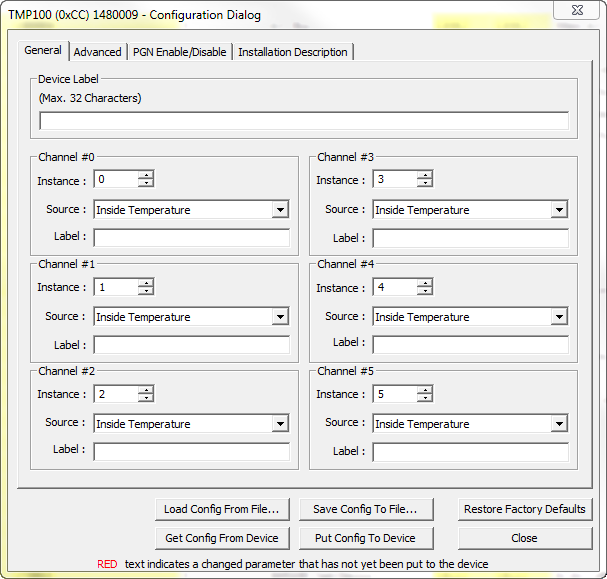

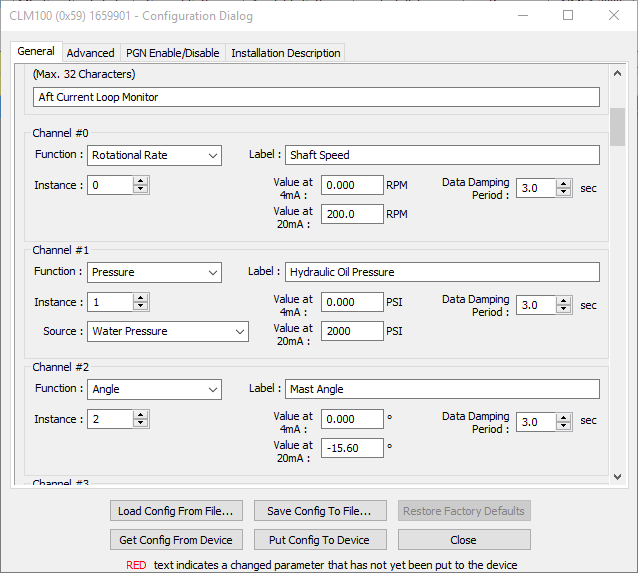

Instance

From here the instance number used in the message sent for

this channel may be set.

Source

This parameter is present only when the channel has been

configured for the function of Temperature, Pressure, Humidity, or Flow Rate.

This parameter selects the type of temperature, pressure, humidity, or flow

rate measurement being performed so that displays can more easily select the

data from the network.

Value at 4mA

Program this parameter to match the reading of the current

loop transducer when it is sourcing a current of 4mA. You can determine this

value by examining the specification of the transducer being used.

Value at 20mA

Program this parameter to match the reading of the current

loop transducer when it is sourcing a current of 20mA. You can determine this

value by examining the specification of the transducer being used.

Data Damping Period

You can configure a damping parameter to smooth the

parametric readings or make them more responsive. The data damping is

configurable between 0.1-25.0 seconds. The default data damping period is 3.0

seconds.

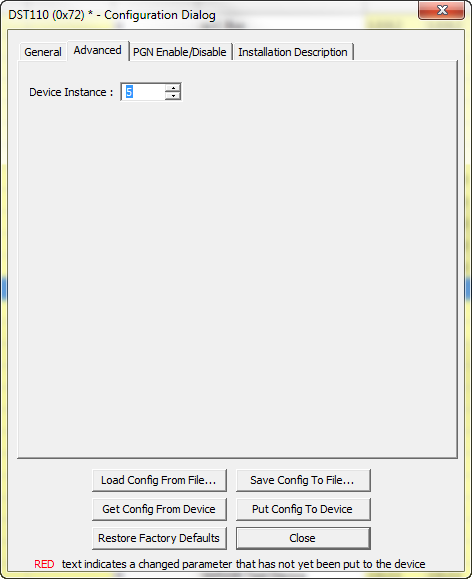

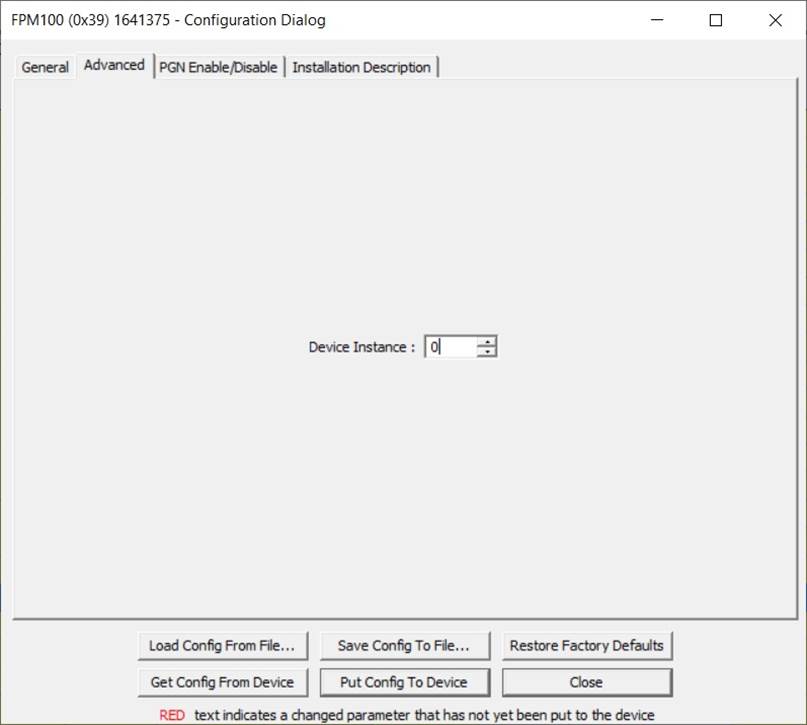

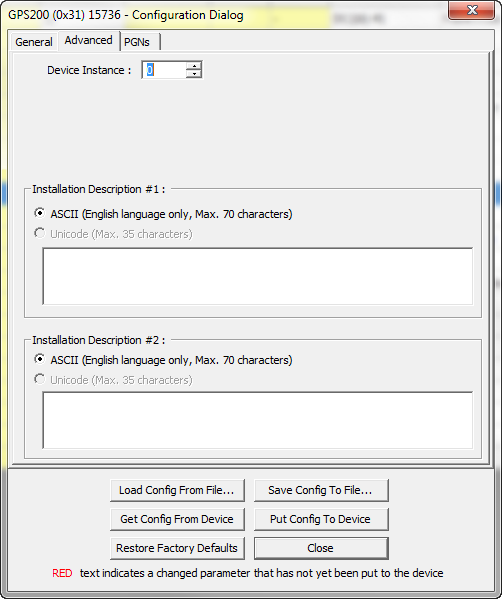

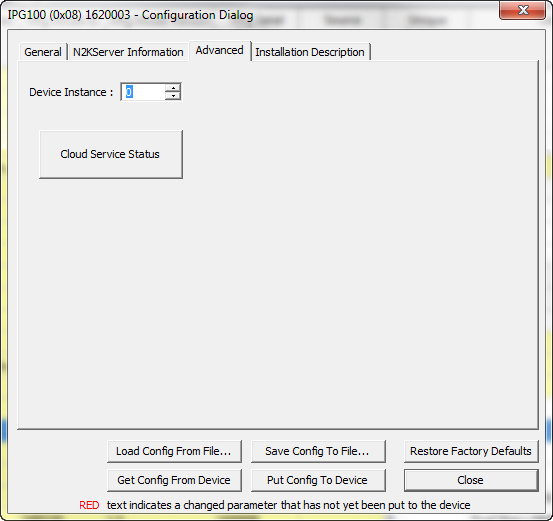

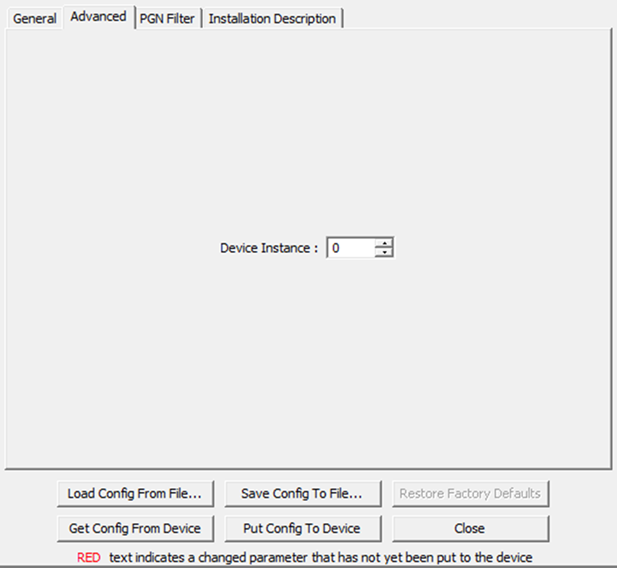

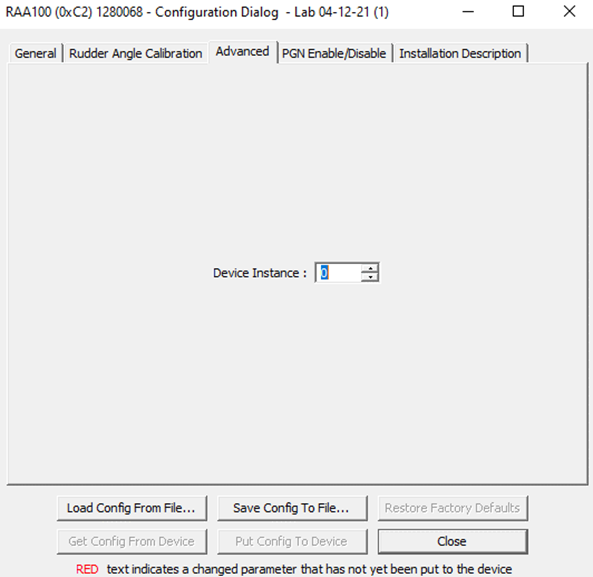

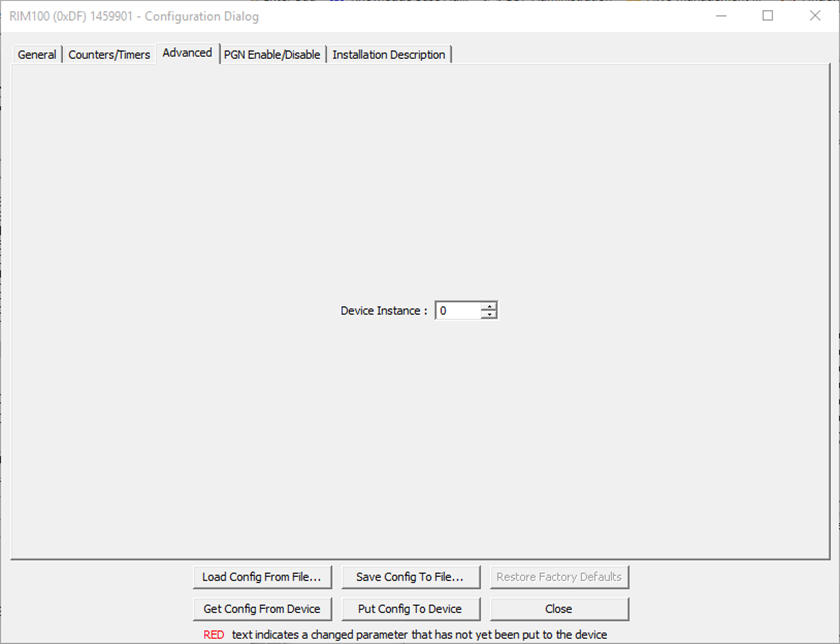

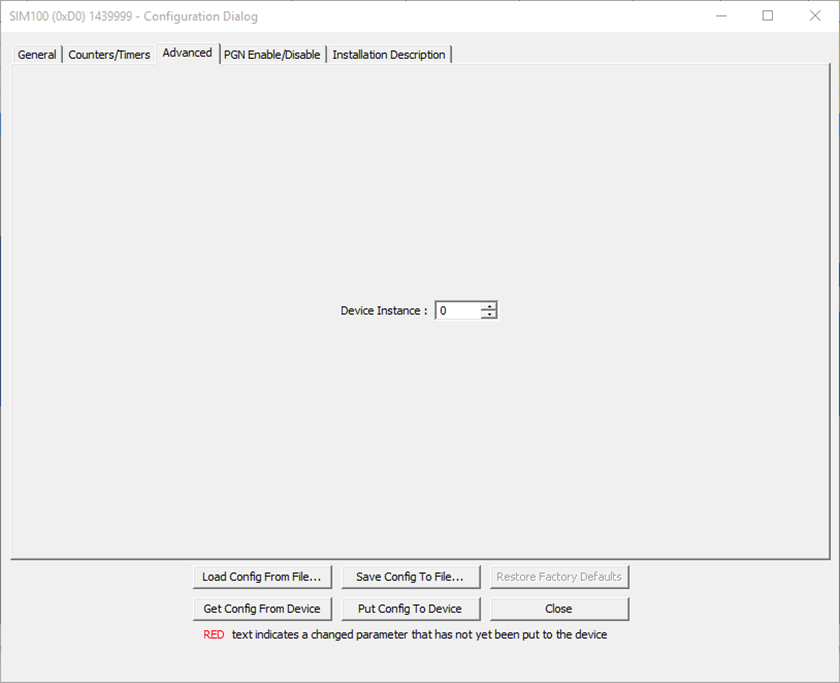

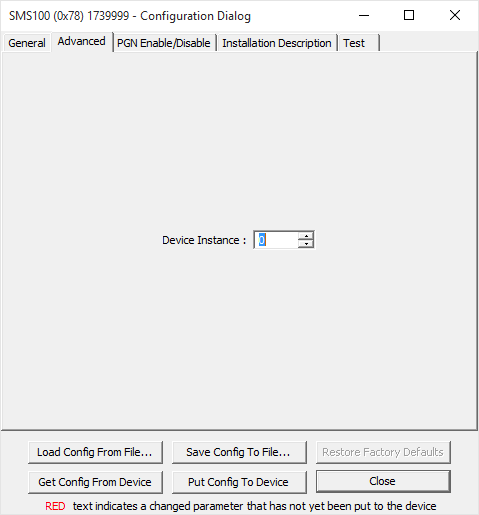

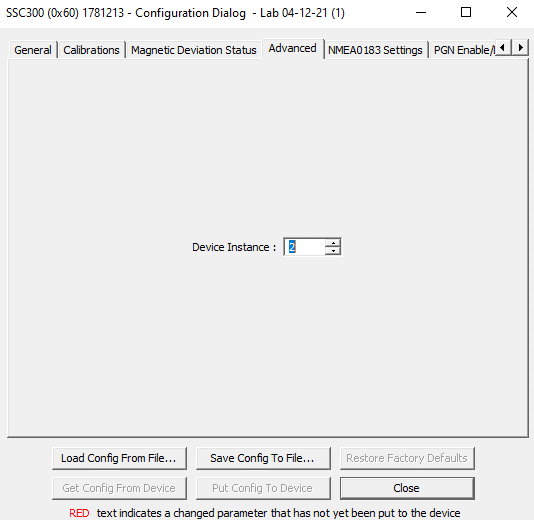

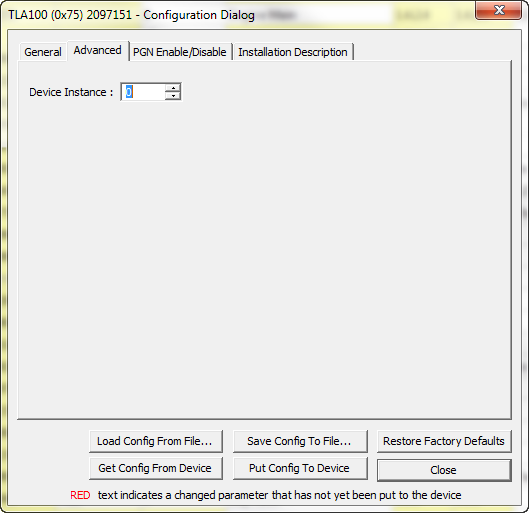

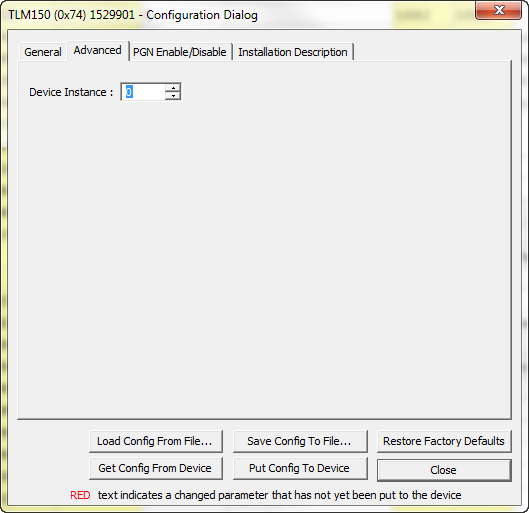

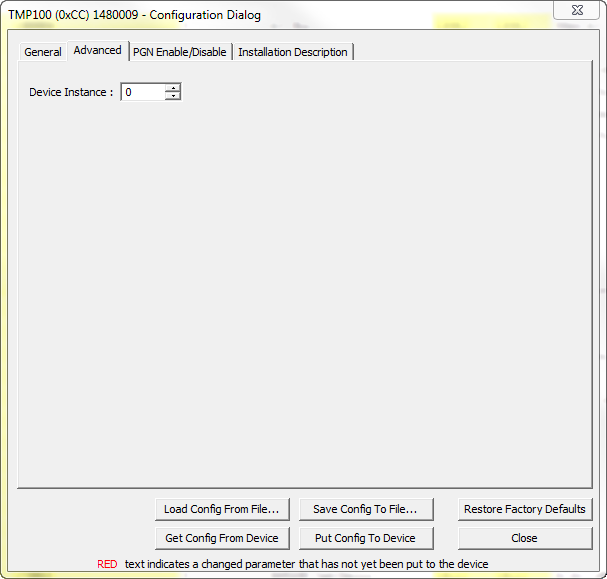

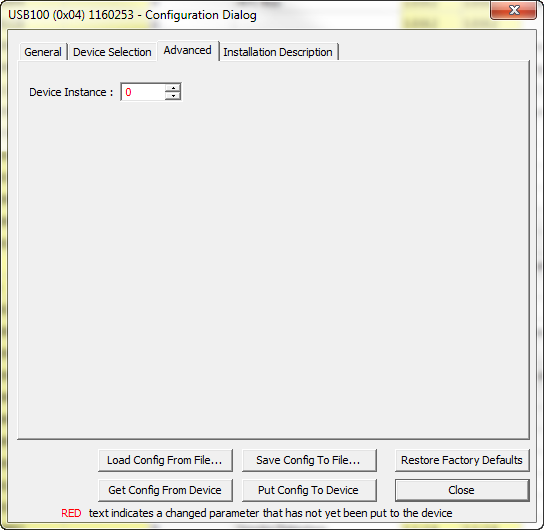

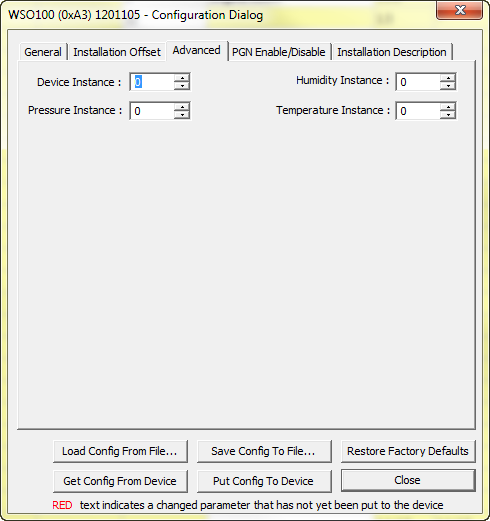

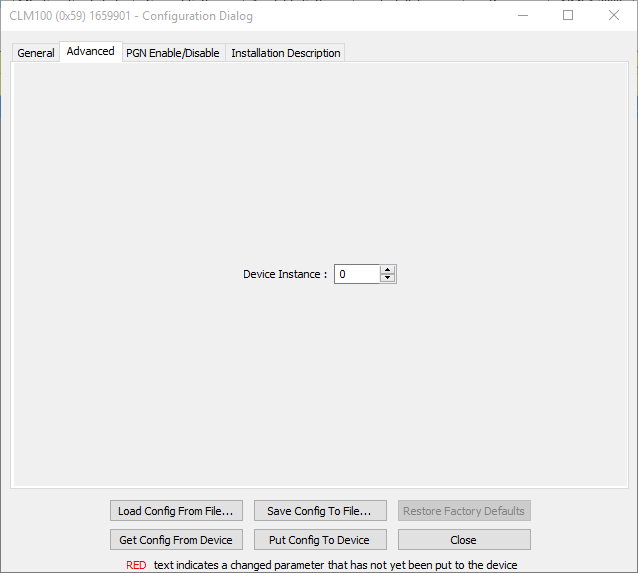

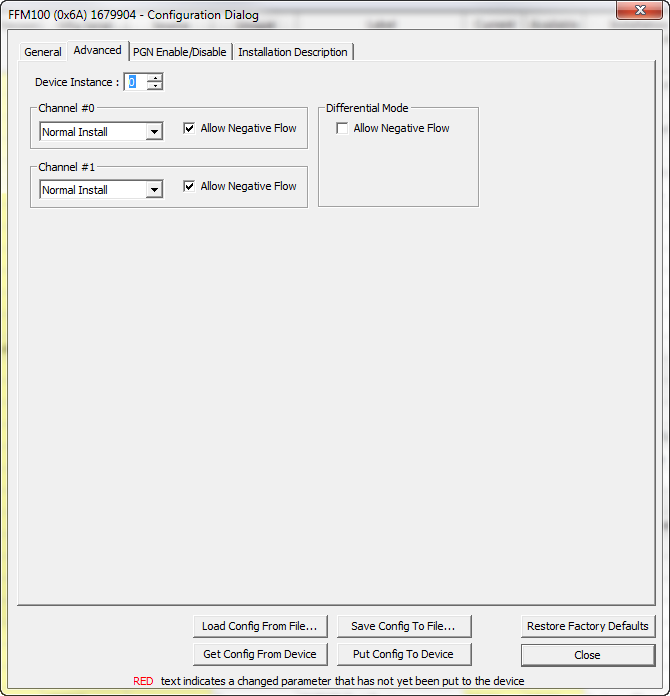

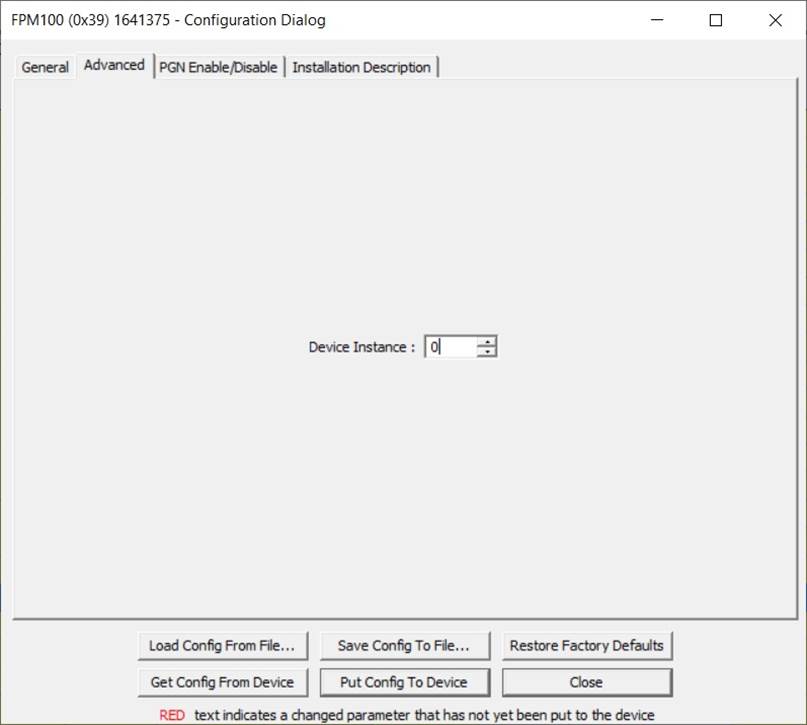

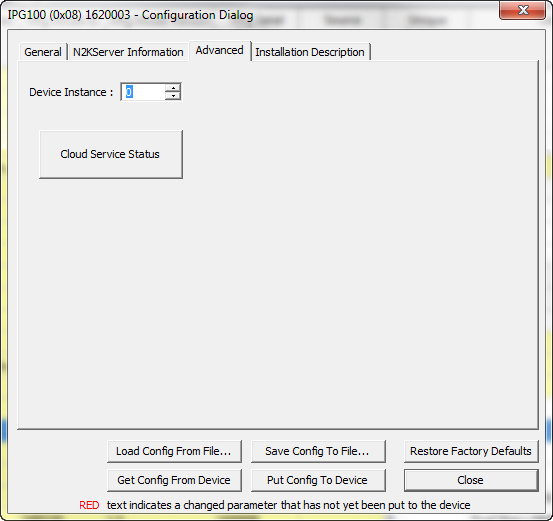

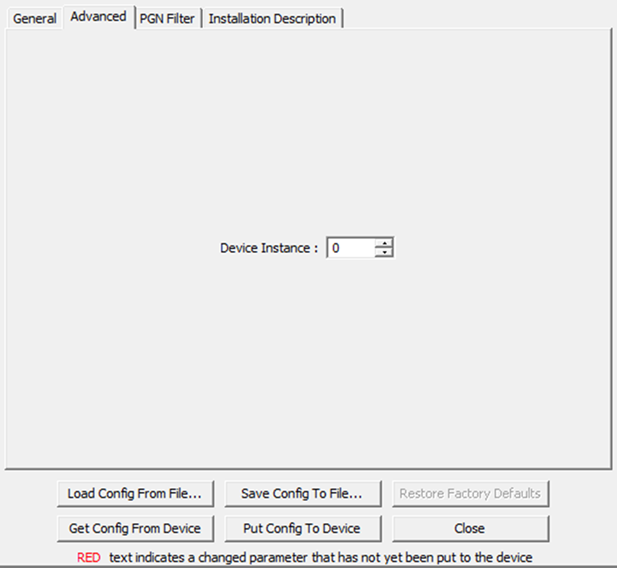

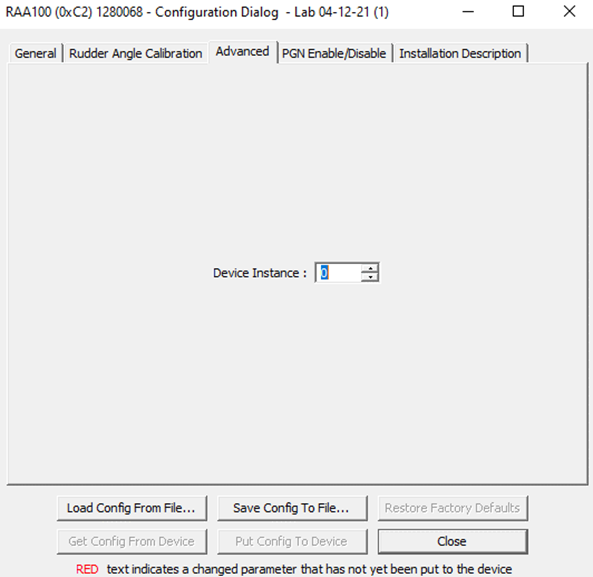

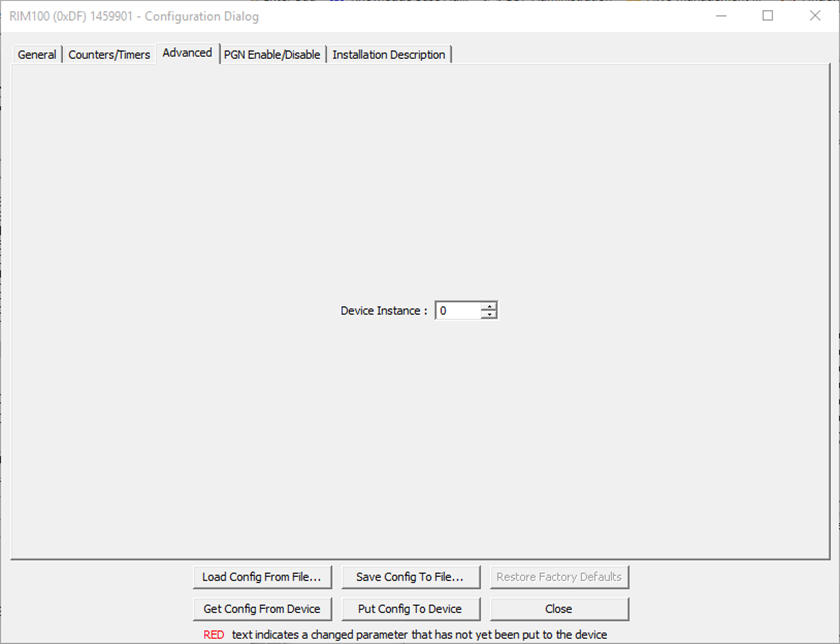

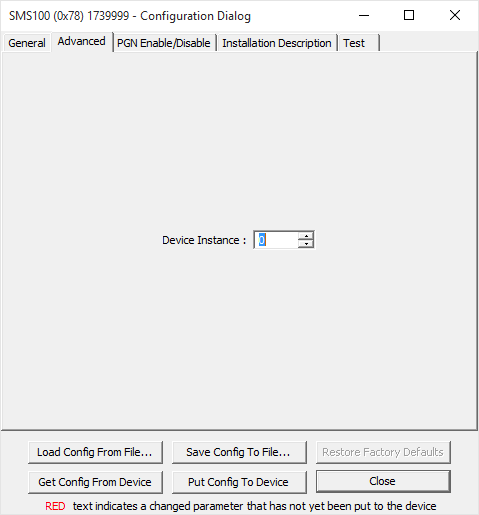

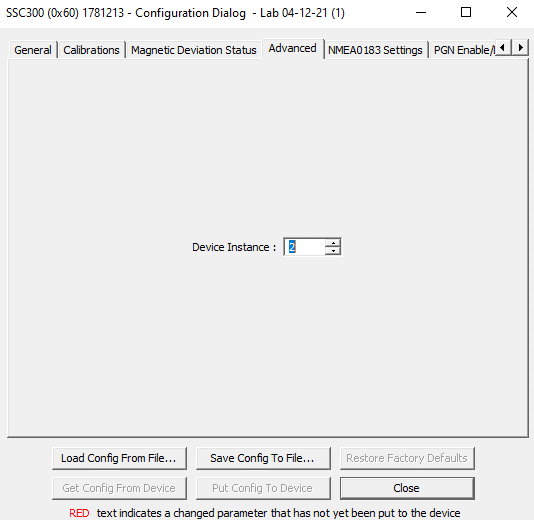

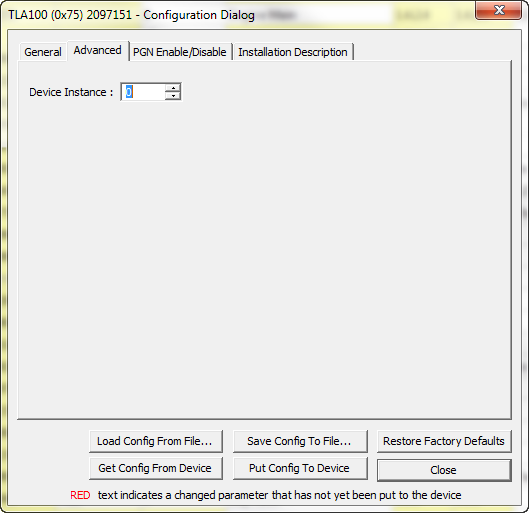

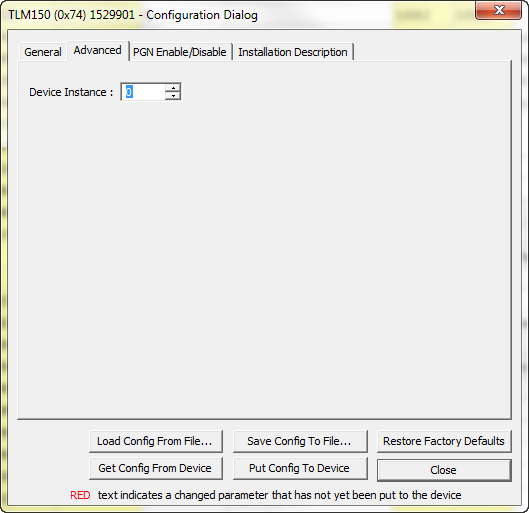

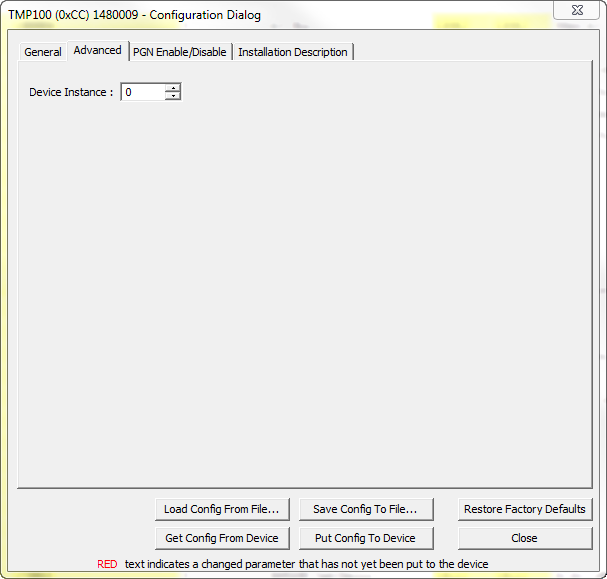

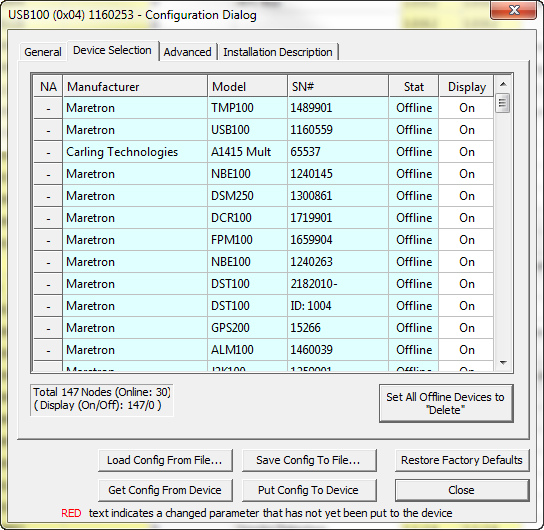

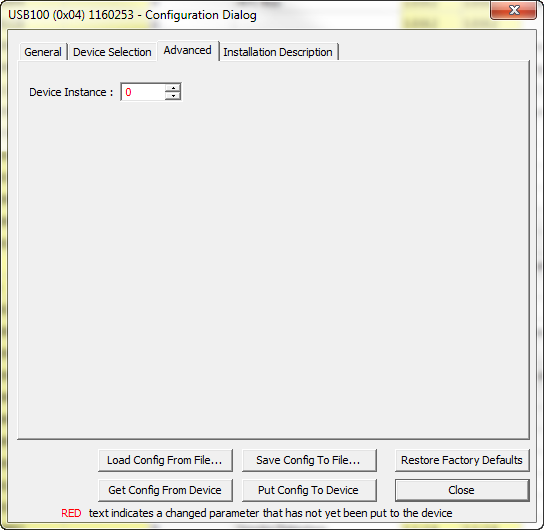

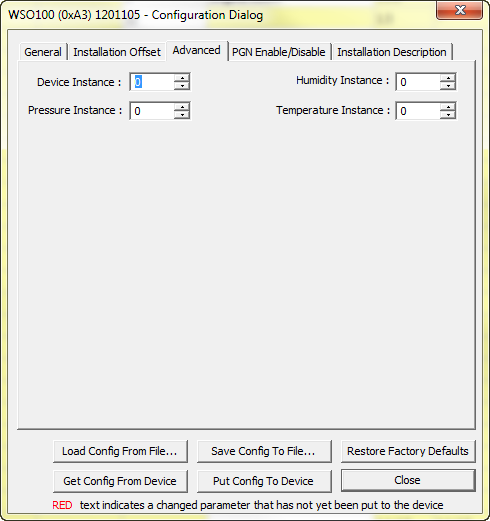

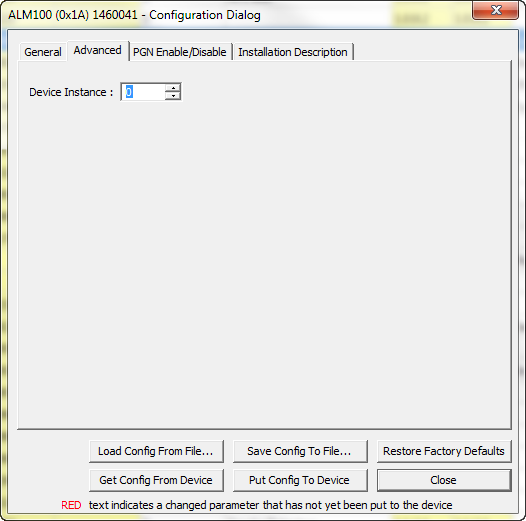

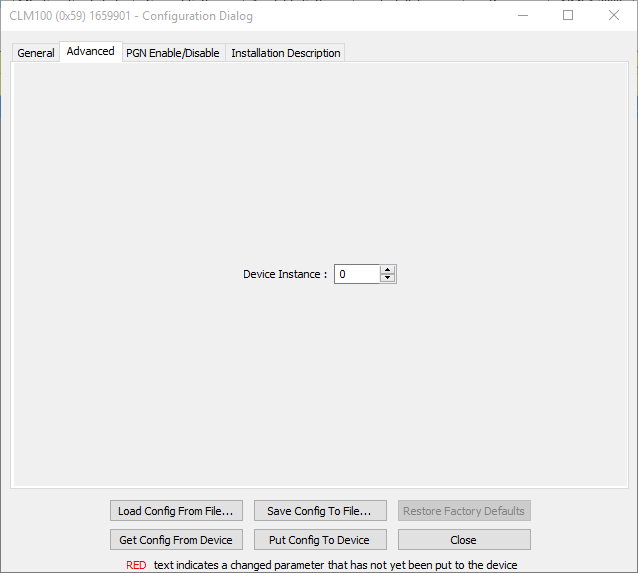

This tab contains entries that need to be changed only in

specific cases; for instance, if there are multiple instances of this device on

a network.

Figure 27 – CLM100 Advanced Tab

Device Instance

The device comes from the factory with the device instance

value set to 0. If you have multiple of these devices on a network, you may

find it necessary to set the device instances of other devices of this type so

that they are different.

