1 General

1.1 Introduction

Congratulations on your purchase of the Maretron DST110 NMEA 2000® Depth, Speed, and Temperature Transducer. Maretron has designed and built your transducer to the highest standards for years of dependable and accurate service. The DST110 detects the water depth with a 235 KHz depth transducer, the water speed with a paddlewheel and Hall effect sensor, and the water temperature with a precision thermistor element.

The Maretron DST110 is designed to operate within the harsh demands of the marine environment. However, no piece of marine electronic equipment can function properly unless installed, calibrated, and maintained in the correct manner. Please read carefully and follow these instructions for installation, calibration, and usage of the Maretron DST110 in order to ensure optimal performance.

1.2 Features

The Maretron DST110 NMEA 2000® Depth/Speed/Temperature Transducer has the following features.

· NMEA 2000® Interface

· 235 KHz Ceramic Transducer for Detecting Water Depth

· 100 Watt RMS Power Output for Depth Measurements up to 100 meters

· Paddlewheel with Hall Effect Sensor for Detecting Speed Through Water

· Advanced Digital Signal Processing for Accurate Speed Indication Down to 1 Knot

· Total Cumulative Distance (distance traveled through the water since installation)

· Cumulative Voyage Distance (distance traveled through the water since last reset)

· Precision Thermistor for Detecting Water Temperature

· Calibration for Compensating Transducer Offset to Waterline or Keel

· Calibration for Compensating Temperature Offset

· Calibration for Compensating Speed Through Water

· Waterproof Enclosure and Cable System

1.3 Quick Install

Installing the Maretron DST110 transducer involves the following five steps. Please refer to the individual sections for additional details.

1. Unpack the Box (Section 2.1)

2. Choose a Mounting Location (Section 2.6)

3. Mount the DST110 Transducer (Section 2.7)

4. Connect the DST110 Transducer (Section 2.8)

5. Calibrate the DST110 Transducer for Waterline or Keel Offset (Section 3.2)

6. (Optional) Calibrate the DST110 Transducer for Temperature Offset (Section 3.3)

7. (Optional) Calibrate the DST110 Transducer Speed Multiplier (Section 3.4)

2 Installation

2.1 Unpacking the Box

When unpacking the box containing the Maretron DST110, you should find the following items.

· 1 – DST110 Insert (with attached cable)

· 1 – Plastic Housing

· 1 – Plastic Hull Nut

· 1 – Rubber Bushing

· 1 – Safety Wire

· 1 – Blanking Plug

· 1 – Tube of Silicone Lubricant

· 1 – Instructions and O-ring for Non-Valve Housings

· 1 – DST110 User’s Manual

· 1 – Warranty Registration Card

If any of these items are missing or damaged, please contact Maretron.

2.2 Housing Material

The DST110 is supplied with a plastic housing that is suitable for most installations. As an option, Maretron offers both a bronze housing material. Please follow these recommendations for determining the right material for your particular installation.

- Plastic housing recommended for fiberglass or metal hulls only. Never install a plastic housing in a wood hull since swelling of the wood may overstress the plastic causing a fracture.

- Bronze housing recommended for fiberglass or wood hulls. Never mount a bronze housing in an aluminum hull because electrolytic corrosion will occur.

- Never install a metal housing in a vessel with a positive ground system.

2.3 Tools and Materials

· Water-based antifouling paint (mandatory in salt water)

· Safety goggles

· Dust mask

· Electric drill with 10 mm (3/8”) or larger chuck capacity

· Drill bit: 3 mm or 1/8”

· Hole saw: 51 mm or 2” (plastic or bronze housing)

· Countersink tool (for installing a flush housing)

· Sandpaper

· Mild household detergent or weak solvent (such as alcohol)

· File (for installation in a metal hull)

· Marine sealant

· Additional washer [for aluminum hull less than 6 mm (1/4”) thick]

· Slip-joint pliers (for installing a bronze housing)

· Zip-ties

· Installation in a cored fiberglass hull (see Section 2.7.2):

o Hole saw for hull interior: 60 mm or 2-3/8”

o Fiberglass cloth and resin

o or Cylinder, wax, tape, and casting epoxy.

2.4 Pretest

Connect the DST110 to the NMEA 2000® network and spin the paddlewheel. Check for a speed reading and the approximate air temperature. If there is no reading or it is inaccurate, return the instrument to the place of purchase.

2.5 Antifouling Paint

Marine growth can accumulate rapidly on the transducer’s surface reducing performance within weeks. Surfaces exposed to salt water must be coated with antifouling paint. Use water-based antifouling paint only. Never use ketone-based paint, since ketones can attack many plastics possibly damaging the sensor.

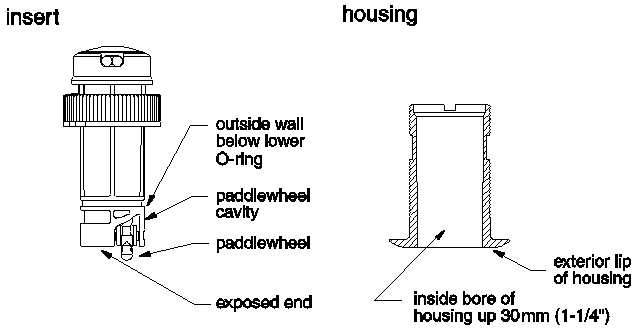

It is easier to apply antifouling paint before installation, but allow sufficient drying time. Reapply paint every 6 months or at the beginning of each boating season. Paint the following surfaces (see Figure 1):

· Outside wall of the insert below the lower O-ring

- Exposed end of the insert

- Paddlewheel cavity

- Paddlewheel

- Exterior lip of the housing

- Bore of the housing up 30 mm (1-1/4”)

- Blanking plug below the lower O-ring including the exposed end

Figure 1 – Antifouling Paint Application

2.6 Choosing a Mounting Location

The selection of a suitable mounting location is important for the optimal performance of the Maretron DST110. The mounting location and orientation of the DST110 should be:

1. Preferably on the starboard side of the hull —where propeller blades are moving downward through the water.

2. Continuously Immersed In Water

3. Where Water Flowing across the Hull is Smooth with a Minimum of Bubbles and Turbulence – especially at high speeds.

4. Where the Transducer Beam is Unobstructed by the Keel or Propeller Shaft(s)

5. Where there is a Minimum Deadrise Angle

6. Accessible from Inside the Vessel – with adequate headroom for the height of the housing, tightening the nuts, and removing the insert. Allow a minimum of 280 mm (11”).

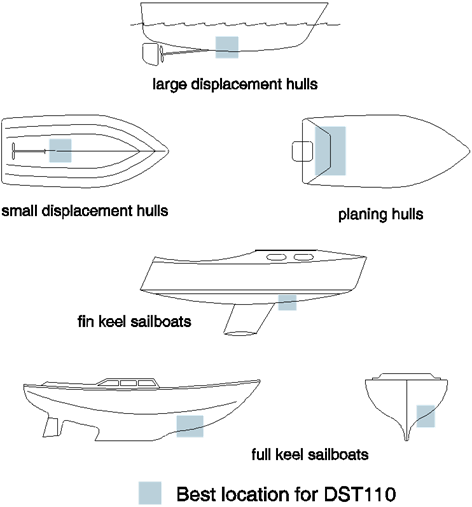

Please follow the following guidelines for different hull types (see Figure 2):

- Displacement Hull Powerboats – Locate amidships near the centerline.

- Planing Hull Powerboats – Mount well aft, on or near the centerline, and well inboard of the first set of lifting strakes to ensure that the DST110 is in contact with the water at high speeds.

- Outboard and I/O – Mount just forward of the engine(s).

- Inboard – Mount well ahead of the propeller(s) and shaft(s).

- Step-hull – Mount just ahead of the first step.

- Boat capable of speeds above 25 knots (29 MPH) – Review the installation location and operating results of similar boats before proceeding.

- Fin Keel Sailboats – Mount on or as close as possible to the centerline and forward of the fin keel 300 to 600 mm (1 to 2’).

- Full Keel Sailboats – Locate amidships and away from the keel at the point of minimum deadrise.

Caution: Do not mount the DST110 in an area of turbulence or bubbles: near water intake or discharge openings; behind strakes, fittings, or hull irregularities.