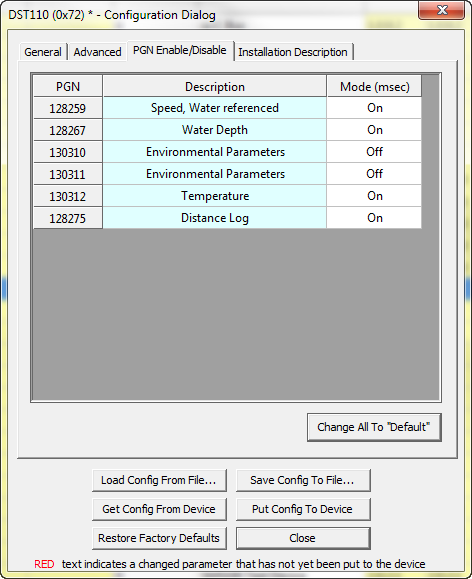

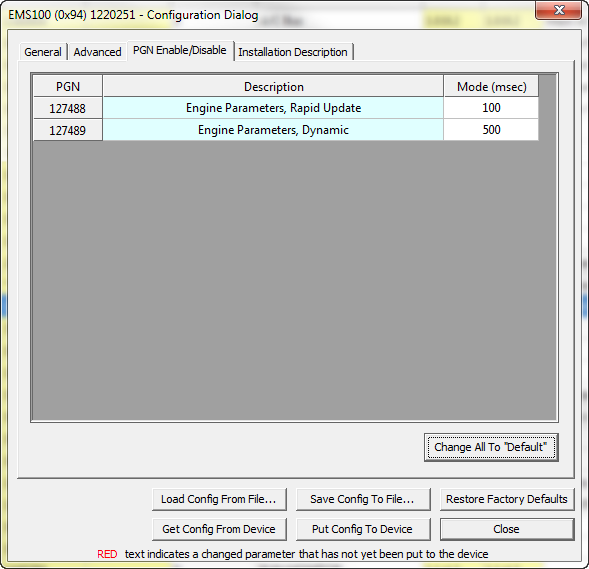

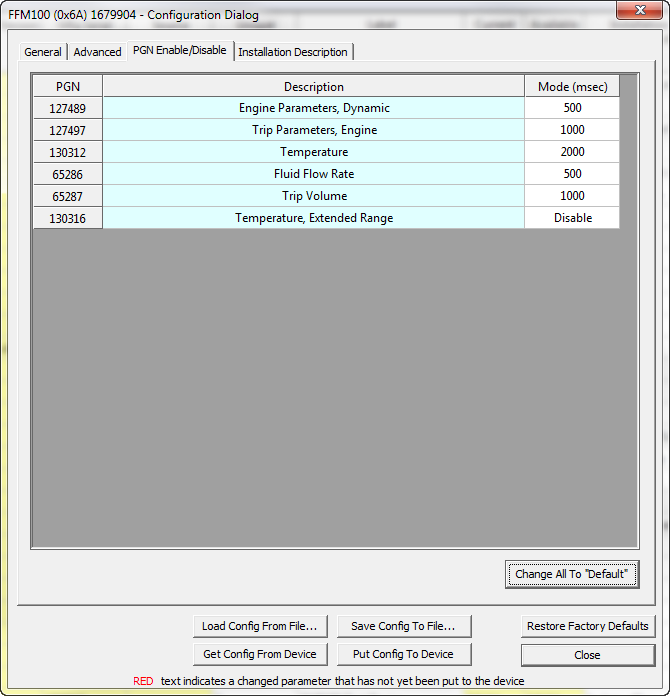

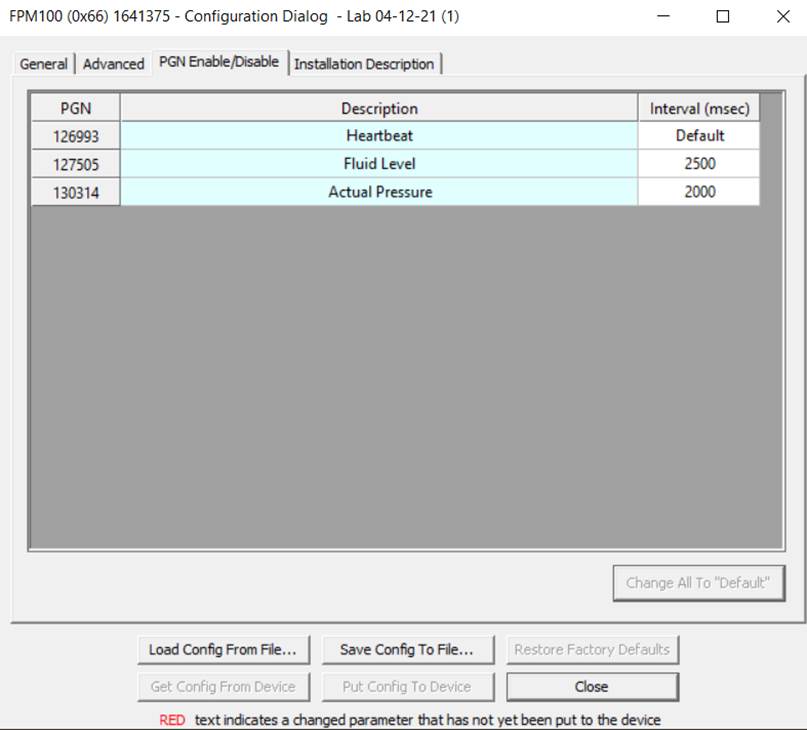

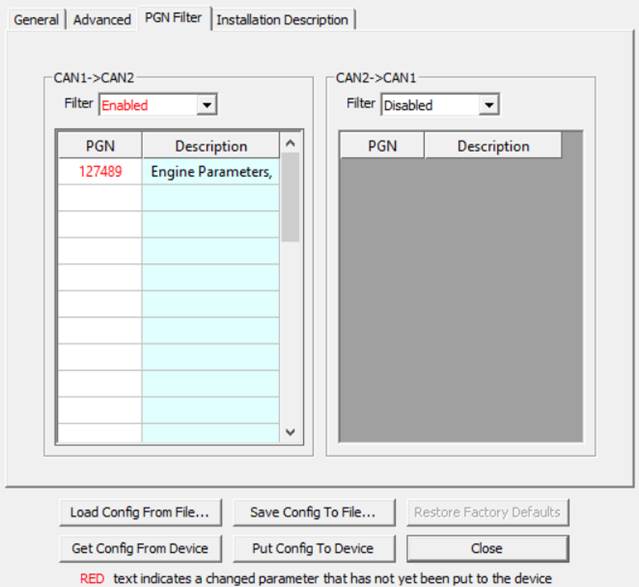

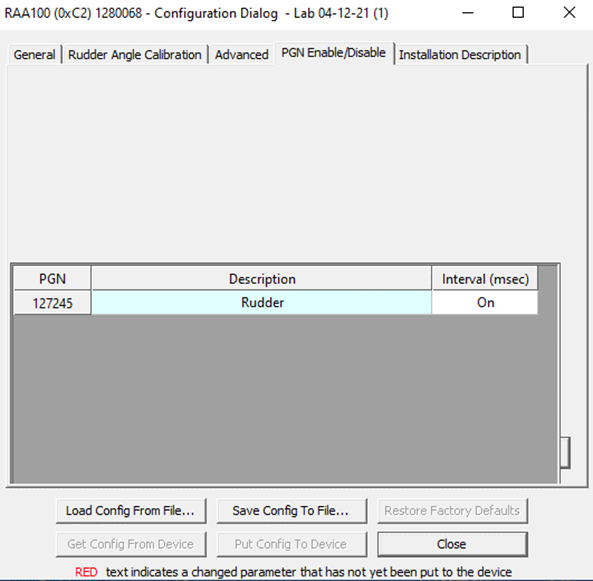

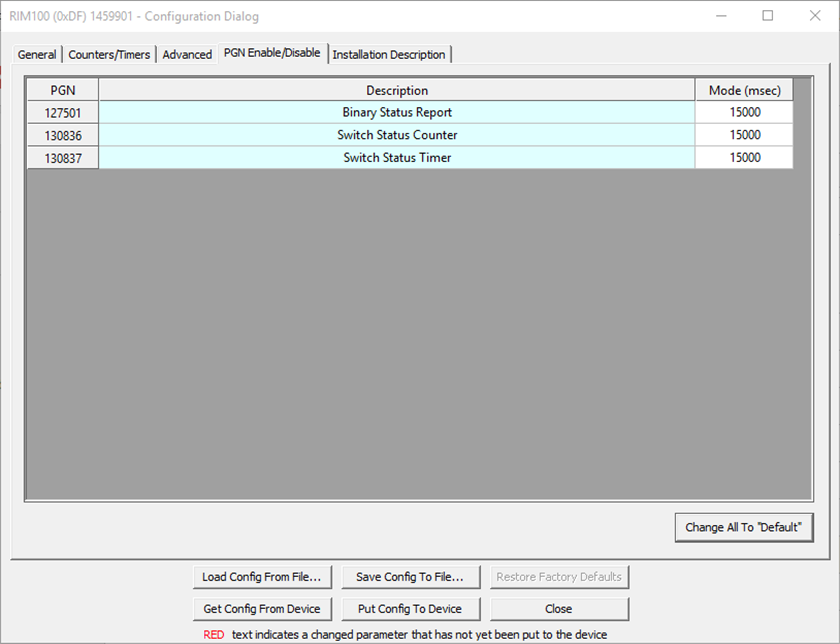

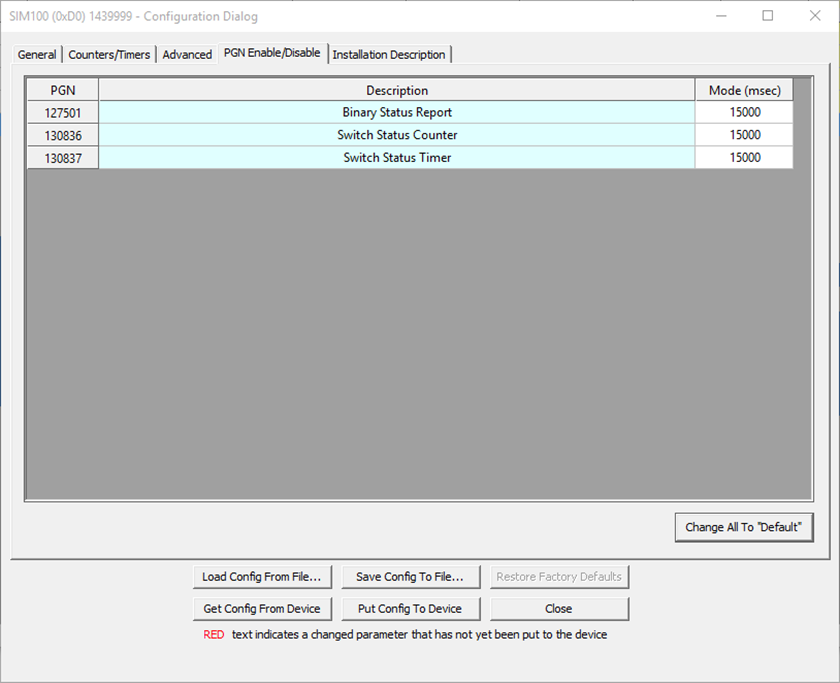

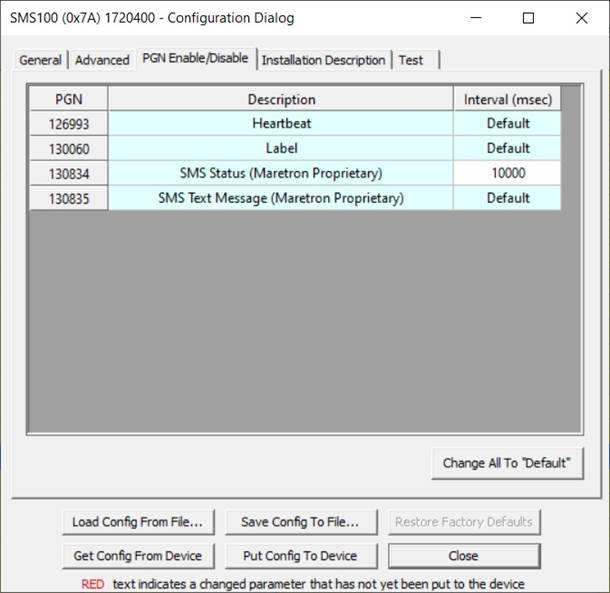

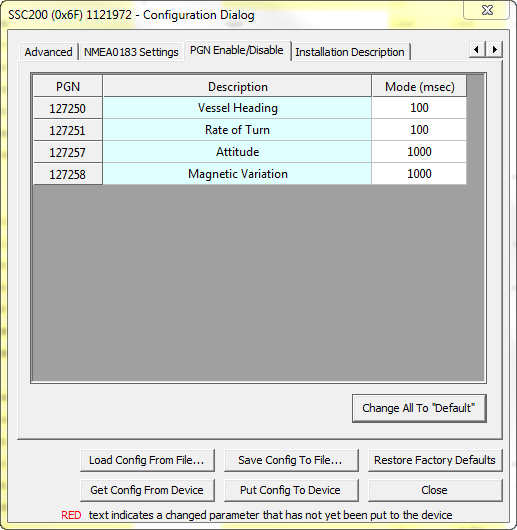

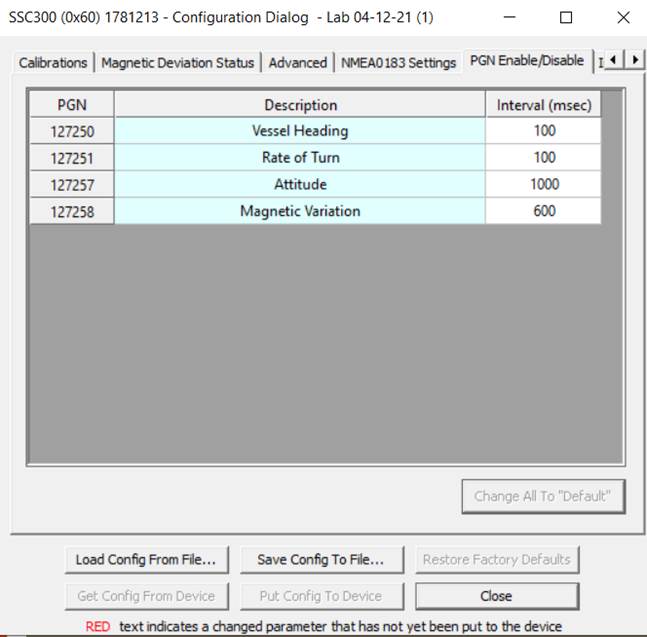

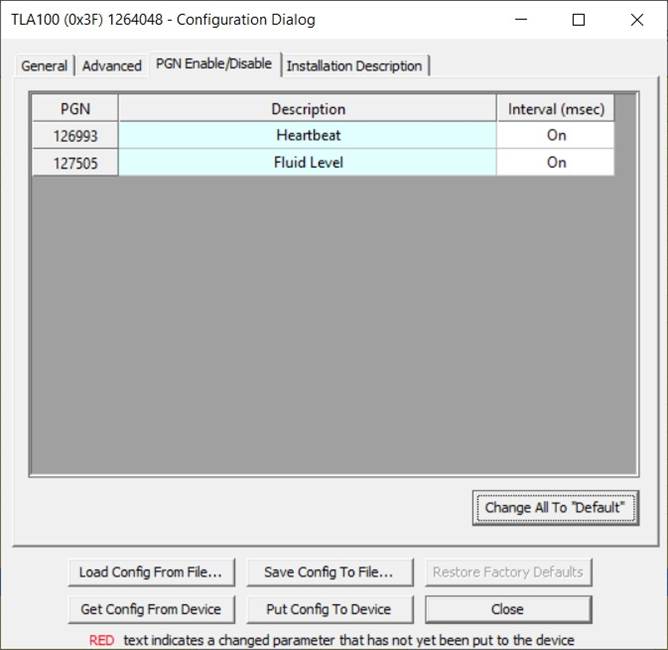

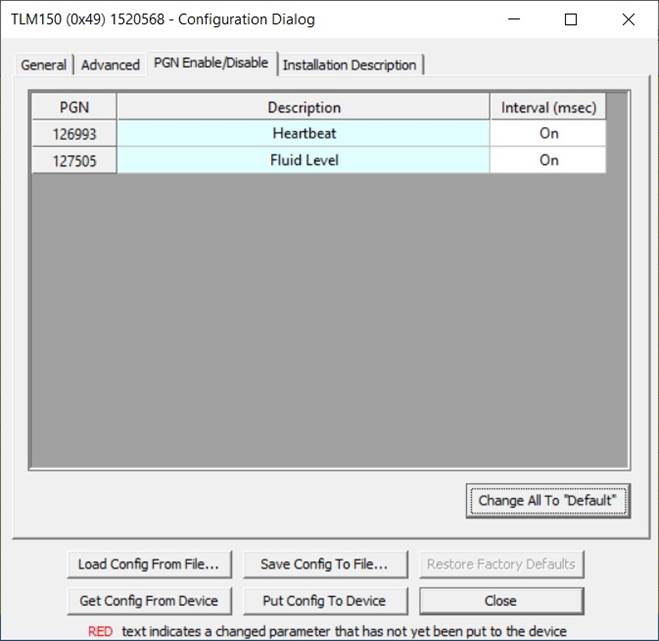

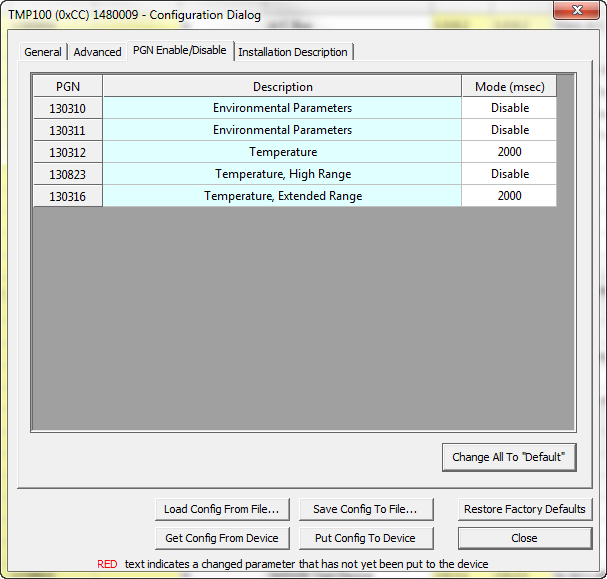

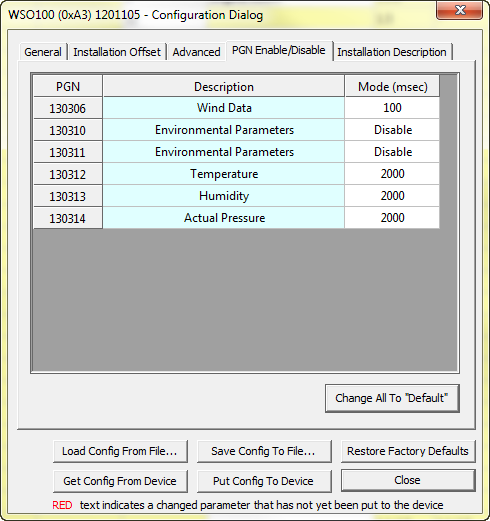

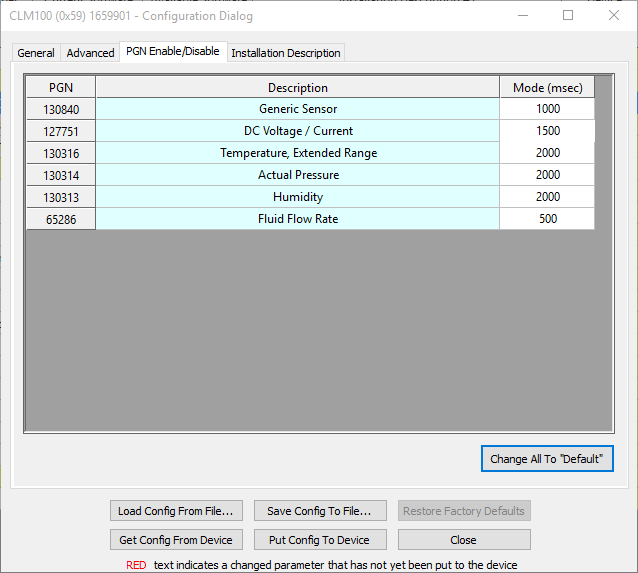

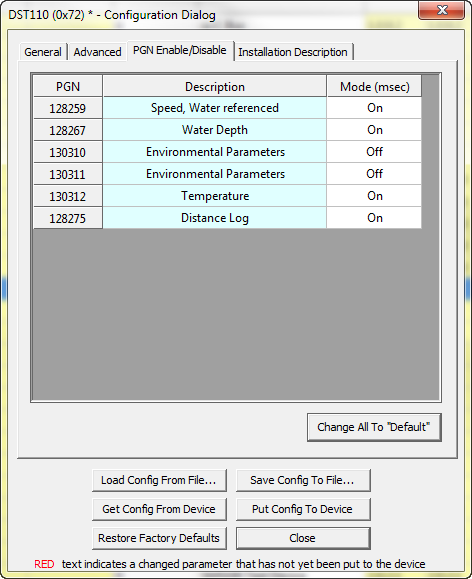

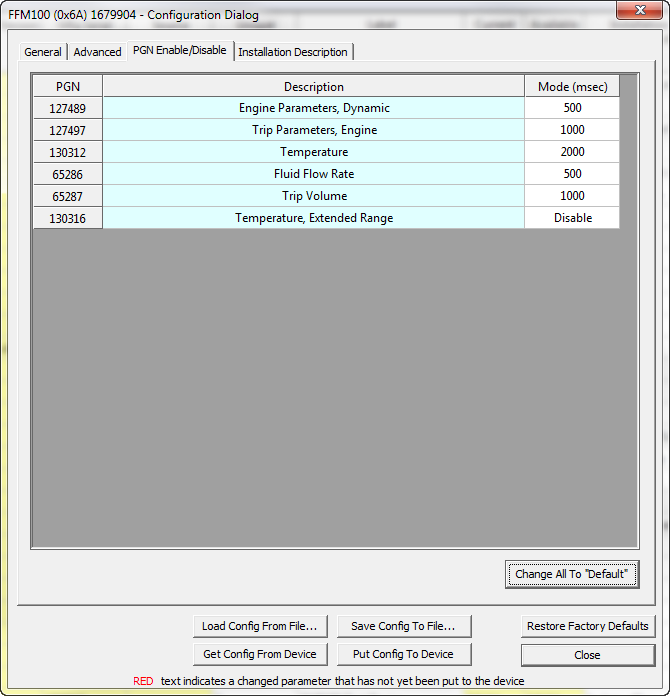

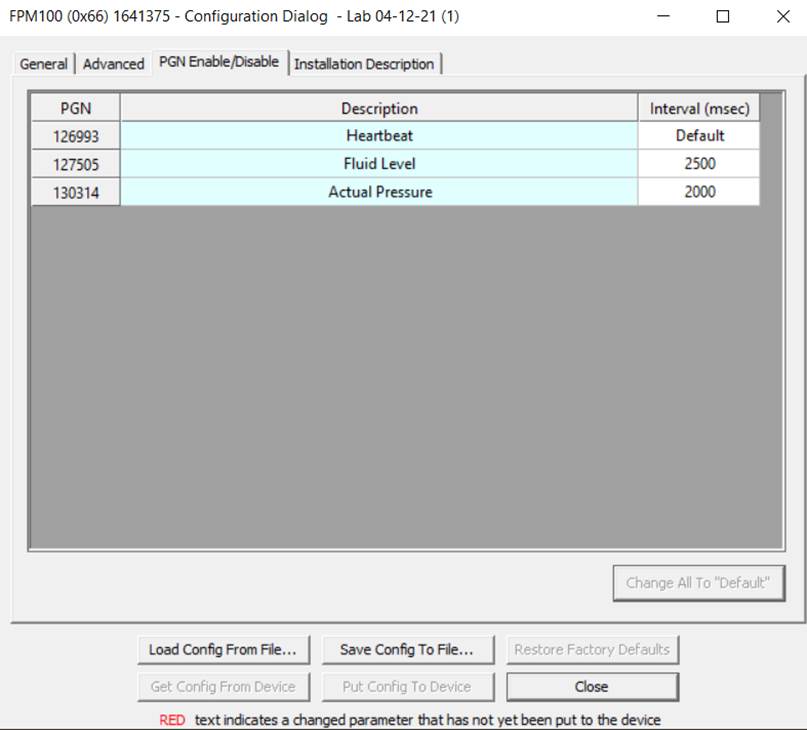

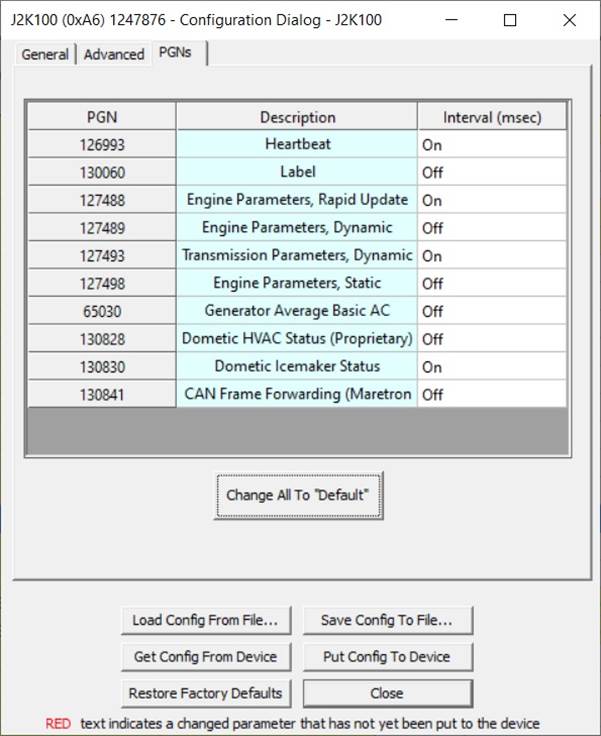

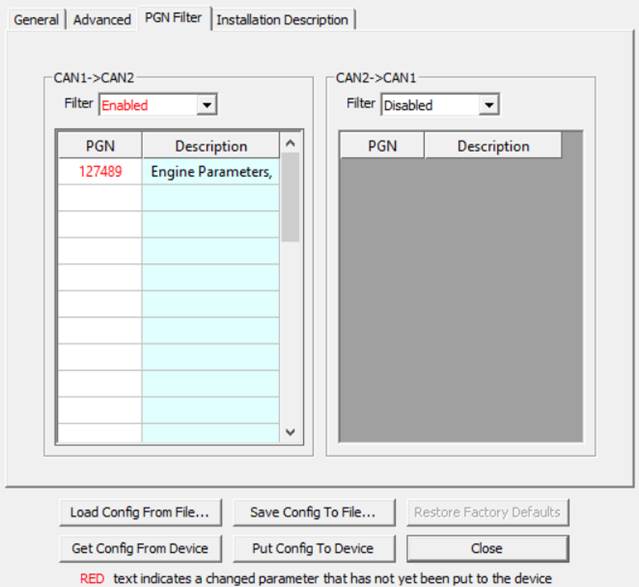

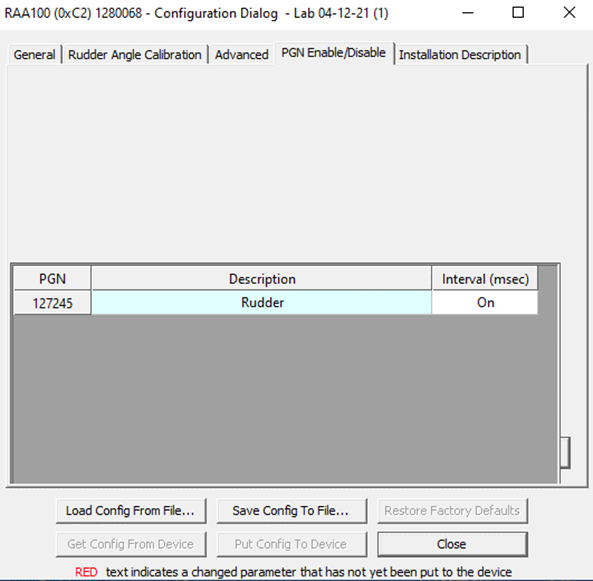

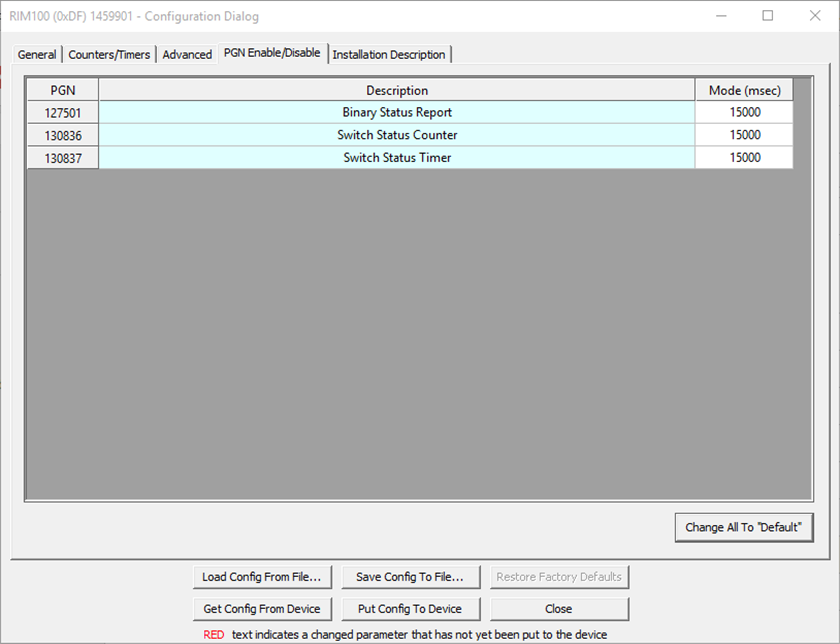

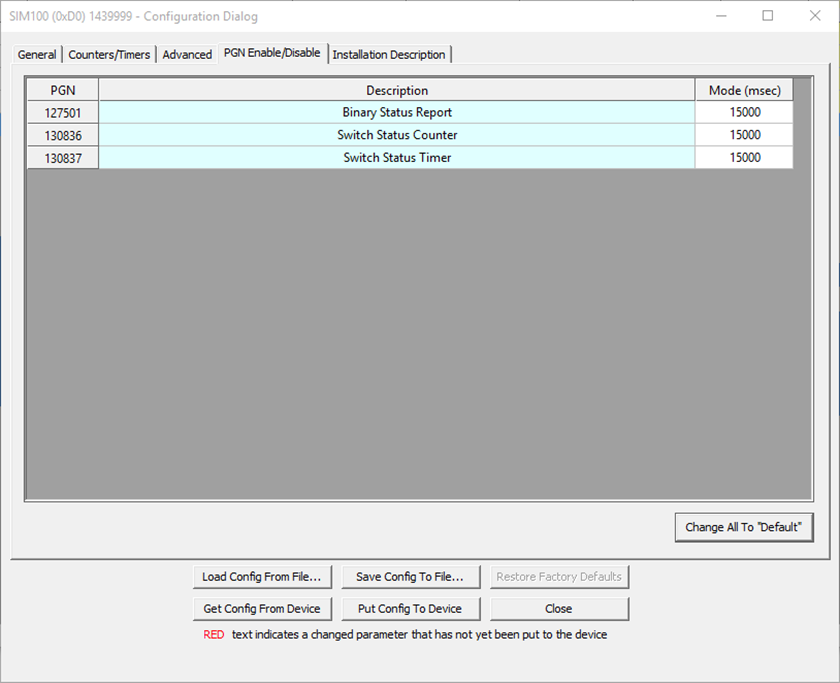

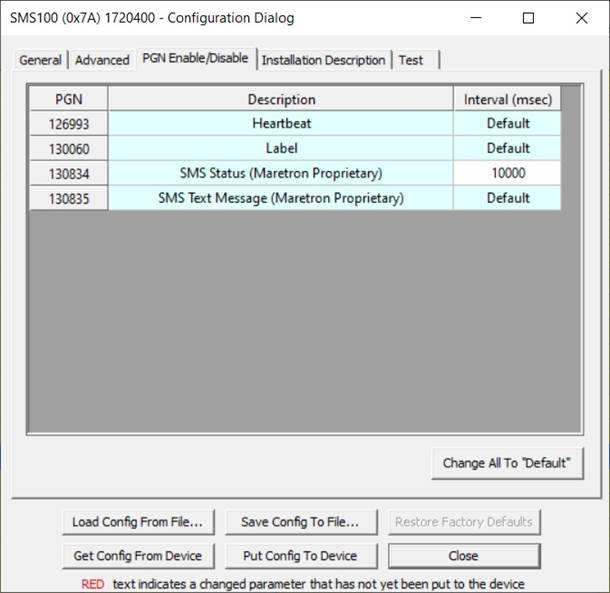

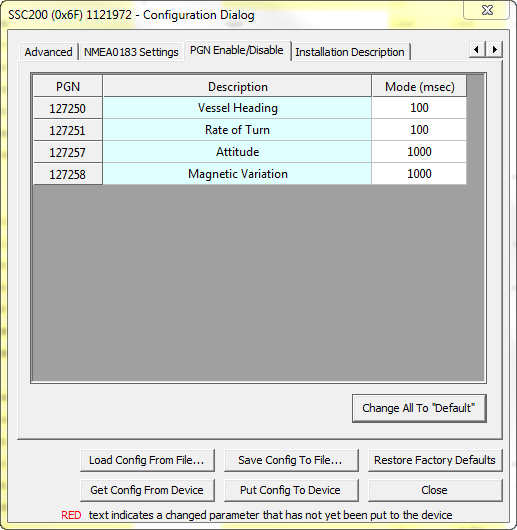

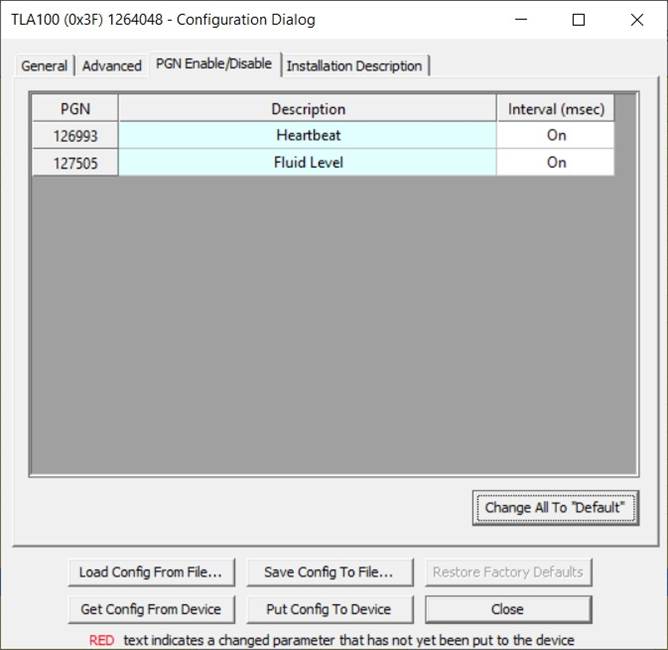

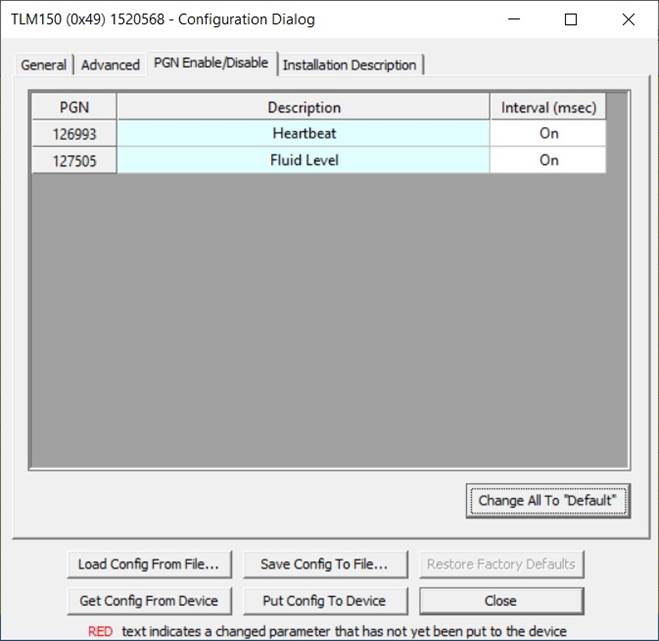

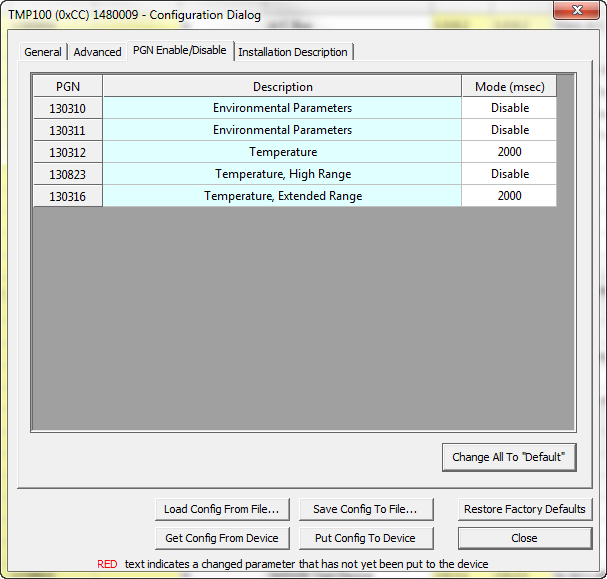

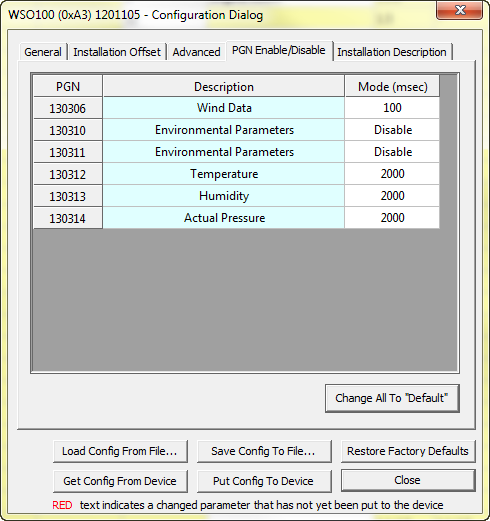

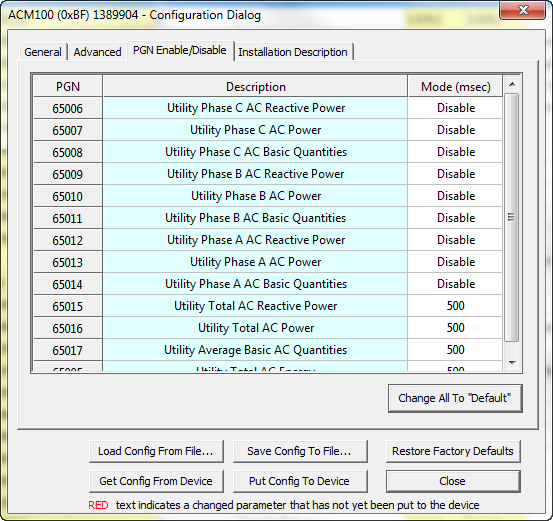

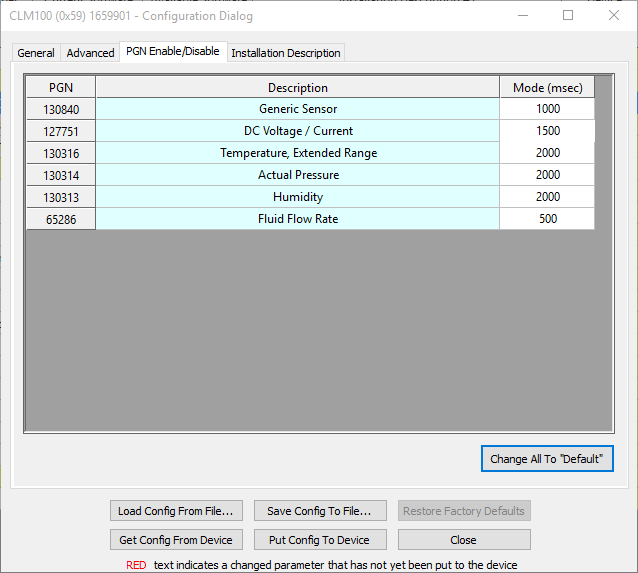

This tab allows you to enable or disable the transmission of

the periodic messages output by the device. You may enable or disable the

transmission of the messages or may program the time interval between

transmissions of a specific message, for devices which support the programming

of time intervals.