Figure 2 – Mounting Locations

2.7 Mounting the DST110

The Maretron DST110 is mounted through the hull. If the hull is a cored fiberglass hull, please follow the instructions in Section 2.7.2. For other hull types, please follow the instructions in Section 2.7.1.

2.7.1 All Hull Types Except Cored Fiberglass

2.7.1.1 Hole Drilling

Warning: Always wear safety goggles and a dust mask.

- Drill a 3 mm or 1/8” pilot hole from inside the hull. If there is a rib, strut, or other hull irregularity near the selected mounting location, drill from the outside.

- Using the 51 mm or 2” hole saw, cut a hole from outside

the hull.

Flush housing – Use a countersink tool to make a “seat” in the hull. - Sand and clean the area around

the hole, inside and outside, to ensure that the sealant will adhere

properly to the hull. If there is any petroleum inside the hull, remove

it with either mile household detergent or a weak solvent (alcohol) before

sanding.

Metal hull – Remove all burrs with a file and sandpaper.

2.7.1.2 Bedding

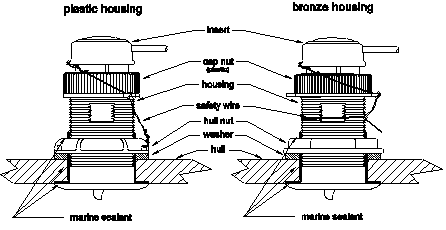

Apply a 2 mm (1/16”) thick layer of marine sealant around the lip of the housing that contacts the hull and up the sidewall of the housing. The sealant must extend 6 mm (1/4”) higher than the combined thickness of the hull, washer(s), and hull nut (see Figure 3). This will ensure there is sealant in the threads to seal the hull and hold the hull nut securely in place.

Figure 3 – Bedding and Installation

2.7.1.3 Installation

Caution: Never pull, carry, or hold the DST110 by the cable as this may damage internal connections.

- From outside the hull, push the housing into the mounting hole using a twisting motion to squeeze out excess sealant (see Figure 3). Align the arrow on the lip of housing to point forward toward the bow. If the DST110 is not installed on the centerline, angle the housing slightly toward the centerline to align it with the water flow.

- From inside the hull, slide the washer onto the housing.

Aluminum hull less than 6 mm (1/4”) thick – Use an additional rubbery, fiberglass, or plastic washer. Never use bronze since electrolytic corrosion will occur. Never use wood since it will swell, possible fracturing the plastic housing. - Screw the hull nut in place.

Wood hull – Allow the wood to swell before tightening the hull nut securely.

Plastic housing – Do not clamp tightly on the wrenching flats, possibly causing the housing to fracture.

Plastic hull nut – Hand-tighten only. Do not over tighten.

Metal hull nut-- Tighten with slip-joint pliers.

- Remove any excess sealant on the outside of the hull to

ensure smooth water flow over the DST110.

Warning: The O-rings must be intact and well lubricated to make a watertight seal. - After the sealant cures, inspect the O-rings on the insert (replace if necessary) and lubricate them with the silicone lubricant supplied.

- Slide the insert into the housing with the arrow on the

top pointing forward toward the bow. Screw the cap nut several turns

until there is resistance. The arrow on the top of the insert, the cable

exit, and the arrow on the lip will all be aligned. Continue to tighten

the cap nut. Be careful not to rotate the housing and disturb the

sealant. Hand tighten only. Do not over tighten.

Warning: Always attach the safety wire to prevent the insert from backing out in the unlikely event that the cap nut fails or is screwed on incorrectly.

- Attach the safety wire.

Plastic housing – Attach the safety wire to one eye in the hull nut. Load the wire in a counterclockwise direction and thread it through one eye in the cap nut. Thread the wire through the eye a second time. Then, lead the wire through the eye in the insert. Twist the wire securely to itself.

Metal housing—Wrap one end

of the safety wire tightly around the housing

and twist it together with the long end. Lead the wire straight up and

through one eye in the cap nut. Thread the wire through the eye a second

time. Then lead the wire counterclockwise and through the eye in the

insert. Twist the wire securely to itself.

This is an important safety step, since attaching the safety wire to a

metal housing is different than attaching it to a plastic housing.

- Route the cable to the network being careful not to

tear the cable jacket when passing it through the bulkhead(s) and other

parts of the boat. Coil any excess cable and secure

it in place with zip-ties to prevent damage.

2.7.1.4 Checking for Leaks

Warning: Never install a thru-hull transducer and leave the boat in the water unchecked for several days.

When the boat is placed in the water, immediately check around the thru-hull transducer for leaks. Note that very small leaks may not be readily observed. It is best not to leave the boat in the water for more than 3 hours before checking it again. If there is a small leak, there may be considerable bilge water accumulation after 24 hours. If a leak is observed, repeat “Bedding” and “Installing” immediately (see Sections 2.7.1.2 and 2.7.1.3).

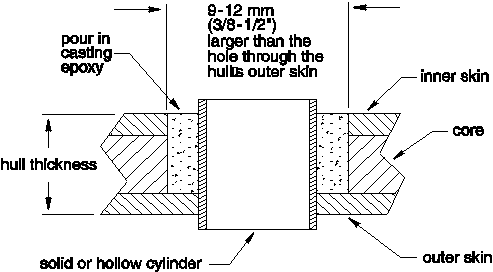

2.7.2 Installation in a Cored Fiberglass Hull

The core (wood or foam) must be cut and sealed carefully. The core must be protected from water seepage, and the hull must be reinforced to prevent it from crushing under the hull not allowing the housing to become loose.

Warning: always wear safety goggles and a dust mask.

Drill a 3 mm or 1/8” pilot

hole from inside the hull. If there is a rib, strut, or other hull irregularity

near the selected mounting location, drill from the outside. (If the hole is

drilled in the wrong location, drill a second hole in a better location. Apply

masking tape to the outside of the hull over the incorrect hole and fill it

with epoxy.)

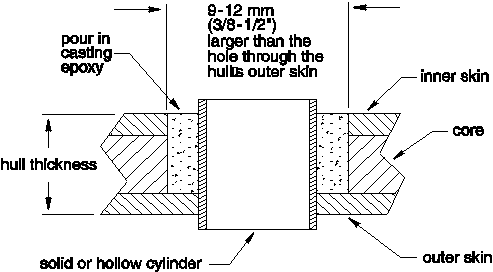

- Figure 5).

Figure 4 – Preparing a Cored Fiberglass Hull

- From inside the hull, use a 60 mm or 2-3/8” hole saw to cut through the inner skin and most of the core. The core material can be very soft. Apply only light pressure to the hole saw after cutting through the inner skin to avoid accidentally cutting the outer skin.

- Remove the plug of core material so the inside of

the outer skin and the inner core of the hull are fully exposed. Sand and

clean the inner skin, core, and the outer skin around the hole.

Caution: Completely seal the hull to prevent water seepage into the core. - If you are skilled with fiberglass, saturate a layer of

fiberglass cloth with a suitable resin and lay it inside the hole to seal

and strengthen the core. Add layers until the hole is the correct

diameter.

Alternatively, a hollow or solid cylinder of the correct diameter can be coated with wax and taped in place. Fill the gap between the cylinder and hull with casting epoxy. After the epoxy has set, remove the cylinder. - Sand and clean the area around the hole, inside and outside, to ensure that the sealant will adhere properly to the hull. If there is any petroleum residue inside the hull, remove it with either mild household detergent or a weak solvent (alcohol) before sanding.

- Proceed with “Bedding” and “Installing” (see Sections 2.7.1.2 and 2.7.1.3).

Figure 5 – Preparing a Cored Fiberglass Hull

2.8 Connecting the DST110

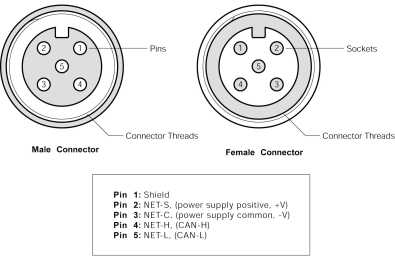

The Maretron DST110 provides a connection to an NMEA 2000® interface through a five pin male connector located on the end of the cable attached to the DST110 (see Figure 6). You connect the DST110 to an NMEA 2000® network by plugging the male connector into a female receptacle of the NMEA 2000® network (note the key on the male connector and keyway on the female connector). Be sure the cable is connected securely and that the collar on the cable connector is tightened firmly. The DST110 is designed such that you can plug or unplug it from an NMEA 2000® network while the power to the network is connected or disconnected. Please follow recommended practices for installing NMEA 2000® network products.