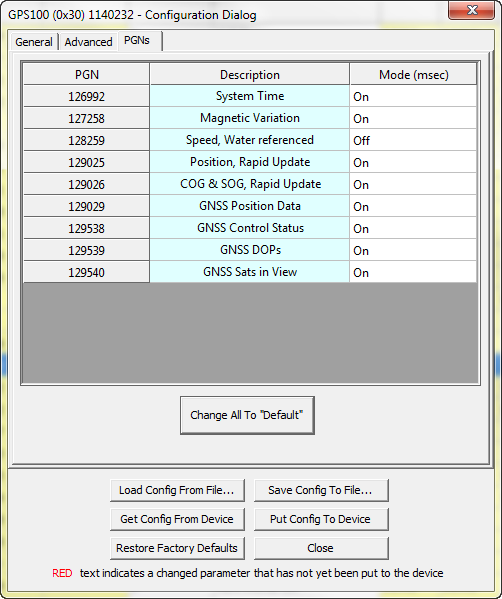

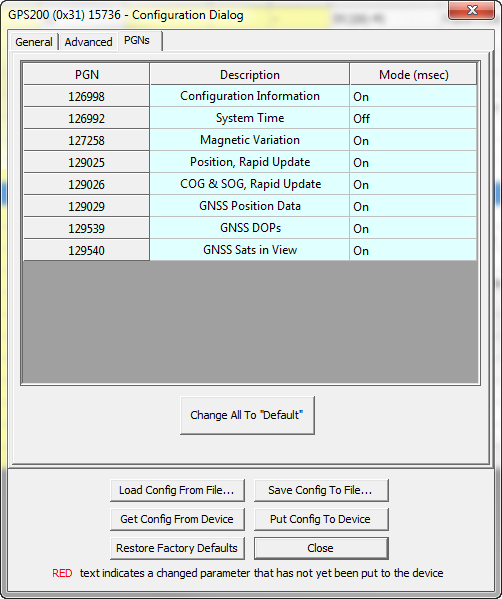

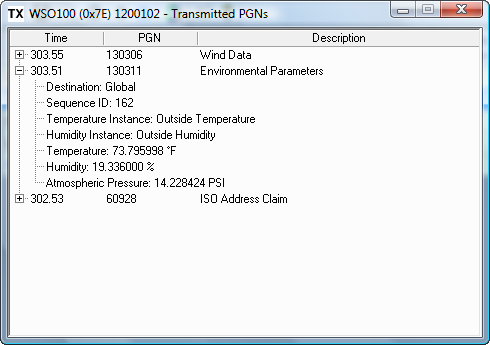

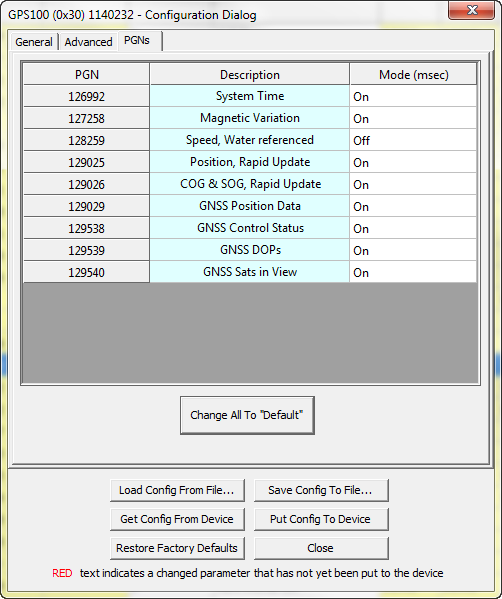

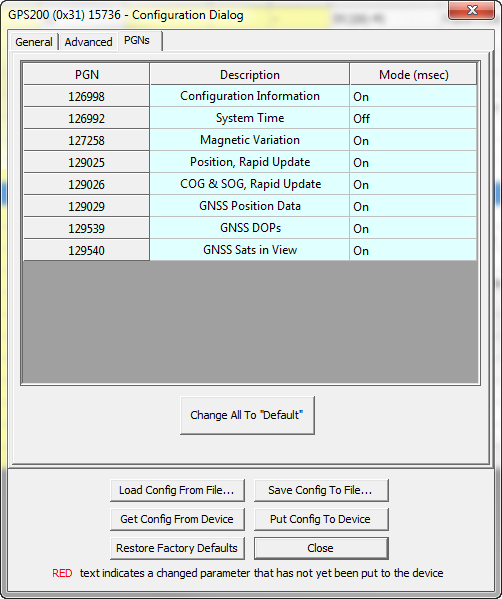

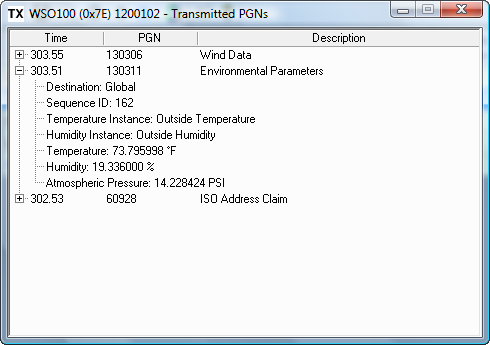

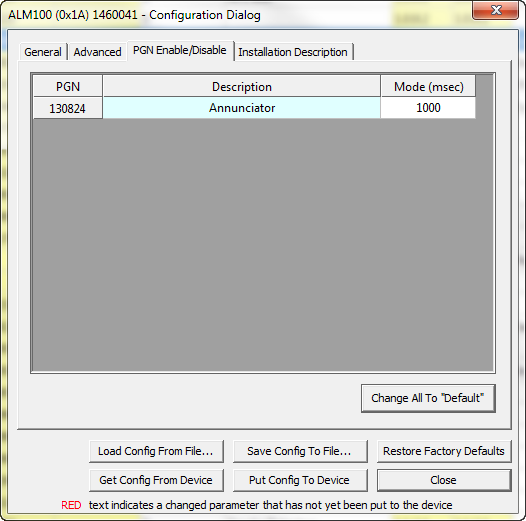

When you first open the PGN Enable/Disable tab, a list of

periodic PGN’s transmitted by the device will appear. The mode column will read

“On”, if the device is currently transmitting the message, or “Off”, if the

message has not yet been detected from the device.

You may configure each periodic message with one of the

following choices:

1) Disable – this

will turn off the periodic transmission of this message

2) Default – this

will turn on the periodic transmission of this message at the default rate

3) A numeric value

that will turn on the periodic transmission of this message at the specified

rate

Figure 28 – CLM100 PGN Enable/Disable Tab

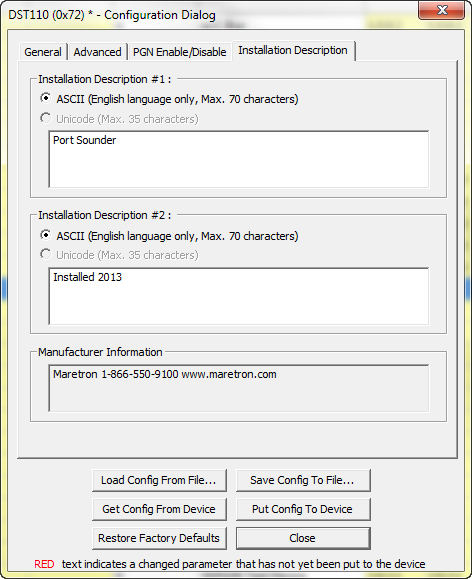

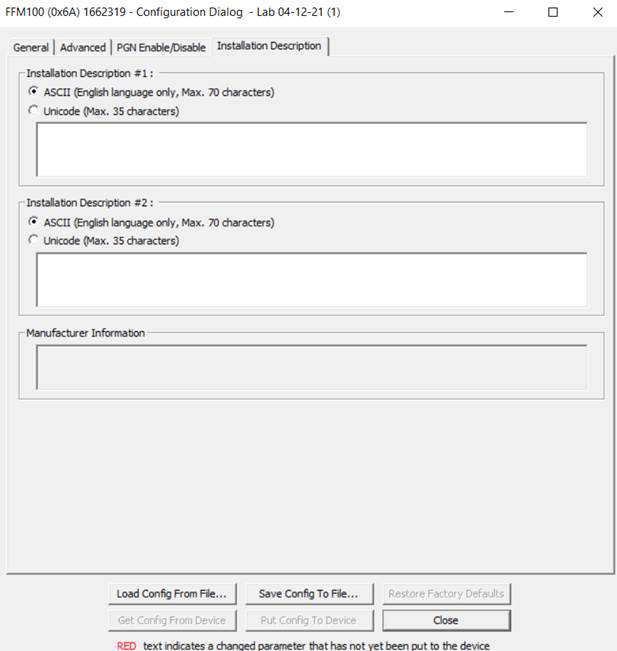

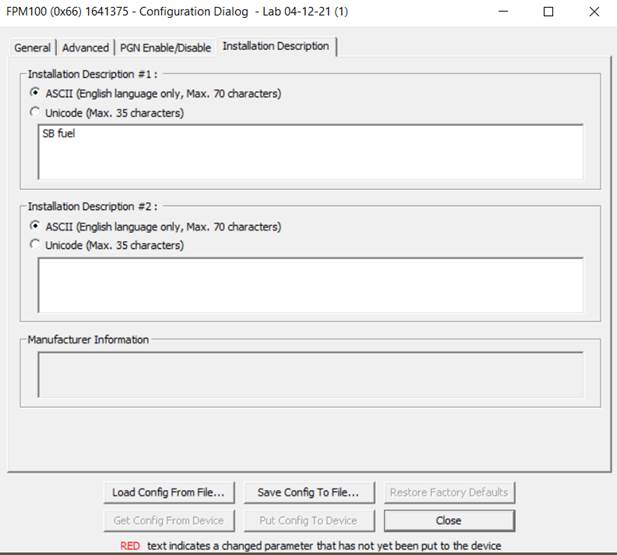

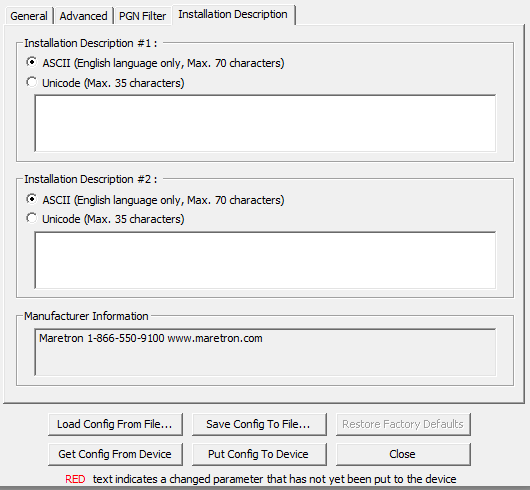

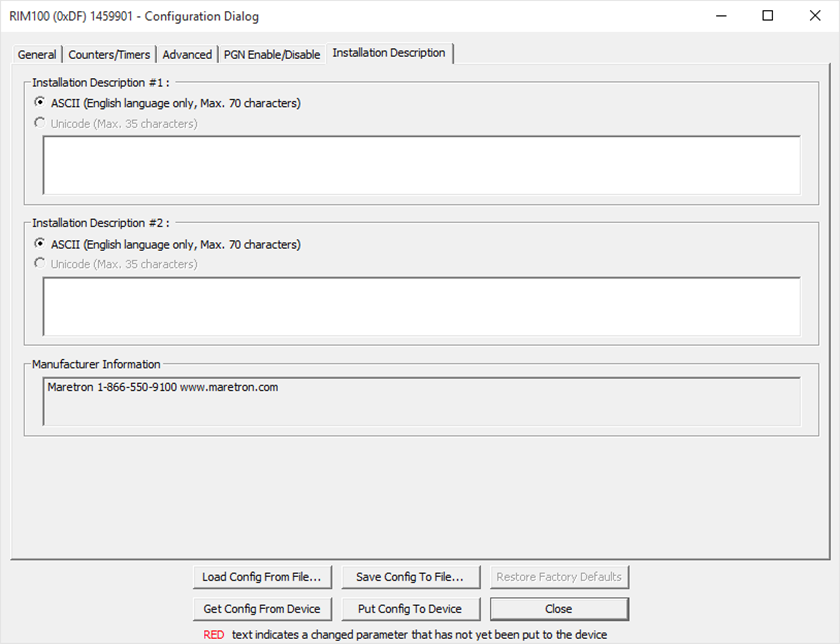

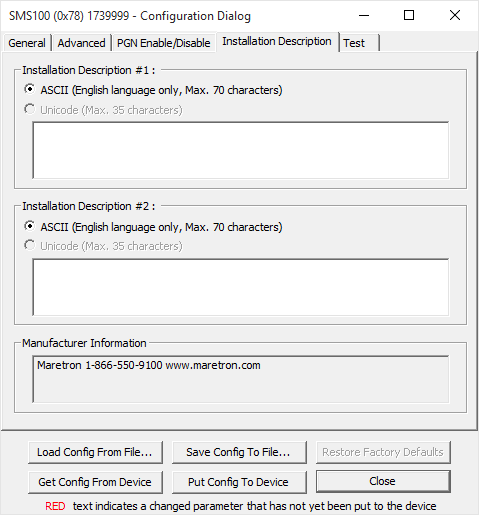

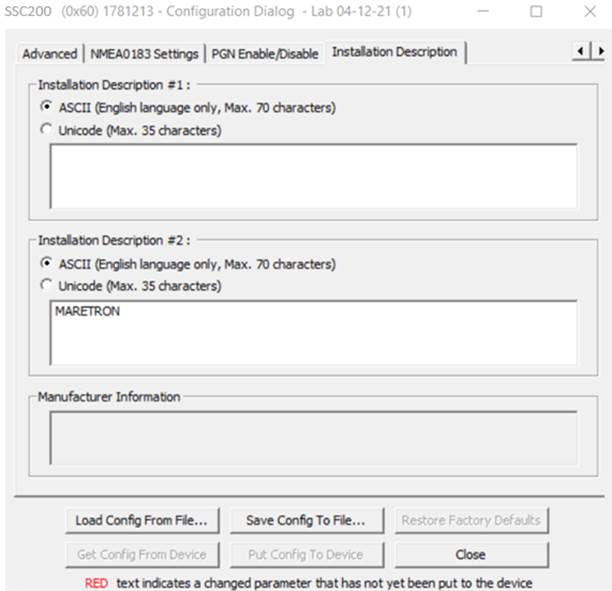

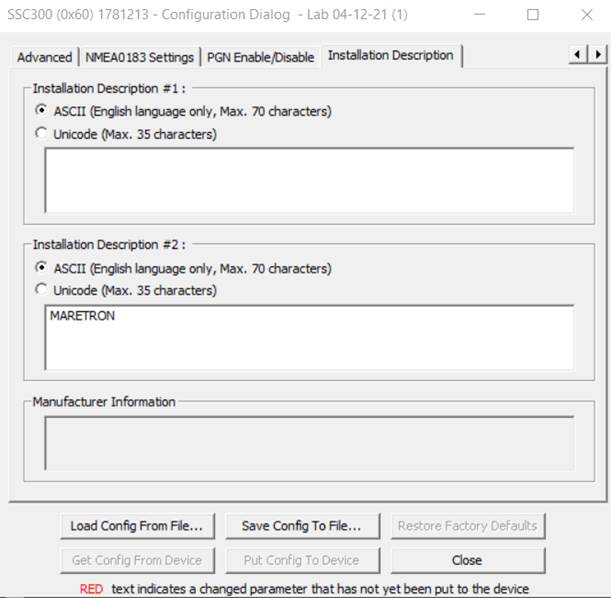

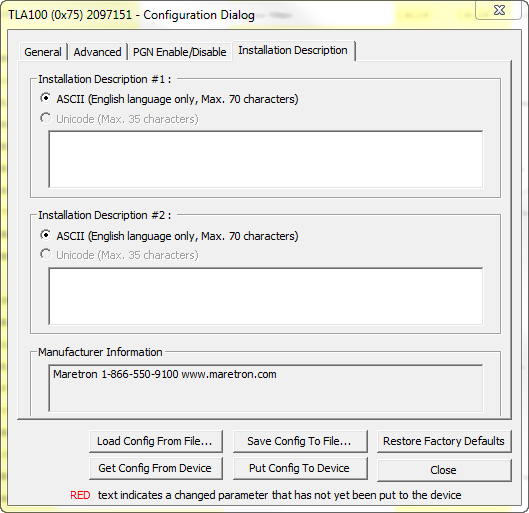

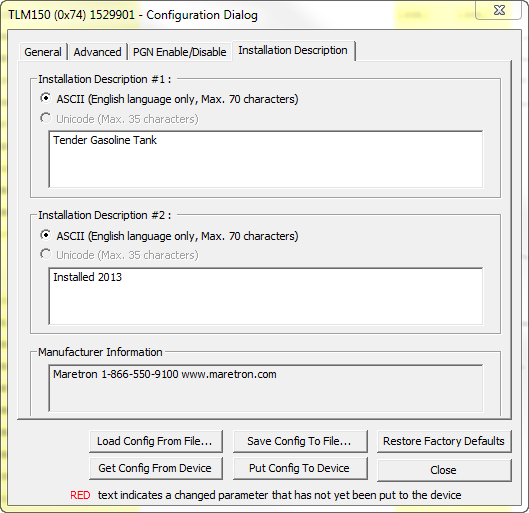

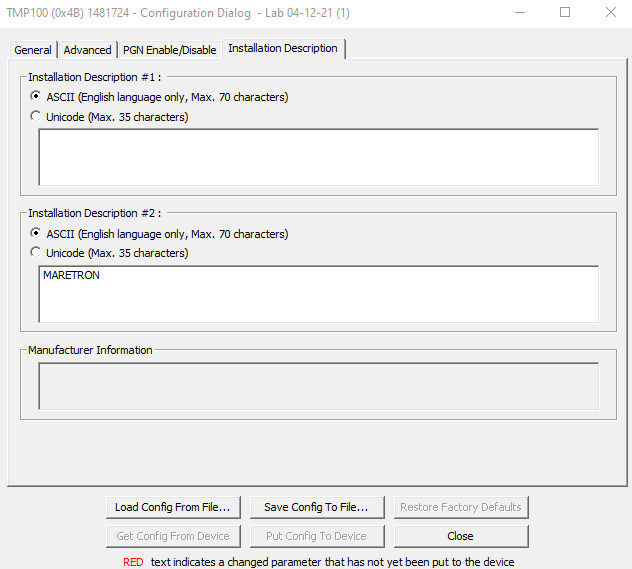

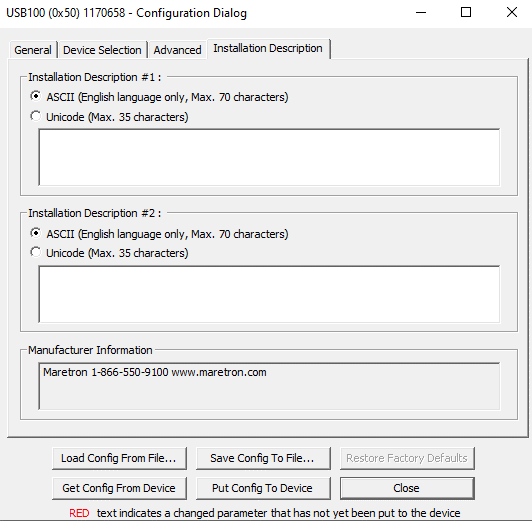

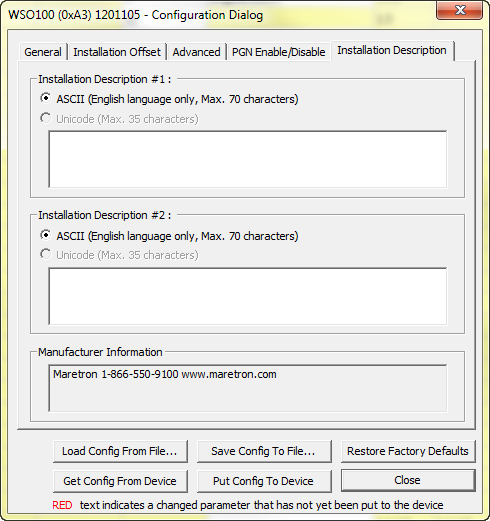

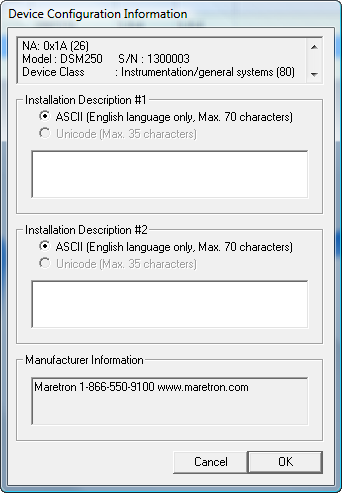

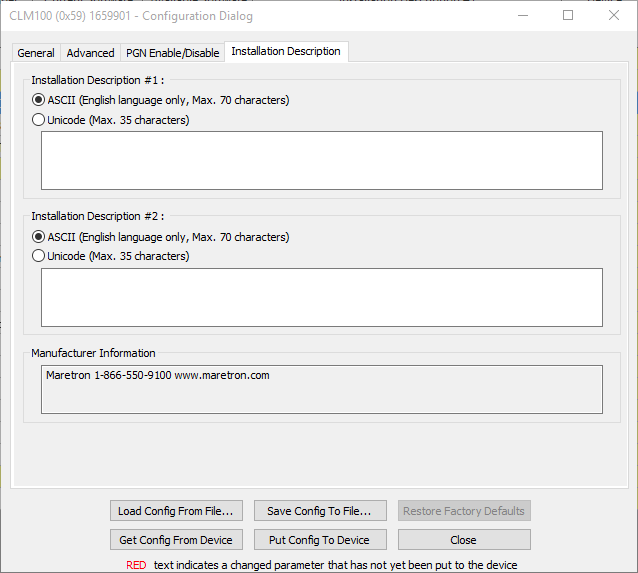

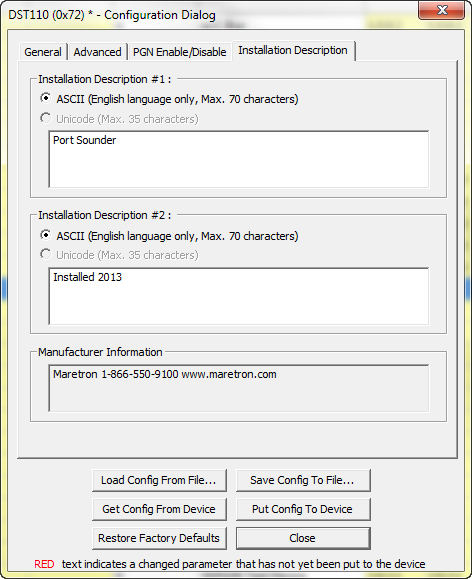

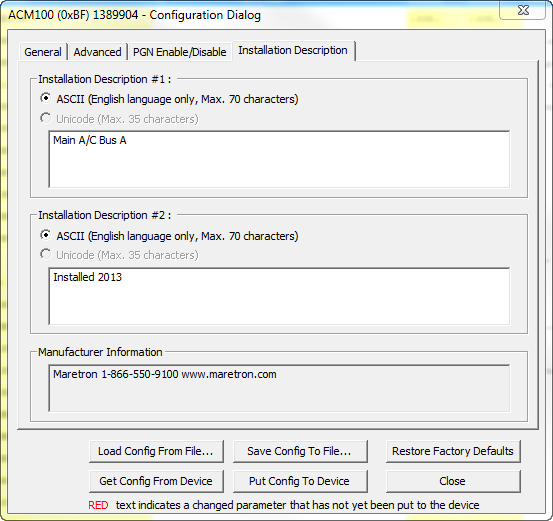

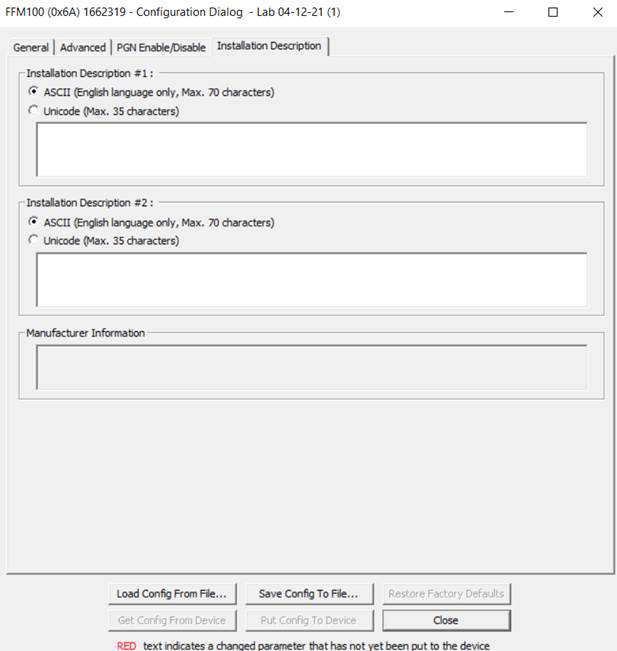

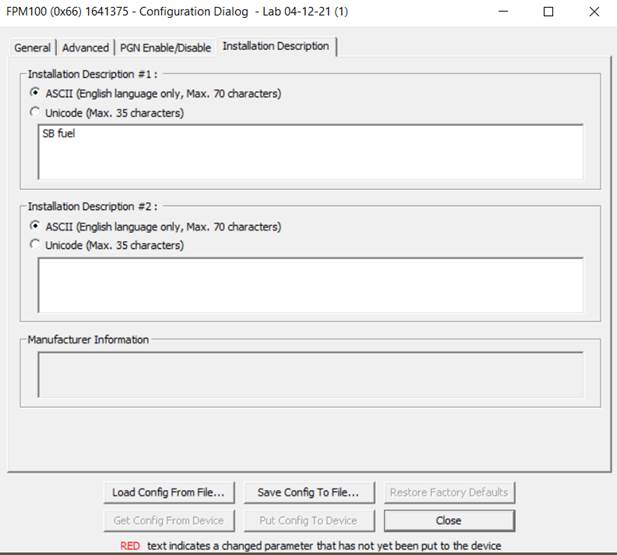

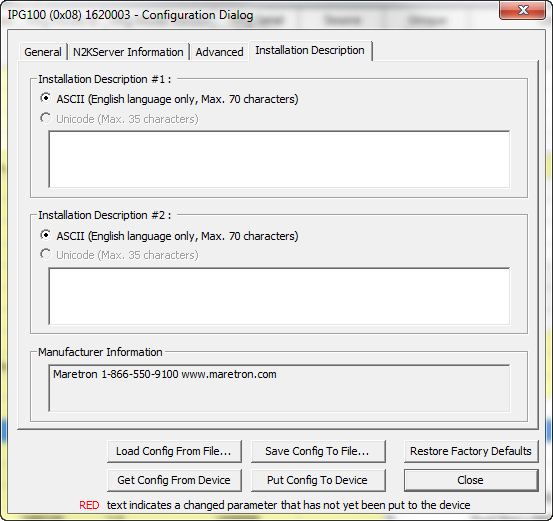

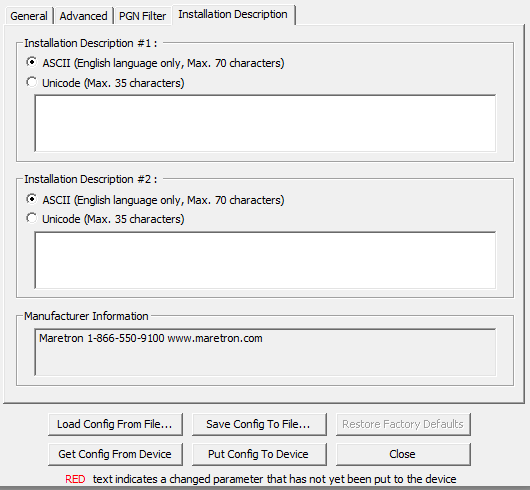

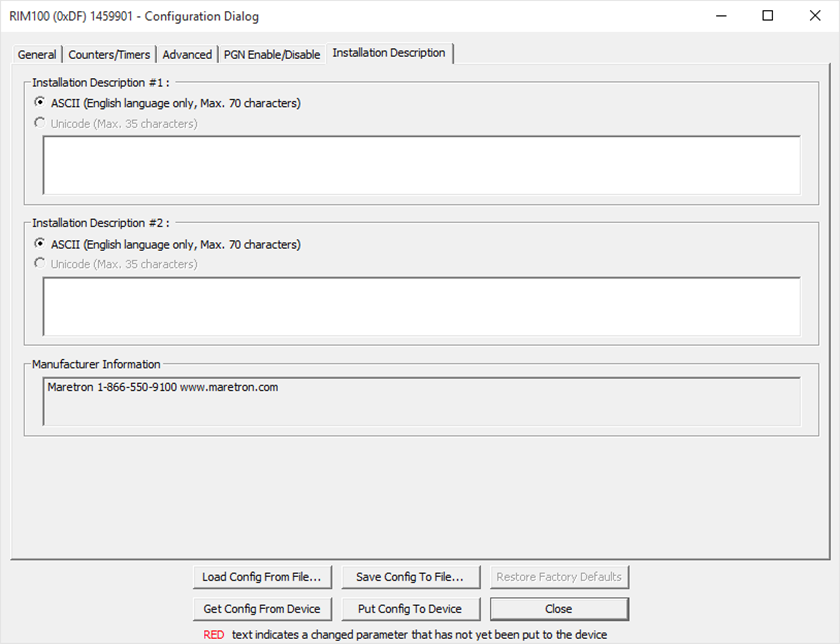

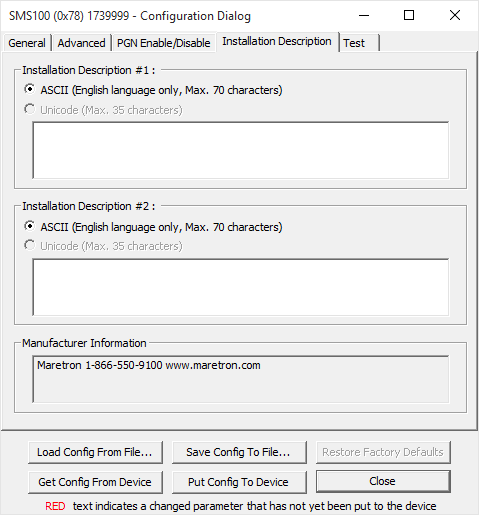

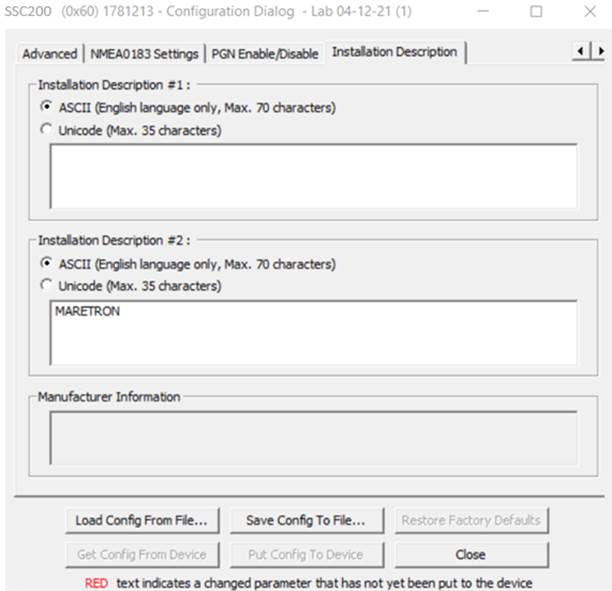

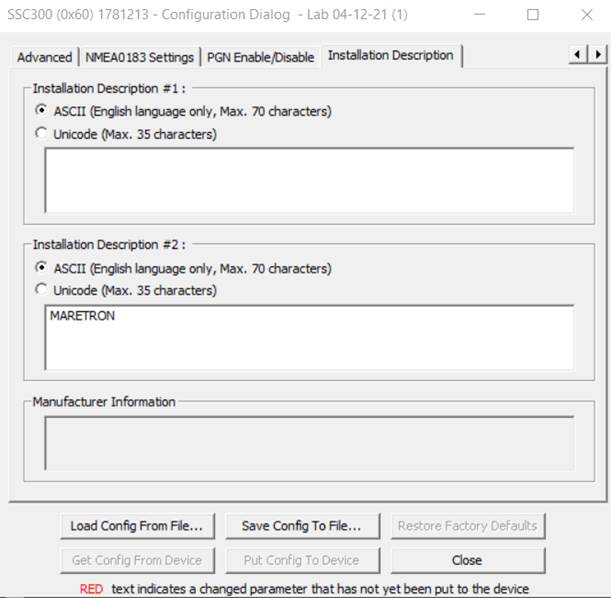

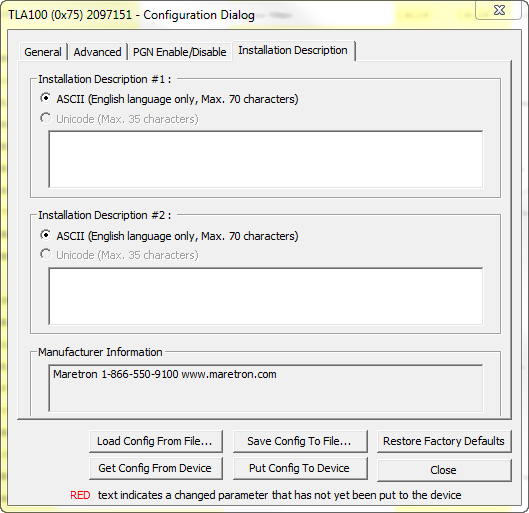

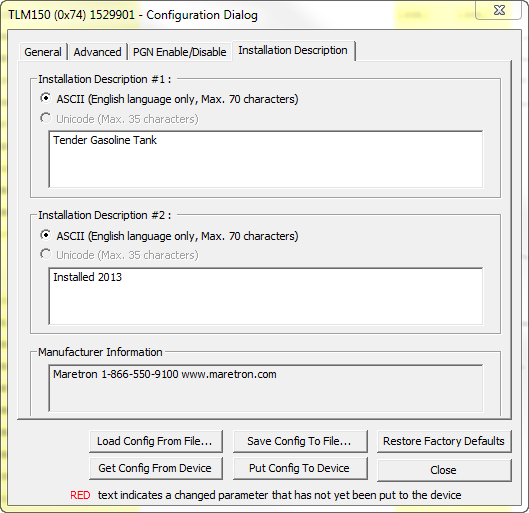

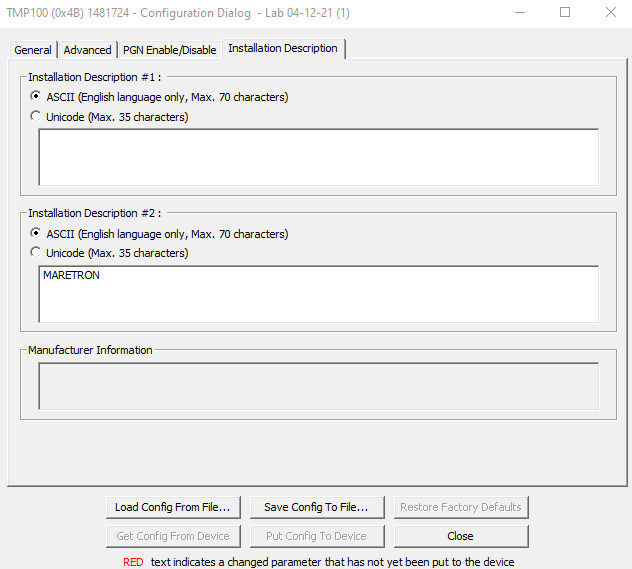

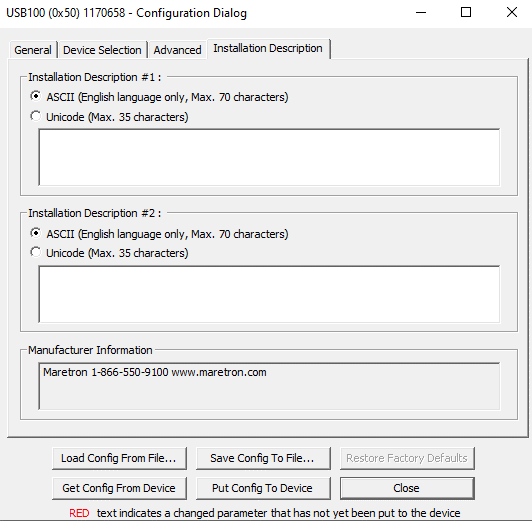

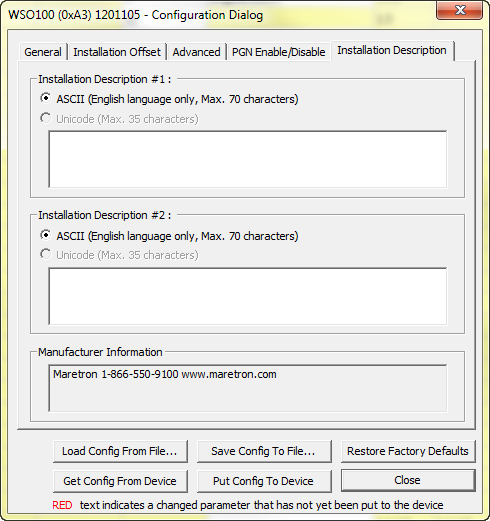

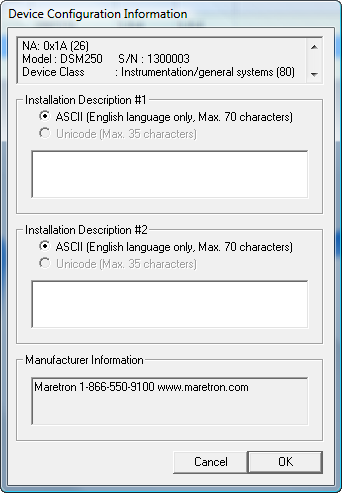

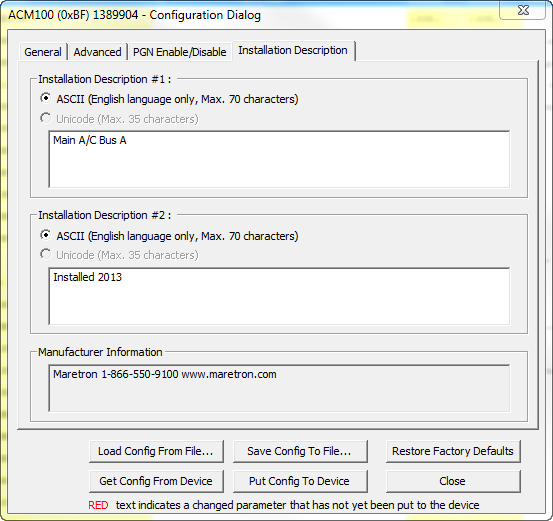

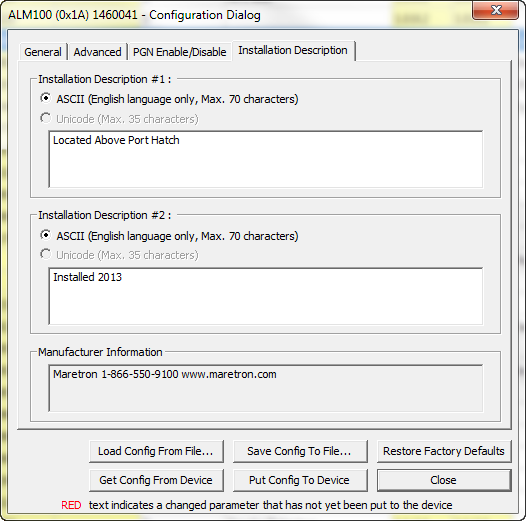

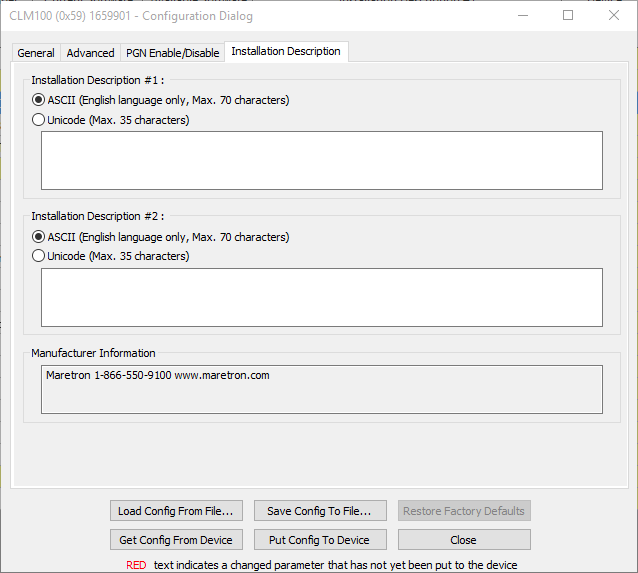

This tab allows you to set values for the installation

description properties of the device.

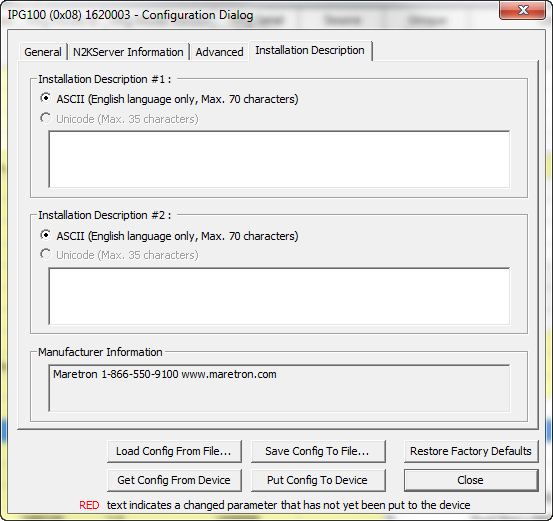

Figure 29 – CLM100 Installation Description Tab

Installation Description #1, #2

This device, along with all other Level A certified NMEA

devices, has two user-entry ‘Installation Description’ fields. You may enter

text into these fields with information specific to the device, such as date

installed, the initials/name of the installer, the physical location of the

device, etc

The CLMD12 is a high power 12 output Solid State Power

Controller featuring Deutsch connectors. In addition to fast switching, low

loss solid state ON/OFF functions, it provides accurate current measurement,

short circuit protection and Pulse-Width Modulation (PWM) function. The outputs

can be connected in parallel for higher current capacity.

Relative to electromechanical relays, the CLMD12 can

increase thermal efficiency by providing lower power dissipation and providing

higher power-to-weight densities.

The CLMD12 can provide reductions in overall vessel weight

and wiring complexity.

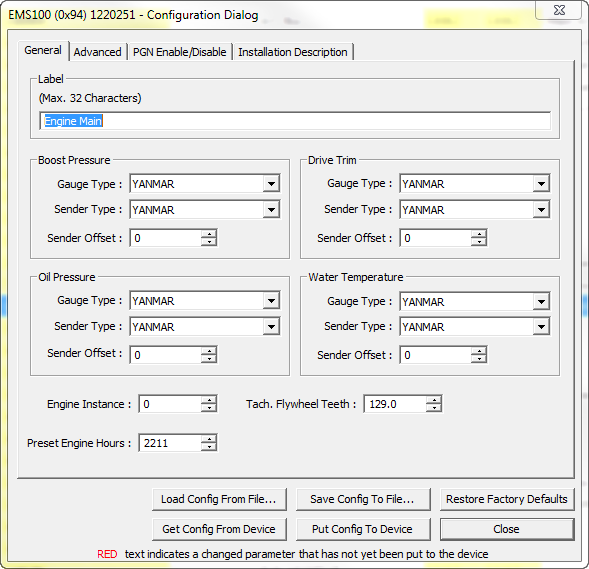

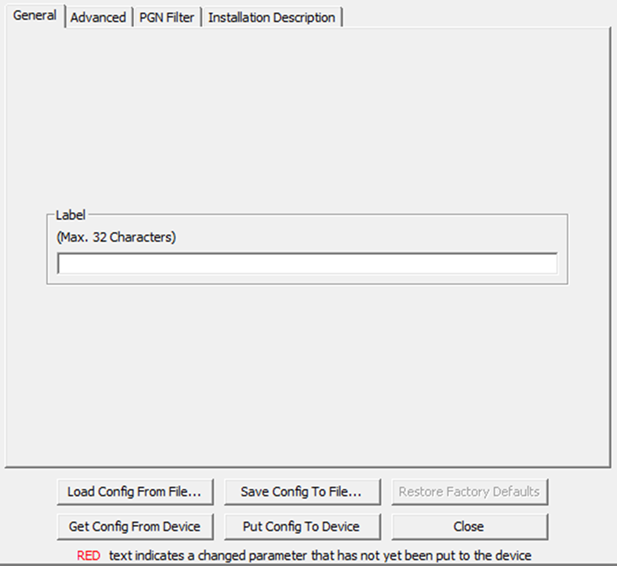

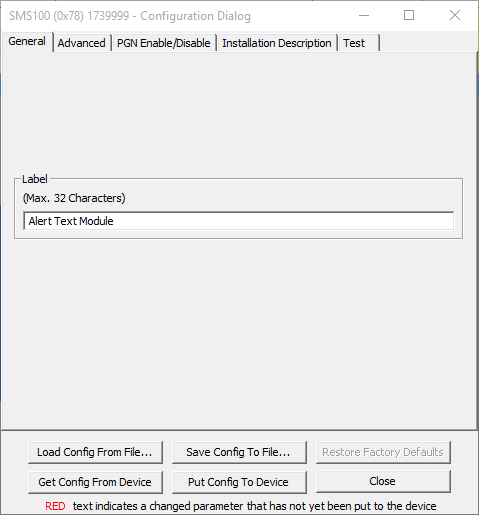

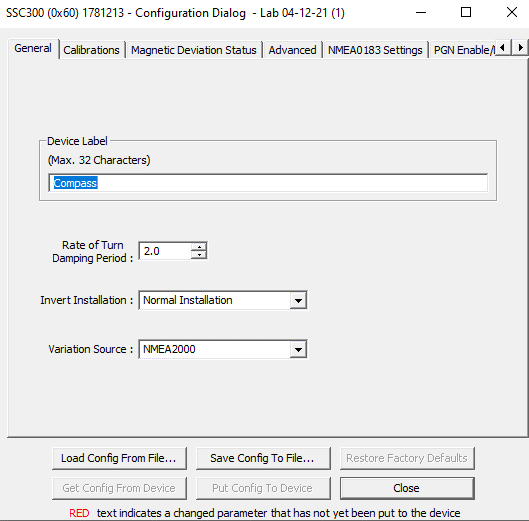

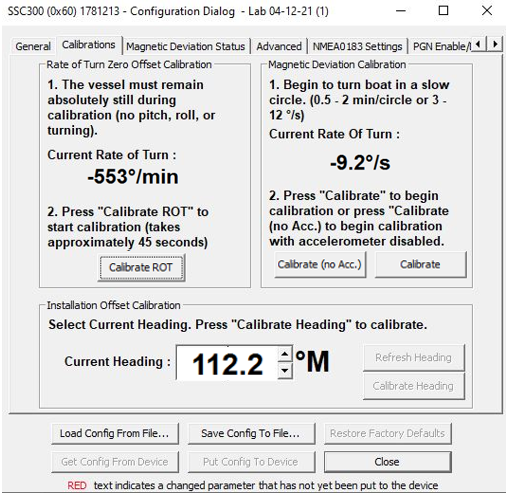

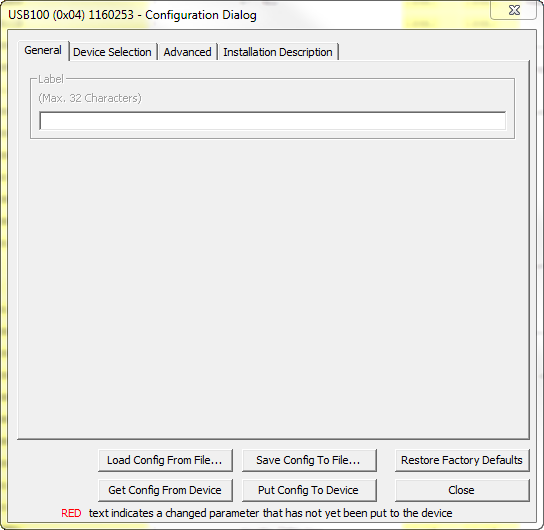

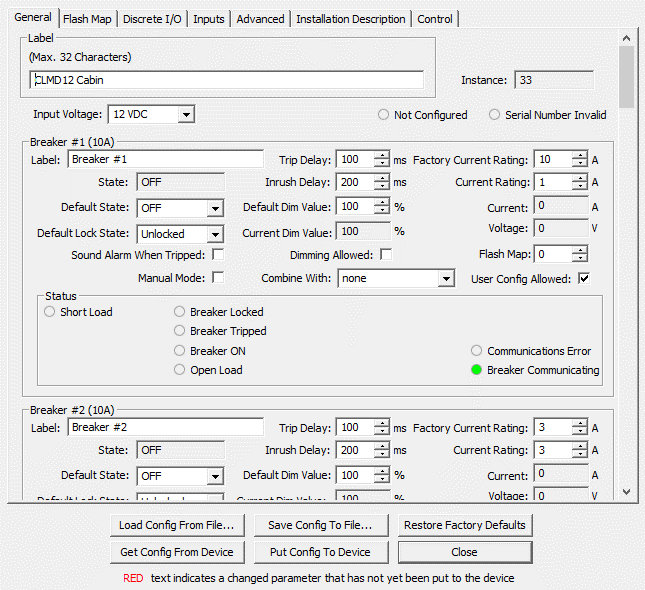

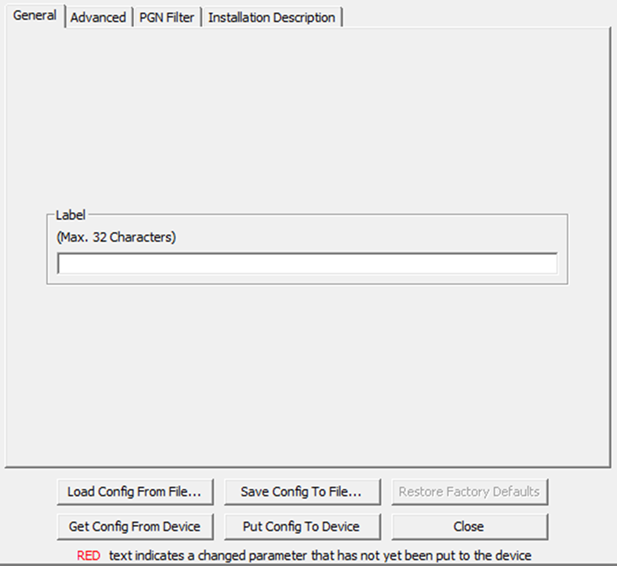

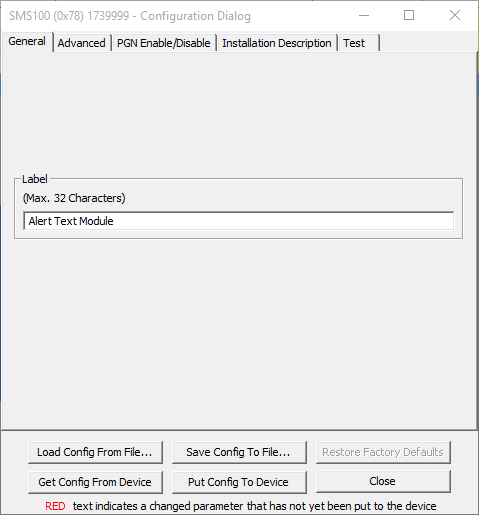

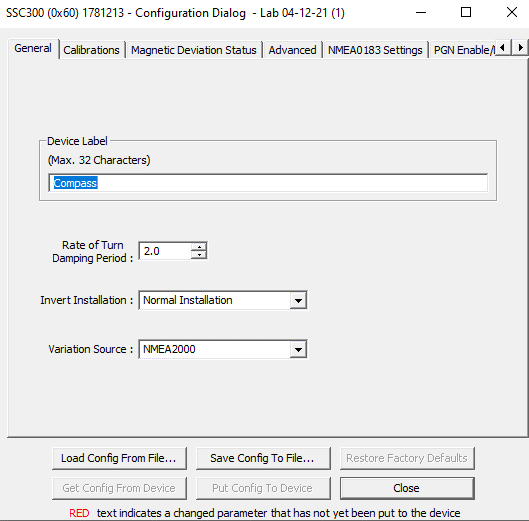

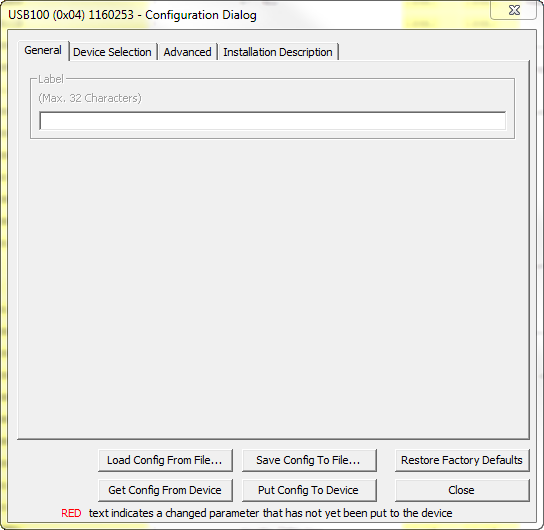

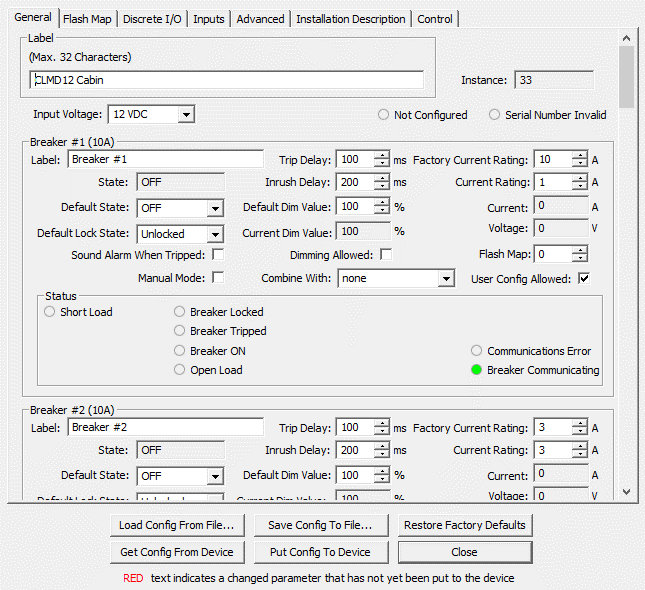

This tab contains commonly used configuration items.

Figure 32 – CLMD12 General Tab

This text box allows you to assign a text label to the

device. This label is visible in Maretron analysis and display products and

allows you to easily identify the particular device.

NMEA 2000 provides a unique instance number for each breaker

box on a vessel. This read-only field shows the instance number assigned to

this device. This instance number value is reflected in the 127501 Binary

Switch Bank Status message. The instance number can be configured by changing

the “Device Instance” field on the “Advanced” tab.

This field allows you to configure nominal expected input

voltage of the CLMD12. Choose from one of the following selections:

·

12 VDC

·

24 VDC

·

36 VDC

·

Undefined

When lit, this read-only field indicates that the CLMD12

does not contain a valid configuration.

When lit, this read-only field indicates that the CLMD12

does not contain a valid serial number. Please contact Maretron support for

assistance.

This section contains settings for the specified circuit

breaker. One of these sections is present for each of the breakers in the unit.

This text box allows you to configure a text label for the

breaker to identify it (for example, “RUNNING LIGHTS” or “HATCH”). For each

breaker, set this to a value which describes the breaker so that you can easily

identify it in display devices.

This read-only field indicates the current state of the

breaker. It will contain one of the following values:

·

OFF

·

ON

This allows you to configure the state of the breaker when

the CLMD12 is powered on. You can set this to one of the following values:

·

OFF

·

ON

·

LAST STATE

This parameter allows you to configure whether the breaker is

locked when the CLMD12 is powered on. You can set this to one of the following

values:

·

LOCKED

·

UNLOCKED

This parameter allows you to configure whether an alarm is

sounded on Carling OctoPlex Touch Screen displays whenever the breaker is

tripped.

Manual Mode

This check

box selection allows you to enable or disable Manual Mode. By default,

devices such as an MFD or N2KView will have direct access to control all CLMD12

breakers. These devices communicate to the breakers by NMEA 2000 PGN 127500 or PGN

127501 via 126208 Command Group Function. When Manual Mode is enabled, commands

from devices using NMEA 2000 PGN 127500 or PGN 127501 via 126208 Command Group

Function is ignored. The CLMD12 instead will only allow for assigned Discrete

I/O functions to control the breaker that has Manual Mode enabled. For more

info regarding Discrete I/O functions please refer to section 5.6.3 ‘Discrete I/O Tab’.

Trip Delay

This parameter allows you to configure the trip delay for

the breaker (the current through the breaker must exceed the current rating of

the breaker for this amount of time for the breaker to trip). This can be set

in the range of 0 ms to 750 ms.

This parameter allows you to configure the inrush delay for

the breaker. When the breaker is switched from OFF to ON, the current through

the breaker can exceed the current rating of the breaker for this amount of

time without the breaker tripping. This allows for a brief period of current

inrush, preventing the circuit from inadvertently tripping when energized. This

can be set in the range of 0 ms to 1500 ms.

This parameter allows you to configure the percent dimming

value for the breaker when the CLMD12 is powered on. This value will be applied

only if the Dimming Allowed box is checked. This can be set in the range of 5%

to 100%.

This read-only field shows the percent dimming value for the

breaker.

This parameter allows you to configure whether the channel

is dimmable. Check this box to allow dimming commands to change the dimming

level of the breaker and clear this box to force the breaker to operate at 100%

dimming level.

This parameter allows you to configure the maximum value to

which the Current Rating can configured. This parameter should be configured to

the current rating for the wire connected to this breaker.

This parameter allows you to configure the desired trip

level for this breaker. Exceeding this current will initiate a trip.

This read-only field shows the real-time current passing

through the breaker.

This read-only field shows the real-time voltage at the load

terminal of the breaker.

This parameter allows you to configure a breaker to use a

flash map. A value of 0 means that the breaker is not assigned to any flash

map, and a value of 1 through 15 assigns the breaker to the flash map

corresponding to that number.

This parameter allows you to group two breakers of equal

rating so that you can power loads up to 180% the normal individual channel

rating. The drop-down list shows only the valid channels that can be combined.

Selecting a different channel will automatically deselect any prior grouping

before selecting the new one.

User Config Allowed

This parameter allows you to configure whether configuration

changes can be made to the breaker. If this is checked, configuration

parameters for the breaker can be changed. If this is cleared, configuration

parameters for the breaker cannot be changed.

This group of indicators show real-time status of the

breaker.

When lit, this read-only field indicates that the breaker

tripped due to a detected short circuit.

When lit, this read-only field indicates that the breaker

has been locked and will not respond to switch commands on the network. The

purpose of the lock feature is to avoid inadvertent or accidental breaker state

changes. The breaker must be unlocked before the breaker state can be remotely

changed again.

When lit, this read-only field indicates that the breaker

has tripped due to an overcurrent condition. Switch the breaker OFF to

acknowledge the ‘breaker tripped’ indication. You can then switch the breaker

back to the ON position.

When lit, this read-only field indicates that the breaker is

in the ON state.

When lit, this read-only field indicates an Open Load (no

load) condition which indicates that the breaker is turned ON but there is

little or no current being drawn. Possible conditions:

·

External switch controlling load is in the OFF position

·

If the connected load is a light, the bulb could be defective

·

The load is mis-wired.

·

The load is very small (less than 1.0 Amp)

When lit, this read-only field indicates that the breaker

has lost communication with the main processor.

When lit, this read-only field indicates that the breaker is

communicating with the network.

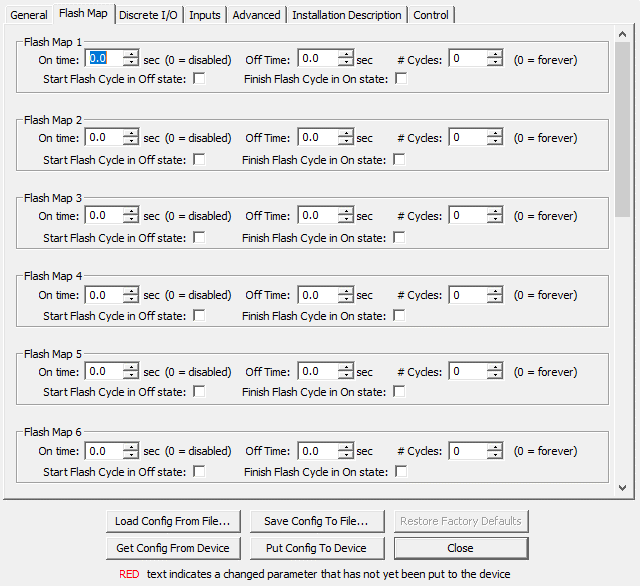

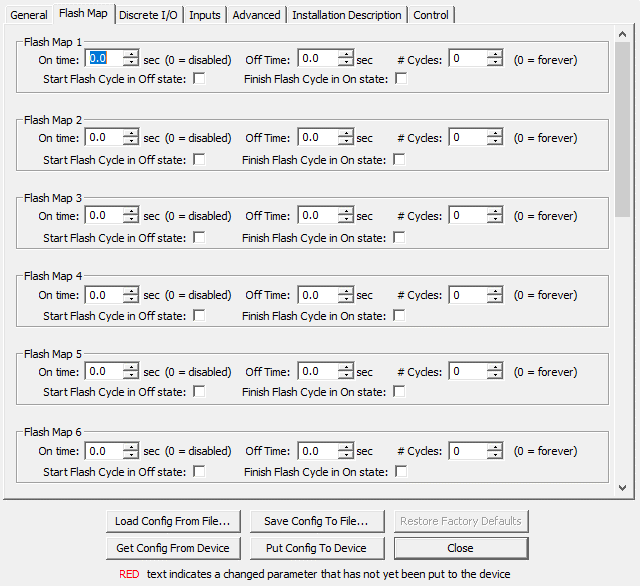

The Flash Function allows control of a breaker to be

periodic. Common uses of this function include turning off a vent fan or light

after a set period of time, etc. Three parameters dictate the behavior of the

circuit and are detailed below. A maximum of 15 flash table entries may be

defined.

Figure 30 - CLMD12 Flash Map Tab

This parameter allows you to configure the number of cycles

that this flash map will execute after a breaker configured to use this flash

map has been switched to the ON state. A value of 0 will repeat the cycle

indefinitely, and values in the range of 1 cycle to 255 cycles will execute

that number of cycles.

This parameter allows you to configure the time that a

breaker will be ON during a cycle. This can be set to a value in the range of 0

seconds to 6553.5 seconds in increments of 0.1 seconds.

This parameter allows you to

configure the time that a breaker will be OFF during a cycle. This can be

set to a value in the range of 0 seconds to 6553.5 seconds in increments of 0.1

seconds. A value of 0 will disable this flash map.

Start Flash Cycle in Off State

When enabled, this parameter allows

you to configure the cycle to start its first cycle in the Off state rather

than in the On state when not enabled.

Finish Flash Cycle in On State

When enabled, this parameter allows you to configure the

cycle to finish cycling in the On state rather than in the Off state when not

enabled.

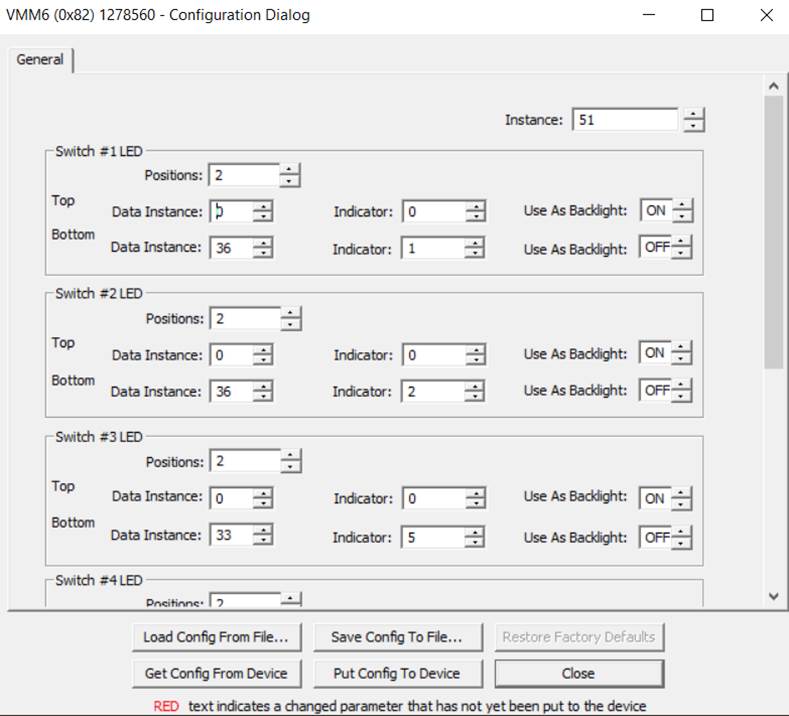

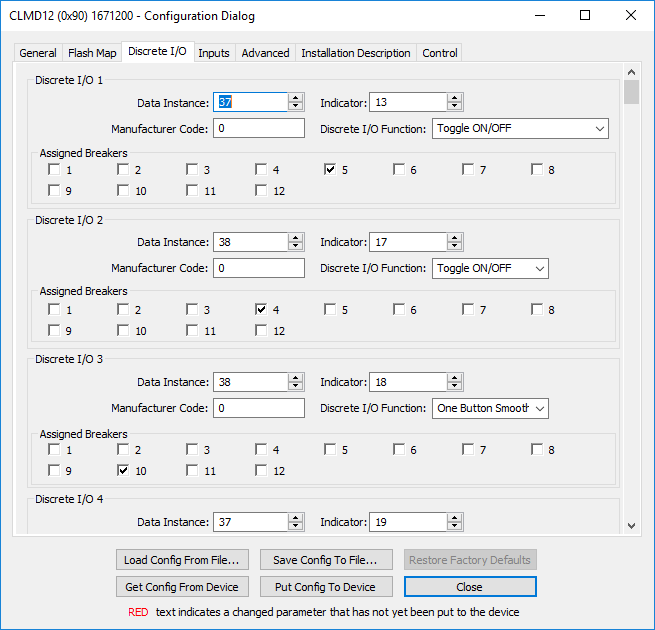

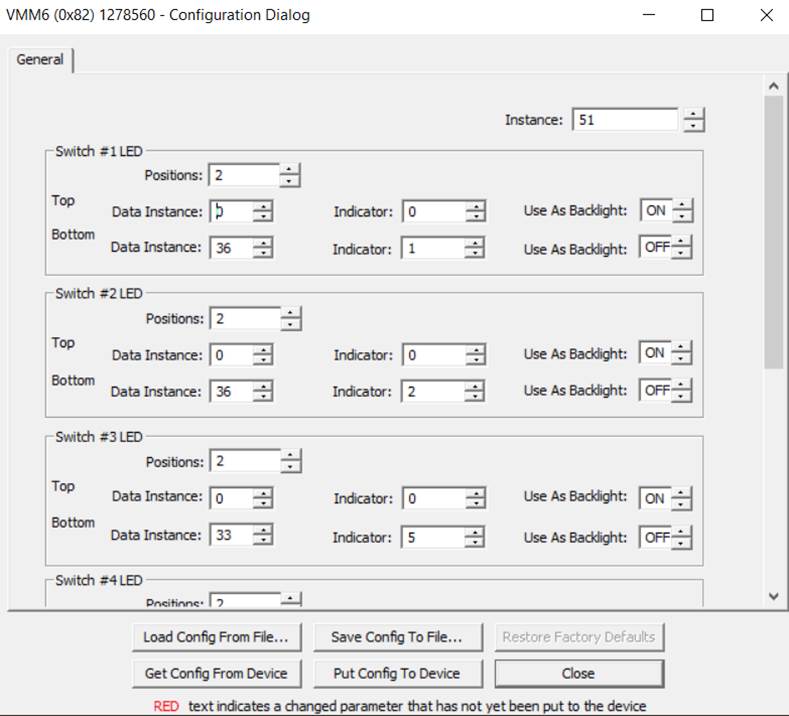

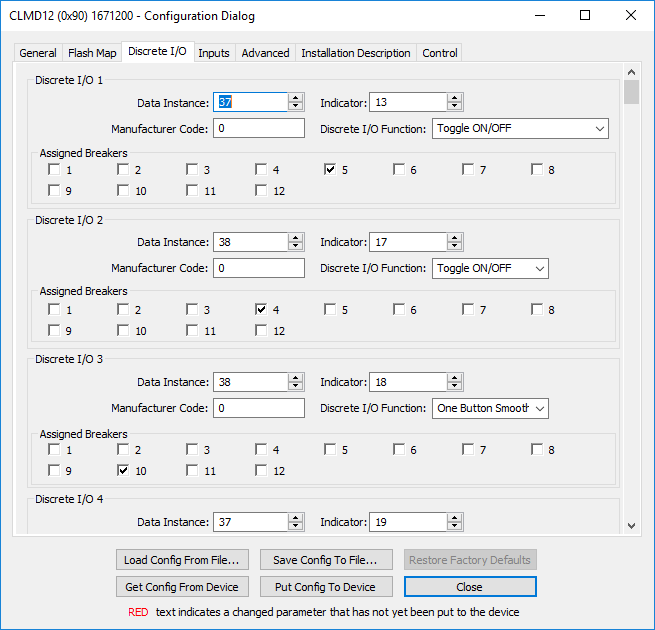

Up to thirty-six (36) Discrete I/O’s can be configured. The

Discrete I/O input signal could be any device transmitting NMEA 2000 PGN 127501

Binary Status Report. NMEA 2000 127501 Binary Status Report output messages are

transmitted from various devices such as a Maretron CLMD, VMM or CKM device.

The output status of the 127501 message can be configured to control the

behavior of the CLMD12’s breakers via the this Discrete I/O configuration. The

127501 Binary Status report message used for Discrete

I/O purposes can pertain to the status of any CLMD product’s hardwired

input ‘OnLevel status’. For example, please refer to the CLMD12 input

‘OnLevels’ in section 5.6.4 ‘Inputs Tab’ / ‘OnLevel(s)’. The 127501 Binary

Status report message used for Discrete I/O purposes can also pertain to the

status of any Maretron CKM key status or VMM switch status. One Discrete I/O

can control multiple breakers up to the box limit. The Discrete I/O state is

maintained independent of any breaker state. Therefore, if a breaker is being

controlled from multiple Discrete I/O input signals, an “out of state”

situation is possible when input signals are switched. For example: two independent

latching signal wall switches connected to a CLMD unit’s hardwired inputs are

controlling the same light (CLMD12 breaker). Depending on the state of the wall

switches signal, a second touch of a wall switch may be required to obtain the

desired action of whether the light/ (CLMD12 Breaker) will be On or Off. For

this reason, proper physical behavior of the input device will need to be

considered. For control of a breaker from multiple points of control such as

the example above, it would be advantageous to use two switches that output

momentary signal behavior instead of latching signal behavior to avoid

undesired control.

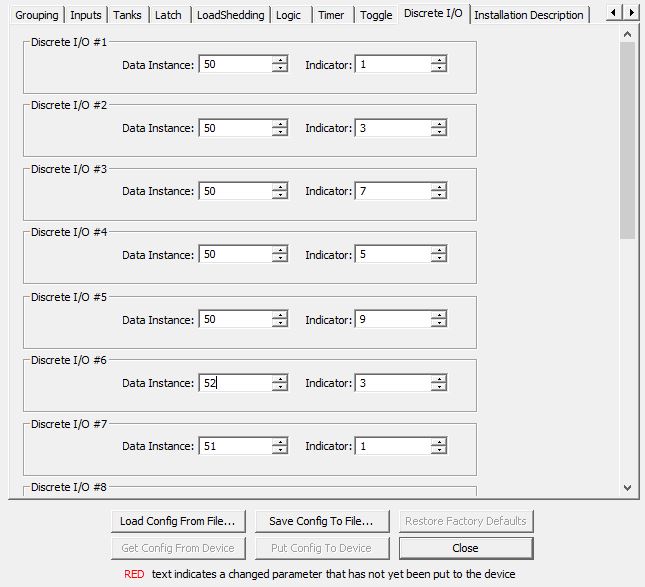

Figure 31 - CLMD12 Discrete I/O

Tab

This parameter allows you to configure the data instance of

the 127501 Binary Status Report message that will be used to control this

discrete I/O circuit. To assign a discrete input from this device to this

discrete I/O circuit, enter the instance value assigned to this device (the

value of the “Instance” field on the “General” tab).

This parameter allows you to configure the indicator number

within the 127501 Binary Status Report status message whose instance field

matches the “Data Instance” parameter for this channel that will be used to

control this discrete I/O circuit.

This parameter allows you to configure the manufacturer code

that must be reported by the device transmitting the 127501 Binary Status

Report message that will be used to control this discrete I/O circuit. Setting

this value to 2047 means that any manufacturer code will be accepted.

This parameter allows you to configure how the specified

127501 Binary Status Report indicator will control the assigned breaker. The

following functions may be selected:

|

Discrete I/O

Function

|

Description

|

|

Always

Turn ON

|

An inactive to active edge

on the monitored signal turns the breaker ON

|

|

Always Turn OFF

|

An inactive to active edge

on the monitored signal turns the breaker OFF

|

|

Toggle ON/OFF

|

An inactive to active edge

on the monitored signal toggles the breaker from OFF to ON or from ON to OFF

|

|

Brighten

|

An inactive to active edge

on the monitored signal increases the dimming level by 1%

|

|

Dim

|

An inactive to active edge

on the monitored signal decreases the dimming level by 1%

|

|

Flash

|

An inactive to active edge

on the monitored signal turns the breaker ON and uses a predefined 1s On 1s

Off flash behavior.

|

|

Turn OFF w/Lock

|

The breaker turns OFF and

stays LOCKED as long as the monitored signal is active. The breaker stays OFF

but becomes UNLOCKED when the monitored signal becomes inactive

|

|

Unlock

|

Unlocks breaker (state does

not change)

|

|

One Button Smooth High-to-Low

|

A single press changes breaker state. Press and hold wall

switch to turn ON; hold for High to Low voltage decrease (5% increments).

Continuing to hold will reset to 100% intensity and repeat.

|

|

One Button Smooth Low-to-High

|

A single press changes breaker state. Press and hold wall

switch to turn ON; hold for Low to High dimming level increase (5%

increments). Continuing to hold will reset to 5% dimming level and repeat.

|

|

Smooth Scroll

|

A momentary touch

turns breaker

ON only; continuing to hold scrolls

dimming level UP and DOWN (last

known state is retained).

|

|

One Button Smooth Scroll

|

A momentary touch

changes breaker state;

continuing to hold scrolls

dimming level UP and DOWN (last

known state is retained).

|

|

Discrete Momentary

|

The

breaker stays on as long as the monitored signal remains active. The breaker

turns OFF when the input becomes inactive.

|

This parameter allows you to configure the breakers that

will be controlled by this discrete I/O channel. You may select any number of

the breakers.

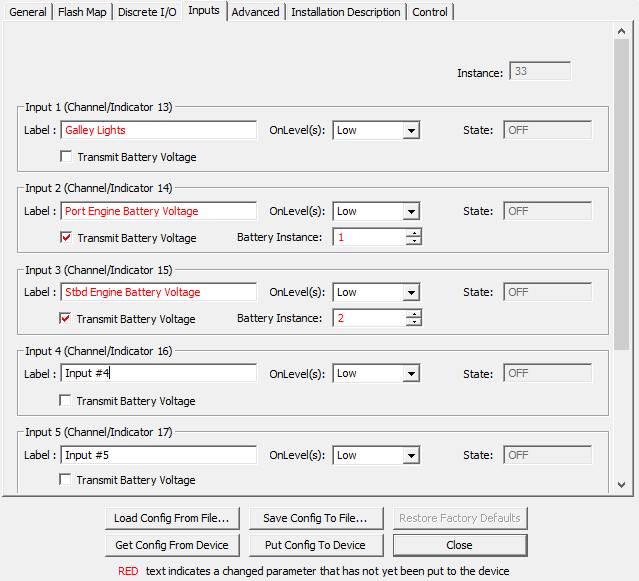

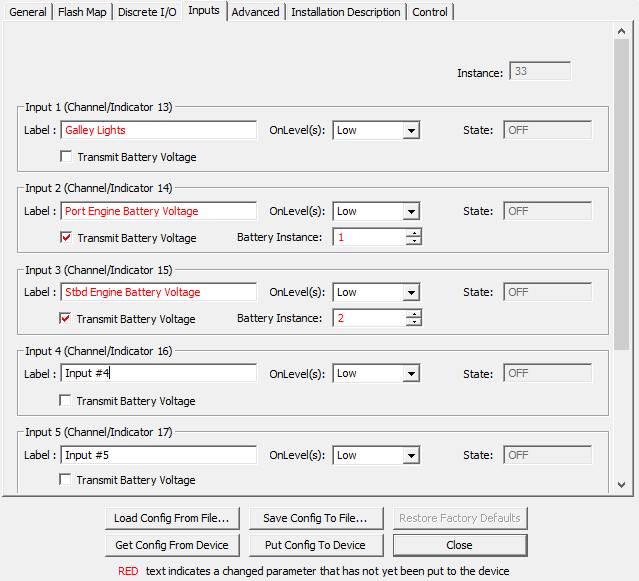

The CLMD12 has seven digital inputs. These inputs can be

configured on the Inputs tab. The states of these input channels are

transmitted in a 127501 Binary Status Report message as indicators 13 (Input

Channel #1) through 19 (Input Channel #7).

Figure 32 - CLMD12 Inputs Tab

This read-only field indicates the data instance used for

this box. The value that appears here can be changed by setting the “Device

Instance” parameter on the Advanced tab.

Label

Each channel has a text label you can set to identify the

input signal monitored by that channel (for example, “BILGE PUMP” or “HATCH”).

For each channel, set this to a value which describes the input being monitored

so that you can easily identify it in display devices.

This parameter allows you to configure the voltage level on

the input signals that corresponds to an ON status on the input as reported on

the network. You can use any of the following settings:

·

High – a high voltage level on the input is represented as an ON

value on the network. A high impedance or a low voltage level on the input is

represented as an OFF value on the network.

·

Low – a low voltage level on the input is represented as an ON

value on the network. A high impedance or a high voltage level on the input is

represented as an OFF value on the network.

·

Both – a high voltage level or a low voltage level on the input

is represented as an ON value on the network. A high impedance on the input is

represented as an OFF value on the network.

State

This read-only field represents the current state of the

input signal as reported on the network.

Transmit Battery Voltage / Battery Instance

When ‘Transmit Battery Voltage’ is enabled, the ‘Battery Instance’

Dialog will appear. By enabling this feature, the CLMD12 will transmit an

instance of 127508 Battery Status PGN on the NMEA 2000 network. The Battery

Status data instance for this PGN is determined by the ‘Battery Instance’

number entered.

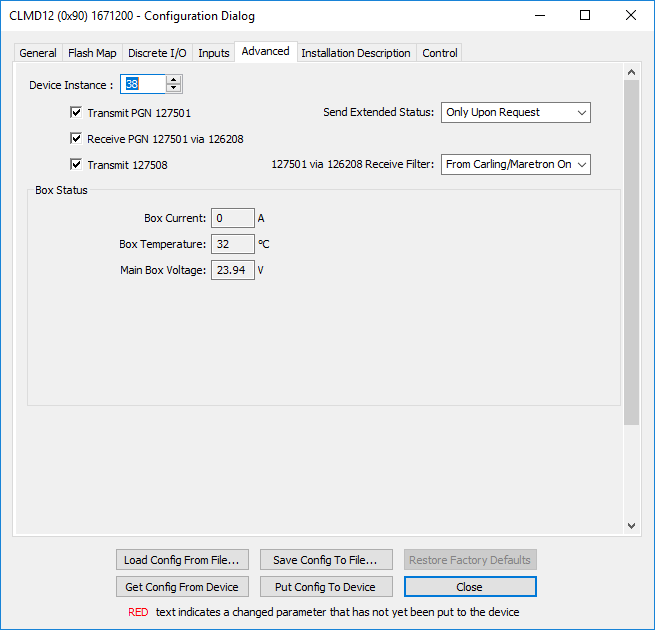

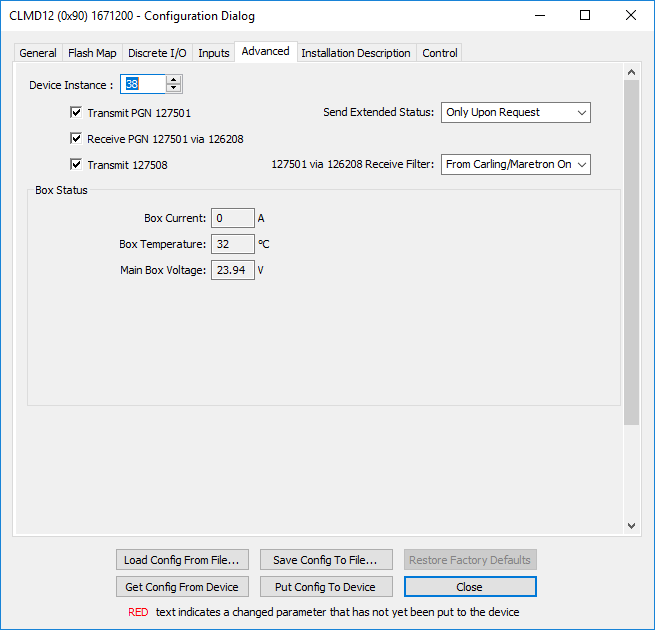

The Advanced tab is used to configure and observe parameters

that do not normally require changing.