Figure 6 – NMEA 2000® Connector Face Views

2.8.1 Checking Connections

Once the NMEA 2000® connection to the Maretron DST110 have been completed, check to see that speed, depth, and temperature information is being properly transmitted by observing an appropriate display. Refer to Section 5, “Troubleshooting”, if no heading information appears, otherwise proceed to Section 3 entitled “Configuring the DST110”.

3 Configuring the DST110

Several parameters of the DST110 are user-programmable. You configure the DST110 using Maretron N2KAnalyzer® software or a Maretron DSM150/DSM250 display or other NMEA 2000® display unit that is capable of configuring the DST110. Please refer to the Maretron N2KAnalyzer User’s Manual, DSM150 User’s Manual, or DSM250 User’s Manual, as appropriate, for details. users with direct access to the NMEA 2000® interface can perform transducer offset calibration directly through the NMEA 2000® interface (see Appendix A).

3.1 Advanced Configuration

3.1.1 Device Instance

NMEA 2000® provides a unique device instance for each class of device on a vessel. This value should be programmed in each DST110 so that each DST110 is associated with a unique device instance number. The default instance number is 0, which is used to indicate the first DST110 that is connected to the network. Other DST110’s or devices transmitting similar information would be numbered 1, 2, and so on. The device instance number is used for parameters sent via the PGN 128267 Water Depth, PGN 128259 Speed, PGN130310 Environmental Parameters, and PGN 128275 Distance Log messages.

3.1.2 Instance Temperature

The temperature instance is used to distinguish this DST110 from other devices on the network transmitting the same data. The Temperature Instance is used for parameters send via the PGN 130311 Environmental Parameters and PGN 130312 Temperature messages.

3.1.3 Installation Description

You can configure the two installation description parameters with any text you wish. Examples include date of installation, location, etc. NMEA 2000 diagnostic tools such as Maretron N2KAnalyzer® can display this information.

3.1.4 NMEA2000 PGN Enable/Disable

The DST110 is capable of transmitting many different kinds of NMEA 2000® messages (or PGNs) associated with depth, speed, and temperature. You may individually enable or disable each of these messages.

3.2 Transducer Depth Offset Calibration

The DST110 measures the depth of the water from the transducer, which may or may not be the waterline depth or the depth of water underneath the keel depending on the mounting location. Fortunately, the DST110 can be calibrated for reporting the offset from the transducer to the waterline or the DST110 can be calibrated to report the offset between the transducer and the lowest point on the vessel. Depth display readings then report either the waterline depth or the depth under keel depending on your preference.

3.3 Temperature Offset Calibration

The Maretron DST110 may be programmed with an offset value which is added to the water temperature measured by the DST110 before the value is transmitted over the NMEA 2000® network.

3.4 Speed Multiplier Calibration

While the Maretron DST110 as shipped from the factory accurately represents the speed of water traveling past the paddlewheel sensor, the speed of water past the sensor might not be the same as the speed of the vessel, due to hull shape or how or where the DST110 is mounted. The DST110 can be programmed with a multiplier by which the internally calculated speed through water is multiplied before the speed through water value is transmitted over the NMEA 2000® network. In this way, the DST110 can be programmed such that its transmitted speed through water can more closely match the speed of the vessel.

3.5 Zeroing the Cumulative Voyage Distance (Log)

The Maretron DST110 automatically logs two different cumulative distances; 1) total cumulative distance since installation, and 2) cumulative voyage distance since reset. You cannot zero out the total cumulative distance since installation but you are able to zero out the cumulative voyage distance since reset.

4 Maintenance

4.1 Using the Blanking Plug

To protect the paddlewheel, use the blanking plug when the boat will be kept in salt water for more than a week, or when the boat is removed from the water, or aquatic growth build-up on the paddlewheel is suspected due to inaccurate readings from the instrument.

Warning: The O-rings must be intact and well lubricated to make a watertight seal.

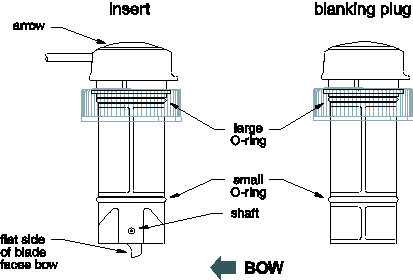

- Inspect the O-rings on the blanking plug (replace if necessary) and lubricate them with the silicone lubricant supplied or petroleum jelly (Vaseline®) (see Figure 7).

- Remove the insert from the housing by removing the safety wire. Loosen the cap nut.

- With the blanking plug ready in one and, pull the insert most of the way out. Remove the insert and rapidly replace it with the blanking plug. With practice, only 250 ml (10 oz.) of water will enter the boat.

- Screw the cap nut several turns until there is resistance.

Continue to tighten the cap nut. Hand-tighten only. Do not

over tighten.

Warning: Always attach the safety wire to prevent the insert from backing out in the unlikely event that the cap nut fails or is screwed on incorrectly. - Reattach the safety wire.

- Winterizing

After the boat has been hauled for winter storage, remove the blanking

plug/insert to let the water drain away before re-inserting it. This

will prevent any water from freezing around the blanking plug/insert and

possibly cracking it.

Figure 7 – Replacing the Paddlewheel and O-rings

4.2 Servicing the Insert

Aquatic growth can accumulate rapidly on the depth transducer’s surface and impede or freeze the paddlewheel’s rotation, reducing performance within weeks. Clean the insert with a soft cloth and mild household detergent. If the fouling is severe, remove the paddlewheel with needle-nose pliers. Use a stiff brush or putty knife to remove the growth taking care to avoid scratching the depth transducer. Lightly wet sand with fine grade wet/dry paper.

The water lubricated paddlewheel bearings have a life of up to 5 years on low-speed boats [less than 10 knots (11 MPH)] and 1 year on high-speed vessels. Paddlewheels can fracture and shafts can bend due to impact with water borne objects and mishandling in boat yards. O-rings must be free of abrasions and cuts to ensure a watertight seal. A replacement Paddlewheel Kit (33-398-04) is available.

- Remove the old paddlewheel shaft with needle-nose pliers (see Figure 7).

- Place the new paddlewheel in the cavity with the flat side of the blade facing the same direction as the arrow on the top of the insert.

- Tap the new shaft into place until the end is flush with the outside wall of the insert.

- Install a large O-ring near the top of the insert. Install a small O-ring near the paddlewheel.

- Place the remaining two O-rings in similar positions on the blanking plug.

4.3 Replacement Parts

Lost, broken, and worn parts should be replaced immediately. If you have purchased a plastic housing and have a wood hull or desire greater strength, purchase a Maretron metal housing. Obtain the following parts from your marine dealer or directly from Maretron.

|

Housing, Nut & Washer |

Paddlewheel, Shaft & O-rings |

|

M33-100 (Bronze)

|

33-398-04PW |

4.4 Connection Checking

Periodically check the security of the cables connected to the NMEA 2000® interface and tighten if necessary.

4.5 Antifouling Paint

Reapply antifouling paint every six months or at the beginning of each boating season (see Section 2.5).

5 Troubleshooting

If you notice unexpected operation of the Maretron DST110, follow the troubleshooting procedures in this section to remedy simple problems.

|

Symptom |

Troubleshooting Procedure |

|

No speed, depth, and temperature output |

Check the connections to the NMEA 2000® connector and tighten if necessary

Ensure that power is supplied to the connected NMEA 2000® cable |

|

No speed output |

Check the DST110 paddlewheel for breakage or fouling |

|

No depth output |

Check the DST110 depth transducer for fouling |

Figure 8 – Troubleshooting Guide

If these steps do not solve your problem, please contact Maretron Technical Support (refer to Section 7 for contact information).