Figure 33

- CLMD12 Advanced Tab

Device Instance

This parameter allows you to configure

the NMEA 2000 device instance used by the device. This value is also used as

the data instance in the 127501 Binary Status Report messages transmitted by

the device and can be seen on the General Tab as well as the Inputs Tab labeled

as “Instance”.

This parameter allows you to configure whether the device

transmits the 127501 Binary Status Report status NMEA 2000 message. If this

field is set, the device will transmit the 127501 Binary Statue Report message

along with proprietary messages. If this field is cleared, the device will not

transmit the 127501 message and will transmit only proprietary messages.

This parameter allows you to configure whether the device

will respond to the NMEA command of an indicator in the 127501 Binary Status

Report message. If this field is set, the device will respond to that message.

If this field is cleared, the device will not respond to that message, but only

to proprietary messages.

This parameter allows you to configure whether the device

will transmit the 127508 Battery Status message to indicate the box

temperature, input voltage, and input current. If this field is set, the device

will transmit the 127508 message. If this field is cleared, the device will not

transmit the 127508 message.

This parameter allows you to configure when the CLMD12 sends

the extended box status proprietary message. There are two settings for this

parameter:

·

Only send when an error is detected

·

Only send upon request

This parameter allows you to configure from which devices

the CLMD12 will accept 126208 NMEA Commands of the 127501 Binary Status Report

message. There are two settings for this parameter:

·

From Carling/Maretron devices only

·

From any manufacturer’s device

Box Current

This read-only field indicates the total current passing

through the device.

Box Temperature

This read-only field indicates the internal temperature of

the device.

Main Box Voltage

This read-only field indicates the voltage of the power

input for the device.

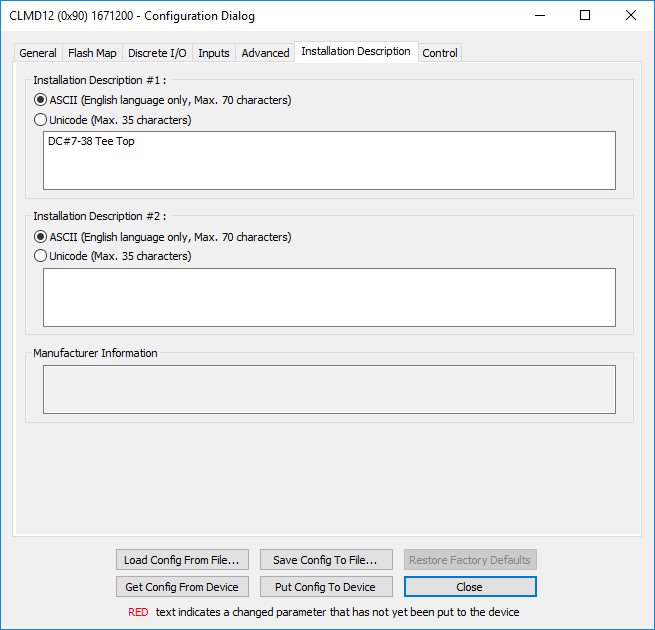

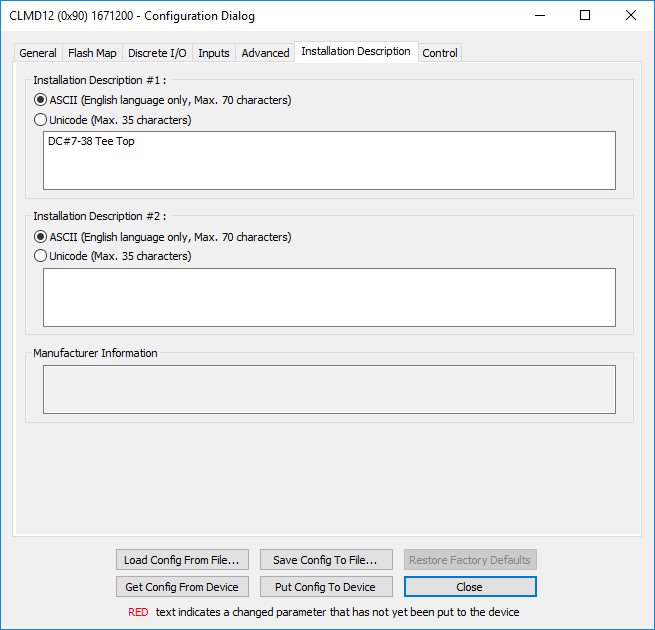

This tab allows you to set values for the installation

description properties of the device.

Figure 34 - CLMD12 Installation

Description Tab

This device, along with all other Level A certified NMEA

devices, has two user-entry ‘Installation Description’ fields. You may

enter text into these fields with information specific to the device, such as

date installed, the initials/name of the installer, the physical location of

the device, etc.

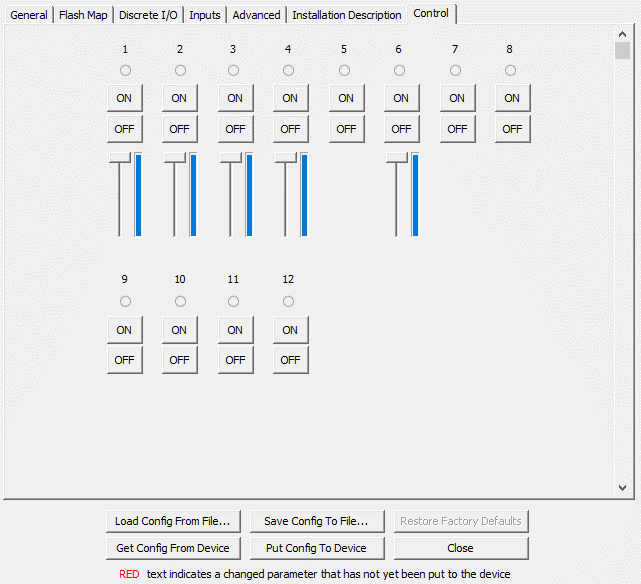

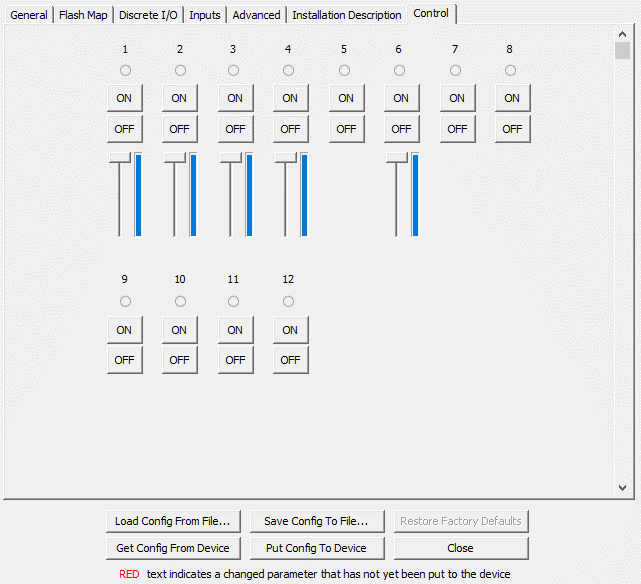

5.6.7

Control Tab

This tab allows you to control the ON/OFF state and dimming

level of the breakers on the device. This is normally used for testing

purposes.

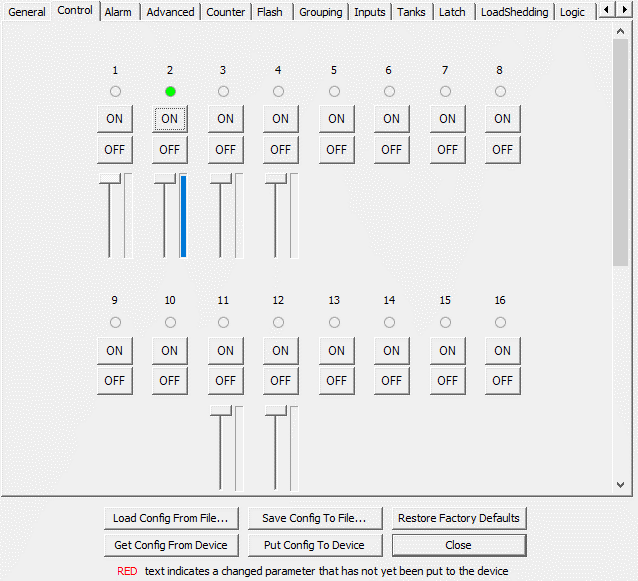

Figure 35 - CLMD12 Control Tab

When lit, this read-only field indicates that the breaker is

in the ON state. When extinguished, this field indicates that the breaker is in

the OFF state.

These buttons replicate Network Input commands. The ON

button allows you to switch the breaker into the ON state and the OFF button

allows you to switch the breaker into the OFF state providing the Direct Network

Input control is enabled by ‘Manual Mode’ on the General Tab is disabled.

The blue slider bar allows you the

configure the dimming level of a breaker between 5% and 100% provided ‘Dimming

Allowed’ on the General Tab is enabled. The read-only green bar graph shows the

real-time dimming level of the breaker.

The CLMD16 will transmit data over

the NMEA 2000 network as it is shipped from the factory; however, it may

require configuration, depending on the type of switches monitored and the

number of similar products on the NMEA 2000 network. There are several

configurable items within the CLMD16, which are detailed in the remainder of

this section.

The CLMD16 is configured using

Maretron N2KAnalyzer. The following subsections describe the configurable

parameters in the CLMD16.

Successful CLMD16 configuration

relies on input signals being applied to the various switching application

logic elements of the CLMD16 software. There are many signals that are

available to connect as inputs for the various logic elements in the switching

application. The table below is a complete list of the available signals.

|

Available Input

Signals:

|

|

Signal Name

|

Description

|

|

None Selected

|

This connects

the specified input to a constant Logic ‘0’ value

|

|

Input 1

through 12 Low

|

The signal on

hardwired input 1 through 12 is in the Low voltage range

|

|

Input 1

through 12 Float

|

The signal on

hardwired input 1 through 12 is in the Float voltage range

|

|

Input 1

through 12 High

|

The signal on

hardwired input for the numbered channel is in the High voltage range

|

|

Network Input

1 through 16

|

The state of

the signal on Network Input for the numbered channel

|

|

Logic Output

1 through 48

|

The state of

the output of Logic Element for the numbered channel

|

|

Latch Output

1 through 16

|

The state of

the output of Latch Element for the numbered channel

|

|

Toggle Output

1 through 16

|

The state of

the output of Toggle Element for the numbered channel

|

|

Timer Output

1 through 16

|

The state of

the output of Delay Timer Element for the numbered channel

|

|

Flash Output

1 through 16

|

The state of

the output of Flash Element for the numbered channel

|

|

Counter

Active 1 through 16

|

The state of

the output of Counter Element 1 through 16

|

|

Over Current

Fault Ch 1 through 16

|

An Over

Current Fault has been detected on Channel 1 through 16

|

|

Ch 1 through

16 Tripped

|

The circuit

breaker for the numbered channel is tripped

|

|

Ch 1 through

16 Thermal Limit Hit

|

The circuit

breaker for the numbered channel has reached its thermal limit

|

|

Discrete I/O

1 through 32

|

The discrete

state I/O of the signal the numbered channel

|

|

Breaker On 1

through 16

|

The state of

an Output Channel for the numbered channel

|

These input

signals will be applied within fields of N2KAnalyzer dialog box fields named:

“Input Signal”, “Enable Signal”, “Set Signal”, “Reset Signal”, “Increment

Signal”, “Decrement Signal”, “Delay Signal”, or “Toggle Signal” depending on

the logic type being used.

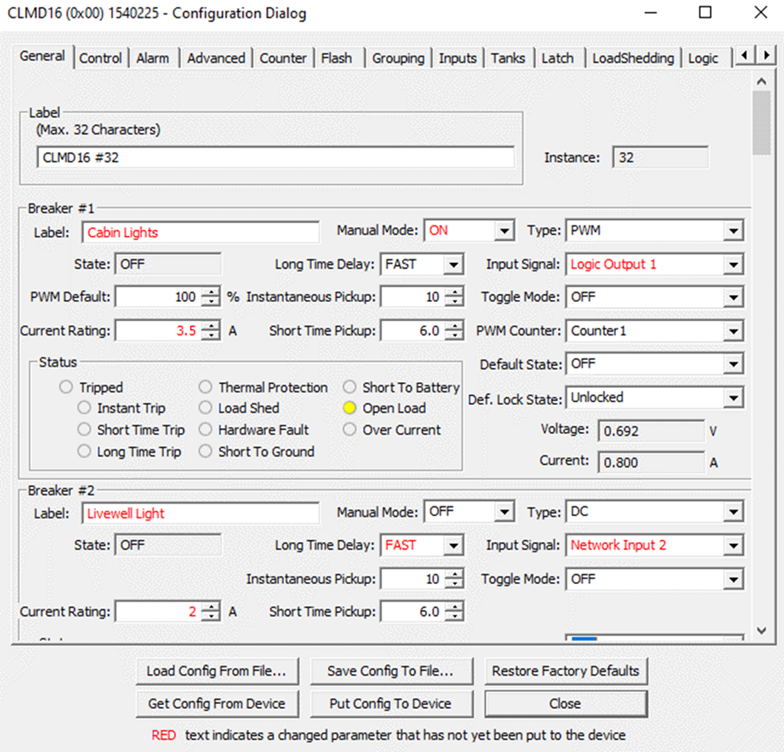

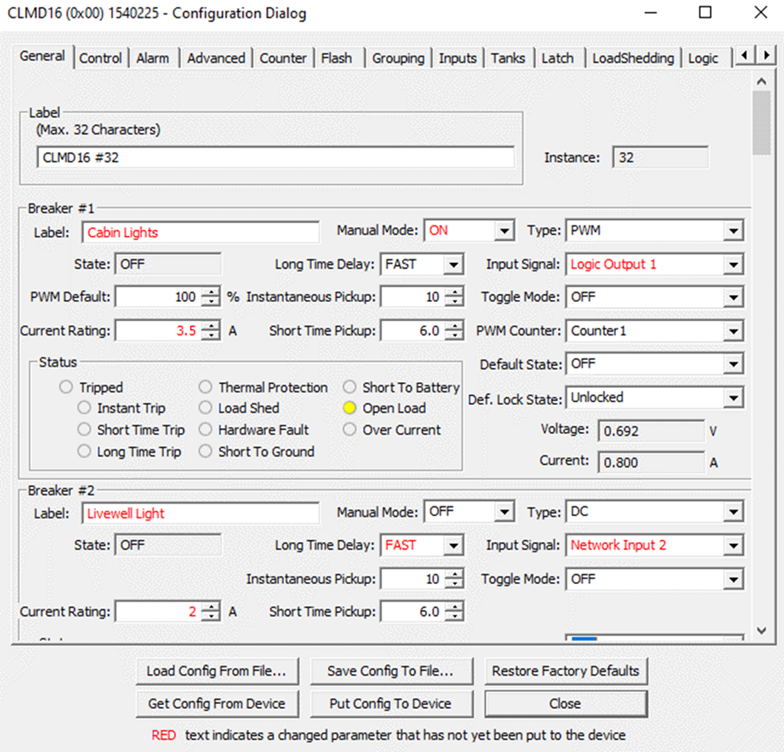

This tab contains commonly used

configuration items.

Figure 36 - CLMD16 General Tab

This text box allows you to assign

a text label to the device. This label is visible in Maretron analysis and

display products and allows you to easily identify the particular device.

NMEA 2000 provides a unique

instance number for each breaker box on a vessel. This read-only field shows

the instance number assigned to this device. This instance number value is

reflected in the 127501 Binary Status Report message. The instance number can

be configured by changing the “Device Instance” field on the “Advanced” tab.

This section contains settings for

the specified electronic circuit breaker (ECB). One of these sections is

present for each of the breakers in the unit.

Label

This text box allows you to

configure a text label for the breaker to identify it (for example, “RUNNING

LIGHTS” or “HATCH”). For each breaker, set this to a value which describes the

breaker so that you can easily identify it in display devices.

Manual Mode

This

drop-down selection allows you to enable or disable Manual Mode. By

default, devices such as an MFD or N2KView will have direct access to control

all CLMD16 breakers. These devices communicate to the breakers by NMEA 2000 PGN 127500 or PGN 127501 via 126208 Command Group

Function. When Manual Mode is enabled, commands from devices using

NMEA 2000 PGN 127500 or PGN 127501 via 126208 Command Group Function is ignored.

The CLMD16 instead will only allow for Network Inputs 1-16 from the Available

Signals list to be used as inputs within the switching application. Please

refer to section 5.7 / ‘Available Input Signals’ for more information on ‘Network

Inputs 1-16’. The Manual Mode feature can be used to funnel commands

from any device using 127500 or 127501 via 126208 PGN into CLMD16 Switching

Application Logic. For example, with Manual Mode On, a breaker’s Network

Input signal received from an MFD may be directed into any CLMD16 Switching

Element(s) then back into the breaker control input allowing for ultimate

configurability such as sequencing, special lighting control, modes, and group

switching commanded by the MFD whereas this function would not be possible

using direct breaker control via NMEA 2000 PGN 127500 or PGN 127501 via 126208

Command Group Function. Manual Mode can also be used to simply ignore

direct breaker commands for breakers that are designated for load sequencing, or

sub-routines controlled elsewhere. Manual Mode also can be used for breakers needing

to be controlled by single designated points rather than NMEA2000 network wide

access to command the breaker.

State

This read-only field indicates the

current state of the breaker. It will contain one of the following values:

- OFF – the breaker is currently off (not supplying power)

- ON – the breaker is currently on (supplying power)

- TRIP/ERROR

– the breaker is currently off (not supplying power) due to an overcurrent

or error condition

PWM Default

This value will be the value that the PWM% will be when the

breaker is turned On if the Counter switching application is not selected.

Please note if PWM is changed via Network Input the value of PWM the next time

the channel is turned On will be the last state of PWM and the PWM Default will

not be applicable until the next power cycle.

Default State

This

allows you to configure the state of the breaker when the CLMD16 is powered on.

You can set this to one of the following values:

- OFF – the breaker will be OFF after the CLMD16 is powered

on

- ON – the breaker will be ON after the CLMD16 is powered on

- LAST

STATE – after the CLMD16 is powered on, the breaker will be set to the

state it was in when power was last removed

Default Lock State

This

parameter allows you to configure whether the breaker is locked when the CLMD16

is powered on. You can set this to one of the following values:

- LOCKED – the breaker is locked; i.e., it’s state will not

change due to network inputs

- UNLOCKED

– the breaker is unlocked and its state will respond normally to network

inputs

Type

This parameter allows you to

configure the desired operating mode for this breaker. You can choose one of

the following:

- DC – the breaker may be controlled OFF and ON.

- PWM – this breaker may be controlled OFF and ON and may be dimmed by

altering the changing duty cycle of the PWM counter assigned to the

breaker.

- Soft Start DC – the breaker may be controlled OFF and ON. When the

breaker is turned ON, the power starts in PWM mode with the duty cycle set

by “Soft Start %” parameter, and then ramps to fully ON over the next one

second time interval.

- Full-Bridge – if both breakers in a H-bridge pair (i.e., 1 and 2, or

11 and 12) are configured to Full-bridge, then the two breakers will work

together as a full bridge (or H-bridge). The full bridge may be controlled

OFF and ON, and its direction may be controlled.

- Soft Start

Full-Bridge – if both breakers in a H-bridge pair (i.e., 1 and 2, or 11

and 12) are configured to Soft Start Full-bridge, then the two breakers

will work together as an full bridge (or H-bridge) with the soft start

feature enabled. The full bridge may be controlled OFF and ON, and its

direction may be controlled. When the breaker is turned ON, the power

starts in PWM mode with the duty cycle set by “Soft State %” parameter,

and then ramps to full ON over the next one second time interval.

Current Rating

This parameter allows you to

configure the desired trip level for this breaker. Exceeding this current for a

time period set by the value of the Long Time Delay parameter along with the i2t

breaker model will initiate a trip.

Instantaneous Pickup

This parameter allows you to

configure the instantaneous pickup for the breaker. This can be set in the

range of 5 to 20 with a resolution of 1. This parameter is a multiplier of the

current rating. For example, if the current rating for the breaker is set to 6

A and the instantaneous pickup parameter is set to a value of 10, then the

instantaneous pickup current will be 60 A (6 A * 10).

Short Time Pickup

This parameter allows you to

configure the short time pickup for the breaker. This can be set in the range

of 1.5 to 6.0 with a resolution of 0.1. This parameter is a multiplier of the

current rating. For example, if the current rating for the breaker is set to 6

A and the short time pickup parameter is set to a value of 4, then the short

time pickup current will be 24 A (6 A * 4).

Input Signal

This parameter allows you to

select the internal signal that determines the state of this breaker. You may choose a signal from the Available

Input Signals list in Section 5.7.

Toggle Mode

This parameter allows you to

select Toggle Mode On or Off. When this mode is enabled, the state of the ECB

will change to the opposite state, whether On or Off, with every Rising Edge of

an ECB Input Signal.

PWM Counter

This parameter allows you to

select which PWM counter controls the dimming level for this breaker. You may

choose any of the eight counter elements.

Long Time Delay

This parameter allows you to

configure the long time delay for the breaker. This can be set to one of the

following values:

- FAST (5 seconds)

- MEDIUM (10 seconds)

- SLOW (20

seconds)

Current

This read-only field shows the

real-time current passing through the breaker.

Voltage

This read-only field shows the

real-time voltage at the load terminal of the breaker.

Status

This group of indicators show

real-time status of the breaker.

Tripped

When lit, this read-only field

shows that the breaker is in the TRIP state.

Instant Trip

When lit, this read-only field

indicates that the breaker has tripped due to the instant trip feature.

Short Time Trip

When lit, this read-only field indicates

that the breaker has tripped due to the short time trip feature.

Long Time Trip

When lit, this read-only field

indicates that the breaker has tripped due to the long time trip feature.

Thermal Protection

When lit, this read-only field

indicates that the breaker has been turned off due to the thermal protection

feature.

Load Shed

When lit, this read-only field

indicates that the breaker has been turned off due to the load shedding feature.

Hardware Fault

When lit, this read-only field

indicates that the breaker has been turned off due to a hardware fault being

detected.

Short To Ground

When lit, this read-only field

indicates that the breaker has been turned off due to it being detected shorted

to ground.

Short To Battery

When lit, this read-only field

indicates that the breaker has been turned off due to it being detected shorted

to the battery or DC supply voltage.

Over Load

When lit, this read-only field

indicates that the breaker has tripped due to an over load being detected.

Open Circuit

When lit, this read-only field

indicates an Open Circuit (no load) condition which indicates that the breaker

is turned ON but there is little, or no current being drawn. Possible

conditions:

- External switch controlling load is in the OFF position

- If the connected load is a light, the bulb could be defective

- The load is mis-wired

- The load is

very small (less than 1.0 Amps)

Breaker Locked

When

lit, this read-only field indicates that the breaker has been locked and will

not respond to switch commands on the network. The purpose of the lock feature

is to avoid inadvertent or accidental breaker state changes. The breaker must

be unlocked before the breaker state can be remotely changed again.

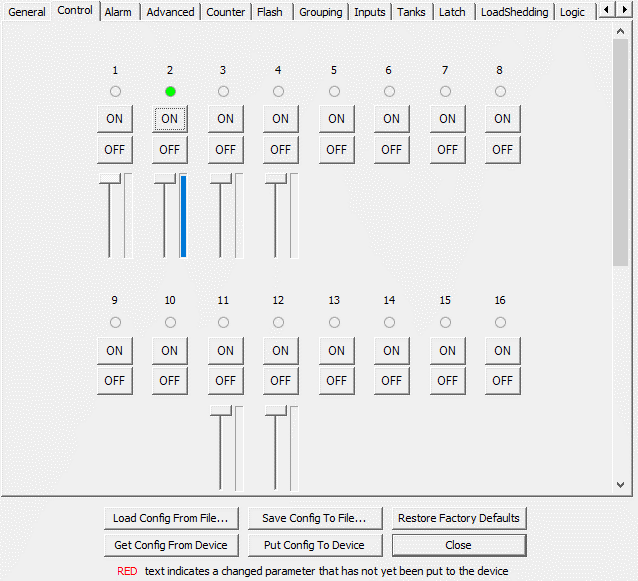

The Control tab allows you to toggle

the configured Network Input channels of the CLMD16. Each On / Off control

number corresponds with Network Input numbers 1-16. When a Network Input is

turned on in this dialog, the associated circuit that the Network Input is

configured to control will be controlled.

Figure 37 – CLMD16 Control Tab

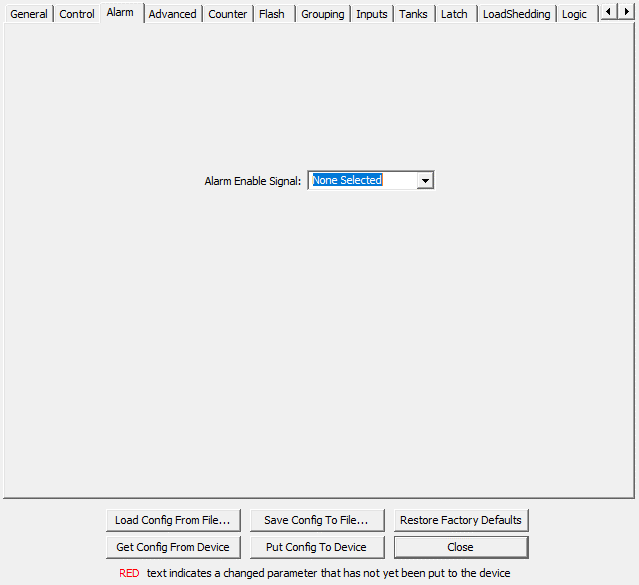

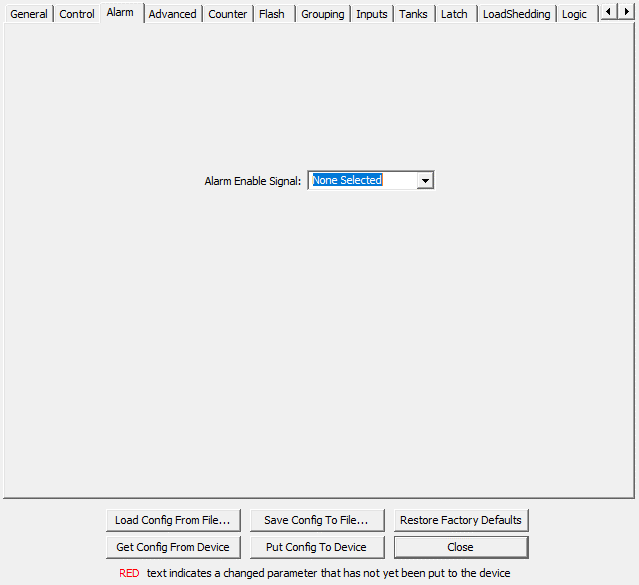

The Alarm tab allows you to select

an internal signal to be used to control the alarm outputs of the CLMD16. You

may choose a signal from the Available Input Signals list in Section 0..

Figure 38

– CLMD16 Alarm Tab

Alarm Enable Signal

This parameter allows you to

select an internal signal to be used to control the alarm outputs. The alarm

outputs are connected whenever this signal is active high. You may choose a

signal from the Available Input Signals list in Section 5.7.

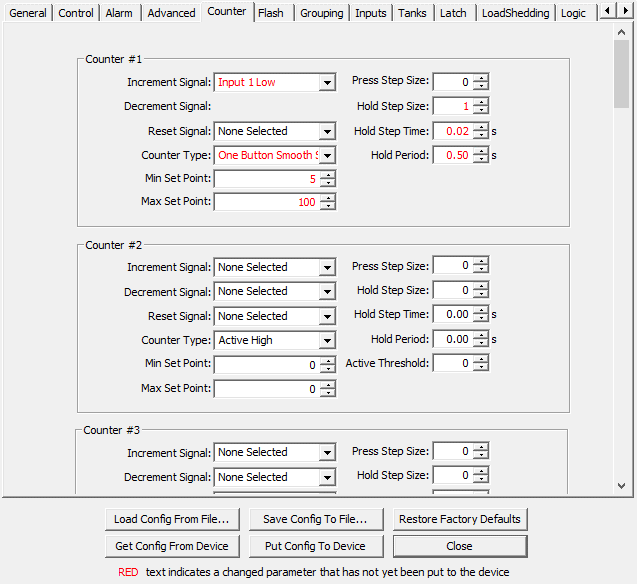

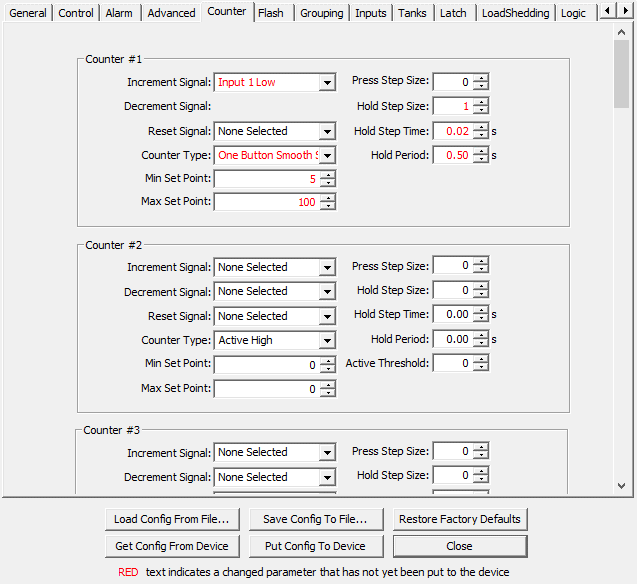

The CLMD16 has sixteen counter

elements.

Figure 39 – CLMD16 Counter Tab

Increment Signal

This parameter allows you to

select a signal to cause the counter to increment in value. You may choose a

signal from the Available Input Signals list in Section 5.7.

Decrement Signal

This parameter allows you to

select a signal to cause the counter to decrement in value. You may choose a

signal from the Available Input Signals list in Section 5.7.

Reset Signal

This parameter allows you to

select a signal to cause the counter to reset its value to the value in the MinSetPoint

parameter. You may choose a signal from the Available Input Signals list in

Section 5.7.

Counter Type

This parameter allows you to

configure the operating mode of the counter. Each counter may be configured in one

of the following modes:

- Active High – the counter increments or decrements as long as

the increment or decrement input signal is in a high state

- Active Low – the counter increments or decrements as long as

the increment or decrement input signal is in a low state

- Rising Edge – the counter increments or decrements once for

every rising edge detected on the increment or decrement input signal

- Falling Edge – the counter increments or decrements once for

every falling edge detected on the increment or decrement input signal

- Change – the counter increments or decrements once for every

rising or falling edge detected on the increment or decrement input signal

- One

Button Smooth Scroll – the counter increments as long as the increment

input signal is in a high state until it reaches the Max Set Point value.

Then, the counter decrements as long as the increment input signal is in a

high state until it reaches the Min Set Point value. The decrement input

signal is ignored.

Min Set Point

This parameter allows you to

configure the value to which the counter is set when the Reset input is

asserted high.

Max Set Point

This parameter allows you to

configure the maximum value that the counter can reach.

Press Step Size

This parameter allows you to

configure the step size by which to increment or decrement the counter when the

increment or decrement input is pressed.

Hold Step Size

This parameter allows you to

configure in Active High or Active Low mode, the value by which to increment or

decrement the counter after the increment or decrement input signal has been

asserted high for HoldPeriods time, and every HeldStepTime

thereafter. If the Rising Edge, Falling Edge, or Change mode is selected, this

is the value by which to increment or decrement the counter on each detected

edge of the increment or decrement input signal.

Hold Periods

This parameter allows you to

configure, in Active High or Active Low mode, the time after

which the input signal is considered “held” if it remains active.

Active Threshold

This parameter allows you to

configure the counter value above which the CounterActive output of the

counter will be asserted high.

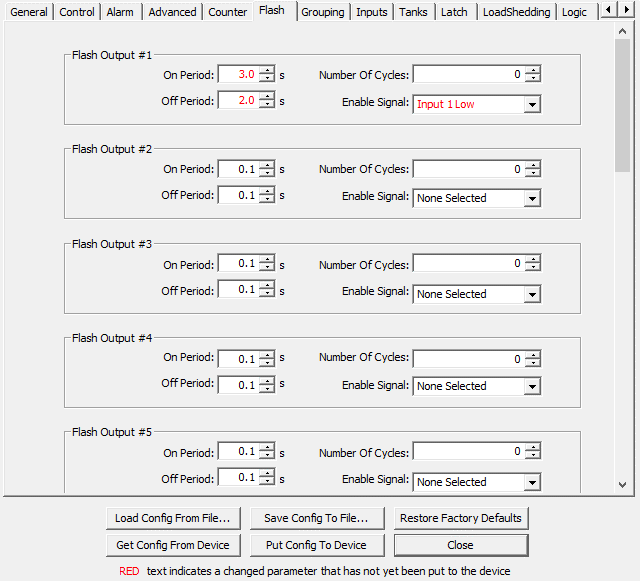

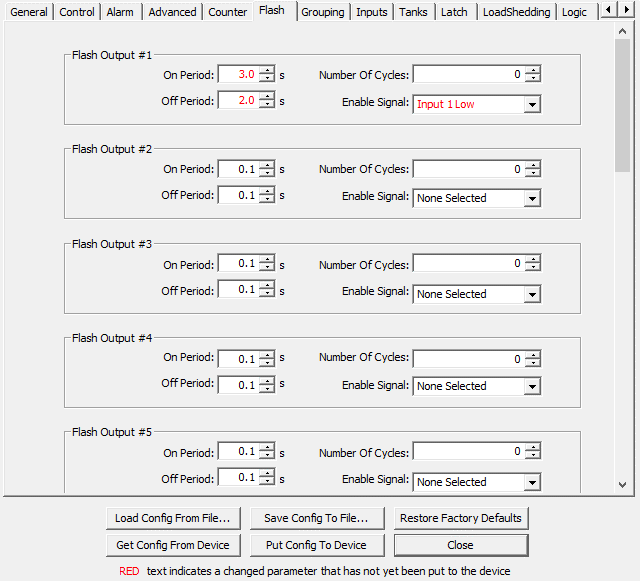

The CLMD16 has sixteen flash

elements.

Figure 40 – CLMD16 Flash Tab

On Period

This parameter allows you to

configure the time period during which the Flash Output signal will be

asserted high for each flash cycle.

Off Period

This parameter allows you to

configure the time period during which the Flash Output signal will be

asserted low for each flash cycle.

Number of Cycles

This parameter allows you to

configure the number of cycles that the Flash element will run once the input

signal is asserted high. If the flash input is asserted low before this number

of cycles has been run, then the Flash Output signal will stop changing

after the next time it is asserted low.

Enable Signal

This parameter allows you to

configure which internal signal will enable the flashing function as long as

this signal is asserted high. You may choose a signal from the Available Input

Signals list in Section 5.7.

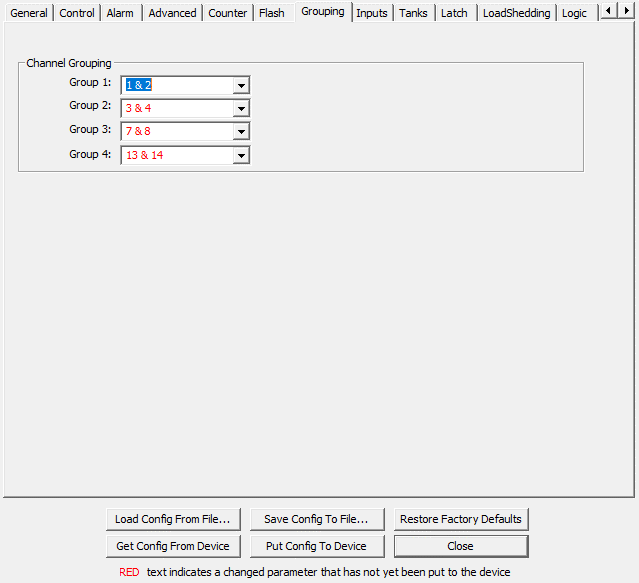

Various combinations of the

breakers in the CLMD16 can be paralleled together to enable the paralleled

breakers to handle higher currents than a single breaker can handle.

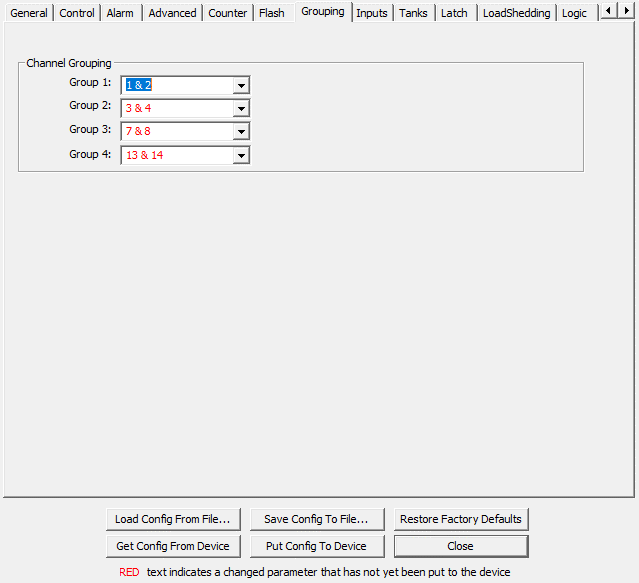

Figure 41 – CLMD16 Grouping Tab

Group 1

This parameter allows to configure

which breakers in the first group of four breakers to operate in parallel. You

may choose from the following:

- No Parallel Outputs – All four breakers operate independently.

- 1 & 2 –

Breakers 1 and 2 operate in parallel, while breakers 11 and 12 operate

independently.

Group 2

This parameter allows to configure

which breakers in the second group of four breakers to operate in parallel. You

may choose from the following:

- No Parallel Outputs – All four breakers operate independently.

- 3 & 4 –

Breakers 3 and 4 operate in parallel, while breakers 5 and 6 operate

independently.

Group 3

This parameter allows to configure

which breakers in the third group of four breakers to operate in parallel. You

may choose from the following:

- No Parallel Outputs – All four breakers operate independently.

- 7 & 8 –

Breakers 7 and 8 operate in parallel, while breakers 9 and 10 operate

independently.

Group 4

This parameter allows to configure

which breakers in the fourth group of four breakers to operate in parallel. You

may choose from the following:

- No Parallel Outputs – All four breakers operate independently.

- 13 & 14

– Breakers 13 and 14 operate in parallel, while breakers 15 and 16 operate

independently.

5.7.7

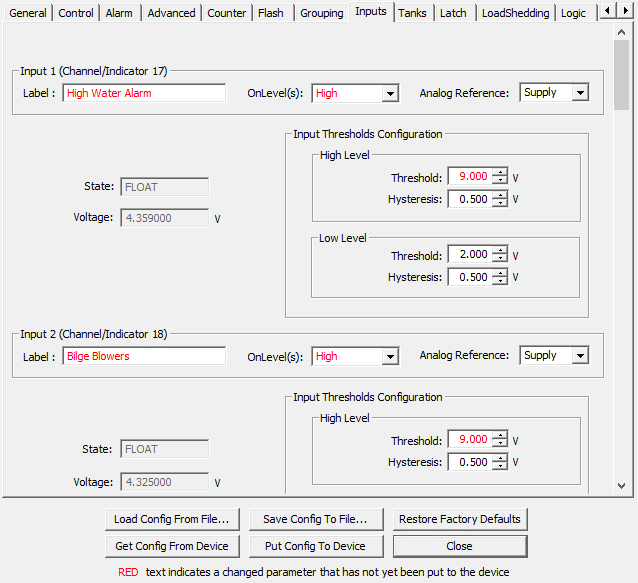

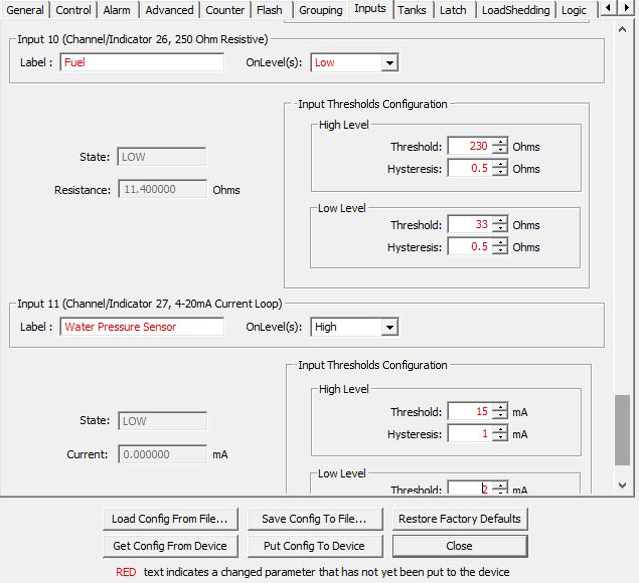

Inputs Tab

This tab allows you to configure

the operation of the analog/digital input signals.

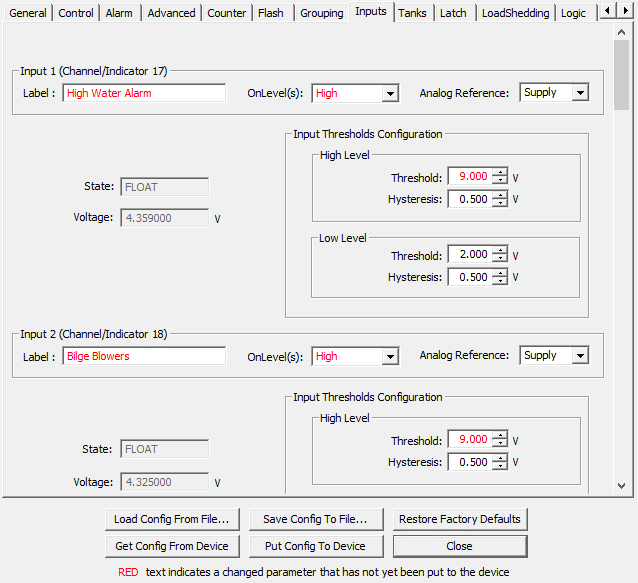

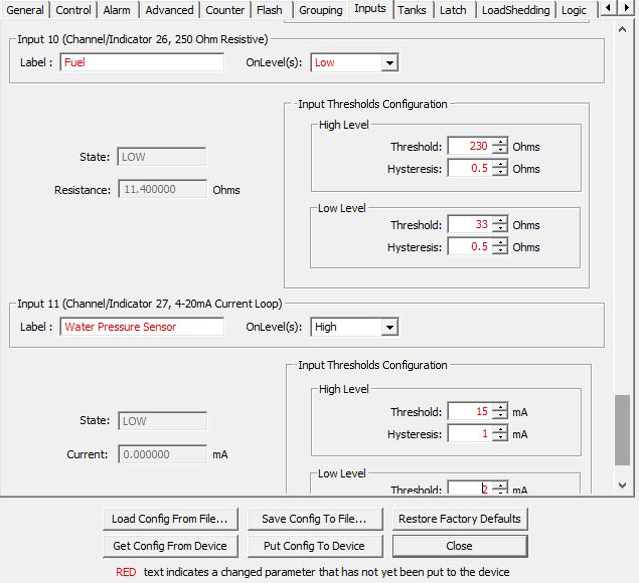

Figure 42 – CLMD16 Inputs Tab

(Channels 1-2)

Figure 43 – CLMD16 Inputs Tab

(Channels 10-11)

Label

This text box allows you to

configure a text label for the input signal to identify it (for example,

“RUNNING LIGHTS” or “HATCH”). For each input signal, set this to a value which

describes the input signal so that you can easily identify it in display

devices.

OnLevel(s)

This field allows you to select

the input signal level that causes the corresponding field in the 127501 Binary

Status Report message to be asserted high. You may select from one of the

following values:

- LOW (the digital input signal being detected LOW will cause the

corresponding field in the 127501 Binary Status Report message to be

asserted HIGH.

- HIGH (the

digital input signal being detected HIGH will cause the corresponding

field in the 127501 Binary Status Report message to be asserted HIGH.

State

This read-only field reflects the

current state of the corresponding binary input signal. This field will take

one of the following three values:

- LOW – the input signal voltage is between 0 V and the Low Threshold

- FLOAT – the input signal voltage is between the Low Threshold and the

High Threshold

- HIGH – the

input signal voltage is between the High Threshold and the Supply Voltage

Voltage/Resistance/Current

This read-only field reflects the

current measured voltage (for channels 1-8), resistance (for channels 9-10), or

current (channel 11).

High Threshold

This numeric field allows you to

program a voltage, resistance, or current value such that when the detected

value on the input signal transitions from below this value to above this

value, the state of the signal shall change from FLOAT to HIGH.

High Hysteresis

This numeric field allows you to

program a hysteresis voltage, resistance, or current value such that when the

detected value on the corresponding input signal transitions from above the High

Threshold minus this value, the state of the output signal shall change from

HIGH to FLOAT.

Low Threshold

This numeric field allows you to

program a voltage, resistance, or current value such that when the detected

value on the input signal transitions from below this value to above this

value, the state of the signal shall change from LOW to FLOAT.

Low Hysteresis

This numeric field allows you to

program a hysteresis voltage, resistance, or current value such that when the

detected voltage on the corresponding input signal transitions from above the

Low Threshold plus this value, the state of the output signal shall change from

FLOAT to LOW.

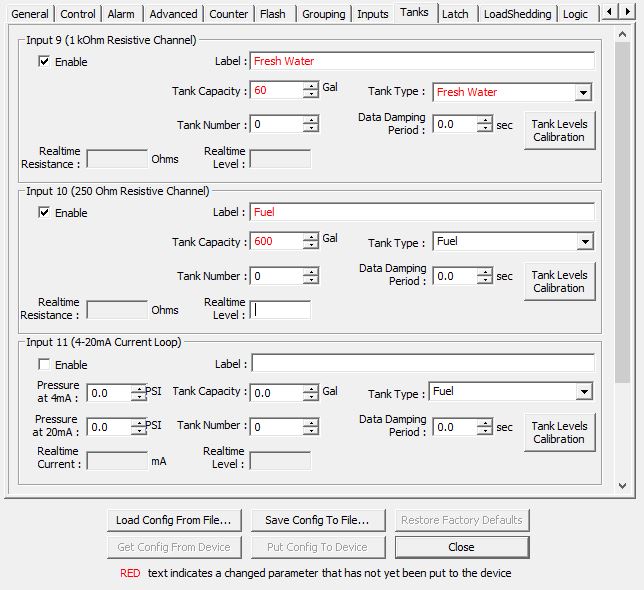

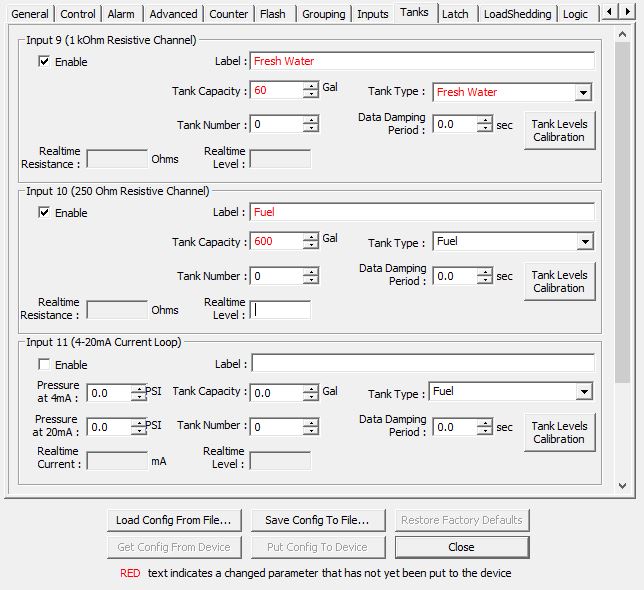

This tab contains parameters for

configuring tank measurement via the two resistive channels and the current

loop channel.

Figure 44 – CLMD16 Tanks Tab

Enable

Each resistive/current loop

measurement tool can be enabled or disabled. If this box is checked, the tank

level corresponding to this channel will be transmitted. If this box is

unchecked, no tank level will be reported for the channel.

If the channel is disabled, no

further configuration is required. The following sections describe in detail

the configuration of the current loop measurement channel when it is enabled.

Label

Program this parameter with a text

string which identifies the parameter being monitored by this channel. Maretron

display products will display this label text when you are selecting data to

display.

Pressure at 4mA (Current Loop channel only)

Program this parameter to match

the pressure reading of the current loop pressure transducer when it is

sourcing a current of 4mA. You can determine this value by examining the

specification of the pressure transducer being used.

Pressure at 20mA (Current Loop channel only)

Program this parameter to match

the pressure reading of the current loop pressure transducer when it is

sourcing a current of 20mA. You can determine this value by examining the

specification of the pressure transducer being used.

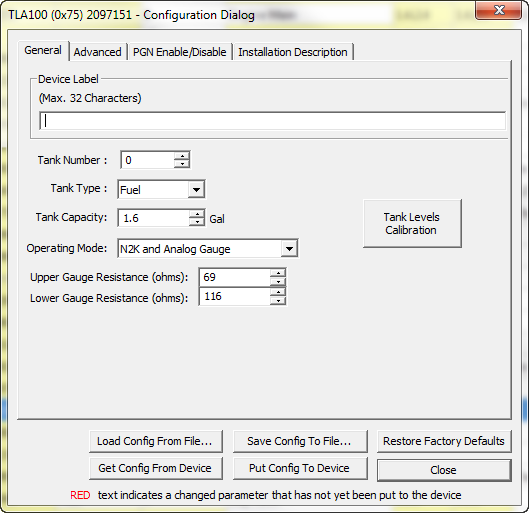

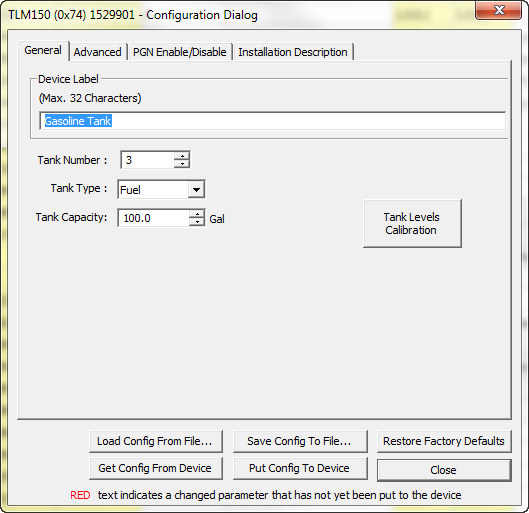

Tank Capacity

In addition to indicating the

fluid level within a tank, the channel also can be configured or programmed

with the attached tank’s capacity. This way, you will be able to view the

tank’s capacity as well as the amount of liquid remaining anywhere on the

vessel where there is an NMEA 2000 compatible display.

Tank Number

As shipped from the factory, the

channel transmits the Tank Number as “0”. The channel supports up to sixteen

tanks (0 through 15) for a given type of tank, which means you can monitor up

to 16 separate fuel tanks or 16 separate fresh water tanks.

Tank Type

As shipped from the factory, the

channel transmits the tank type as “Fuel”. You can reconfigure the channel for

any of these tank types:

- Fuel

- Fresh Water

- Waste Water

- Live Well

- Oil

- Black Water

- Reserved-1

through Reserved-7 (if none of the above types apply)

Data Damping Period

You can configure a damping

parameter to smooth the tank level or pressure/vacuum readings or make them

more responsive. The data damping is configurable between 0.2 – 25.0 seconds.

The default data damping for a channel is 15.0 seconds.

Realtime Resistance (Resistive Channels Only)

This read-only field shows the

resistance currently being measured on the applicable resistive input signal.

Realtime Current (Current Loop Channel Only)

This read-only field shows the

current being measured on the current loop input signal.

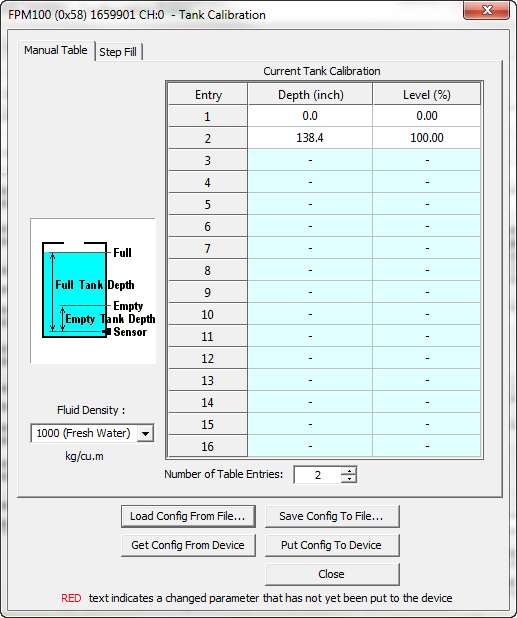

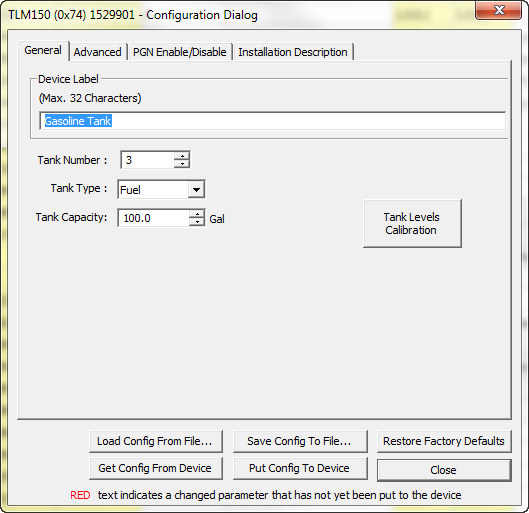

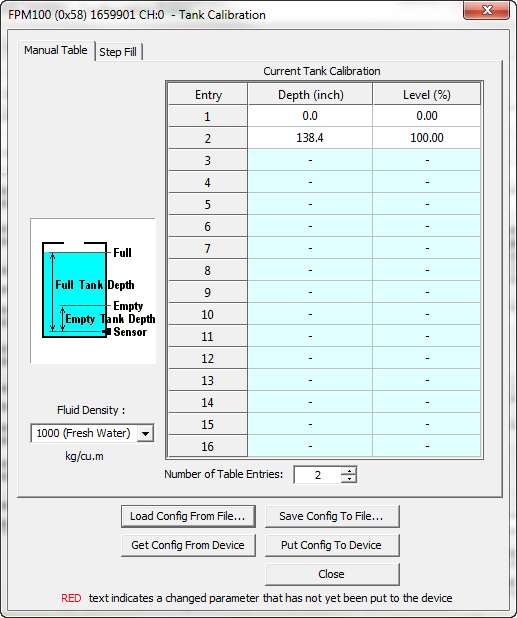

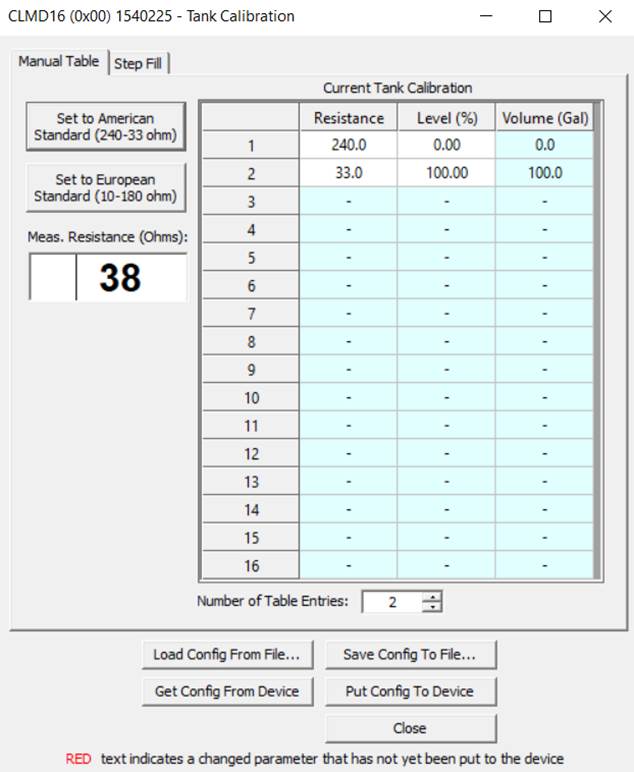

Tank Levels Calibration

Pressing this button opens the

Tank Calibration dialog, which is shown below.

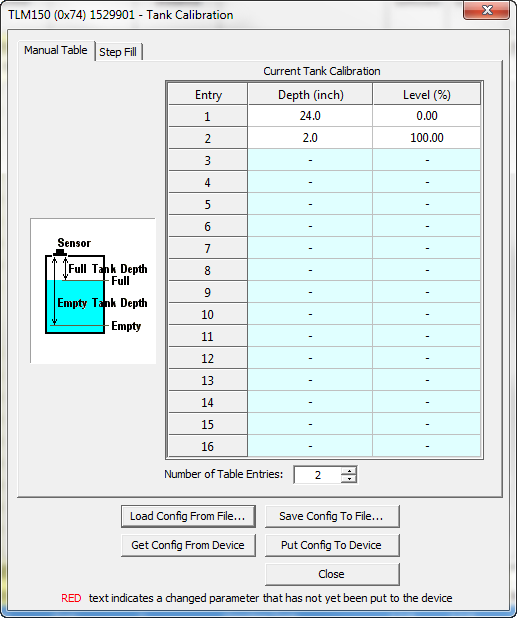

There are two methods of calibration:

Manual Table and Step Fill Table

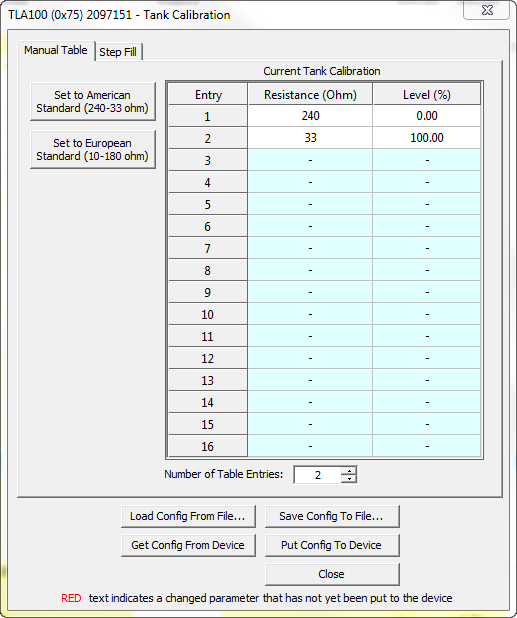

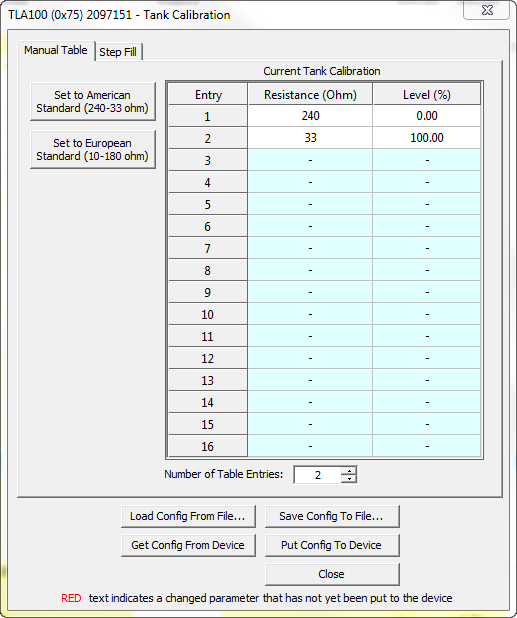

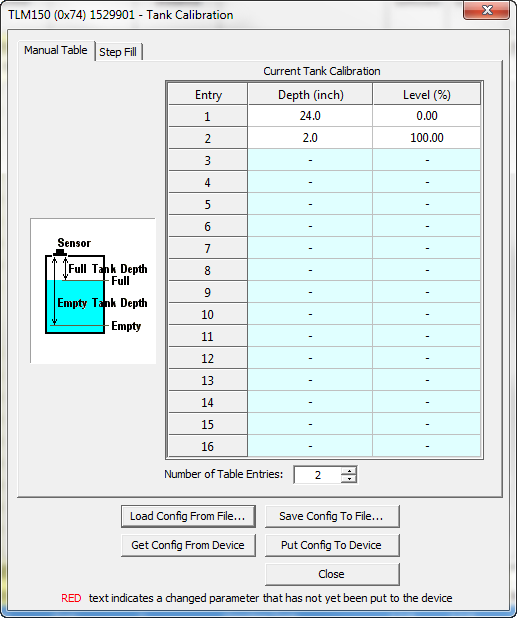

Manual Table

Using the manual table method, you

enter each entry of the measured parameter (resistance for the resistance

channels or depth for the current loop channel) and the level of fluid in the

tank. The table may have as few as 2 entries (for a tank with rectangular

cross-section) or as many as 16 entries (for a tank with a complex

cross-section).

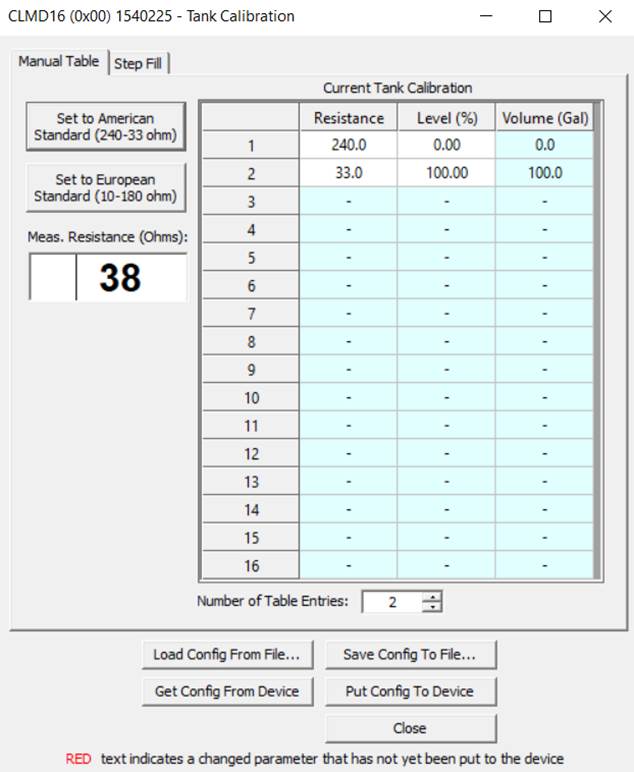

Figure 45 – CLMD16 Resistive

Tank Calibration Manual Table Window

Fluid Density

For the current loop channel, to

convert the pressure measured into the height of a column of fluid, the channel

must know the density of the fluid being measured. This control allows you to

program the channel with the proper fluid density. You may choose from Diesel

Fuel 20, Diesel Fuel 60, Fresh Water, or you may enter a different numeric

density value appropriate to the fluid whose depth is being measured.

Number of Table Entries

You may choose the number of

entries to be in the calibration table. Two is sufficient for a tank with a

rectangular cross-section. The channel supports up to 16 table entries for

supporting tanks with more complex cross-sections.

Current Tank Calibration

This grid shows the values of the

tank calibration table. Each line of the grid has two entries:

For the two resistance channels:

1)

Resistance – this is the resistance value of the level sender

2)

Level (%) – this is the percent full the tank is at the specified resistance

3)

Tank Depth – this is the height of the fluid above the pressure sensor

port

4)

Level (%) – this is the percent full the tank is at the specified tank

depth

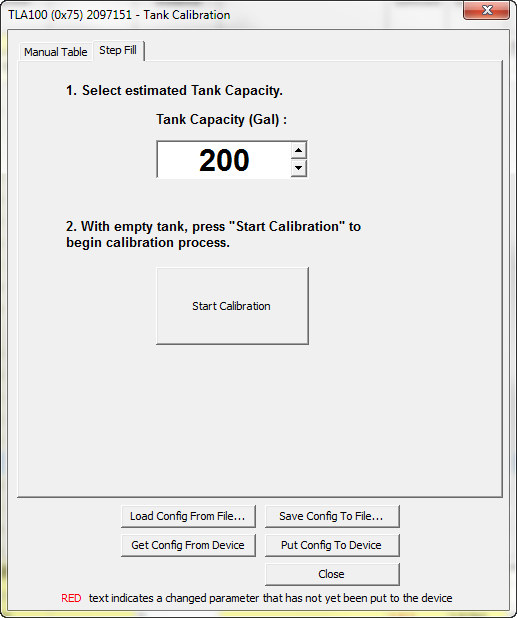

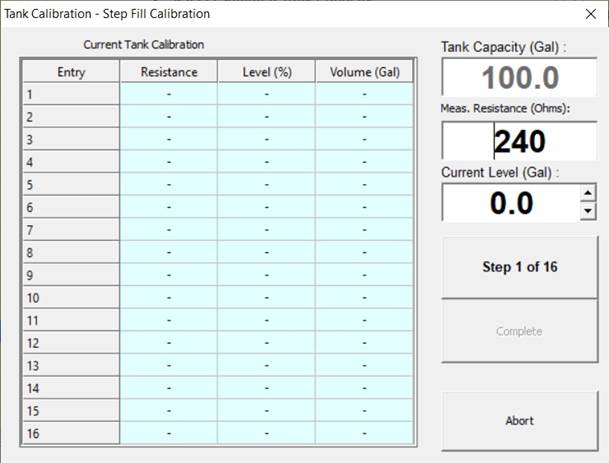

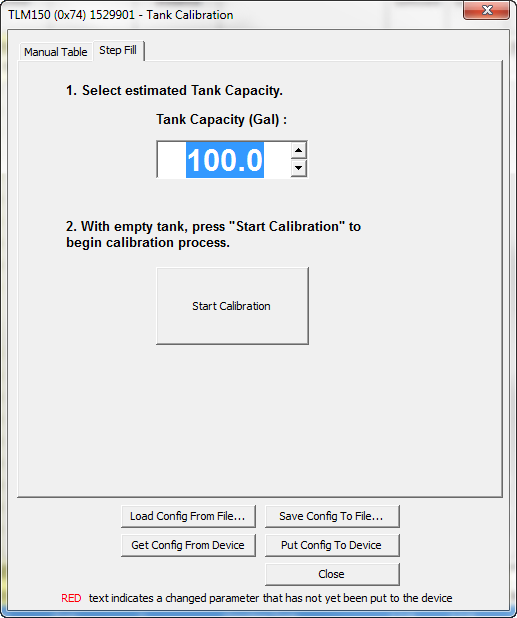

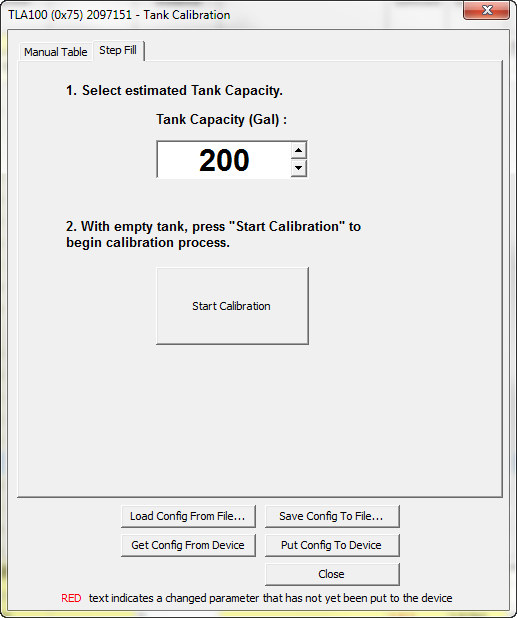

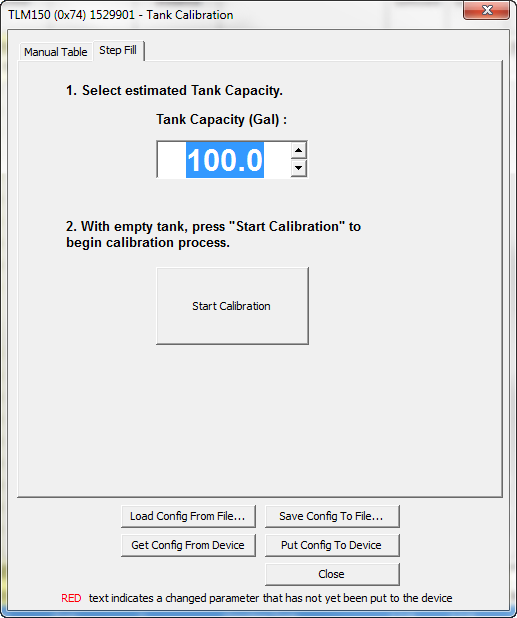

Step Fill Table

In the Step Fill Table method, you

start with an empty tank, and then fill the tank with fluid, stopping at

intermediate points to enter the amount of fluid put into the tank thus far,

ending once the tank is full. You may enter between two and sixteen calibration

points.

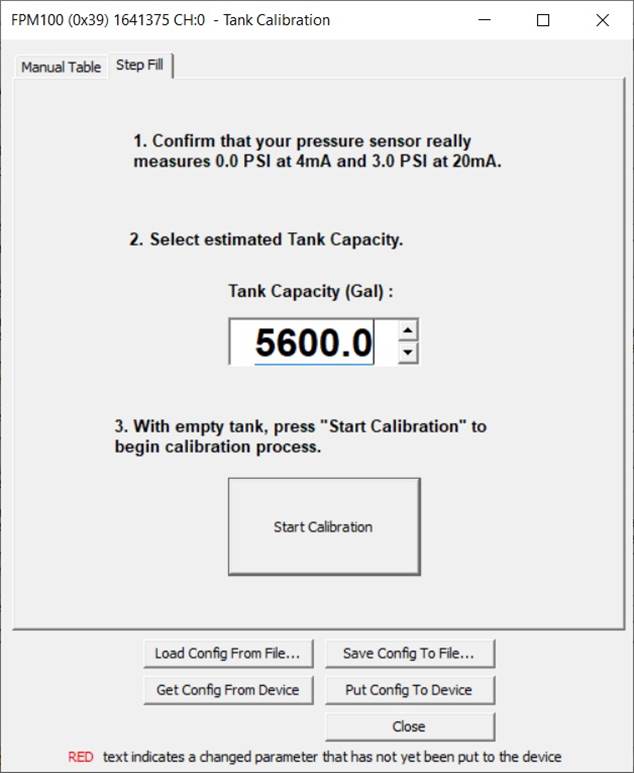

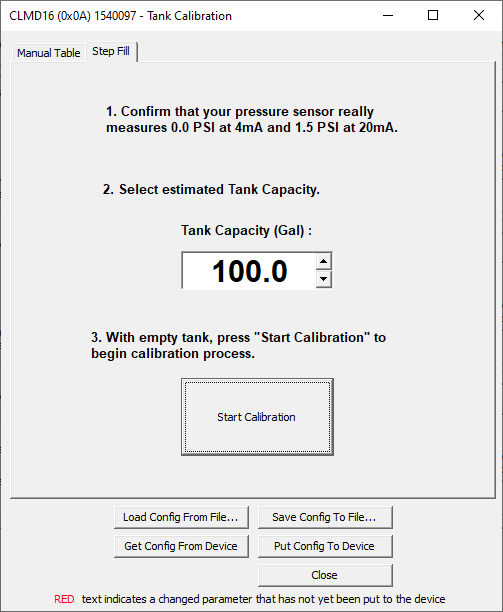

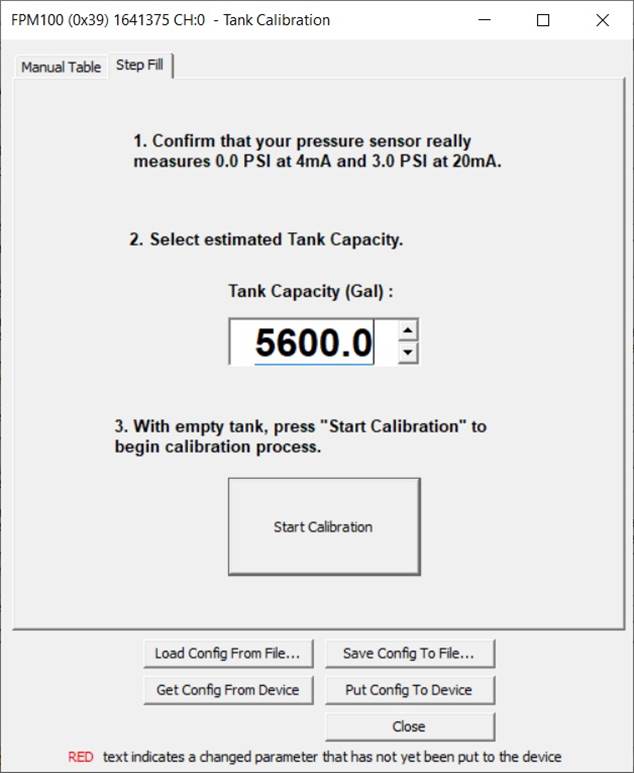

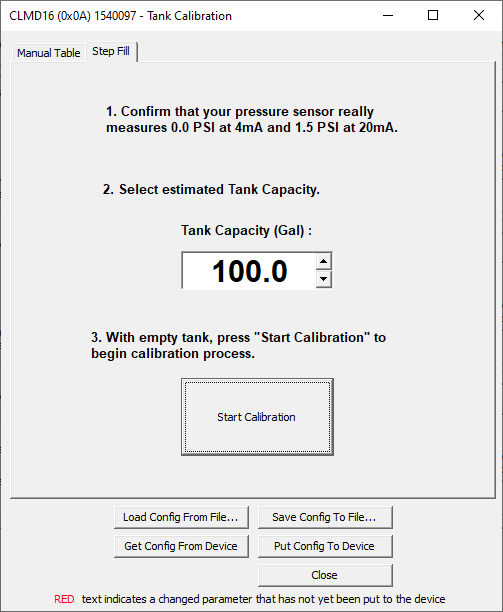

Figure 46 – CLMD16 Current Loop

Step Fill Calibration Initial Window

To use this method, use the

following steps:

1)

Enter the estimated total capacity of the tank into the “Total Capacity”

text box.

2)

Press the “Start Calibration” button. You will now see the Step Fill

Calibration window displayed, as shown below.

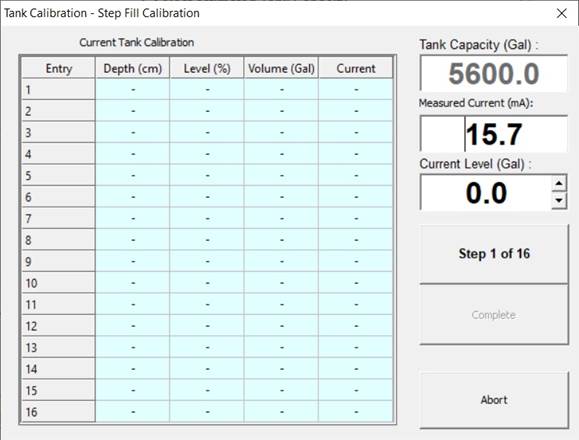

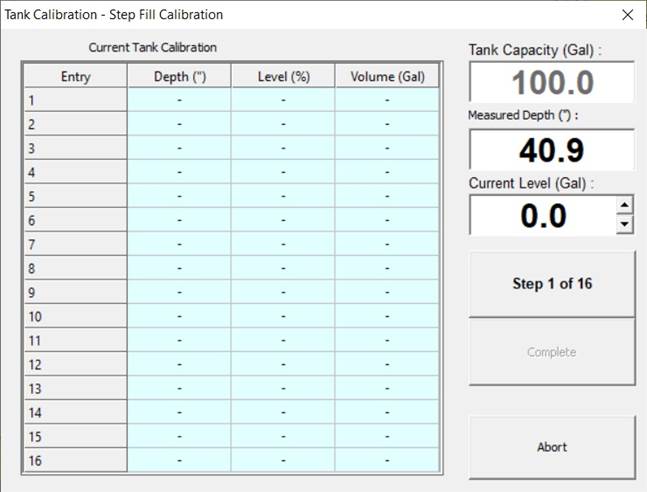

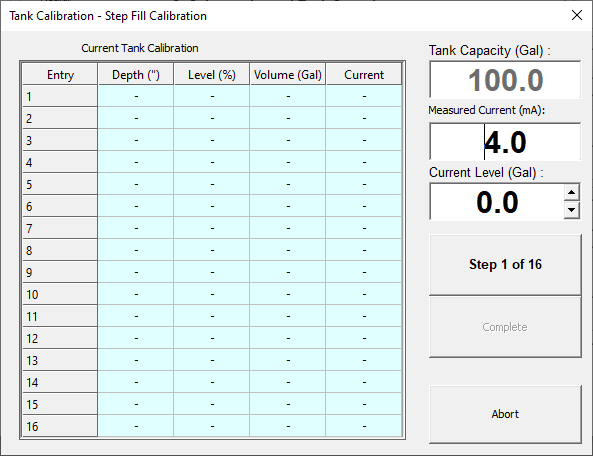

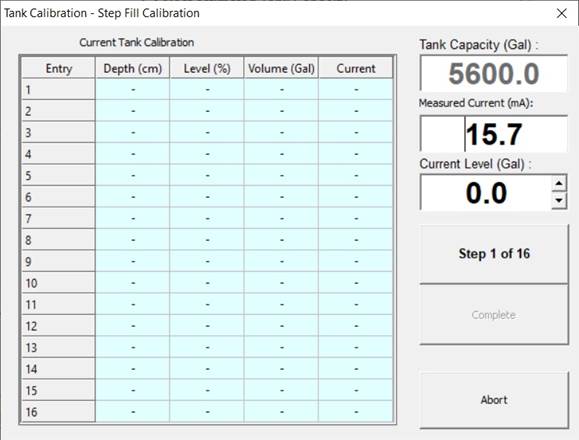

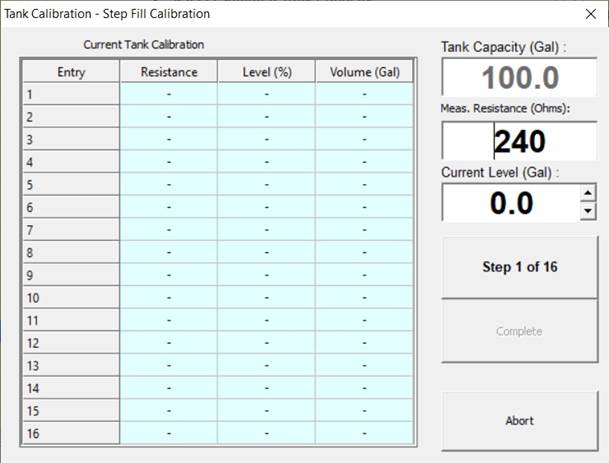

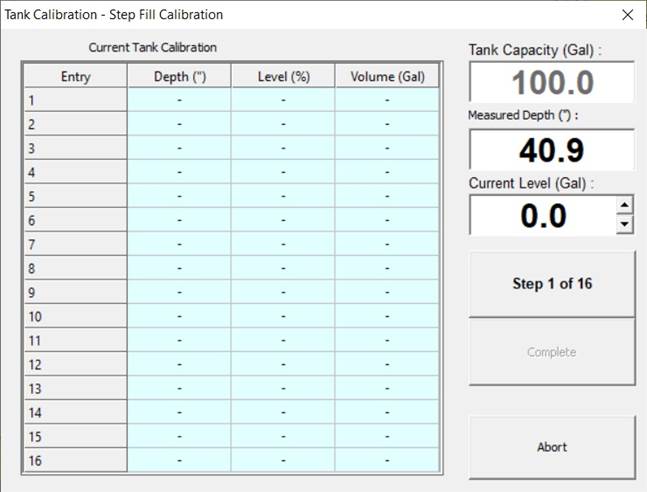

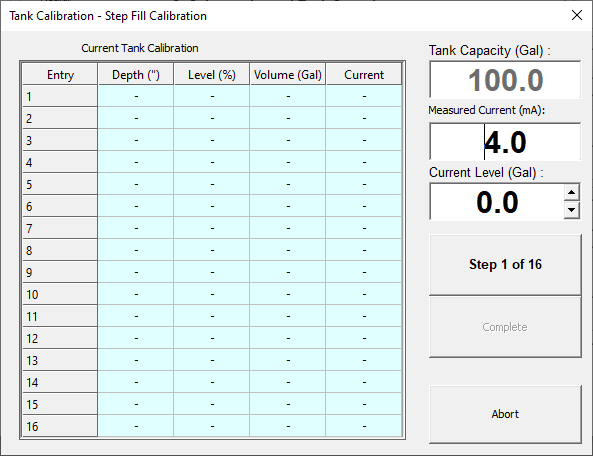

Figure 47 – CLMD16 Current Loop

Step Fill Calibration Initial Window

3)

Enter “0” into the Current Level text box, and press “Step”. You have

now entered the first point of the table.

4)

Partially fill the tank. Enter the amount of fluid pumped into the tank

into the “Current Level” text box, and press “Step” (if you make a mistake

entering a level, you can press “Back” and re-enter the level. If you want to

cancel the process, press the “Abort” button).

5)

Repeat the previous step until the tank is completely filled.

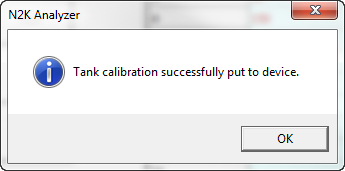

Once you have entered the last

point, where the tank is 100% full, press “Complete”. This will cause the table

to be stored in the device.

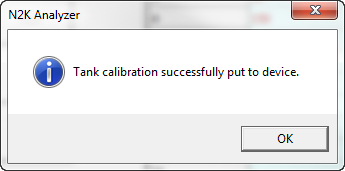

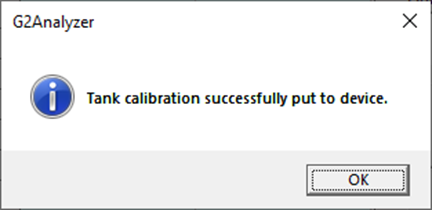

Figure 48 – CLMD16 Current Loop

Tank Fill Confirmation Dialog Box

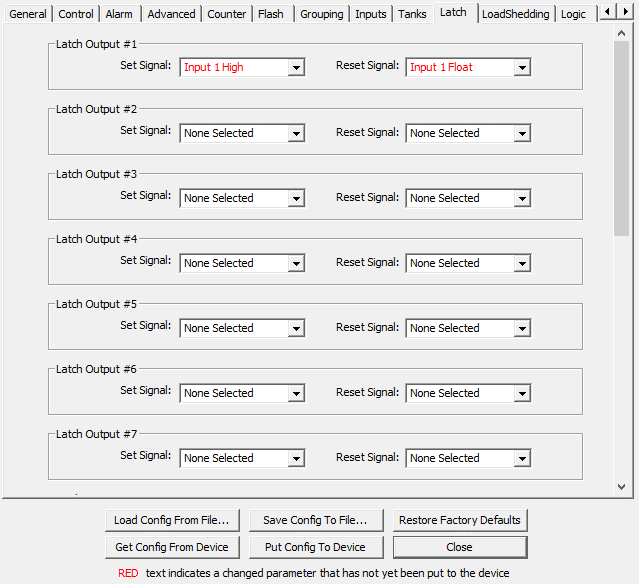

5.7.9

Latch Tab

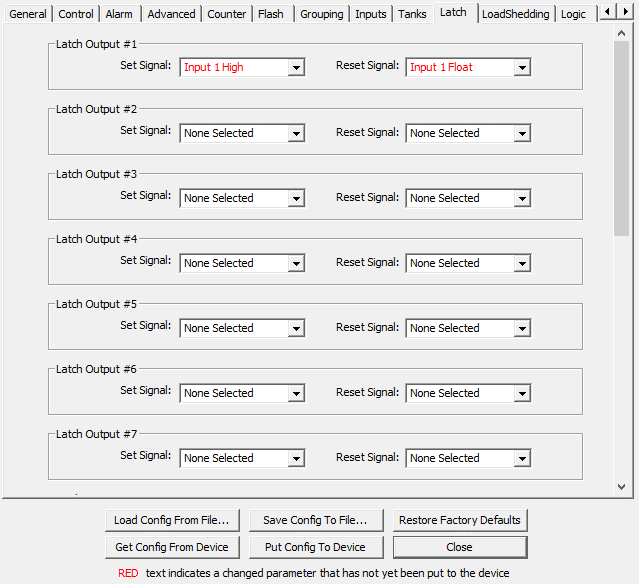

The CLMD16 provides sixteen

latches for use in the development of switching applications. Each latch

element consists of a single SET-RESET latch.

Figure 49 – CLMD16 Latch Tab

Set Signal

This parameter allows you to

select the internal signal to be connected to the SET input of the latch

element. You may choose a signal from the Available Input Signals list in

Section 5.7.

Reset Signal

This parameter allows you to

select the internal signal to be connected to the RESET input of the latch

element. You may choose a signal from the Available

Input Signals list in Section 5.7.

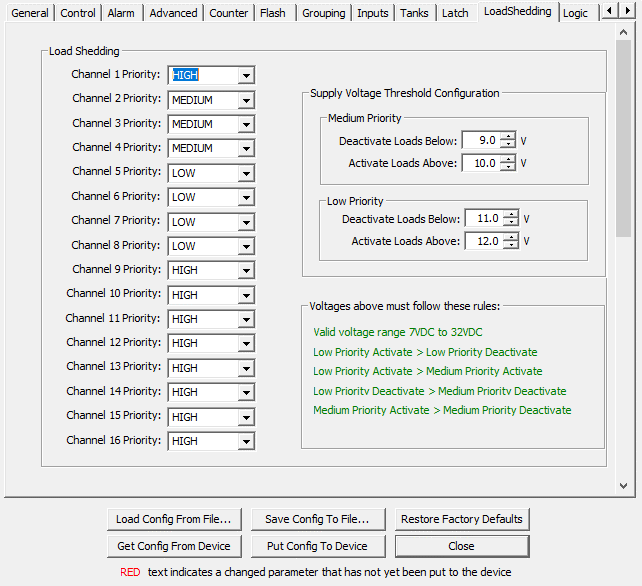

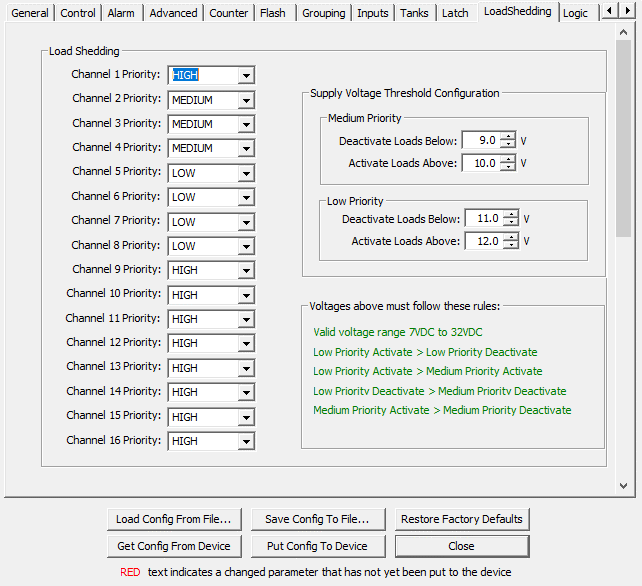

The CLMD16 implements load

shedding, which allows specified loads to be turned off when the DC supply

voltage drops below programmed levels.

Figure 50 – CLMD16 Load Shedding

Dialog

Channel x Priority

This programmable parameter allows

you to specify the priority level of the breaker channel. You may select from

one of the following values:

- HIGH – channels with this priority are never turned off

- MEDIUM

- LOW

Medium Priority Deactivate Loads Below

This programmable parameter allows

you to specify a voltage value such that when the DC supply voltage drops below

this level, channels with MEDIUM priority will be disabled.

Medium Priority Activate Loads Above

This programmable parameter allows

you to specify a voltage value such that when the DC supply voltage rises above

this level, channels with MEDIUM priority will be enabled.

Low Priority Deactivate Loads Below

This programmable parameter allows

you to specify a voltage value such that when the DC supply voltage drops below

this level, channels with LOW priority will be disabled.

Low Priority Active Loads Above

This programmable parameter allows

you to specify a voltage value such that when the DC supply voltage rises above

this level, channels with LOW priority will be enabled.

The CLMD16 provides forty-eight

logic elements for use in development of applications. Each logic element

consists of a three-input lookup table, enabling any three-input Boolean logic

function to be realized.

Figure 51 – CLMD16 Logic Dialog

Input A

This signal is connected to the

first input of the lookup table for this logic element. You may choose a signal

from the Available Input Signals list in Section 5.7.

Input B

This signal is connected to the

second input of the lookup table for this logic element. You may choose a

signal from the Available Input Signals list in Section 5.7.

Input C

This signal is connected to the

third input of the AND gate for this logic element. You may choose a signal

from the Available Input Signals list in Section 5.7.

Lookup Table

The lookup table consists of eight

rows, one for each possible combination of values for the three input signals.

Set the value in the Output row of the table to the desired output

signal value corresponding to the A, B, and C signal

values for that row.

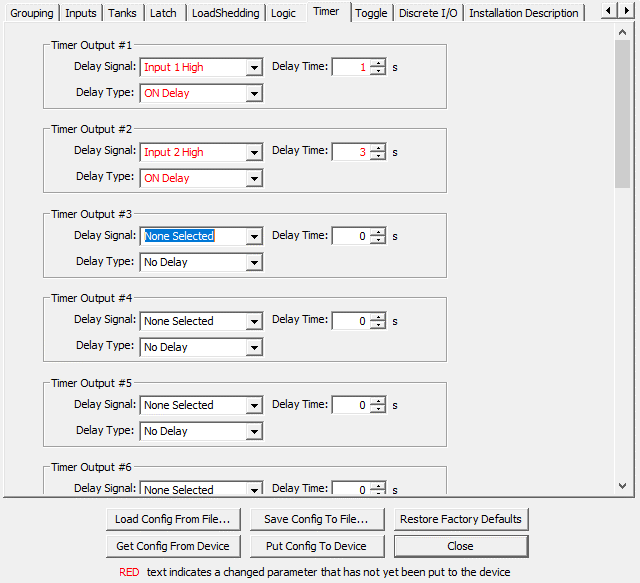

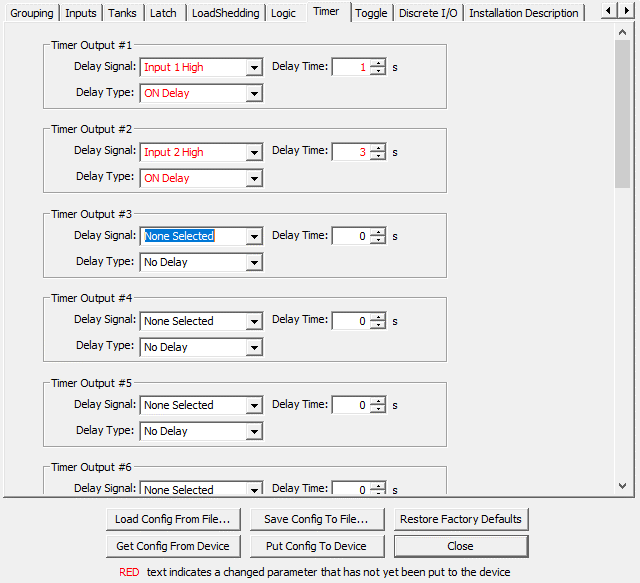

The CLMD16 provides sixteen timer

elements for use in constructing switching applications.

Figure 52 – CLMD16 Timer Dialog

Delay Signal

This parameter allows you to

select the internal signal to connect to the input of the timer element. You

may choose a signal from the Available Input Signals list in Section 5.7.

Delay Type

This parameter allows you to

select the type of delay implemented by this timer function. You may select

from one of the following choices:

- No Delay – the input signal is passed through to the output signal

with no delay introduced.

- OFF Delay – the input signal is passed through to the output signal

with ON to OFF transitions delayed by the time specified by the Delay Time

parameter.

- ON Delay –

the input signal is passed through to the output signal with OFF to ON

transitions delayed by the time specified by the Delay Time parameter.

Delay Time

This parameter allows you to

select the amount of time by which to delay the appropriate edges of the input

signal to produce the output signal.

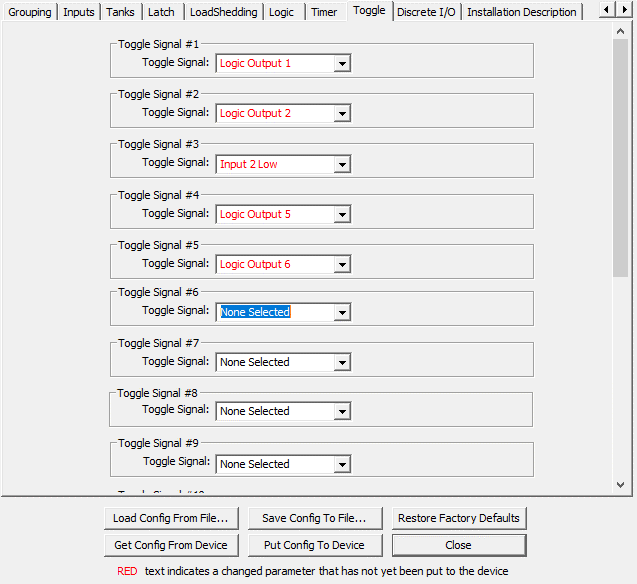

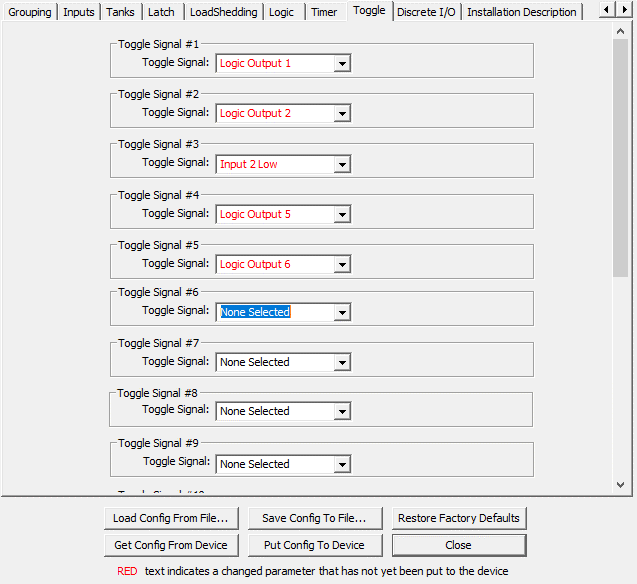

The CLMD16 provides sixteen toggle

flip-flop elements for use in developing switching applications.

Figure 53 – CLMD16 Toggle Tab

Toggle Signal

This parameter allows you to

select the internal signal to connect to the input of the timer element. You

may choose a signal from the Available Input Signals list in Section 5.7.

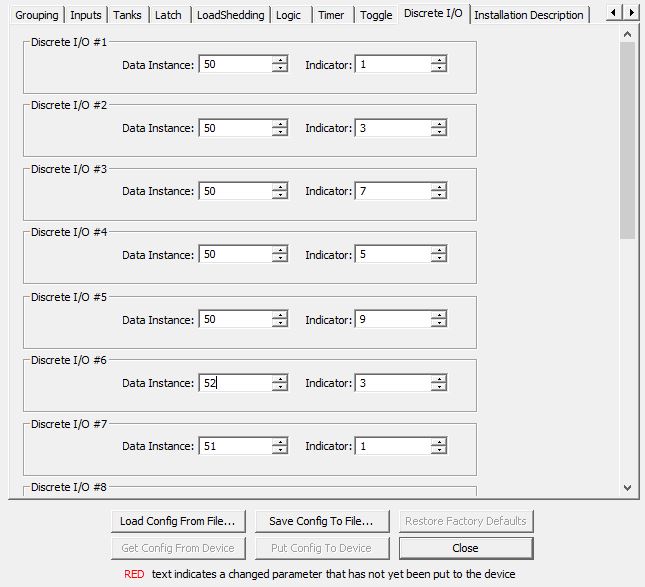

Figure 54 – CLMD16 Discrete I/O

Tab

Discrete I/O #n

When a device transmitting the

127501 Binary Status Report message is part of the installation, it can be

configured to create an input signal for the CLMD16. Up to thirty-two Discrete

I/O signals can be programmed.

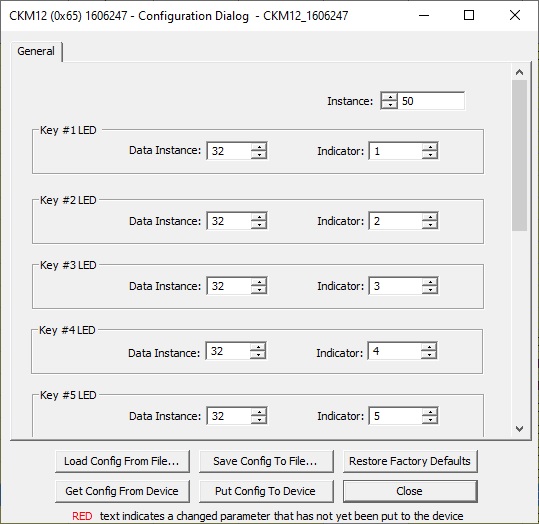

Data Instance

This parameter allows you to

configure the data instance of the 127501 Binary Status Report message that

will be used to create this discrete I/O signals. To assign a discrete input

from this device to this discrete I/O signal, enter the instance value assign

to this device (the value of the “Instance” field on the “General” tab).

Indicator

This

parameter allows you to configure the indicator number within the 127501 Binary

Status Report status message whose instance field matches the “Data Instance”

parameter for this channel that will be used to create this discrete I/O

signal.

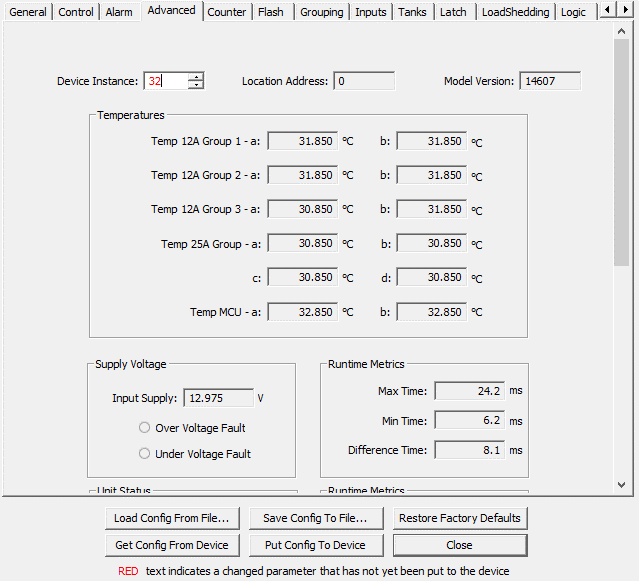

The Advanced tab is used to

configure and observe parameters that do not normally require changing.

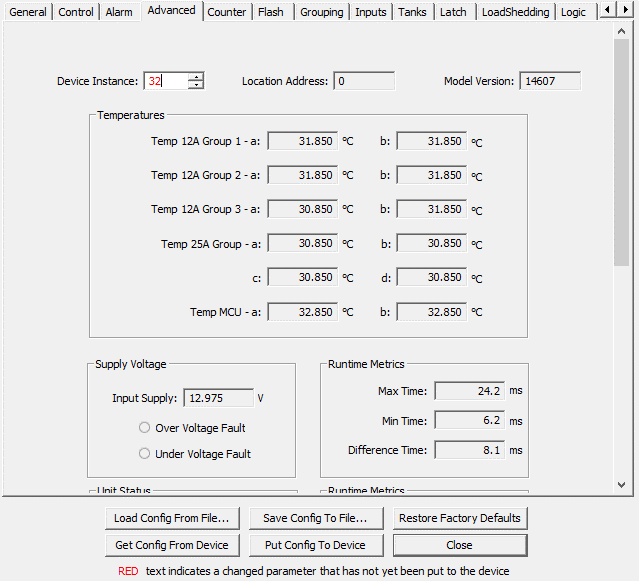

Figure 55

– CLMD16 Advanced Tab (Upper Portion)

Figure 56 – CLMD16 Advanced Tab

(Lower Portion)

Device Instance

This parameter allows you to

configure the NMEA 2000 device instance used by the device. This value is also

used as the data instance in the 127501 Binary Status Report messages

transmitted by the device and can be seen on the General Tab as well as the

Inputs Tab labeled as “Instance”.

Location Address

This read-only field displays the

value of the four active-low Address #1 through Address #4 inputs. Address #4

is the most significant bit, and Address #1 is the least significant bit.

Model Version

This read-only field shows the

internal version number of the CLMD16 application software.

Temperatures:

Temp 12A Group 1

These two read-only fields (a and

b) display the temperature measured by the two temperature sensors in the

CLMD16 located near the 12 Amp Group 1 channels.

Temp 12A Group 2

These two read-only fields (a and

b) display the temperature measured by the two temperature sensors in the

CLMD16 located near the 12 Amp Group 2 channels.

Temp 12A Group 3

These two read-only fields (a and

b) display the temperature measured by the two temperature sensors in the

CLMD16 located near the 12 Amp Group 3 channels.

Temp 25A Group

These four read-only fields (a, b,

c, and d) display the temperature measured by the four temperature sensors in

the CLMD16 located near the 25 Amp Group channels.

Temp MCU

These two read-only fields (a and

b) display the temperature measured by the two temperature sensors in the

CLMD16 located near the system microcontroller.

Supply Voltage:

Input Supply

This read-only field displays the

voltage that is present on the DC Power Connection Stud with respect to the DC

Ground Connection Stud.

Over Voltage Fault

This read-only indicator is lit

red if the voltage between the DC Power Connection Stud and the DC Power Ground

Stud is higher than the recommended operating range.

Under Voltage Fault

This read-only indicator is lit

red if the voltage between the DC Power Connection Stud and the DC Power Ground

Stud is lower than the recommended operating range.

Execution Time Metrics:

Max Time

This read-only field displays the

longest loop time used by internal calculations.

Min Time

This read-only field displays the

shortest loop time used by internal calculations.

Difference Time

This read-only field displays the

average loop time used by internal calculations.

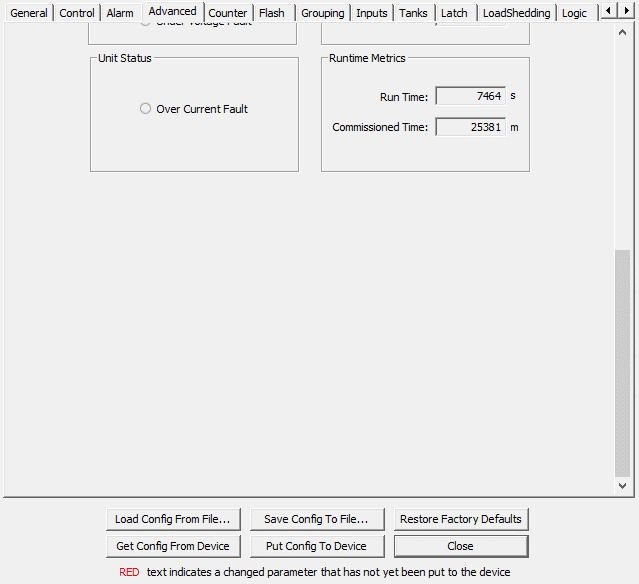

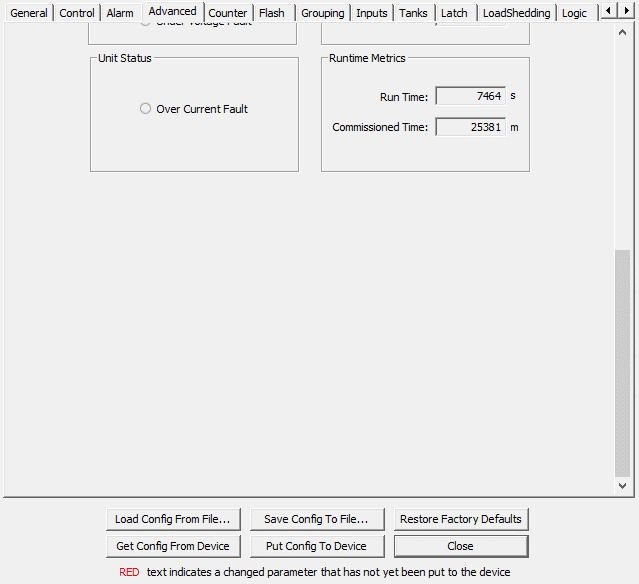

Unit Status:

Over Current Fault

This read-only indicator is lit

red if the CLMD16 has been shut down because the total current through the

CLMD16 is in excess of the 125 Amp specification.

Runtime Metrics:

Run Time

This read-only field displays the

total amount of time the CLMD16 has been operational since it was last powered

on.

Commissioned Time

This read-only field displays the

total amount of the time the CLMD16 has been operational since it was built.

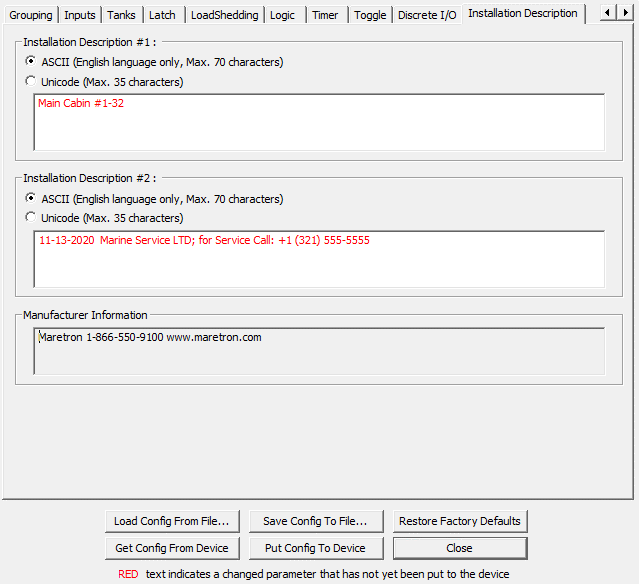

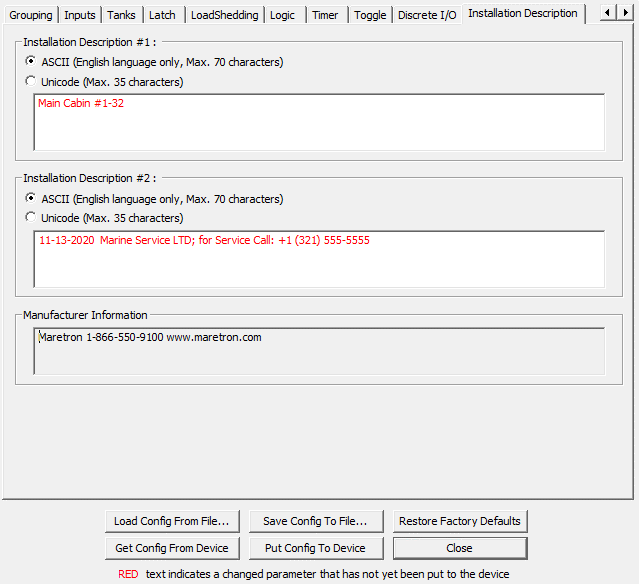

5.7.16 Installation

Description Tab

This tab allows you to set values

for the installation description properties of the device.

Figure 57

– CLMD16 Installation Description Tab

Installation Description #1, #2

This device, along with all other

Level A certified NMEA devices, has two user-entry ‘Installation Description’

fields. You may enter text into these fields with information specific to the

device, such as date installed, the initials/name of the installer, the

physical location of the device, etc.

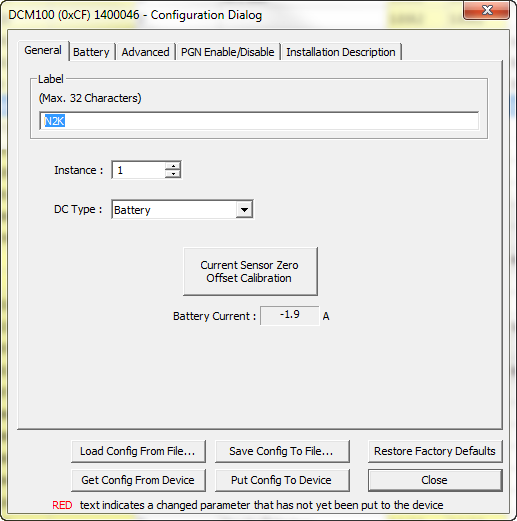

5.8

DCM100

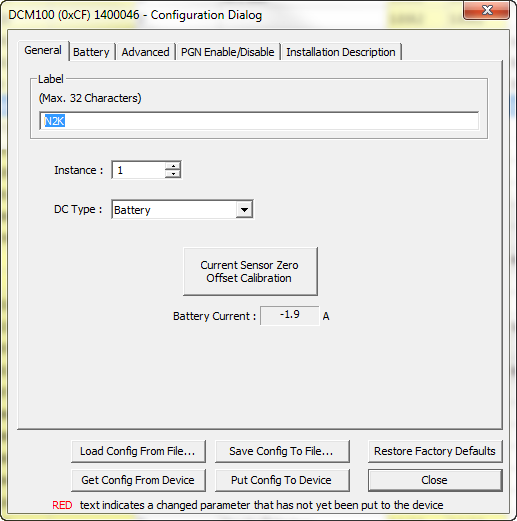

This tab contains commonly-used configuration items.

Figure 58 – DCM100 General Tab

Label

This text box allows you to assign a text label to the

device. This label is visible in Maretron analysis and display products and

allows you to easily identify the particular device.

NMEA 2000 provides a unique instance number for each DC

power source on a vessel.

You can configure the DCM100 as to what type of DC power

source it is monitoring. Except for the “Battery” type, the value of this

parameter is used only for reporting the power source type over the NMEA 2000

network. However, if you select the “Battery” type, many battery-related

options become available.

The following DC Types are selectable:

·

Battery

·

Alternator

·

Converter

·

Solar Cell

·

Wind Generator

Current Sensor Zero Offset Calibration

The DCM100 is shipped with a Hall-effect current sensor. To

match the DCM100 unit and the sensor to one another and ensure maximum

accuracy, you should perform this calibration step while there is no current

flowing through the current sensor.

Battery Current

This display-only field shows the current provided by the

battery. If there is no current flowing through the current sensor, this field

should read near zero after current sensor zero offset calibration is

performed.

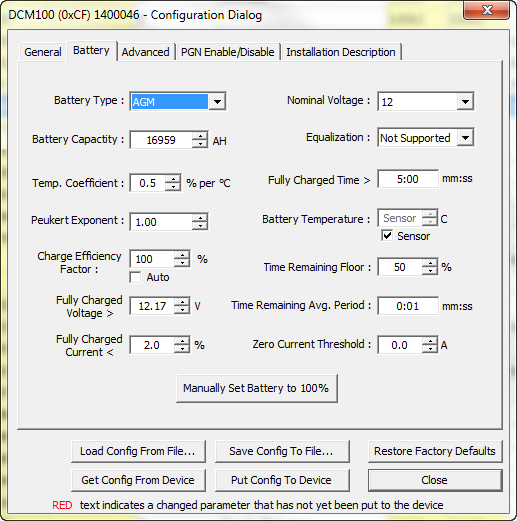

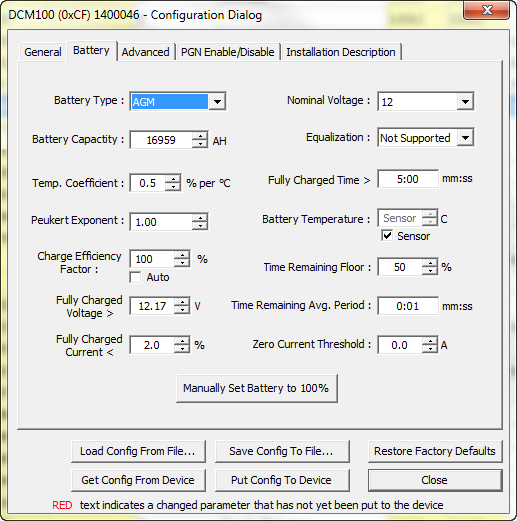

This tab provides a means to program the DCM100 with

characteristics of the battery being monitored.

Please note that this tab is only functional when “DC Type”

is set to “Battery” in the General tab.

Figure 59 – DCM100 Battery Tab

The available battery types are Flooded/Wet, Gel, AGM, Li-Ion,

NiCad, NiMH, ZnO and Other. Selecting one of these types causes the remaining

parameters to be set to appropriate default values.

Set this field to the value of the capacity of the battery

in Amp-hours at 25°C.

The capacity of a battery generally increases with

increasing temperature. So that the DCM100 can properly calculate the battery’s

state of charge, configure this parameter with the increase in battery

capacity, in percent, per increase in temperature, in degrees Celsius. The

temperature coefficient can be set to a value between 0%/°C – 5%/°C.

The Peukert Exponent for the battery can be set to a value

between 1.0 and 1.5. Please refer to the DCM100 User’s Manual for

details.

The Charge Efficiency Factor for the battery can be set to a

value between 5% and 100%. Please refer to the DCM100 User’s Manual for

details.

For the DCM100 to determine when a battery is fully charged,

it uses three parameters. The “Fully Charged Voltage” indicates the value

voltage at which the battery is considered fully charged if the battery voltage

remains above this value and the battery current remains below the “Fully

Charged Current” for the amount of time defined by the “Fully Charged Time”

parameter.

For the DCM100 to determine when a battery is fully charged,

it uses three parameters. The “Fully Charged Voltage” indicates the value

voltage at which the battery is considered fully charged if the battery voltage

remains above this value and the battery current remains below the “Fully

Charged Current” for the amount of time defined by the “Fully Charged Time”

parameter.

Nominal Voltage

You may program here the nominal voltage of the battery,

which is used only for reporting over the NMEA 2000 network. Available choices

are 6, 12, 24, 32, 36, 42, and 48 Volts.

You may indicate here whether the battery supports

equalization. This is used only for reporting over the NMEA 2000 network. Available

choices are “Supported” and “Not Supported”.

For the DCM100 to determine when a battery is fully charged,

it uses three parameters. The “Fully Charged Voltage” indicates the value

voltage at which the battery is considered fully charged if the battery voltage

remains above this value and the battery current remains below the “Fully Charged

Current” for the amount of time defined by the “Fully Charged Time” parameter.

For the DCM100 to properly determine battery capacity and

state of charge, it must know the temperature of the battery. If you are using

a TR3K temperature sensor attached to the battery, you should set this

parameter to “Sensor”. Otherwise, if no temperature sensor is available, you

can set this parameter to the estimated battery temperature, between -25°C and

125°C.

The DCM100 calculates the time, given the current being

discharged from the battery, before the battery becomes discharged. By default,

the DCM100 considers a battery to be discharged when its state of charge

reaches the “Time Remaining Floor” value, which is by default set to 50%. If

you desire to use some other state of charge value for the “Time Remaining

Floor”, you may change this parameter to the desired value.

If loads on the battery are switching on and off frequently,

the battery time remaining value calculated by the DCM100 can vary

significantly. You may change the time over which current readings are averaged

by changing this parameter anywhere in the range of 1 second to 32 minutes.

The current sensor reading can drift slightly at zero

current, depending on temperature. Over a long period of time, this can cause

the DCM100 to calculate that a battery is discharging slowly, even though it is

not. The Zero Current Threshold parameter indicates a reading from the current

sensor below which no current is considered to be flowing into or out of the

battery.

Manually Set Battery to 100%

If you know that the battery is fully charged, press this

button to immediately set the battery state of charge to 100%.

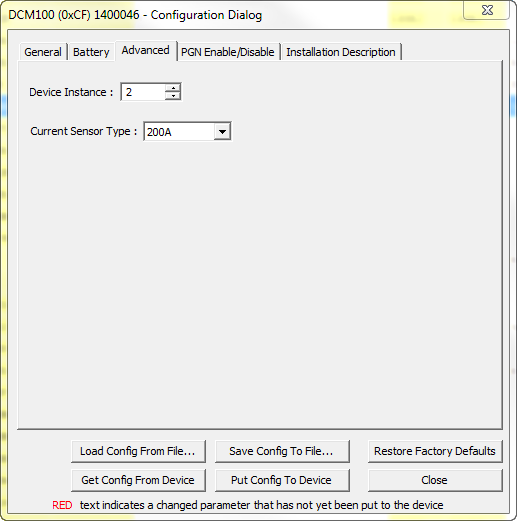

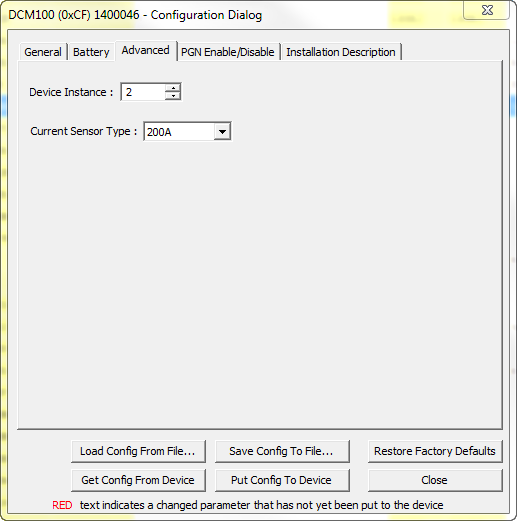

This tab contains entries that need to be changed only in

specific cases; for instance, if there are multiple instances of this device on

a network.

.

.

Figure 60 – DCM100 Advanced Tab

Device Instance

The device comes from the factory with the device instance

value set to 0. If you have multiple of these devices on a network, you may

find it necessary to set the device instances of other devices of this type so

that they are different.

Current Sensor Type

From the factory, the DCM100 is configured to use a 200A Hall

Effect current sensor. If you are using a 400A or 600A current sensor, you

should configure the DCM100 for the proper sensor type by selecting it in this

field.

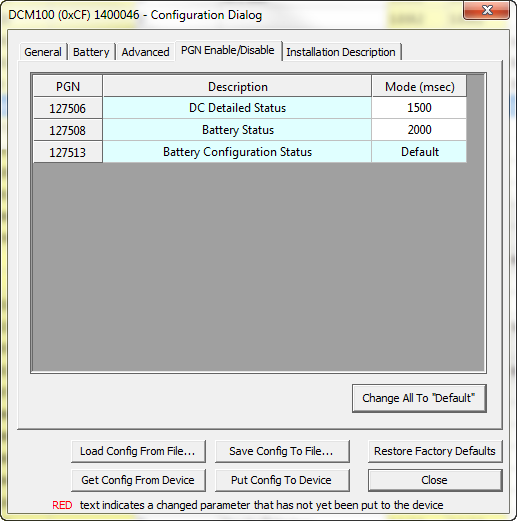

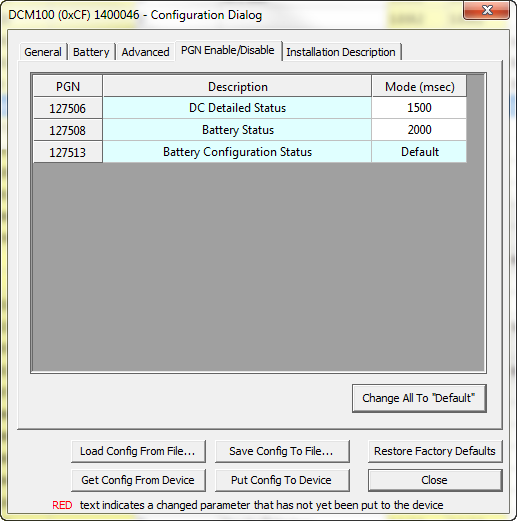

This tab allows you to enable or disable the transmission of

the periodic messages output by the device. You may enable or disable the

transmission of the messages or may program the time interval between

transmissions of a specific message, for devices which support the programming

of time intervals.

When you first open the PGN Enable/Disable tab, a list of

periodic PGN’s transmitted by the device will appear. The mode column will read

“On”, if the device is currently transmitting the message, or “Off”, if the

message has not yet been detected from the device.

You may configure each periodic message with one of the

following choices:

1) Disable – this

will turn off the periodic transmission of this message

2) Default – this

will turn on the periodic transmission of this message at the default rate

3) A numeric value

that will turn on the periodic transmission of this message at the specified

rate

Figure 61 – DCM100 PGN Enable/Disable Tab

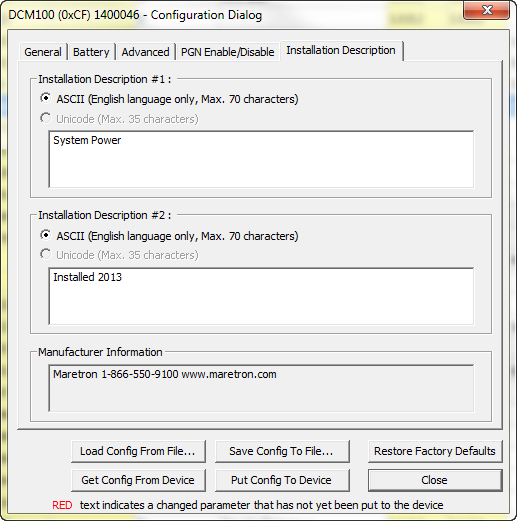

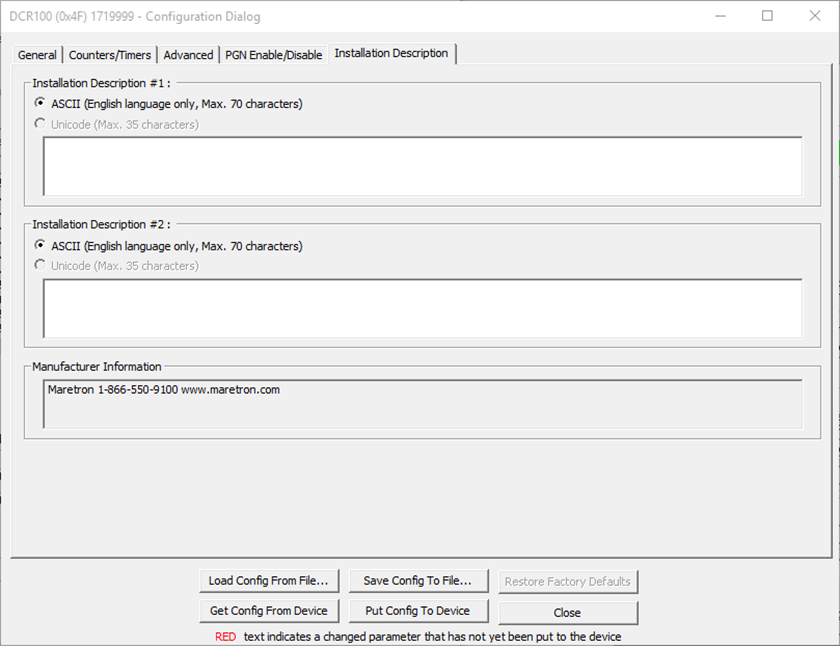

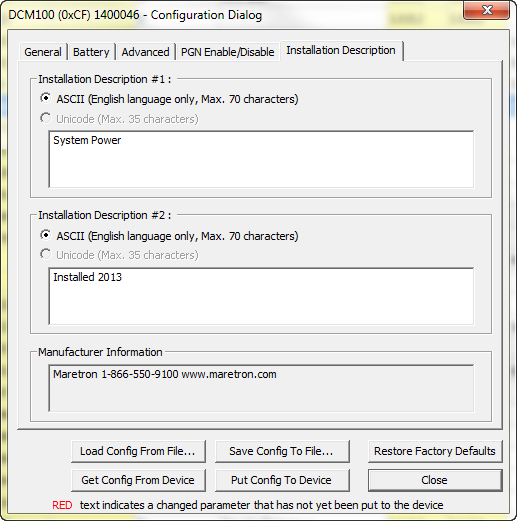

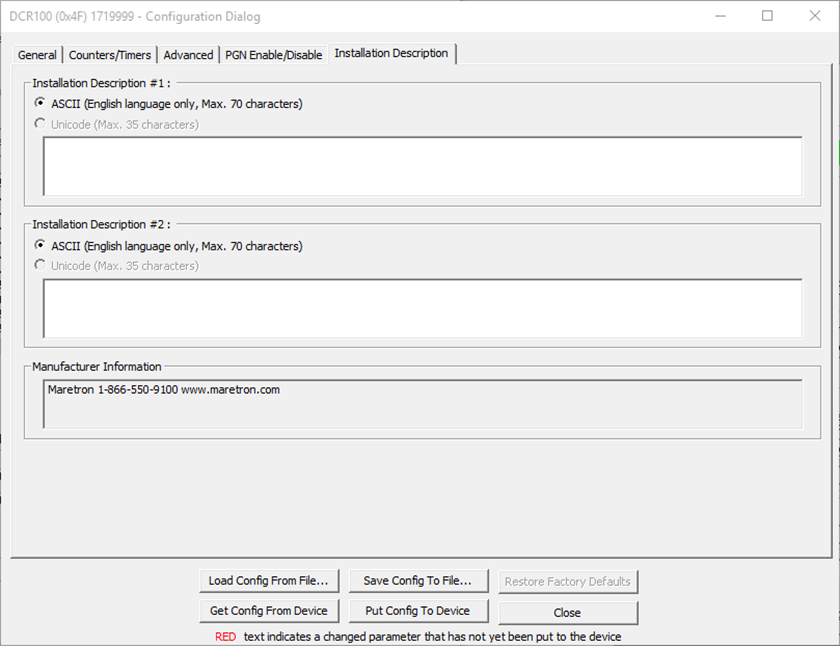

This tab allows you to set values for the installation

description properties of the device.

Figure 62 – DCM100 Installation Description Tab

Installation Description #1, #2

This device, along with all other

Level A certified NMEA devices, has two user-entry ‘Installation Description’

fields. You may enter text into these fields with information specific to the

device, such as date installed, the initials/name of the installer, the

physical location of the device, etc.

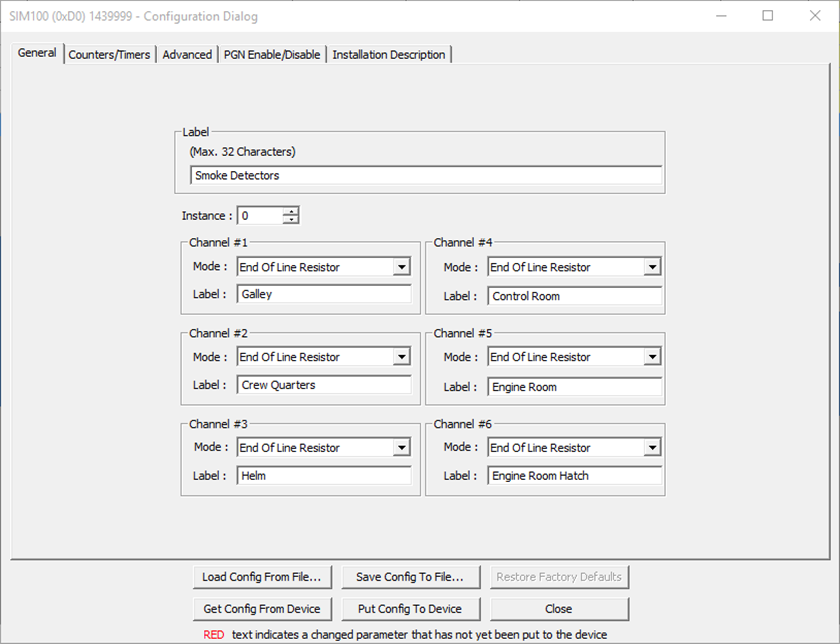

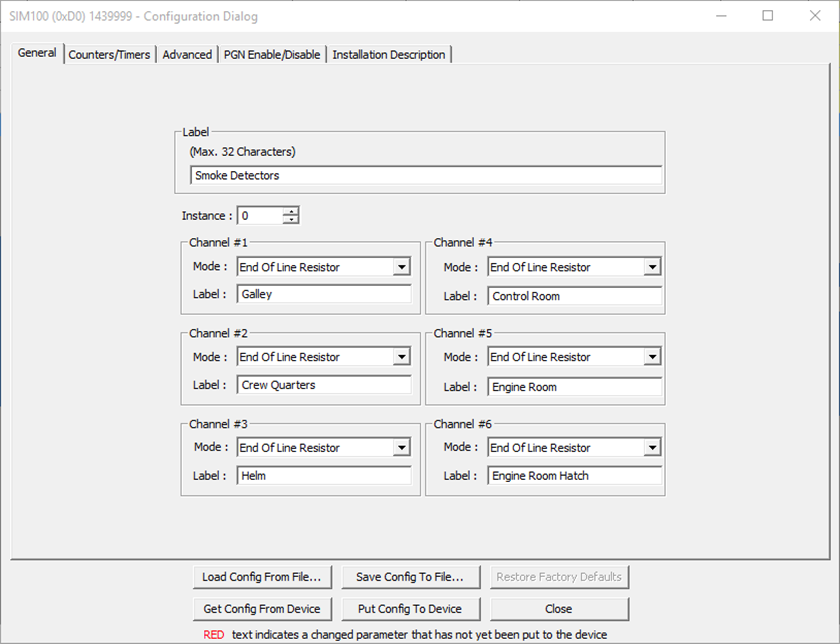

5.9

DCR100

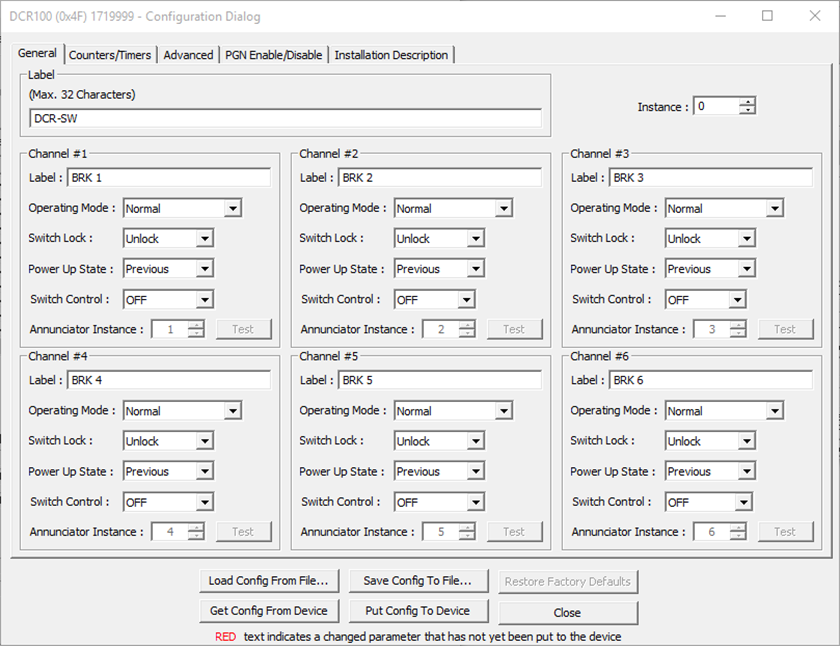

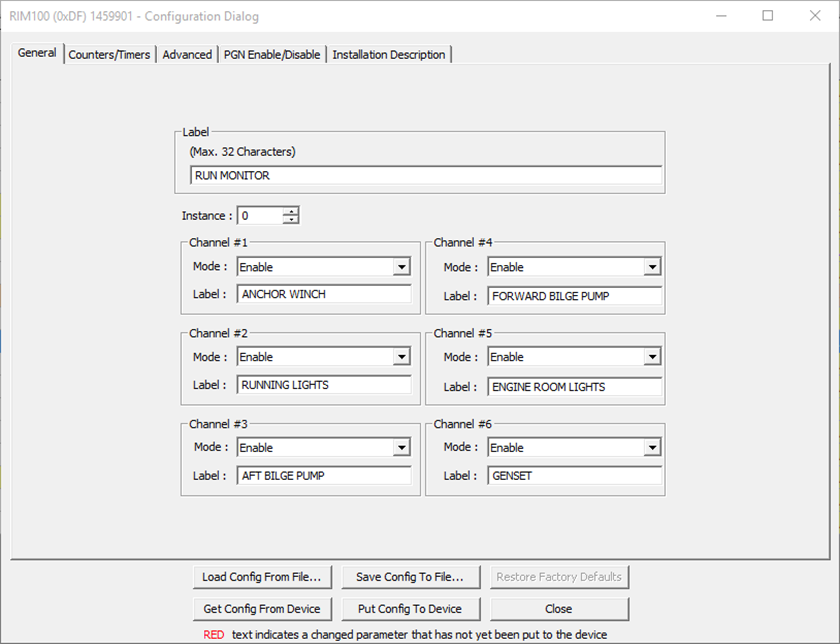

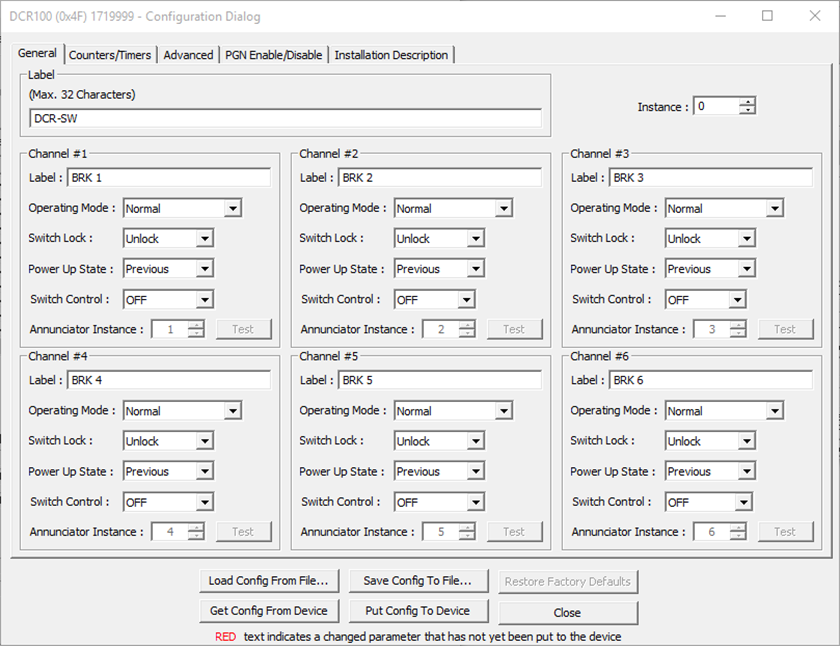

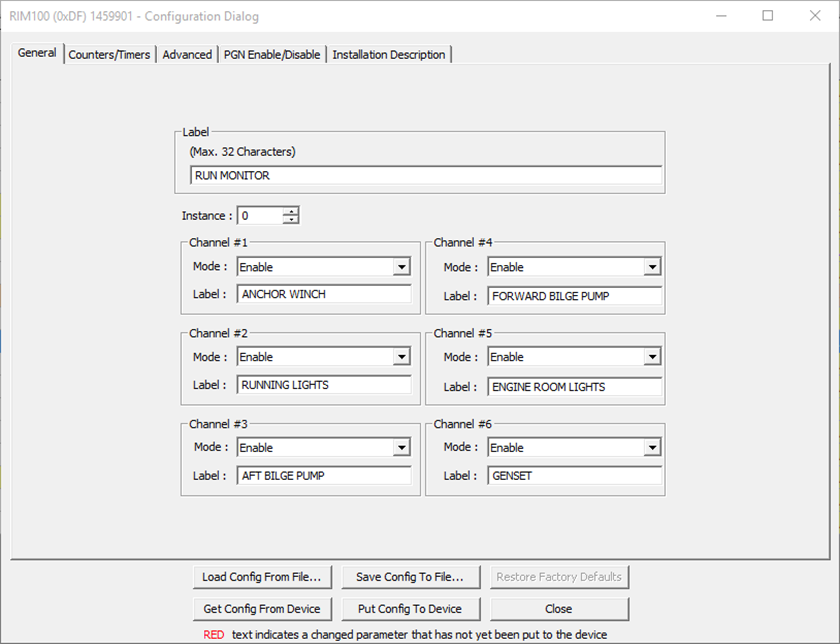

This tab contains commonly-used configuration items.

Figure 63 – DCR100 General Tab

Label

This text box allows you to assign a text label to the

device. This label is visible in Maretron analysis and display products and

allows you to easily identify the particular device.

Channel #x Label

Each channel has a text label you can set to identify the

load controlled by that channel (for example, “EXHAUST FAN” or “NAV LIGHTS”).

For each channel, set this to a value which describes the load being controlled

so that you can easily identify it in display devices.

Channel #x Operating Mode

DCR100 channels have two operating modes: “Normal”, in which

the DCR100 channel responds to standard NMEA 2000 switching commands, and

“Annunciator”, in which the channel may be connected to a power source for a

sounder or a light to be activated in the case of an alert generated by a DSM

series display or by N2Kview software.

Channel #x Switch Lock

This menu allows you to view the lock status of each switch.

When a switch is locked, it will not respond to the on and off commands

transmitted over the NMEA 2000 network until it has been unlocked. This menu is

disabled if the channel is set to “Annunciator Mode”.

Channel #x Power Up State

This menu allows you to configure the state of the switch

when the DCR100 is first powered up. You may set the state to ON, OFF, or

Previous State (the state of the switch when power was last applied to the

DCR100). This menu is disabled if the channel is set to “Annunciator Mode”.

Channel #x Switch Control

This entry will show the current state of the relay channel,

either “Off” (open) or “On” (closed). You may use this menu entry to turn the

relay channel on or off.

Channel #x Annunciator Instance

This entry allows you to program the instance number for the

channel in Annunciator Mode. You may use a value between 0 and 15. This

instance number is used by the DSM series display or N2Kview when selecting

annunciators to sound when programming an alert.

Channel #x Test

Press this button to verify functionality of the channel in

Annunciator mode. This will cause the annunciator to sound or light briefly.

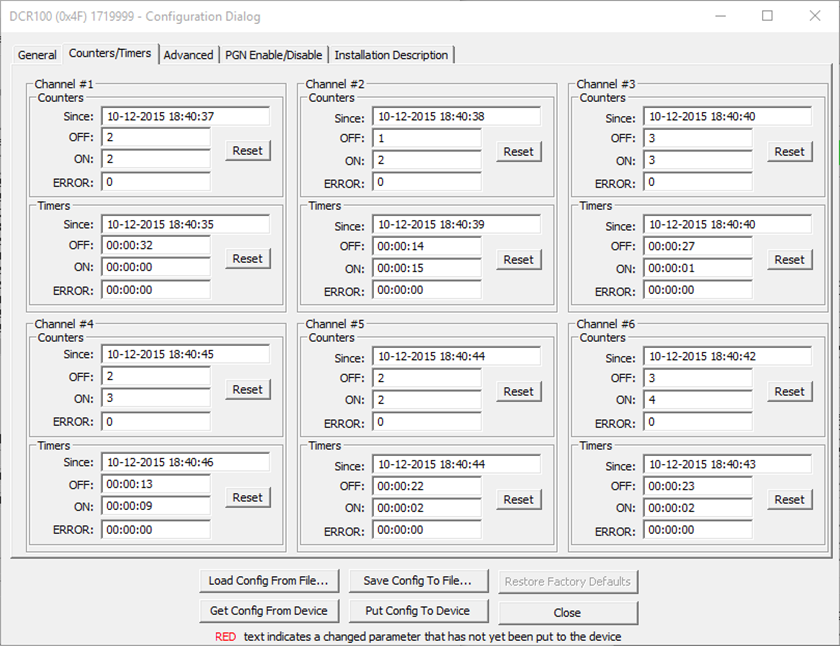

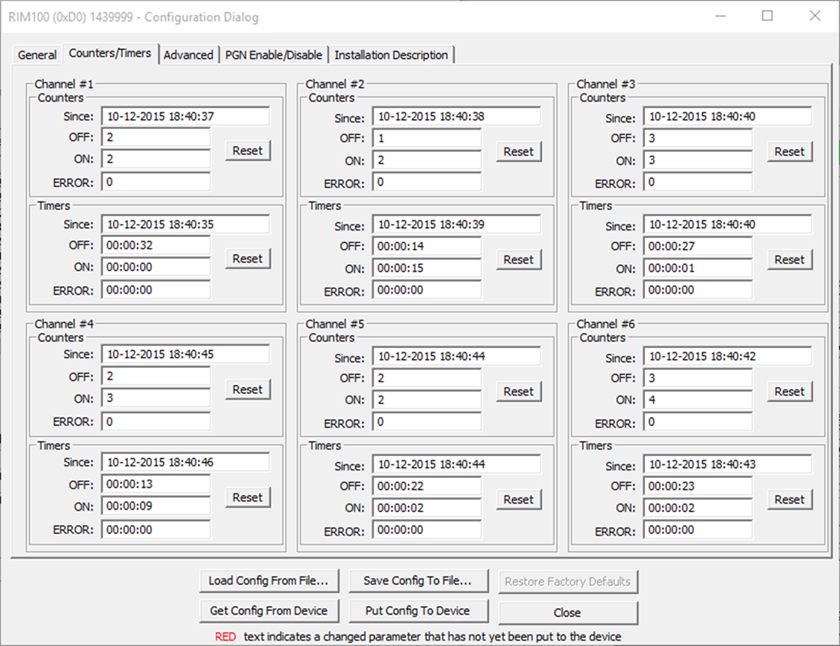

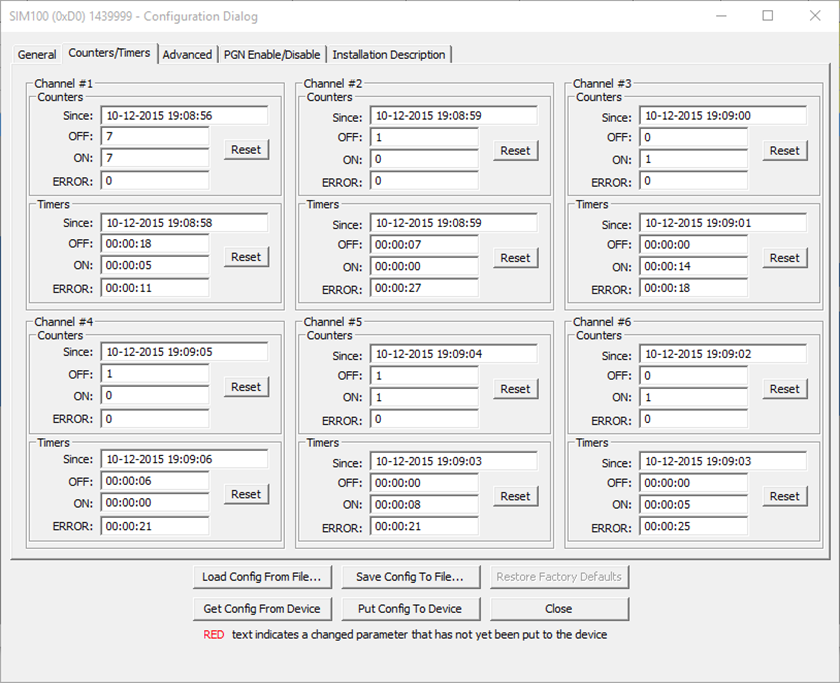

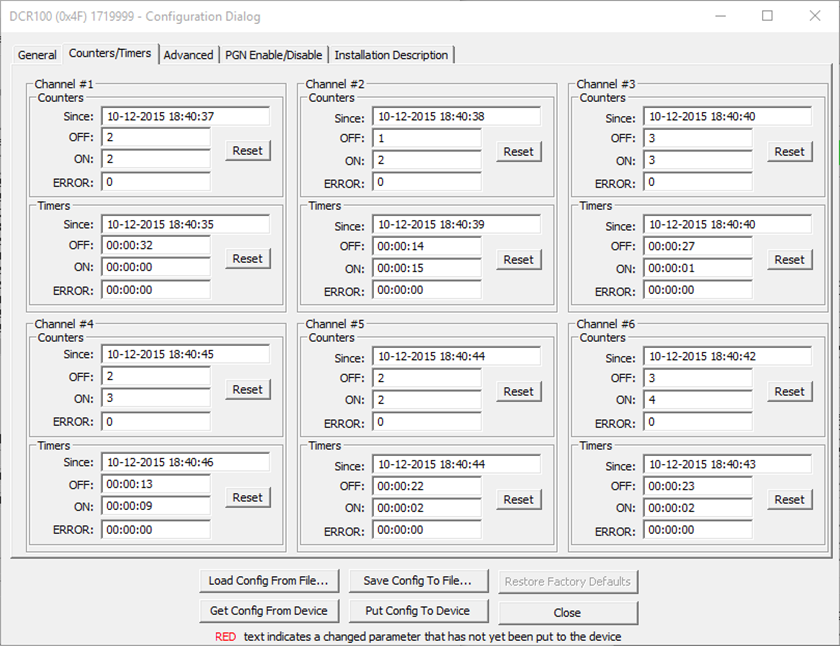

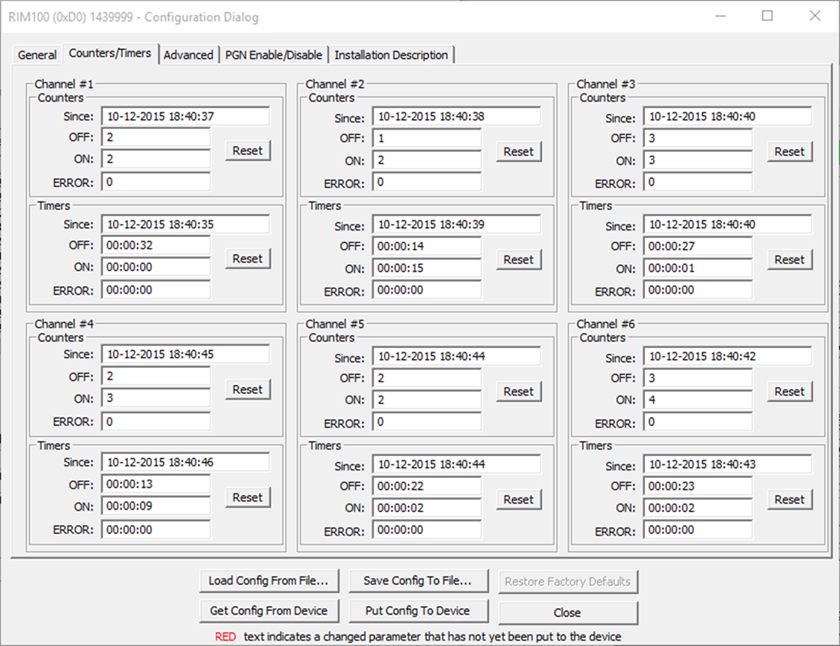

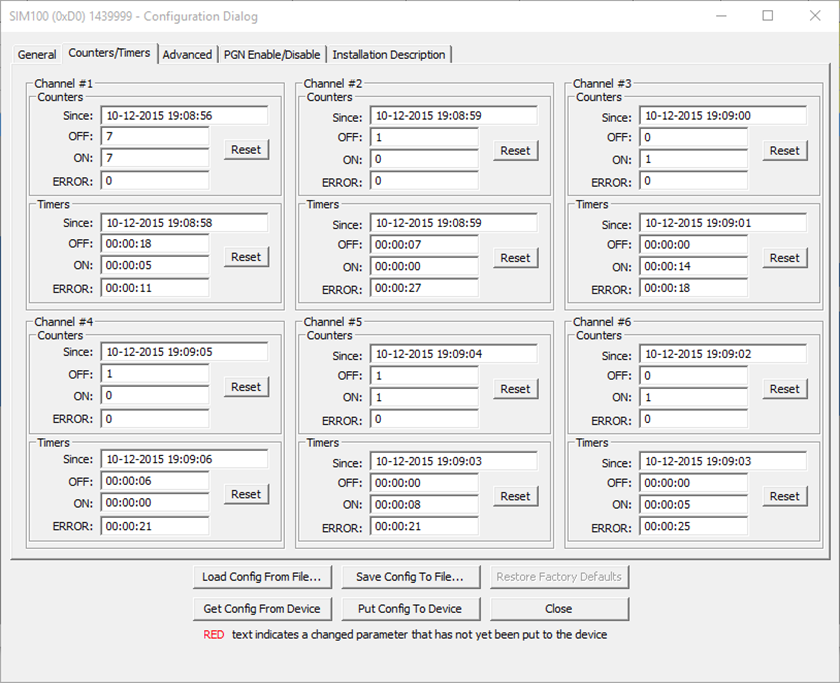

This tab contains controls to view the state of and to reset

the hardware counters and timers in the DCR100.

Figure 64 – DCR100 Counters/Timers Tab

Each channel of the DCR100 maintains counters that track how

many times the channel has transitioned into each of the states OFF, ON, and

ERROR. The “Counters” section of this dialog for each channel has the following

fields:

·

Since: the time and date that the channel’s counter was

last reset (this requires that a source of time and date, usually a GPS

receiver, be present on the NMEA 2000 network.

·

OFF: the number of times that this channel has

transitioned into the OFF state since the channel’s counters were last reset.

·

ON: the number of times that this channel has transitioned

into the ON state since the channel’s counters were last reset.

·

ERROR: the number of times that this channel has

transitioned into the ERROR state since the channel’s counters were last reset.

·

Reset: Pressing this button will reset the OFF, ON, and

ERROR counters to zero values, and will update the “Since:” field for this

channel’s counters to the current time and date.

Each channel of the DCR100 maintains timers of the elapsed

time that the channel has spent in each of the states OFF, ON, and ERROR. The

“Timers” section of this dialog for each channel has the following fields:

·

Since: the time and date that the channel’s timer was last

reset (this requires that a source of time and date, usually a GPS receiver, be

present on the NMEA 2000 network.

·

OFF: the elapsed time that this channel has been in the

OFF state since the channel’s timer were last reset.

·

ON: the elapsed time that this channel has been in the ON

state since the channel’s timers were last reset.

·

ERROR: the elapsed time that this channel has been in the

ERROR state since the channel’s timers were last reset.

·

Reset: Pressing this button will reset the OFF, ON, and

ERROR timers to zero values, and will update the “Since:” field for this

channel’s timers to the current time and date.

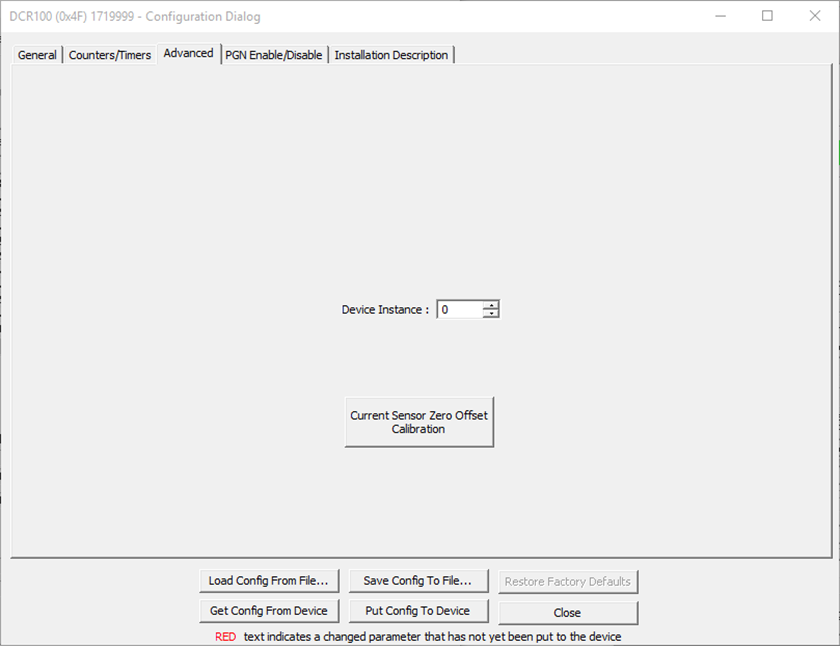

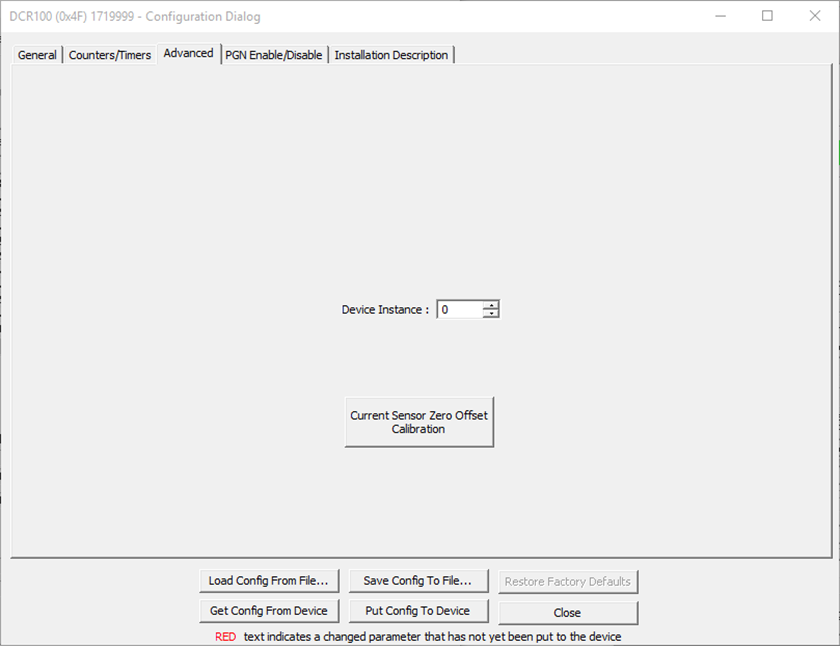

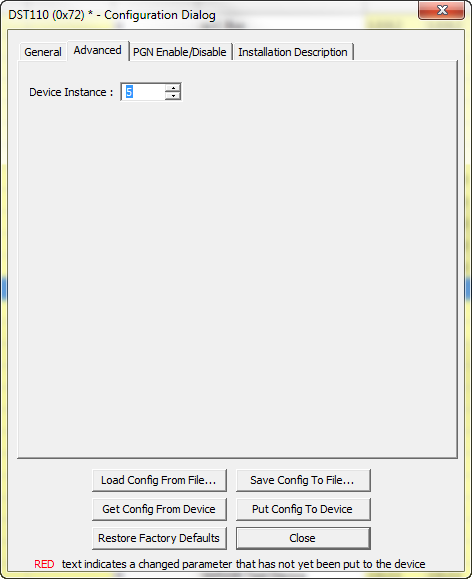

This tab contains entries

that need to be changed only in specific cases; for instance, if there are

multiple instances of this device on a network.

Figure 65 – DCR100 Advanced Tab

Device Instance

The device comes from the factory with the device instance

value set to 0. If you have multiple of these devices on a network, you may

find it necessary to set the device instances of other devices of this type so

that they are different.

Current Sensor Zero Offset Calibration

The DCR100 contains Hall-effect current sensors. Press this

button to calibrate the zero-current reading of the sensors. To ensure maximum

accuracy, you should perform this calibration step while there is no current

flowing through the current sensors.

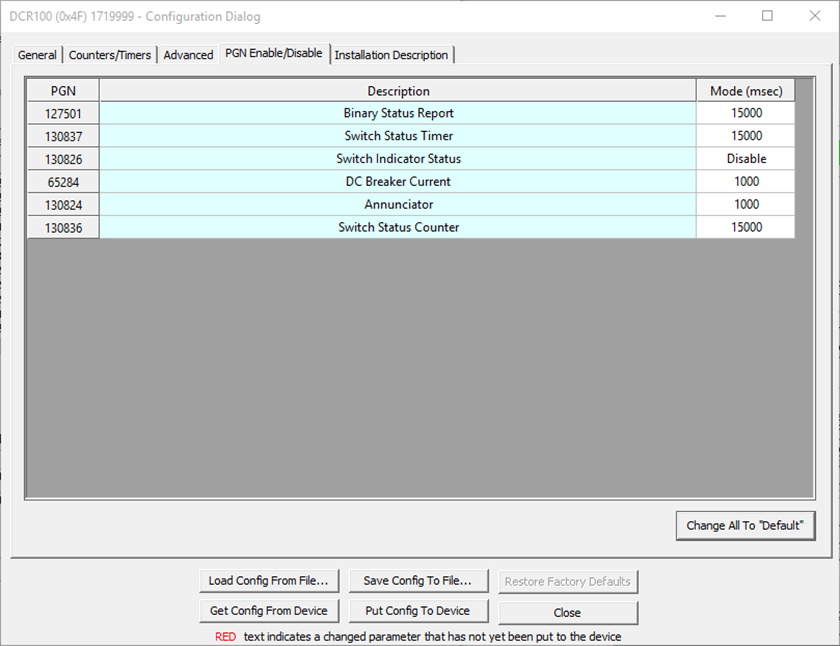

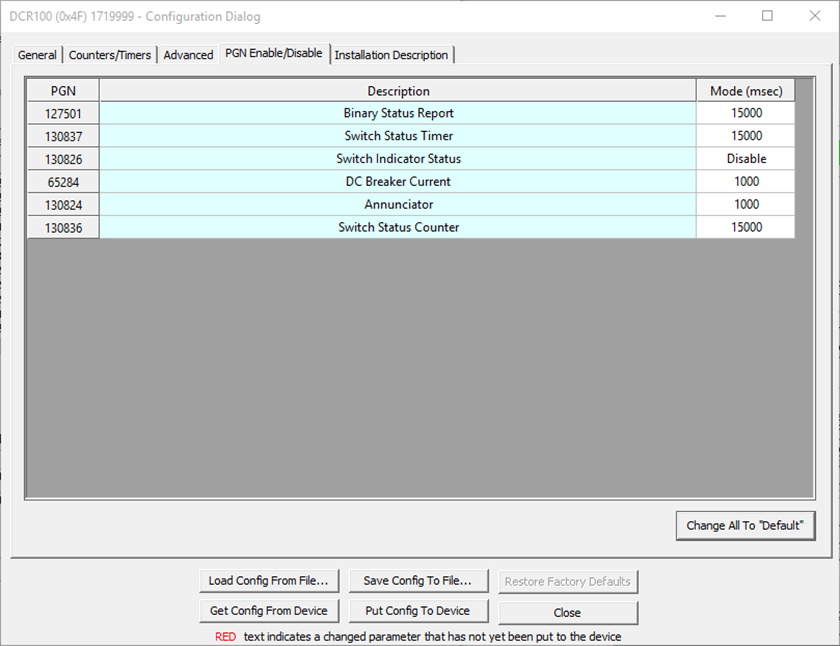

This tab allows you to enable or disable the transmission of

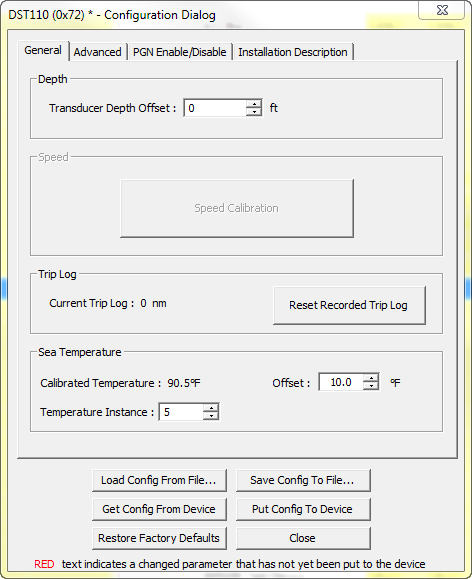

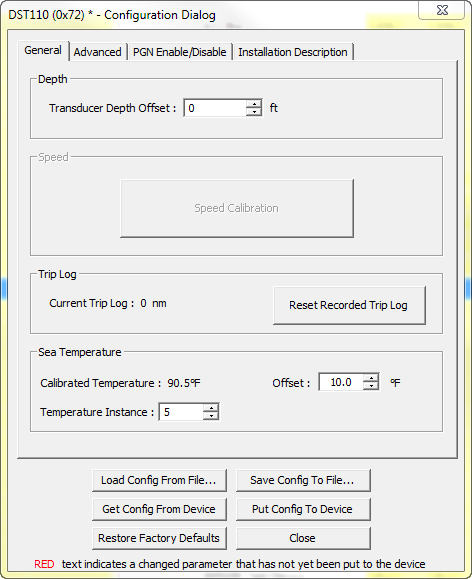

the periodic messages output by the device. You may enable or disable the