6 Technical Specifications

Specifications

|

Parameter |

Value |

Comment |

|

Depth Operating Frequency |

235 kHz |

Wide Beam Angle |

|

Beam Width |

10° x 44° |

-3dB |

|

Transmission Power |

100 W |

2% Duty Cycle |

|

Minimum Depth |

0.6 m |

Deadrise Angle Tolerant |

|

Maximum Depth |

100 m |

No Calibration Required |

|

Depth Accuracy |

±20cm |

0.6 – 7 meters |

|

±3% |

7 – 100 meters |

|

|

Depth Tracking Speeds |

Up to 50 knots |

High Speed Bottom Tracking Capability |

|

Depth Update Rate |

1 second |

|

|

Speed Sensor |

Paddlewheel |

No Calibration Required |

|

Speed Range |

1 – 50 knots |

Microprocessor Signal Processing Accuracy |

|

Speed Update Rate |

1 second |

|

|

Water Temperature Range |

-10°C to 40°C |

Fast Response Time |

|

Water Temperature Accuracy |

±1.0°C |

No Calibration Required |

|

Water Temperature Resolution |

0.01°C |

|

|

Deadrise Angle |

?22° |

|

Certifications

|

Parameter |

Comment |

|

NMEA 2000® Standard |

Level B+ |

|

Maritime Navigation and Radiocommunication Equipment & Systems |

IEC 61162-3 |

|

Maritime Navigation and Radiocommunication Equipment & Systems |

IEC 60945 |

|

FCC and CE Mark |

Electromagnetic Compatibility |

NMEA 2000 Parameter Group Numbers (PGNs) - See Appendix B for Details

|

Description |

PGN # |

PGN Name |

Default Rate |

|

Periodic Data PGNs |

128267 |

Water Depth |

1 Time/Second |

|

128259 |

Speed (Water Referenced) |

1 Time/Second |

|

|

130310 |

Environmental Parameters (Water Temperature) |

2 Times/Second |

|

|

130311 |

Environmental Parameters (Water Temperature) |

2 Times/Second (Disabled) |

|

|

130312 |

Temperature |

0.5 Times/Second (Disabled) |

|

|

128275 |

Distance Log |

1 Time/Second |

|

|

Response to Requested PGNs |

126464 |

PGN List (Transmit and Receive) |

N/A |

|

126996 |

Product Information |

N/A |

|

|

126998 |

Configuration Information |

N/A |

|

|

Protocol PGNs |

059392 |

ISO Acknowledge |

N/A |

|

059904 |

ISO Request |

N/A |

|

|

060928 |

ISO Address Claim |

N/A |

|

|

065240 |

ISO Address Command |

N/A |

|

|

126208 |

NMEA Request/Command/Acknowledge |

N/A |

Electrical

|

Parameter |

Value |

Comment |

|

Operating Voltage |

9 to 16 Volts |

DC Voltage |

|

Power Consumption |

<200mA |

Average Current Drain |

|

Load Equivalence Number (LEN) |

4 |

NMEA 2000® Spec. (1LEN = 50 mA) |

|

Reverse Battery Protection |

Yes |

Indefinitely |

Mechanical

|

Parameter |

Value |

Comment |

|

Size |

2.94” Dia. X 4.91” Tall (74.7mm Dia. X 125 mm Tall) |

Including Mounting Flanges |

|

Weight |

12 Oz. (340 g) |

|

|

Mounting |

Lexan/Bronze |

Bronze Optional |

|

Hole Diameter for Mounting |

2” (51 mm) |

|

Environmental

|

Parameter |

Value |

|

IEC 60945 Classification |

Submerged |

|

Degree of Protection |

IP68 |

|

Operating Temperature |

-10°C to 40°C |

|

Storage Temperature |

-30°C to 70°C |

|

Vibration |

2-13.2Hz @ ±1mm, 13.2-100Hz @ 7m/s2 per IEC 60945-8.7 |

|

Water Immersion |

per IEC 60945-8.9 |

|

Corrosion (Salt Mist) |

4 times 7days @ 40°C, 95%RH after 2 hour Salt Spray Per IEC 60945-8.12 |

|

Electromagnetic Emission |

Conducted and Radiated Emission per IEC 60945-9 |

|

Electromagnetic Immunity |

Conducted, Radiated, Supply, and ESD per IEC 60945-10 |

7 Technical Support

If you require technical support for Maretron products, you can reach us in one of the following ways:

Telephone: 1-866-550-9100

Fax: 1-602-861-1777

E-mail: [email protected]

World Wide Web: http://www.maretron.com

Mail: Maretron,

LLP

Attn:

Technical Support

9014 N.

23rd Ave Suite 10

Phoenix,

AZ 85021 USA

8 Maretron (2 Year) Limited Warranty

Maretron warrants the DST110 to be free from defects in materials and workmanship for two (2) years from the date of original purchase. If within the applicable period any such products shall be proved to Maretron’s satisfaction to fail to meet the above limited warranty, such products shall be repaired or replaced at Maretron’s option. Purchaser's exclusive remedy and Maretron’s sole obligation hereunder, provided product is returned pursuant to the return requirements below, shall be limited to the repair or replacement, at Maretron’s option, of any product not meeting the above limited warranty and which is returned to Maretron; or if Maretron is unable to deliver a replacement that is free from defects in materials or workmanship, Purchaser’s payment for such product will be refunded. Maretron assumes no liability whatsoever for expenses of removing any defective product or part or for installing the repaired product or part or a replacement therefore or for any loss or damage to equipment in connection with which Maretron’s products or parts shall be used. With respect to products not manufactured by Maretron, Maretron’s warranty obligation shall in all respects conform to and be limited to the warranty actually extended to Maretron by its supplier. The foregoing warranties shall not apply with respect to products subjected to negligence, misuse, misapplication, accident, damages by circumstances beyond Maretron’s control, to improper installation, operation, maintenance, or storage, or to other than normal use or service.

Snap-in paddlewheel carriers, paddlewheels, paddlewheel bearings, and paddle shafts are consumable items, and are specifically excluded from this warranty.

THE FOREGOING WARRANTIES ARE EXPRESSLY IN LIEU OF AND EXCLUDES ALL OTHER EXPRESS OR IMPLIED WARRANTIES, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND OF FITNESS FOR A PARTICULAR PURPOSE.

Statements made by any person, including representatives of Maretron, which are inconsistent or in conflict with the terms of this Limited Warranty, shall not be binding upon Maretron unless reduced to writing and approved by an officer of Maretron.

IN NO CASE WILL MARETRON BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES, DAMAGES FOR LOSS OF USE, LOSS OF ANTICIPATED PROFITS OR SAVINGS, OR ANY OTHER LOSS INCURRED BECAUSE OF INTERRUPTION OF SERVICE. IN NO EVENT SHALL MARETRON’S AGGREGATE LIABILITY EXCEED THE PURCHASE PRICE OF THE PRODUCT(S) INVOLVED. MARETRON SHALL NOT BE SUBJECT TO ANY OTHER OBLIGATIONS OR LIABILITIES, WHETHER ARISING OUT OF BREACH OF CONTRACT OR WARRANTY, TORT (INCLUDING NEGLIGENCE), OR OTHER THEORIES OF LAW WITH RESPECT TO PRODUCTS SOLD OR SERVICES RENDERED BY MARETRON, OR ANY UNDERTAKINGS, ACTS OR OMISSIONS RELATING THERETO.

Maretron does not warrant that the functions contained in any software programs or products will meet purchaser’s requirements or that the operation of the software programs or products will be uninterrupted or error free. Purchaser assumes responsibility for the selection of the software programs or products to achieve the intended results, and for the installation, use and results obtained from said programs or products. No specifications, samples, descriptions, or illustrations provided Maretron to Purchaser, whether directly, in trade literature, brochures or other documentation shall be construed as warranties of any kind, and any failure to conform with such specifications, samples, descriptions, or illustrations shall not constitute any breach of Maretron’s limited warranty.

Warranty Return Procedure:

To apply for warranty claims, contact Maretron or one of its dealers to describe the problem and determine the appropriate course of action. If a return is necessary, place the product in its original packaging together with proof of purchase and send to an Authorized Maretron Service Location. You are responsible for all shipping and insurance charges. Maretron will return the replaced or repaired product with all shipping and handling prepaid except for requests requiring expedited shipping (i.e. overnight shipments). Failure to follow this warranty return procedure could result in the product’s warranty becoming null and void.

Maretron reserves the right to modify or replace, at its sole discretion, without prior notification, the warranty listed above. To obtain a copy of the then current warranty policy, please go to the following web page: