1 General

1.1 Introduction

Congratulations on your purchase of the Maretron DSM410 NMEA 2000® 4.1” High Bright Graphic Display. Maretron has designed and built your display to the highest standards for years of dependable and accurate service.

Maretron’s DSM410 is a high-resolution color display that allows easy interpretation of NMEA 2000® instrument and navigation data through custom display configurations, with an easy-to-use five-key illuminated keypad.

The Maretron DSM410 is designed to operate within the harsh demands of the marine environment. However, no piece of marine electronic equipment can function properly unless installed, configured, and maintained in the correct manner. Please read carefully and follow these instructions for installation, configuration, and usage of the Maretron DSM410 in order to ensure optimal performance.

1.2 Firmware Revision

This manual corresponds to DSM410 firmware revision 1.7.2.

1.3 DSM410 Features

The Maretron DSM410 has the following features.

· NMEA 2000® Interface

· Waterproof NMEA 2000® Connector

· Sealed Waterproof Enclosure

· Powered Directly from NMEA 2000® Network

· Flush Mounting

· Backlit Capacitive Touch Keys

· Visual and Audible Alarms

· 16 User Configurable Favorite Screens (Automatic or Manual Scrolling between Screens)

· Capable of Viewing Virtually all NMEA 2000® Information including Batteries, Engines, Generators, Shore Power, Tanks, Navigation, Weather and More

1.4 Quick Install

Installing the Maretron DSM410 display involves the following four steps. Please refer to the individual sections for additional details.

· Unpack the Box (Section 2.1)

· Choose a Mounting Location (Section 2.2)

· Mount the DSM410 (Section 2.3)

· Connect the DSM410 (Section 2.4)

2 Installation

2.1 Unpacking the Box

When unpacking the box containing the Maretron DSM410, you should find the following items:

· 1 – DSM410 NMEA 2000® Multi-function Graphic Display

· 1 – DSM410 Bezel

· 4 – Mounting Screws

· 1 – DSM410 User’s Manual USB Flash Drive

· 1 – Warranty Registration Card

If any of these items are missing or damaged, please contact Maretron.

2.2 Choosing a Mounting Location

The DSM410 is housed in a waterproof enclosure (IEC IP67 rating – protected against the effects of temporary immersion in water) and can be mounted in either an outdoor location or an indoor location.

2.3 Mounting the DSM410

The DSM410 can be flush mounted. Maretron suggests a location at which the display can be viewed from a relatively straight angle, and at which the keys are easily touched.

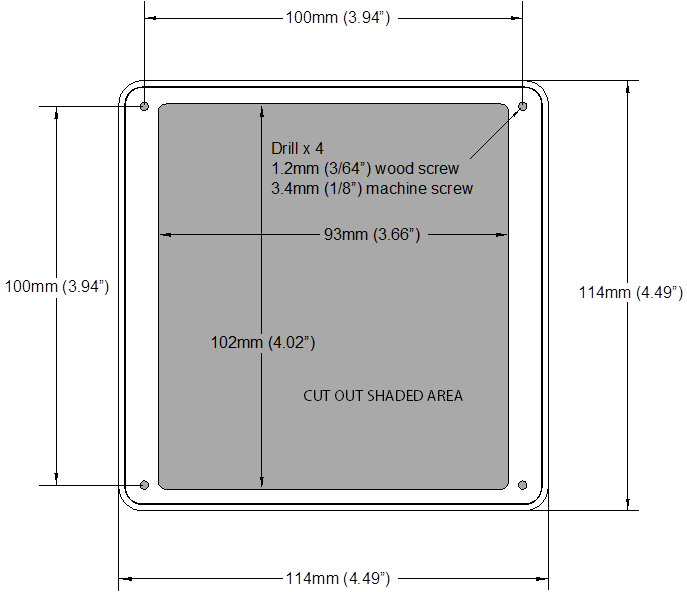

2.3.1 Flush Mounting the DSM410

The DSM410 can be directly mounted to any suitable surface. You may choose to secure the DSM410 to the mounting surface with the included wood screws or machine screws, or you may use silicone or a similar adhesive if you do not have easy access to the rear side of the mounting surface. The steps for this type of mounting are as follows:

1. Attach the Mounting Template (see Section 13) to the surface where the DSM410 is to be located.

a. Make sure the template is level by using one of the horizontal lines as a guide.

b. Scotch tape works well for securing the template.

2. If securing with machine screws, drill the four mounting holes all the way through the mounting surface at the locations indicated on the Mounting Template.

a. Use a 4.3mm or 0.17” drill bit.

3. Cut a hole for the body of the display.

4. Remove the template from the mounting surface.

5. Place the DSM410 on the mounting surface, with the body of the DSM410 inserted into the large hole. If mounting with silicone adhesive, apply the adhesive to the portion of the DSM410 that will come into contact with the mounting surface once installed.

6. If mounting with machine screws, insert the screws into the front of the DSM410 and tighten to nuts on the back side of the mounting surface.

a. Use M3 machine screws.

b. Don’t over tighten the screws.

7. Snap the bezel over the DSM410. Please pay attention to the orientation of the bezel. The top and bottom edges of the bezel and the DSM410 have one snap fitting, while the left and right edges have two snap fittings.

2.4 Connecting the DSM410

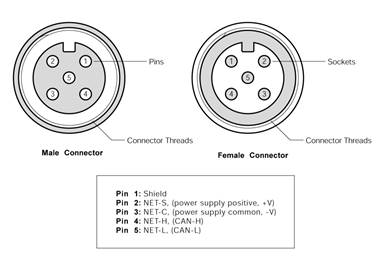

The Maretron DSM410 provides a connection to an NMEA 2000® interface through a standard Micro NMEA 2000® connector that can be found on the back of the unit. The NMEA 2000® connector is a five-pin male connector (see Figure 1). You connect the DSM410 to an NMEA 2000® network using a Maretron NMEA 2000® cable (or compatible cable) by connecting the female end of the NMEA 2000® network cable to the male connector on the DSM410 (note the key on the male connector and keyway on the female connector). Be sure the cable is connected securely and that the collar on the cable connector is tightened firmly. Connect the other end of the cable (male) to the NMEA 2000® network in the same manner. The DSM410 is designed such that you can plug or unplug it from an NMEA 2000® network while the power to the network is connected or disconnected. Please follow recommended practices for installing NMEA 2000® network products.

Figure 1 – NMEA 2000® Connector Face View

2.4.1 Checking the Connection

Once the NMEA 2000® connection to the Maretron DSM410 has been completed, observe the display to check to see that information is being properly received. One way to verify connectivity is to enter the device selection menu, which is described in Section 5.2.3.2. Refer to Section 10, “Troubleshooting”, if no information appears.

3 Operating the DSM410

3.1 Turning the DSM410 On

To turn on the DSM410, press the power key (the leftmost of

the five keys on the keypad). The DSM410 will display a warning and ask you to

press the Accept key (![]() ) to acknowledge the warning and

continue operation of the DSM410 (see Figure 2 below).

) to acknowledge the warning and

continue operation of the DSM410 (see Figure 2 below).

Figure 2 – DSM410 Power Up Screen

Alternatively, you may power down the DSM410 by pressing and holding the power key (see Section 3.2 below for details).

3.2 Turning the DSM410 Off

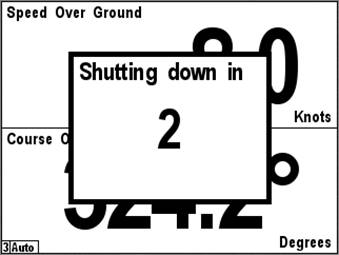

To turn the DSM410 off, press and hold the power key. The DSM410 will display a countdown screen, which can be seen in Figure 3. If you continue to hold the power key, the DSM410 will power down in approximately three seconds. If you release the power key before these three seconds have elapsed, the DSM410 will return to its current operational state.

Figure 3 – Powerdown Countdown Screen

3.3 Keypad Essentials

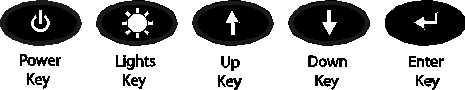

The DSM410 has a five-key keypad located below the screen. Each key has slightly different functions depending on the operating mode. Figure 4 below shows the DSM410 keys and their names.

Figure 4 – Keypad and Key Names

In the normal viewing mode where your favorite screens are displayed, the keys on the DSM250 keypad have the following functions:

Power Key (![]() ) – turns the DSM250 off (see

section 3.1 on page 4 for details). A momentary press of this key can also be

used to accept or cancel an Alert (see section 8.2.1 on page 234

for details).

) – turns the DSM250 off (see

section 3.1 on page 4 for details). A momentary press of this key can also be

used to accept or cancel an Alert (see section 8.2.1 on page 234

for details).

Lights Key (![]() ) – a quick press cycles the

backlight brightness between three programmed brightness levels (see Section 5.2.4.3 on page 32 for details), while a long press cycles the DSM250 through 8

programmable color palettes (see Section 5.2.4.4 on Page 32).

) – a quick press cycles the

backlight brightness between three programmed brightness levels (see Section 5.2.4.3 on page 32 for details), while a long press cycles the DSM250 through 8

programmable color palettes (see Section 5.2.4.4 on Page 32).

Up Key (![]() ) – switches the display from

the current favorite screen to the next highest numbered favorite screen that

is enabled for that particular mode.

) – switches the display from

the current favorite screen to the next highest numbered favorite screen that

is enabled for that particular mode.

Down Key (![]() ) – switches the display from

the current favorites screen to the next lowest numbered favorite screen that

is enabled for that particular mode

) – switches the display from

the current favorites screen to the next lowest numbered favorite screen that

is enabled for that particular mode

Enter Key (![]() ) – changes from favorite

screens mode to menu mode

) – changes from favorite

screens mode to menu mode

In menu mode, a legend appears along the bottom of the screen displaying the function of each of the keys. The functions differ slightly depending on whether a menu is being accessed, a selection is being made from a list of possible data values, or a numeric value is being increased or decreased.

3.3.1 Navigating in a Menu

When accessing a menu, the keys on the DSM410 keypad have the following functions:

Power Key (![]() ) – turns the DSM410

off (see Section 3.1 on page 4 for details).

) – turns the DSM410

off (see Section 3.1 on page 4 for details).

Back Key (![]() ) – returns to the next

higher-level menu. If already at the top-level menu, exits menu mode returns to

favorite screens mode. Menu levels are indicated with indentation of the text

within the menus.

) – returns to the next

higher-level menu. If already at the top-level menu, exits menu mode returns to

favorite screens mode. Menu levels are indicated with indentation of the text

within the menus.

Scroll Up Key (![]() ) – changes the currently

selected (or highlighted) menu item from the presently selected one to the one immediately

above it. If the top menu item is already selected, the selection wraps to the

bottom menu item.

) – changes the currently

selected (or highlighted) menu item from the presently selected one to the one immediately

above it. If the top menu item is already selected, the selection wraps to the

bottom menu item.

Scroll Down Key (![]() ) – changes the currently

selected (or highlighted) menu item from the presently selected one to the one

immediately below it. If the bottom menu item is already selected, the

selection wraps to the top menu item.

) – changes the currently

selected (or highlighted) menu item from the presently selected one to the one

immediately below it. If the bottom menu item is already selected, the

selection wraps to the top menu item.

Enter Key (![]() ) – if the currently selected

menu item has a submenu, opens that submenu. If the currently selected menu

item has an editable value (indicated by a colon (:) followed by the data

value, moves the selection to the editable value and changes the keys to edit

mode.

) – if the currently selected

menu item has a submenu, opens that submenu. If the currently selected menu

item has an editable value (indicated by a colon (:) followed by the data

value, moves the selection to the editable value and changes the keys to edit

mode.

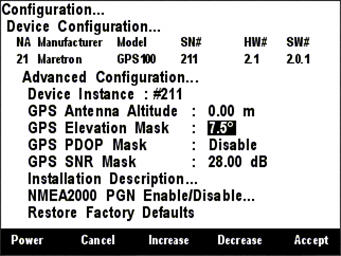

3.3.2 Choosing a Value from a List

When editing a value chosen from a list, the keys on the DSM410 keypad have the following functions:

Power Key (![]() ) – turns the DSM410

off (see Section 3.1 on page 4 for details).

) – turns the DSM410

off (see Section 3.1 on page 4 for details).

Back Key (![]() ) – aborts the edit and restores

the editable value to its previous value

) – aborts the edit and restores

the editable value to its previous value

Scroll Up Key (![]() ) – changes the currently

selected editable value from the presently selected one to the one immediately

above it in the list of possibilities. If the top menu item is already

selected, the selection wraps to the bottom menu item.

) – changes the currently

selected editable value from the presently selected one to the one immediately

above it in the list of possibilities. If the top menu item is already

selected, the selection wraps to the bottom menu item.

Scroll Down Key (![]() ) – changes the

currently selected editable value from the presently selected one to the one

immediately below it in the list of possibilities. If the bottom menu item is

already selected, the selection wraps to the top menu item.

) – changes the

currently selected editable value from the presently selected one to the one

immediately below it in the list of possibilities. If the bottom menu item is

already selected, the selection wraps to the top menu item.

Enter Key (![]() ) – Accepts the currently

displayed value and stores it.

) – Accepts the currently

displayed value and stores it.

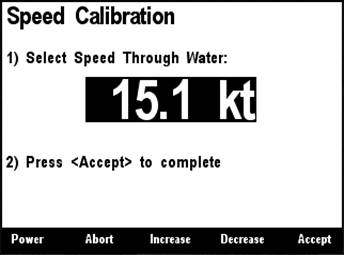

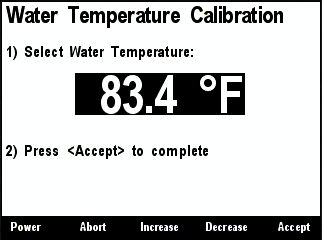

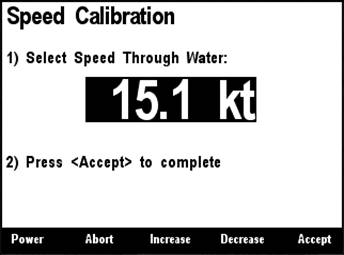

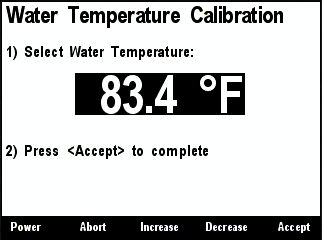

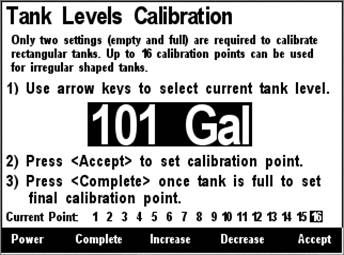

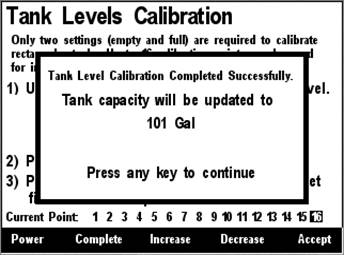

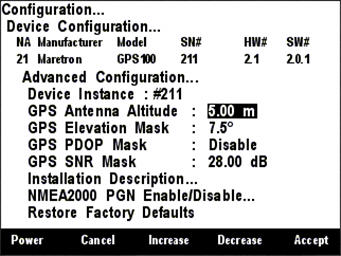

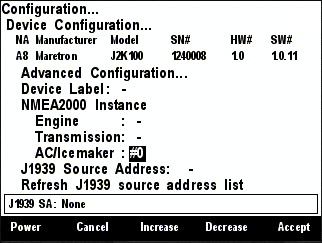

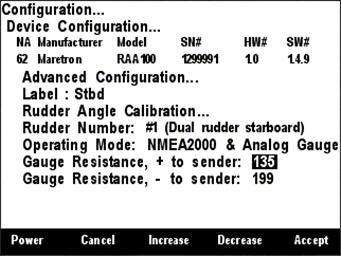

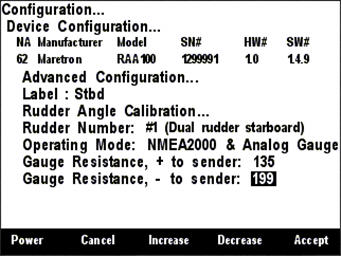

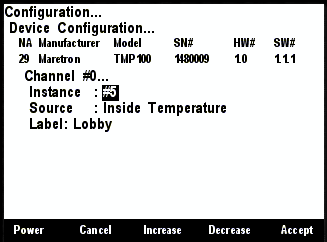

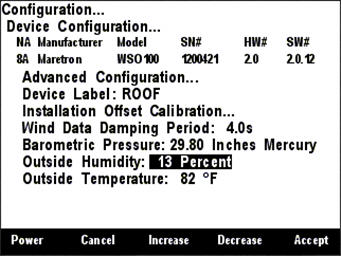

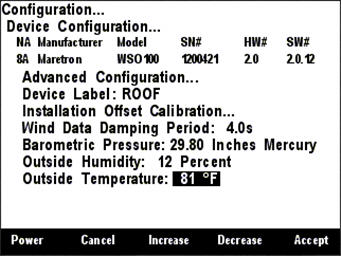

3.3.3 Entering a Numeric Value

When editing a numeric value, the keys on the DSM410 keypad have the following functions:

Power Key (![]() ) – turns the DSM410

off (see Section 3.1 on page 4 for details).

) – turns the DSM410

off (see Section 3.1 on page 4 for details).

Cancel Key (![]() ) – aborts the edit and restores

the editable value to its previous value

) – aborts the edit and restores

the editable value to its previous value

Increase Key (![]() ) – increases the editable value

) – increases the editable value

Decrease Key (![]() ) – decreases the editable value

) – decreases the editable value

Accept Key (![]() ) – Accepts the currently

displayed value and stores it.

) – Accepts the currently

displayed value and stores it.

3.3.4 Entering a Textual Value

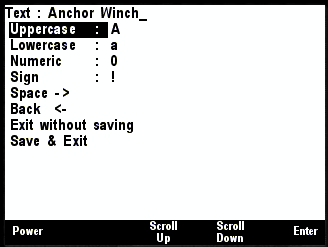

When entering a text string, the following menu will be presented:

Figure 5 – Entering a Textual Value

The top line contains the textual string that has already been entered. New characters are appended one at a time to the end of the line, at the position marked by the underscore.

To append an uppercase character, use the Scroll Up and Scroll Down buttons to select Uppercase and then press Enter to go across to the characters. Now use the Scroll Up and Scroll Down buttons again to select the required character, and press Enter to transfer the character to the cursor position. If another uppercase character is required, repeat this last step, or press the Back button top return to the choices on the left.

To append a lowercase character, use the Scroll Up and Scroll Down buttons to select Lowercase and then press Enter to go across to the characters. Now use the Scroll Up and Scroll Down buttons again to select the required character, and press Enter to transfer the character to the cursor position. If another lowercase character is required, repeat this last step, or press the Back button top return to the choices on the left.

To append a numeral, use the Scroll Up and Scroll Down buttons to select Numeric and then press Enter to go across to the numbers. Now use the Scroll Up and Scroll Down buttons again to select the required numeral, and press Enter to transfer the numeral to the cursor position. If another numeral is required, repeat this last step, or press the Back button top return to the choices on the left.

To append a punctuation character or other symbol, use the Scroll Up and Scroll Down buttons to select Sign and then press Enter to go across to the sign characters. Now use the Scroll Up and Scroll Down buttons again to select the required character, and press Enter to transfer the character to the cursor position. If another sign character is required, repeat this last step, or press the Back button top return to the choices on the left.

To append a space, use the Scroll Up and Scroll Down buttons to select Space and then press Enter.

To delete the character immediately preceding the underscore, use the Scroll Up and Scroll Down buttons to select Back and then press Enter. Note that it is not possible to delete the entire text string; use the Back function repeatedly to delete the characters one at a time.

To abort the entire textual edit, and return to the original field without changing the contents of the field, use the Scroll Up and Scroll Down buttons to select Exit without Saving and then press Enter.

To enter the text string in the original field, use the Scroll Up and Scroll Down buttons to select Save and Exit and then press Enter.

3.4 Settings Lock Mode

Sometimes, it is desirable to lock the settings of the DSM410 in order to keep them from being inadvertently changed. The DSM410 has a settings lock mode in which the settings of the DSM410 cannot be changed. To enter the lock mode, do the following steps:

1. Begin with the DSM410 powered off.

2. Press and hold the Up and Enter buttons.

3. While you are holding these two buttons, press and release the Power button.

4. Once the DSM410 has powered on and is displaying the warning screen, you may release the two buttons you are holding.

5. The DSM410 is now in settings lock mode. You can verify this by pressing the Enter key to display the main menu. You should see only the “Alert Status” and “Favorite Screens Mode” menu entries.

6. To exit settings lock mode, repeat steps 1-4. When you enter the main menu, you should again see all menu entries appear.

4 Important Concepts

4.1 Favorite Screens

The DSM410 can display many different types of information in many different configurations. It is capable of displaying up to four distinct windows on its screen at one time. Rather than making you select from among the many types of available information any time you want to change the displayed data, the DSM410 has the concept of “Favorite Screens”. A “Favorite Screen” is a combination of display settings, data to display, and formats in which to display the data. The DSM410 supports up to 16 different favorite screens.

4.2 Categories and Data Types

The DSM410 is capable of displaying many types of information. In order to make it easier to locate a specific type of information to display, the different types of information are organized into general categories:

· AC Bus

· AC Generator

· AC Utility

· Anchor Watch

· DC

· Depth

· Electrical

· Elec. Distribution

· Engine

· Environment

· Fluid Flow

· Fuel Management

· GPS

· Heading

· Humidity

· Indicator

· Mechanical

· Motion

· Navigation

· Pressure/Vacuum

· Rudder

· SMS (Text) Status

· Special Device

· Speed

· Tank

· Temperature

· Time/Date

· Transmission

· VDR

· Vessel

· Wind

The following sections explore each category in detail and spell out all of the data types that are available for display, if the appropriate sensors are installed in the network.

4.2.1 AC Bus

Average Frequency – displays average frequency of the AC power on the bus

Average L-N Voltage – displays average line to neutral RMS voltage of the AC power on the bus

Average L-L Voltage – displays average line to line RMS voltage of the AC power on the bus

Phase A Frequency – displays frequency of the AC power on phase A of the Bus

Phase A L-N Voltage – displays phase A Line-to-Neutral RMS voltage of the AC Bus

Phase AB L-L Voltage – displays phase A Line-to-phase B Line RMS voltage of the AC Bus

Phase B Frequency – displays frequency of the AC power on phase B of the bus

Phase B L-N Voltage – displays phase B Line-to-Neutral RMS voltage of the AC Bus

Phase BC L-L Voltage – displays phase B Line-to-phase C Line RMS voltage of the AC Bus

Phase C Frequency – displays frequency of the AC power on phase C of the bus

Phase C L-N Voltage – displays phase C Line-to-Neutral RMS voltage of the AC Bus

Phase CA L-L Voltage – displays phase C Line-to-phase A Line RMS voltage of the AC Bus

4.2.2 AC Generator

Average Current – displays the average current of the AC power on the generator

Average Frequency – displays the average frequency of the AC power on the generator

Average L-N Voltage – displays average line to neutral RMS voltage of the AC power on the generator

Average L-L Voltage – displays average line to line RMS voltage of the AC power on the generator

Total Real Power – displays real power output by the generator

Total Reactive Power – displays reactive power output by the generator

Total Apparent Power – displays apparent power output by the generator

Total Power Factor – displays power factor of the generator

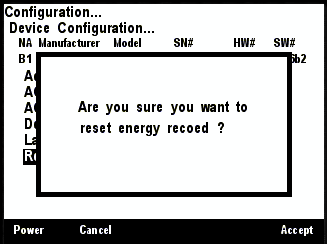

Total kWH Export – displays total energy produced by the generator (for the Maretron ACM100, this parameter’s value may be reset to zero with the control mode of the display – see Section 5.2.7.14 for details)

Total kWH Import – displays total energy consumed by the generator (for the Maretron ACM100, this parameter’s value may be reset to zero with the control mode of the display – see Section 5.2.7.14 for details)

Phase A Current – displays phase A current of the Generator

Phase A Frequency – displays frequency of the AC power on phase A of the Generator

Phase A L-N Voltage – displays phase A Line-to-Neutral RMS voltage of the Generator

Phase AB L-L Voltage – displays phase A Line-to-phase B Line RMS voltage of the Generator

Phase A Real Power – displays real power output on phase A of the generator

Phase A Reactive Power – displays reactive power output on phase A of the Generator

Phase A Apparent Power – displays apparent power output on phase A of the Generator

Phase A Power Factor – displays power factor of phase A of the Generator

Phase B Current – displays phase B current of the Generator

Phase B Frequency – displays frequency of the AC power on phase B of the Generator

Phase B L-N Voltage – displays phase B Line-to-Neutral RMS voltage of the Generator

Phase BC L-L Voltage – displays phase B Line-to-phase C Line RMS voltage of the Generator

Phase B Real Power – displays real power output on phase B of the generator

Phase B Reactive Power – displays reactive power output on phase B of the Generator

Phase B Apparent Power – displays apparent power output on phase B of the Generator

Phase B Power Factor – displays power factor of phase B of the Generator

Phase C Current – displays phase C current of the Generator

Phase C Frequency – displays frequency of the AC power on phase C of the Generator

Phase C L-N Voltage – displays phase C Line-to-Neutral RMS voltage of the Generator

Phase CA L-L Voltage – displays phase C Line-to-phase A Line RMS voltage of the Generator

Phase C Real Power – displays real power output on phase C of the generator

Phase C Reactive Power – displays reactive power output on phase C of the Generator

Phase C Apparent Power – displays apparent power output on phase C of the Generator

Phase C Power Factor – displays power factor of phase C of the Generator

4.2.3 AC Utility

Average Current – displays average current of the AC power on the utility

Average Frequency – displays average frequency of the AC power on the utility

Average L-N Voltage – displays average line to neutral RMS voltage of the AC power on the utility

Average L-L Voltage – displays average line to line RMS voltage of the AC power on the utility

Total Real Power – displays real power output by the utility

Total Reactive Power – displays reactive power output by the utility

Total Apparent Power – displays apparent power output by the utility

Total Power Factor – displays power factor of the utility

Total kWH Export – displays total energy produced by the utility (for the Maretron ACM100, this parameter’s value may be reset to zero with the control mode of the display – see Section 5.2.7.14 for details)

Total kWH Import – displays total energy consumed by the utility (for the Maretron ACM100, this parameter’s value may be reset to zero with the control mode of the display – see Section 5.2.7.14 for details)

Phase A Current – displays phase A current of the Utility

Phase A Frequency – displays frequency of the AC power on phase A of the Utility

Phase A L-N Voltage – displays phase A Line-to-Neutral RMS voltage of the Utility

Phase AB L-L Voltage – displays phase A Line-to-phase B Line RMS voltage of the Utility

Phase A Real Power – displays real power output on phase A of the Utility

Phase A Reactive Power – displays reactive power output on phase A of the Utility

Phase A Apparent Power – displays apparent power output on phase A of the Utility

Phase A Power Factor – displays power factor of phase A of the Utility

Phase B Current – displays phase B current of the Utility

Phase B Frequency – displays frequency of the AC power on phase B of the utility

Phase B L-N Voltage – displays phase B Line-to-Neutral RMS voltage of the Utility

Phase BC L-L Voltage – displays phase B Line-to-phase C Line RMS voltage of the Utility

Phase B Real Power – displays real power output on phase B of the Utility

Phase B Reactive Power – displays reactive power output on phase B of the Utility

Phase B Apparent Power – displays apparent power output on phase B of the Utility

Phase B Power Factor – displays power factor of phase B of the Utility

Phase C Current – displays phase C current of the Utility

Phase C Frequency – displays frequency of the AC power on phase C of the utility

Phase C L-N Voltage – displays phase C Line-to-Neutral RMS voltage of the Utility

Phase CA L-L Voltage – displays phase C Line-to-phase A Line RMS voltage of the Utility

Phase C Real Power – displays real power output on phase C of the Utility

Phase C Reactive Power – displays reactive power output on phase C of the Utility

Phase C Apparent Power – displays apparent power output on phase C of the Utility

Phase C Power Factor – displays power factor of phase C of the Utility

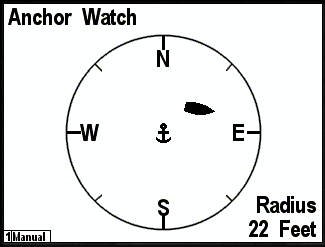

4.2.4 Anchor Watch

The DSM410 provides a graphical display of the Anchor Alert (section 8.3.7.9) parameters. When the vessel is anchored, the position of vessel at the point of dropping the anchor is entered in to the Anchor Alert plus the maximum distance that the boat can drift from that position (normally a little more than the amount of Anchor Chain that you have let out). If the boat moves beyond that radius, an Alert is triggered. The Anchor Watch display shows the last reported position of the vessel relative to the reported Anchor Drop position and the radius of the alert (see section 7.1 for more details on the display).

You may use the control mode of the display to easily set the Anchor Drop position. See Section 7.1 for details.

4.2.5 DC

The DSM410 supports the display of information for up to 64 DC sources including alternators, batteries, solar cells, wind generators, etc., with special parameters for batteries (i.e., State of Charge, Time Remaining, etc.).

Current – displays electrical current being sourced to/from the battery

Voltage – displays voltage measured at the battery

Battery Temperature – displays battery case temperature

Battery State of Charge – displays estimated state of charge of the battery (please consult the battery monitor’s documentation for details)

Battery Time Remaining – displays estimated time remaining for the battery given its current temperature and rate of discharge (please consult the battery monitor’s documentation for details)

Ripple Voltage – displays magnitude of the AC component riding on top of the DC voltage

Power – displays the power produced or consumed by the battery

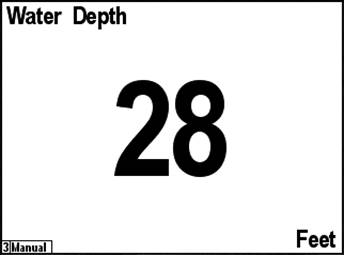

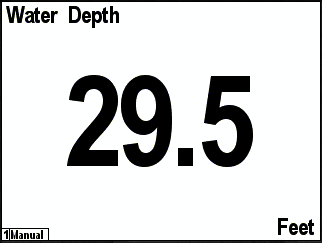

4.2.6 Depth

Transducer Offset – when negative, it displays distance from the depth transducer to the bottom of the keel, when positive it displays distance between the depth transducer and the waterline

Water Depth – displays the current water depth including the transducer offset. If the transducer offset is programmed to a negative number, then the water depth represents the depth below the keel. If the transducer offset is positive, then the water depth represents water line depth.

Water Below Transducer – displays the distance from the depth transducer to the sea or lake bottom (the transducer offset is not taken into account)

4.2.7 Electrical

Resistance – displays electrical resistance

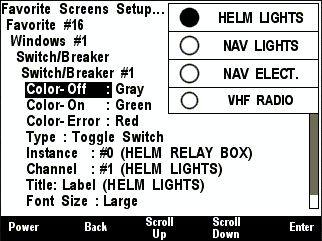

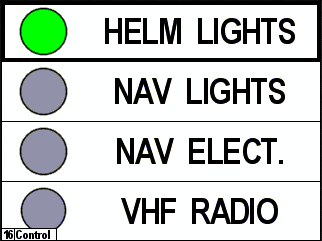

4.2.8 Elec. Distribution

The DSM410 supports control of the DCR100, Carling OctoPlex AC and DC Boxes, and other electrical distribution devices that utilize NMEA Command of the 127501 Binary Switch Status message for controlling loads.

Switch/Breaker – controls the ON/OFF state of a switch or circuit breaker

Breaker Current – displays current through a switch or circuit breaker

Hardware OFF Counter – displays the value of a hardware counter in Maretron’s DCR100, SIM100 and RIM100 that count the number of the times the indicator has transitioned to the OFF state. This counter may be reset with the control mode of the display – see Section 5.2.7.14 for details)

Hardware ON Counter – displays the value of a hardware counter in Maretron’s DCR100, SIM100 and RIM100 that count the number of the times the indicator has transitioned to the ON state. This counter may be reset with the control mode of the display – see Section 5.2.7.14 for details)

Hardware ERROR Counter – displays the value of a hardware counter in Maretron’s DCR100, SIM100 and RIM100 that count the number of the times the indicator has transitioned to the ERROR state. This counter may be reset with the control mode of the display – see Section 5.2.7.14 for details)

Hardware OFF Timer – displays the value of a hardware timer in Maretron’s DCR100, SIM100 and RIM100 that accumulates the elapsed time that the indicator has spent in the OFF state. This timer may be reset with the control mode of the display – see Section 5.2.7.14 for details)

Hardware ON Timer – displays the value of a hardware timer in Maretron’s DCR100, SIM100 and RIM100 that accumulates the elapsed time that the indicator has spent in the ON state. This timer may be reset with the control mode of the display – see Section 5.2.7.14 for details)

Hardware ERROR Timer – displays the value of a hardware timer in Maretron’s DCR100, SIM100 and RIM100 that accumulates the elapsed time that the indicator has spent in the ERROR state. This timer may be reset with the control mode of the display – see Section 5.2.7.14 for details)

4.2.9 Engine

The DSM410 supports the display of information for up to 64 engines.

Boost Pressure – displays the boost pressure of a supercharger or turbocharger

Hours – displays the number of hours of operation reported by the engine

Coolant Pressure – displays the engine’s coolant pressure

Coolant Temp. – displays the engine’s coolant temperature

Exhaust Gas Temp. – displays the temperature of the engine’s exhaust gas

Fuel Pressure – displays the pressure of the fuel for the engine

Fuel Rate – displays the rate of fuel consumption for the engine

Oil Pressure – displays the engine’s oil pressure

Oil Temp. – displays the engine’s oil temperature

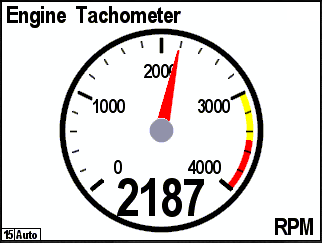

Tachometer – displays the rotational speed of the engine

Tilt/Trim – displays the tilt or trim of the drive

Voltage – displays the electrical power supply voltage measured at the engine

Fuel Economy (Dis./Vol.) – displays the current fuel economy for the engine

Fuel Consumption (Vol./Dis.) – displays the current fuel consumption for the engine

Percent Load – displays the current load on the engine as a percentage of rated load

Percent Torque – displays the current torque from the engine as a percentage of rated torque

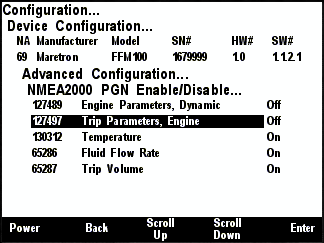

Trip Fuel Used – displays the total amount of fuel consumed by that engine on the present trip (fuel flow transducers that are capable of being reset via the 126208 NMEA 2000® command of the Trip Fuel Used field of the 127497 Trip Parameters, Engine message, such as the Maretron FFM100, may be reset with the control mode of the display – see Section 5.2.7.14 for details)

Warning – displays warning conditions generated by the engine

4.2.10 Environment

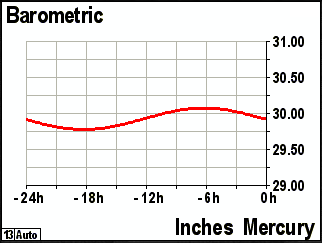

Barometric – displays the current atmospheric (barometric) pressure

Heat Index – displays the current heat index based on air temperature and humidity

Humidity Inside – displays the relative humidity from an indoor humidity sensor

Humidity Outside – displays the relative humidity for an outdoor humidity sensor

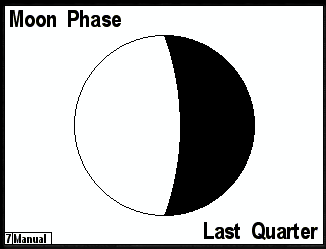

Moon Phase – displays the phase of the moon at the current time and position

Sunrise – displays the local time of sunrise for the current day and position

Sunset – displays the local time of sunset for the current day and position

Dew Point – displays the current dew point based on air temperature and humidity

Temp Engine Room – displays the air temperature from a sensor mounted in an engine room

Temp Inside – displays the air temperature from a sensor mounted inside the vessel

Temp Main Cabin – displays the air temperature from a sensor mounted inside the main cabin

Temp Outside – displays the air temperature from a sensor mounted outside

Temp Sea – displays the current temperature of the water

Twilight AM – displays the time of nautical twilight before sunrise for the current day and position

Twilight PM – displays the time of nautical twilight after sunset for the current day and position

Weather – displays a screen with a wide variety of weather-related data (See Section 7.14 for details)

Wind Chill – displays the current wind chill based on air temperature and wind speed

4.2.11 Fluid Flow

Flow Rate – displays the current rate of flow of a fluid

Trip Volume – displays the total volume of fluid through the sensor on the present trip (fluid flow transducers that are capable of being reset via the NMEA 2000 command of the Trip Volume field of the 65287 Trip Volume (Maretron Proprietary) message, such as the Maretron FFM100, may be reset with the control mode of the display – see Section 5.2.7.14 for details)

4.2.12 Fuel Management

|

|

WARNING: Maretron fuel management products are designed to be accurate and reliable; however they should be used only as aids for fuel management and not as a replacement for traditional fuel management techniques. BEWARE: Conditions can quickly change that drastically effect time and distance to empty.

You should not use the fuel management data types unless you fully understand all the parameters associated with fuel management. All fuel tanks and all engines must be included when setting up the DSM410 plus there must be accurate fuel rate sensors installed on the vessel and accurate speed information in order for the DSM410 to properly display fuel management information. You should also note that fuel levels may contain significant error if the boat is not sitting level in the water (i.e., sailboat heeled over or a power boat riding bow up won’t necessarily report the correct amount of fuel). Even when setup correctly, the DSM410 should be used only as an aid and not the sole source for fuel management information. |

Total Fuel Economy – displays distance traveled per unit fuel used (for example, miles per gallon or kilometers per liter) using the specified GPS and specified engine instances within the favorite screen setup (see Section 5.2.6.4.2 for details).

Total Fuel Rate – displays rate of fuel usage per unit time (for example, gallons or liters per hour) for all engine instances specified within the favorite screen setup (see Section 5.2.6.4.2 for details)

Total Fuel Remaining – displays total fuel remaining in all fuel tanks specified within the favorite screen setup (see Section 5.2.6.4.2. In order for the DSM410 to properly calculate total fuel remaining, tank monitors connected to the network must provide tank capacity in addition to fluid level.

Distance to Empty – displays the distance you can travel before all fuel is consumed, assuming all conditions remain the same. The DSM410 computes distance to empty using several different parameters including the total fuel remaining (see above) and fuel economy (also discussed above). Remember, conditions can rapidly change that may drastically effect distance to empty. For example, if you are going out to sea with the wind and current behind you, the distance to empty may indicate that there is enough fuel to return home when in fact there isn’t enough fuel to return. Distance to empty is only applicable if the conditions remain the same.

Time to Empty – displays the amount of time you can travel before all fuel is consumed, assuming all conditions remain the same. The DSM410 computes time to empty using total fuel remaining (see above) and the engine(s) fuel rate. Remember, conditions can rapidly change that may drastically effect time to empty. For example, if you are going out to sea with the wind and current behind you, the time to empty may indicate that there is enough fuel to return home when in fact there isn’t enough fuel to return. Time to empty is only applicable if the conditions remain the same.

Total Fuel Capacity – displays the total capacity of all fuel tanks. The DSM410 can only compute total fuel capacity assuming all totalized tanks are transmitting their capacity.

Total Fuel Level – displays the percentage of fuel remaining in all fuel tanks.

Total Fuel Consumption – displays the total volume of fuel used per unit of distance traveled (for example, gallons per mile or liters per km) using the specified GPS and specified engine instances within the favorite screen setup (see Section 5.2.6.4.2 for details).

Total Trip Fuel Used – displays the total volume of fuel used on the current trip from by all engines or fuel flow monitors that support the transmission of trip fuel used information on the network (fuel flow transducers that are capable of being reset via the 126208 NMEA 2000® command of the Trip Fuel Used field of the 127497 Trip Parameters, Engine message, such as the Maretron FFM100, may be reset with the control mode of the display – see Section 5.2.7.14 for details).

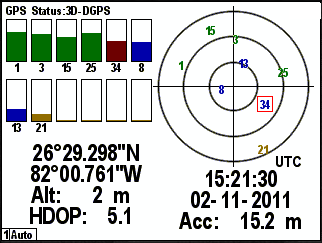

4.2.13 GPS

Course Over Ground – displays the current Course over Ground (either true or magnetic depending on the “Heading:” setting found under the “Units…” menu item)

Lat/Lon – displays the current latitude and longitude of the vessel

Speed Over Ground – displays the current speed over ground

Status – displays the current operating mode and status of the specified GPS receiver

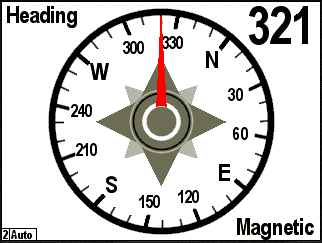

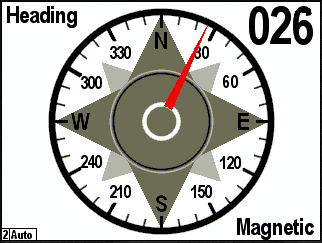

4.2.14 Heading

Magnetic/True – displays the current heading of the vessel (the direction the vessel is pointing) relative to true or magnetic north depending on the unit setting of the heading parameter (see Section 5.2.7.1)

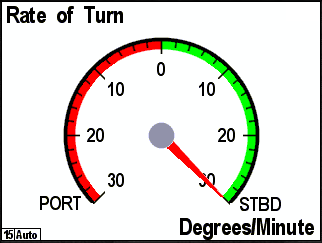

Rate of Turn – displays the angular rate of rotation of the vessel about the vertical axis

Variation – displays the magnetic variation used to convert between true and magnetic headings

4.2.15 Humidity

Inside – displays the relative humidity from an indoor humidity sensor

Outside – displays the relative humidity from an outdoor humidity sensor

User Defined 129 – User Defined 144 – displays the relative humidity from humidity sensors of user-defined types

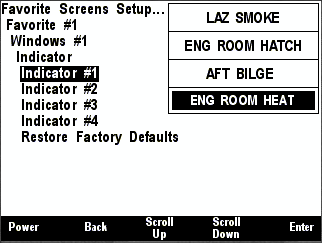

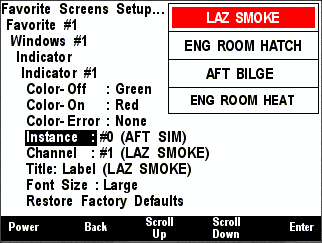

4.2.16 Indicator

Status – displays the on/off status of an indicator

Hardware OFF Counter – displays the value of a hardware counter in Maretron’s DCR100, SIM100 and RIM100 that count the number of the times the indicator has transitioned to the OFF state. This counter may be reset with the control mode of the display – see Section 5.2.7.14 for details)

Hardware ON Counter – displays the value of a hardware counter in Maretron’s DCR100, SIM100 and RIM100 that count the number of the times the indicator has transitioned to the ON state. This counter may be reset with the control mode of the display – see Section 5.2.7.14 for details)

Hardware ERROR Counter – displays the value of a hardware counter in Maretron’s DCR100, SIM100 and RIM100 that count the number of the times the indicator has transitioned to the ERROR state. This counter may be reset with the control mode of the display – see Section 5.2.7.14 for details)

Hardware OFF Timer – displays the value of a hardware timer in Maretron’s DCR100, SIM100 and RIM100 that accumulates the elapsed time that the indicator has spent in the OFF state. This timer may be reset with the control mode of the display – see Section 5.2.7.14 for details)

Hardware ON Timer – displays the value of a hardware timer in Maretron’s DCR100, SIM100 and RIM100 that accumulates the elapsed time that the indicator has spent in the ON state. This timer may be reset with the control mode of the display – see Section 5.2.7.14 for details)

Hardware ERROR Timer – displays the value of a hardware timer in Maretron’s DCR100, SIM100 and RIM100 that accumulates the elapsed time that the indicator has spent in the ERROR state. This timer may be reset with the control mode of the display – see Section 5.2.7.14 for details)

4.2.17 Mechanical

dB – displays a level (sound, power) measured by a sensor that transmits a decibel level

Force – displays mechanical force from a load cell

Strain – displays the amount of mechanical strain an object is subjected to

4.2.18 Motion

Acceleration – displays acceleration

Angle – displays an angle transmitted by an angle sensor (e.g., mast rotation angle)

Angular Velocity – displays angular velocity

Angular Acceleration – displays angular acceleration

Distance – displays a linear distance

Rotational Rate – displays rotational rate (e.g., shaft speed)

Velocity – displays linear velocity

4.2.19 Navigation

The DSM410 is not a primary navigation device; that is, it does not provide means for entering and storing waypoint and route data. The DSM410 can receive information on the current leg of the voyage from a primary navigation device (such as a chart plotter or PC with navigation software and NMEA 2000® interface) and display this information.

Bearing Orig to Dest – displays the direction from the origin waypoint to the destination waypoint

Bearing To Waypoint – displays the bearing to the destination waypoint

Course Over Ground – displays the current Course over Ground (always referenced to true north)

Cross Track Error – displays the cross-track error (minimum distance from the boat to the programmed route)

Distance To Waypoint – displays the distance to the destination waypoint

Est. Time of Arrival – displays the Estimated Time of Arrival at the waypoint

Lat/Lon – displays the current latitude and longitude of the vessel

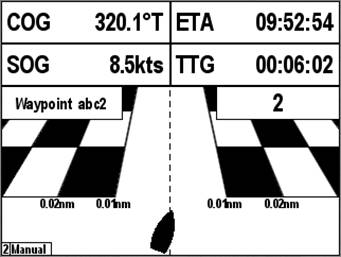

Rolling Road – displays navigation information for the current leg of the route

Set/Drift – displays the direction (set) and speed (drift) of the water current

Speed Over Ground – displays current Speed over Ground (relative to the earth, not the water)

Time To Go – displays the estimated Time to Go until arrival at the waypoint

VMG to Waypoint – displays the Velocity Made Good; that is, the speed at which the distance to the waypoint is decreasing

Waypoint Number – this displays the number of the destination waypoint

4.2.20 Pressure/Vacuum

Altimeter – displays the current altimeter pressure reading

Barometric – displays the current atmospheric (barometric) pressure

Compressed Air – displays the current pressure of compressed air

Engine Boost – displays the boost pressure of a supercharger or turbocharger

Engine Coolant – displays the coolant pressure for an engine

Engine Fuel – displays the fuel pressure for an engine

Engine Oil – displays the oil pressure for an engine

Filter – displays the current pressure at a fuel filter

Fuel – displays the current fuel pressure

Hydraulic Oil – displays hydraulic oil pressure

Oil – displays the current oil pressure

Steam – displays steam pressure

Transmission Oil – displays oil pressure for an transmission

User Defined 129 – User Defined 144 – displays pressure from a pressure sensor of a user-defined type

Water – displays water pressure

4.2.21 Rudder

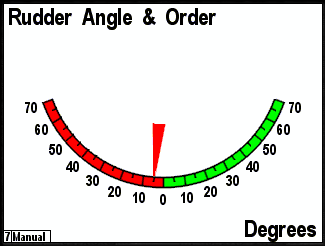

The DSM410 supports the display of information for up to four rudders.

Rudder Angle & Order – displays the angle of the vessel’s rudder as indicated by the rudder sensor, as well as the angle to which the rudder has been commanded by an autopilot or steering device

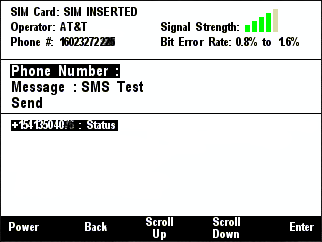

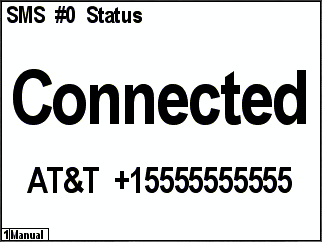

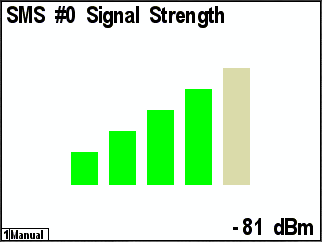

4.2.22 SMS (Text) Status

Status – displays the status of the Maretron SIM100 SMS (Text) device

Signal Strength – displays the signal strength of the cellular network

Indicator – displays whether the Maretron SIM100 SMS (Text) device has a connection to the cellular network

4.2.23 Special Device

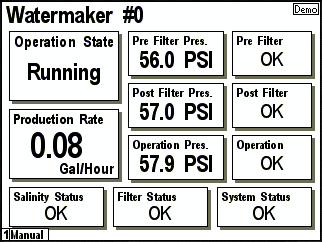

Watermaker – displays a screen with several different parameters associated with Sea Recovery watermakers

4.2.24 Speed

Speed Through Water – displays the speed of the boat relative to the water

Speed Over Ground – displays Speed over Ground (relative to the earth, not the water)

Total Log – displays the total distance traveled by the vessel since the log indicator was installed

Trip Log – displays the distance traveled by the vessel since the trip indication of the log indicator was last reset (the trip log value from log transducers that are capable of being reset via the NMEA 2000® command of the Distance Since Last Reset field of the 128275 Distance Log message, such as the Maretron DST110, may be reset with the control mode of the display – see Section 5.2.7.14 for details)

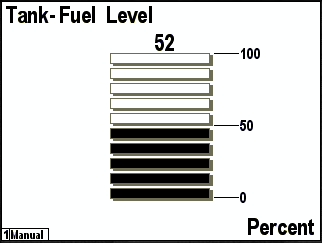

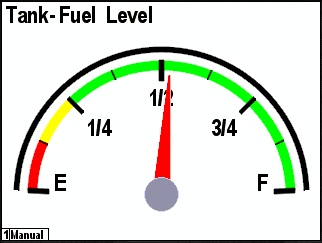

4.2.25 Tank

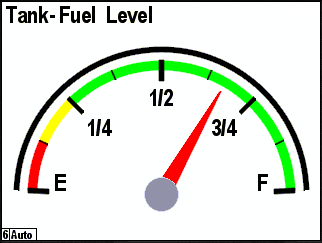

The DSM410 supports the display of information for up to sixteen tanks types (16 fuel plus 16 water, etc.).

Capacity – displays the fluid capacity of the tank

Level – displays the level of fluid in the tank as a percentage of its capacity

Remaining – displays the amount of fluid in the tank

4.2.26 Temperature

The display supports the display of temperatures. Each temperature sender on the bus is required to state the source of the temperature, which may be one of:

Bait Well

Battery

Dew Point

Engine Coolant

Engine Oil

Engine Room

Exhaust Gas

Freezer

Heat Index

Heating System

Inside

Live Well

Main Cabin

Outside

Refrigeration

Sea

Transmission Oil

User Defined 129 – User Defined 144

Wind Chill

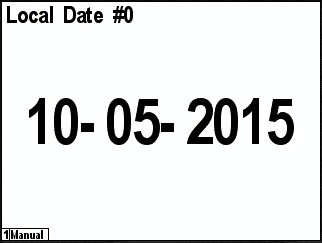

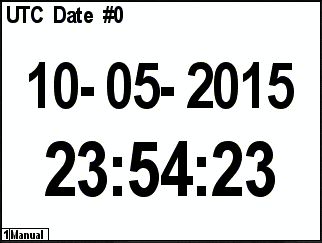

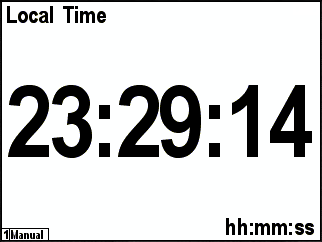

4.2.27 Time/Date

Local Date – displays the current date referenced to the local time offset (see Section 5.2.7.12, on page 43 for details on how to set the local time offset)

UTC Date – displays the current date referenced to Universal Time Coordinated

Moon Phase – displays the phase of the moon at the current time and position

Sunrise – displays the local time of sunrise for the current day and position

Sunset – displays the local time of sunset for the current day and position

Local Time – displays the current time referenced to the local time offset (see Section 5.2.7.12, on page 43 for details on how to set the local time offset)

UTC Time – displays the current time referenced to Universal Time Coordinated (also known as Greenwich Mean Time, or GMT)

Twilight AM – displays the time of nautical twilight (i.e., the time of day when the sun is 12 degrees below the horizon in the morning) for the current day and position

Twilight PM – displays the time of nautical twilight (i.e., the time of day when the sun is 12 degrees below the horizon in the evening) for the current day and position

4.2.28 Transmission

The DSM410 supports the display of information for up to four transmissions.

Gear – displays the current gear of the transmission (forward, neutral, or reverse)

Oil Pressure – displays the pressure of the oil in the transmission

Oil Temp. – displays the temperature of the oil in the transmission

Warning – displays warning indications generated by the transmission

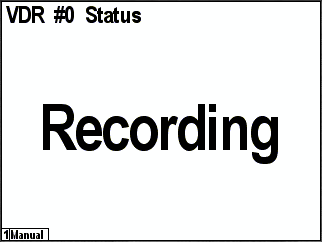

4.2.29 VDR

The DSM410 supports display of status of a Vessel Data Recorder.

Status – displays the operating state of the VDR

Memory Capacity – displays the total memory capacity of the USB flash drive in the VDR

Memory Used – displays the total amount of memory used on the USB flash drive in the VDR

Memory Available – displays the total amount of memory remaining on the USB flash drive in the VDR

Percent Used – displays the percentage of the memory capacity of the USB flash drive in the VDR that is filled with data

Percent Available – displays the percentage of the memory capacity of the USB flash drive in the VDR that is still available for data storage

4.2.30 Vessel

Heave – displays heave (vessel movement along the vertical axis)

Keel – displays the height of a swing keel

Pitch – displays the pitch of the vessel (rotation about the horizontal axis perpendicular to the ship’s keel)

Roll – displays the roll of the vessel (rotation about the horizontal axis parallel to the ship’s keel)

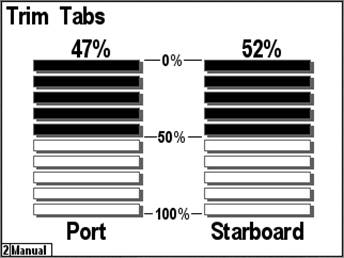

Trim Tabs – displays the position of the vessel’s trim tabs

Trim Tab Port – displays the position of the port trim tab

Trim Tab Starboard – displays the position of the starboard trim tab

4.2.31 Wind

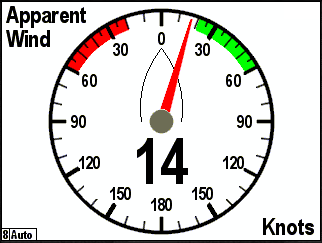

Apparent Direction – displays the angle of the wind relative to the vessel center line as it appears to an observer on the deck of a moving or stationary vessel (does not subtract out the speed of the vessel)

Ground Direction – displays the angle of the wind relative to true or magnetic north (depending on the unit setting of the “heading” parameter, see Section 5.2.7.1) measured relative to a stationary observer, calculated using heading, course over ground (COG), and speed over ground (SOG)

True Direction – displays the angle of the wind relative to the vessel center line (vessel’s speed is subtracted from Apparent wind direction), calculated using speed through water (STW) or speed over ground (SOG) (depending on the unit setting of the “Wind True Vessel Ref.” Parameter, see Section 5.2.7.6)

Apparent Speed – displays the speed of the wind as it appears to an observer on the deck of a moving or stationary vessel (does not subtract out the speed of the vessel)

Ground Speed – displays the speed of the wind relative to a stationary observer, calculated using heading, course over ground (COG), and speed over ground (SOG)

True Speed – displays the speed of the wind as it would appear to an observer if the vessel was stopped in the water, calculated using speed through water (STW) or speed over ground (SOG) (depending on the unit setting of the “Wind True Vessel Ref.” Parameter, see Section 5.2.7.6)

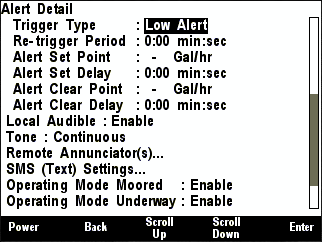

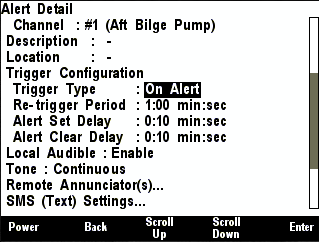

4.3 Alerts

An alert is a signal to a user that there is either an alarm or warning condition requiring user intervention.

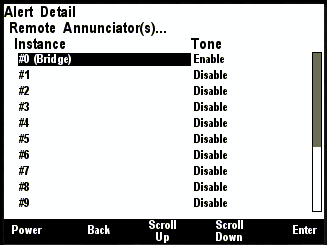

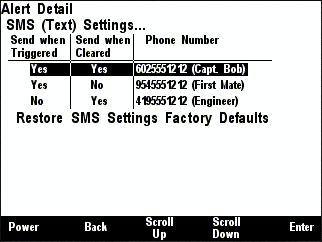

Alerts are integrated in an NMEA2000® system. For each Alert, one device acts as a master, or Alert Source, and monitors a parameter against a preset threshold. When the parameter crosses this threshold, the Alert is displayed on the Alert Source and an Alert Message is sent out on the NMEA2000® bus to other devices capable of displaying Alerts. Optionally, an Annunciator message is sent to devices capable of sounding an audio alarm (e.g. the ALM100). Currently, the DSM150, DSM250, DSM410, and the N2KView™ Vessel Monitoring Software are capable of generating and receiving Alert Messages.

The Alert may be accepted or cancelled from any capable device, in which case an Alert Response Message is sent to the Alert Source, which in turn will turn the Annunciators off and inform the devices on the bus of the new Alert Status.

The DSM410 can support the definition of up to 40 alerts.

4.3.1 Alert Types

There are two classes of alerts, which are distinguished by their severity:

· Alarm – An alarm is a type of alert announcing a condition requiring immediate attention or user intervention. Alarms are shown in red (when Active), and always appear above the warnings on the Alert Status Screen.

· Warning – A warning is a type of alert announcing a condition requiring non-immediate attention for precautionary reasons. Warnings are shown in yellow (when Active), and always appear below alarms on the Alert Status Screen.

4.3.2 Alert Terminology

The following alert terminology, consistent with International Maritime Organization Code on Alarms and Indicators, is used in N2KView™ and the DSM410.

· Accept – The user action of acknowledging the existence of an alert. Alerts are only accepted when they are Active

· Cancel – The user action of removing an alert from the list of displayed alerts. Alerts may only be cancelled if the condition causing the alert has been removed.

· Clear – An alert is cleared when the condition causing the alert is removed. This is not a user action.

· Trigger – An alert is triggered when the condition monitored by the alert is met.

4.3.3 Alert Priority

Each alert has a priority which you can define, ranging from 0 to 4000 with 0 the highest or most important priority and 4000 the lowest or least important priority. Alarms always have a higher priority than Warnings (i.e. an Alarm with a priority of 4000 has a higher priority than a warning with priority 0).

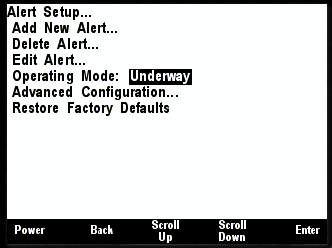

4.3.4 Vessel Alert Operating Modes

You can configure alerts to operate in one or more fixed operating modes, 1) disabled, 2) moored, 3) underway, or 4) anchored. This allows you to easily enable or disable groups of individual alarms depending on the vessel’s operating mode. Setting the vessel alert operating mode is described in section 8.6.

The Operating Mode is one of:

· Disabled – All alerts are disabled. This mode should be used when the vessel is in storage, dry-dock, or otherwise out of operation.

· Moored – This mode is used when the vessel is secured to a structure that is permanently attached to the ground like a pier, wharf, dock, or mooring buoy.

· Underway – This mode is used when the vessel is not moored nor anchored.

· Anchored – This mode is used when the vessel is secured to the sea floor with an anchor.

|

NOTE

The DSM410 will always display global alerts generated by other devices on the network, regardless of the Operating Mode selected. |

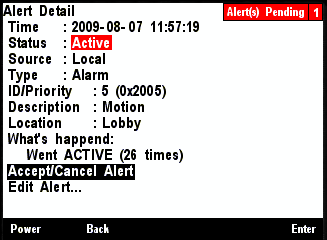

4.3.5 Alert States

Alerts exist in one of five states.

· Disabled – A Disabled Alert is an alarm or warning that has yet to be enabled or activated. In this state, no action will be taken regardless of the value of the monitored parameter. A Disabled Alert May be enabled in which case it transitions to the Inactive state

· Inactive – An Inactive alert is an alarm or warning that has been enabled, but the condition causing the alert is not present. If the alert condition becomes true, the alert will become an Active Alert. An Inactive alert may be disabled, which causes it to transition to the Disabled state. New alerts are created in the Inactive State.

· Active – An Active alert is an alarm or warning where the condition to trigger the alert has been met, and is still present and the operator has not accepted the alert. An active alert is indicated by a flashing indicator on the Alert Status Screen, and by a flashing colored box at the top right of the DSM410 screen. This box will be visible on all screens. Also, annunciators that are programmed to sound when this alert is active will be sounding during this state. An active alert can be accepted by the user (causing it to become an Accepted Alert) or disabled by the user (causing it to become a Disabled Alert). If the condition causing the alert is rectified, the alert transitions to the Awaiting Cancel state.

· Accepted – An Accepted alert is an alarm or warning which was Active and has been accepted by the user. A solid indicator on the Alert Status Screen indicates an Accepted alert; annunciators are silenced. Normally, an alert is a serious matter that requires immediate attention and requires a deliberate attempt to remove the condition that caused the alert. Sometimes it isn’t practical to immediately remove the condition that caused the alert; accepting the alert will silence the annunciators while the appropriate user action is being taken.

To prevent an alert that has accepted by the user from being forgotten, an accepted alert will transition back to being Active after a period of time set by the user. If the condition causing the alert is rectified (cleared), the alert will transition to the Inactive state.

You may disable the alert at this time, causing it to become a Disabled Alert.

4.3.6 Available Alert Classes

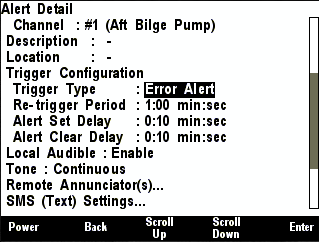

The DSM410 has several classes of alerts, depending on the parameter for which an alert is being configured.

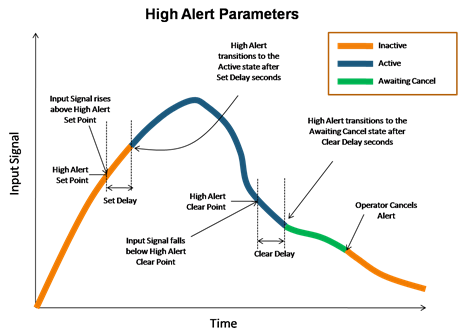

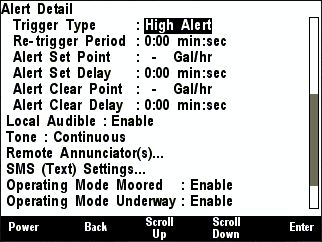

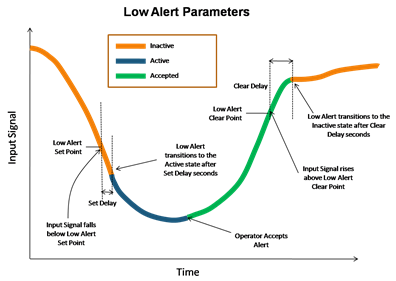

· Low Alert – The alert will become active if the monitored value drops below the value in this alert for longer than the time specified in the Set Delay field.

· High Alert – The alert will become active if the monitored value rises above the value specified in this alert for longer than the time specified in the Set Delay field.

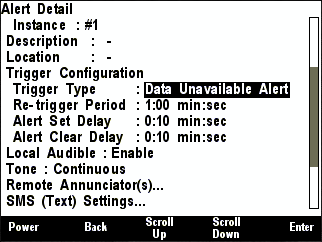

· Data Unavailable Alert – The alert will become active if the monitored value is not received, or is received but with a value of “Data Not Available”, for longer than the time specified in the Set Delay field.

· On Alert – The alert will become active if the monitored switch or flag becomes “ON” for longer than the time specified in the Set Delay field.

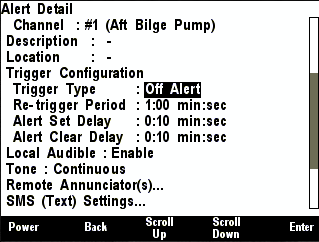

· Off Alert – The alert will become active if the monitored switch or flag becomes “OFF” for longer than the time specified in the Set Delay field.

· Tripped Alert – The alert will become active if the monitored circuit breaker becomes “Tripped” for longer than the time specified in the Set Delay field.

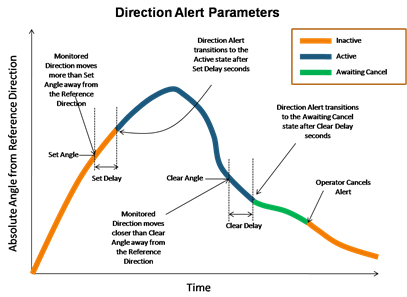

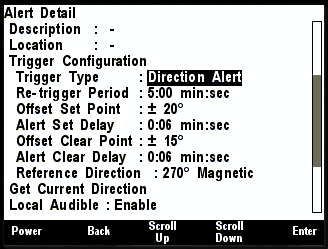

· Course Alert – The alert will become active if the monitored course differs from the Reference Direction by more than the Offset COG Set Point for longer than the time specified in the Set Delay field.

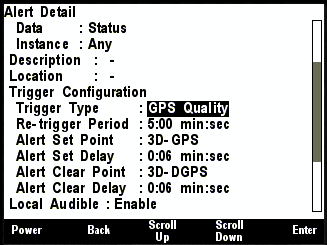

· GPS Quality Alert – The alert will become active if the GPS Quality drops below the level set in the GPS Quality Alert Set field for longer than the time specified in the Set Delay field.

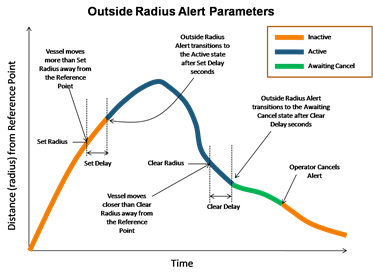

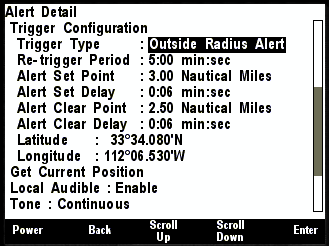

· Outside Radius Alert – The alert will become active if the distance between the current GPS position and the Reference Latitude and Longitude rises above the value in the Outside Radius Alert Set field for longer than the time specified in the Set Delay field.

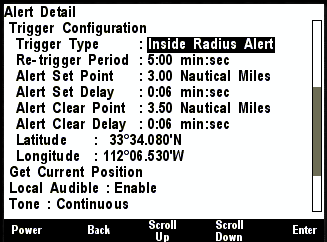

· Inside Radius Alert – The alert will become active if the distance between the current GPS position and the Reference Latitude and Longitude falls below the value in the Outside Radius Alert Set field for longer than the time specified in the Set Delay field.

· Anchor Alert – Similar to the Outside Radius Alert, this alert will become active if the distance between the current GPS position and the Reference Latitude and Longitude rises above the value in the Outside Radius Alert Set field for longer than the time specified in the Set Delay field. The Anchor Alert is more suited for smaller radii, and can be displayed graphically in the Anchor Watch Display.

· Direction Alert – The alert will become active if the monitored course differs from the Reference Direction by more than the Offset Wind Direction Set Point for longer than the time specified in the Set Delay field.

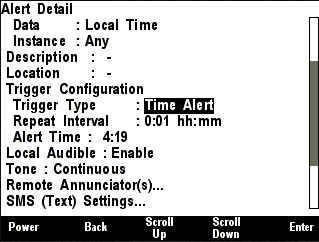

· Timer Alert – The alert will become active when the time reaches the time specified in the Alarm Time field, and thereafter after the intervals specified in the Repeat Interval field.

5 Operating Modes

The DSM410 has two main operating modes including normal viewing of information in the favorite screens mode (Section 5.1) and the menu mode (Section 5.2). Also, the control mode is a sub mode of the favorite screens mode, in which certain control and reset functions may be performed (Section 5.2.7.14).

5.1 Favorite screens modes

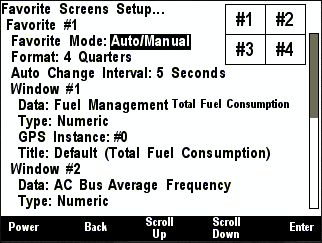

After the power up screen (see Section 3.1), the DSM410 always enters the favorite screens mode. In the favorite screens modes, the DSM410 displays one of up to sixteen “favorite” screens. Each “favorite” screen can display one, two, three, or four information displays. Each information display can show any displayable data in any display type supported by that data. In favorite screens mode, the DSM410 can operate in one of two ways:

Manual mode – a particular “favorite” screen remains on the display until you select another one, or

Auto mode – the DSM410 automatically cycles between “favorite” screens, at time intervals which are individually programmable for each “favorite” screen.

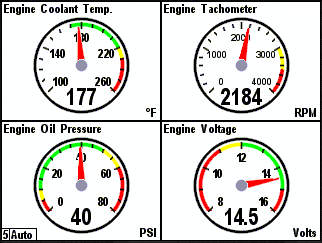

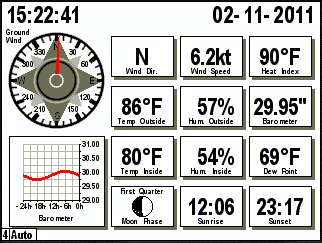

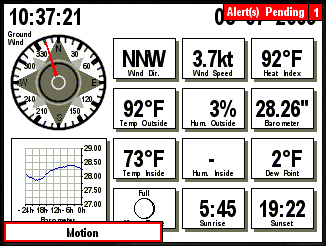

An example screen of the DSM410 running in favorite screens mode can be seen in Figure 6 below.

Figure 6 – DSM410 Running in Favorite Screens Mode

The very bottom left hand corner of the screen shows two important parameters: 1) it indicates which favorite screen is being displayed (in this case Favorite #5), and 2) it indicates that the DSM410 is currently operating in the Auto mode. Manual would appear in place of Auto if the DSM410 was operating in Manual mode.

5.2 Menu Mode

The menu mode is entered while viewing favorite screens by

pressing the Enter key (![]() ).

).

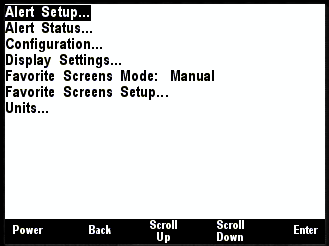

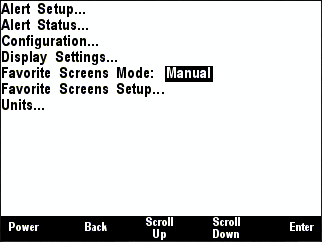

In menu mode, the DSM410 may be configured by scrolling up and down the menu and selecting one of the submenus found there. The DSM410 Main Menu can be seen in Figure 7 below.

Figure 7 – Main Menu

The menu has the following structure

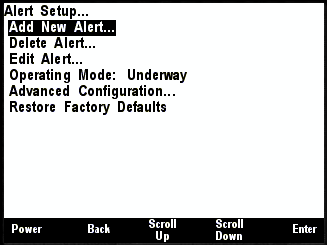

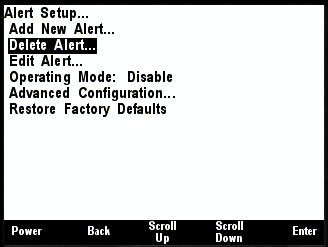

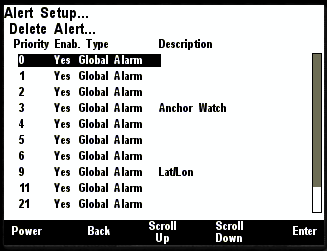

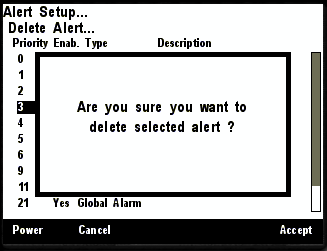

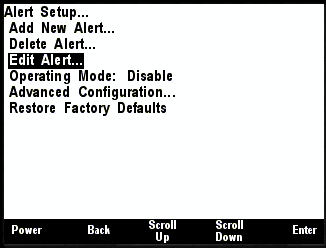

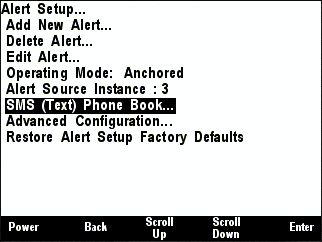

Alert Setup… (5.2.1)

Add New Alert… (8.2)

Delete Alert… (8.4)

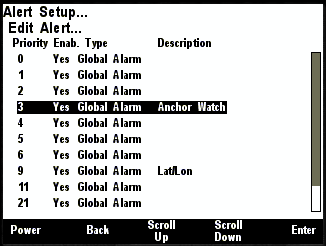

Edit Alert… 8.5)

Operating Mode (8.6)

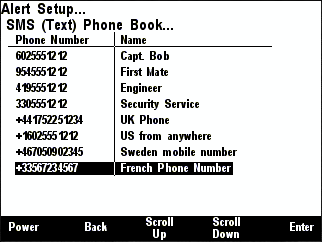

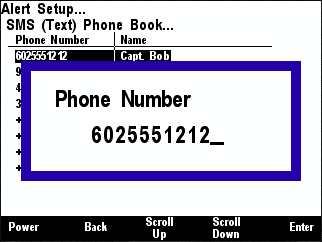

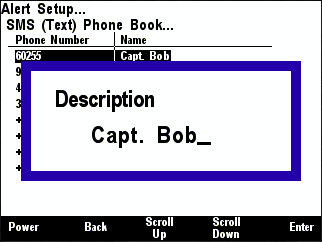

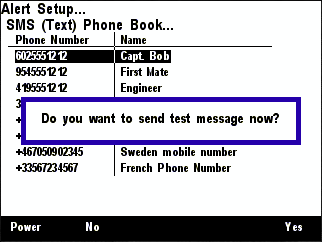

SMS (Text) Phone Book… (0)

Advanced Configuration… (8.8)

Restore Factory Defaults (8.9)

Alert Status… (5.2.2)

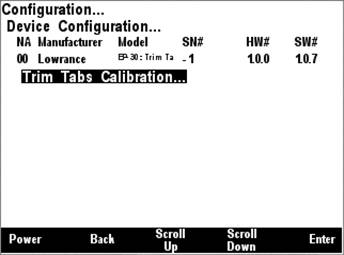

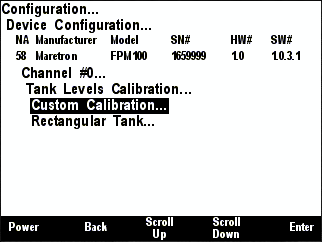

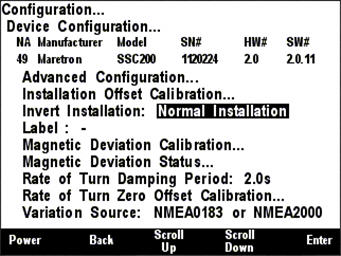

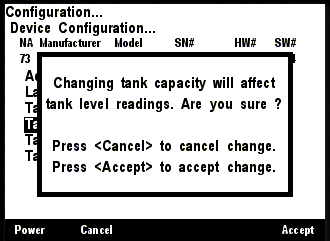

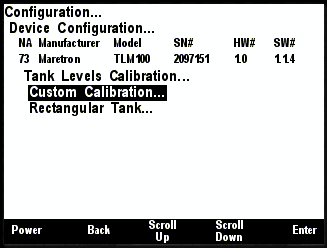

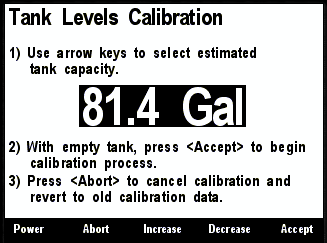

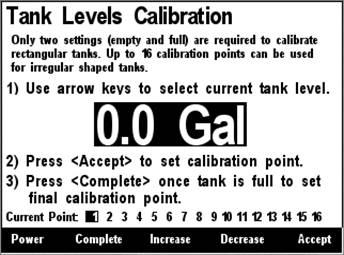

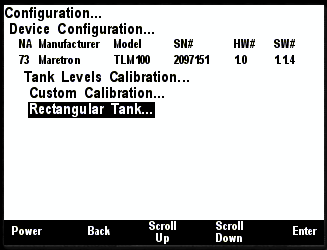

Configuration…

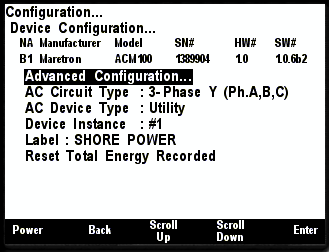

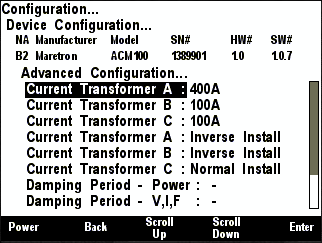

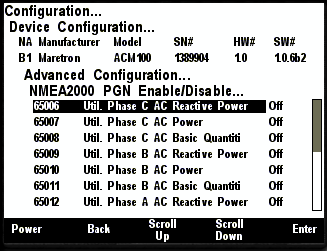

Device Configuration… (5.2.3.1)

Device Selection… (5.2.3.2)

Display Settings…

Advanced Configuration… (5.2.4.1)

Advanced Information… (5.2.4.2)

Backlight… (5.2.4.3)

Color Setup… (5.2.4.4)

Demo Mode (5.2.4.5)

Keypad Beep (5.2.4.6)

Label (5.2.4.7)

Language (5.2.4.8)

Software Version (5.2.4.9)

Favorite Screens Mode (5.2.4.7)

Favorite Screens Setup… (5.2.6)

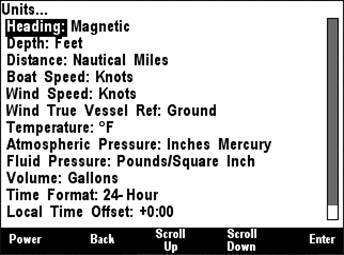

Units… (5.2.6.4.2)

5.2.1 Alert Setup Menu

Selecting Alert Setup… from the Main Menu allows you to create, delete, and edit the Alerts stored in the DSM410, and to change the operating mode of the vessel. See section 7.25 for details on the Alerts.

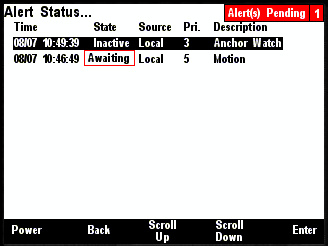

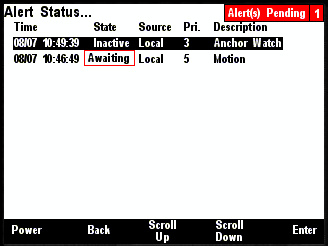

5.2.2 Alert Status

Selecting Alert Status… from the Main Menu will display a list of currently active Alerts in the DSM410. See section 8.1.1 for details on the Alert Status Screen.

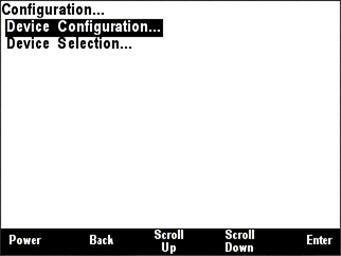

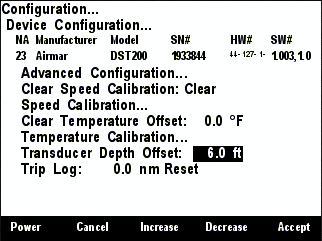

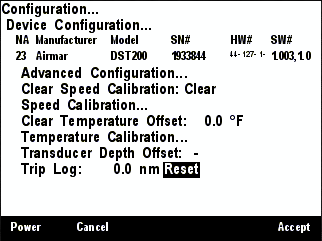

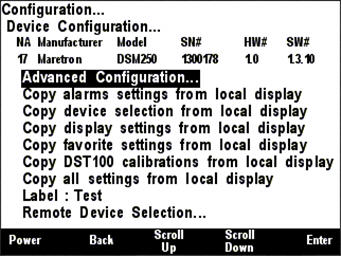

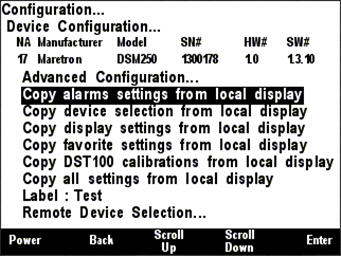

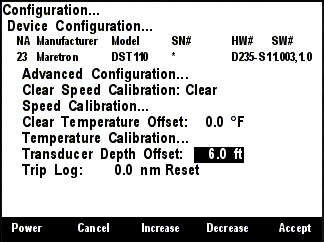

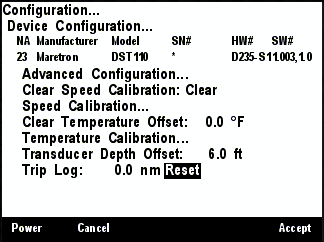

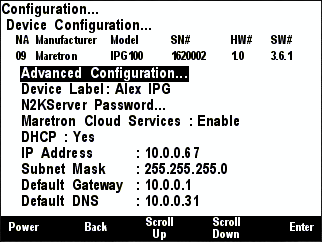

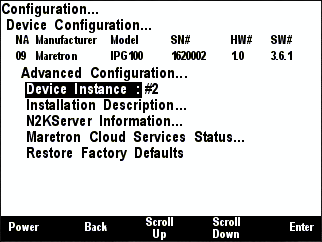

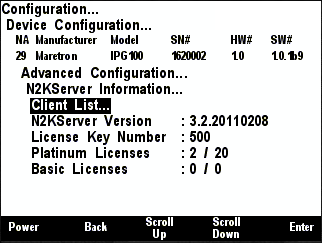

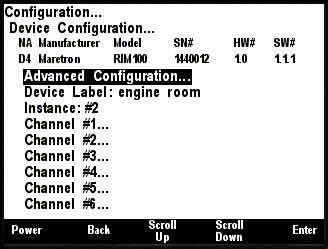

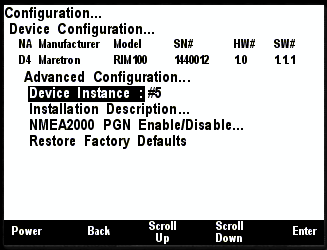

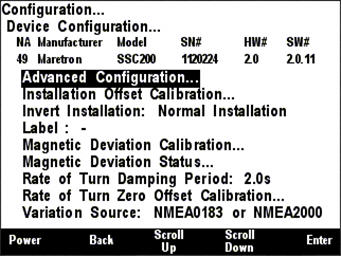

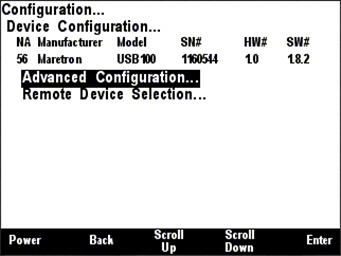

5.2.3 Configuration Menu

The configuration menu allows you to change the configuration of certain types of Maretron NMEA 2000® devices, as well as to select from which NMEA 2000® nodes data may be received.

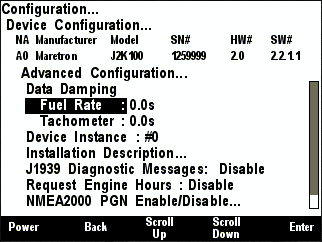

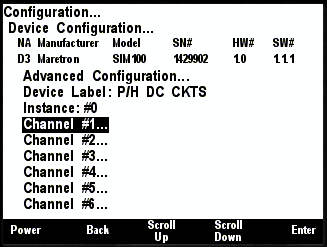

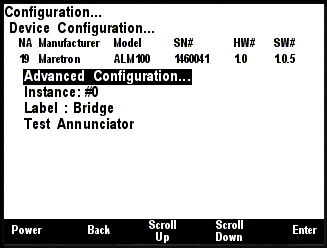

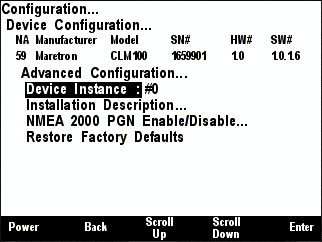

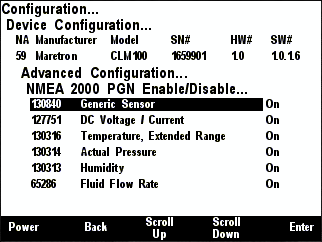

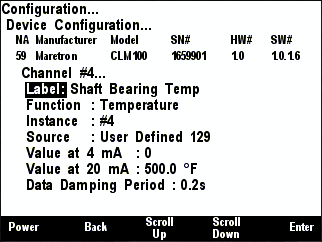

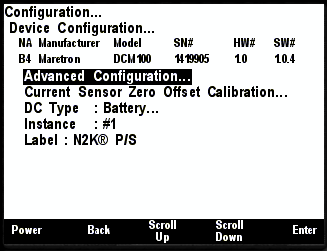

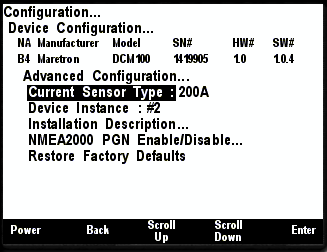

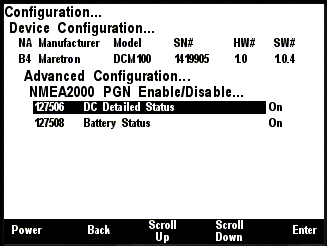

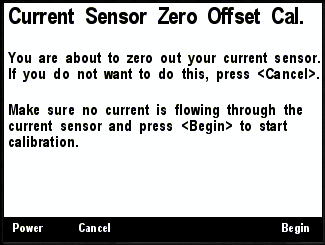

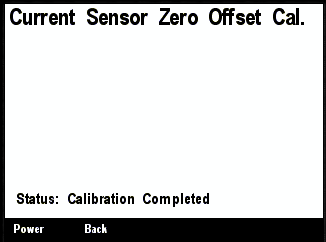

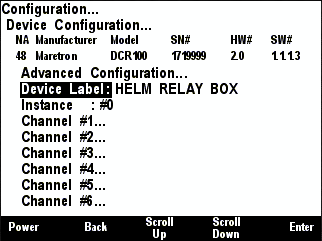

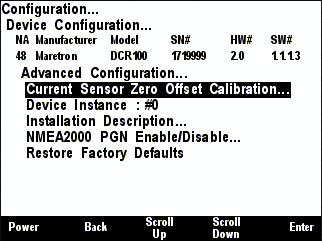

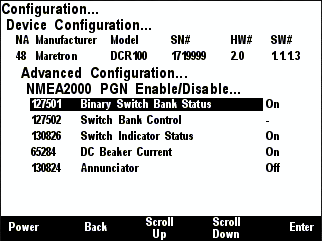

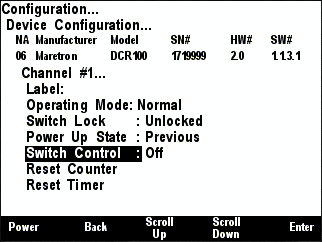

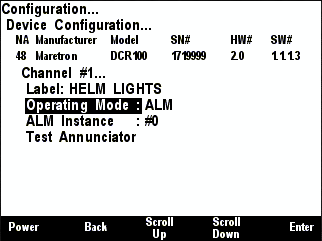

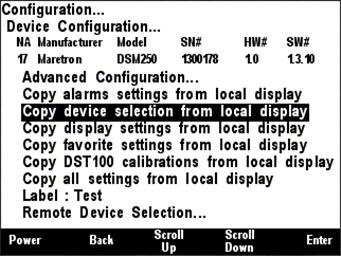

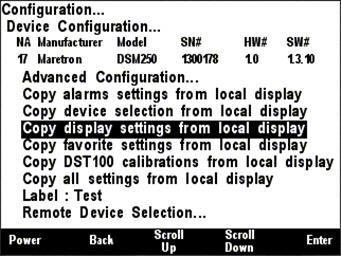

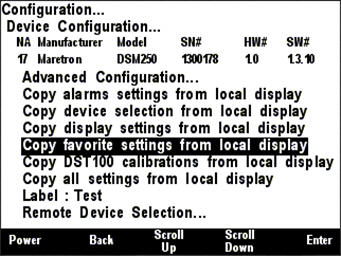

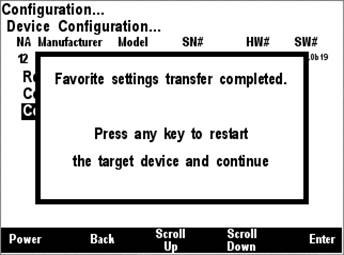

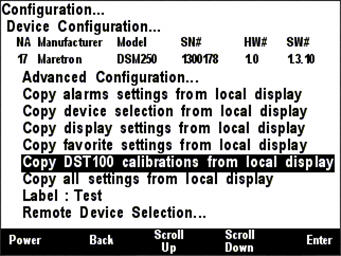

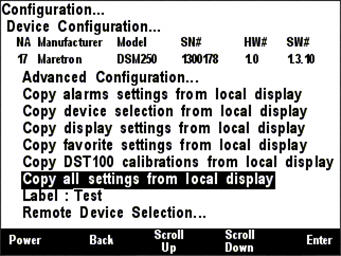

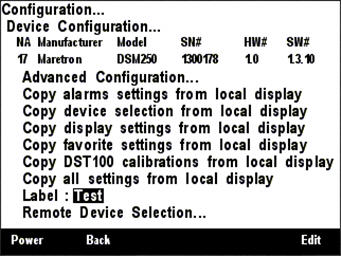

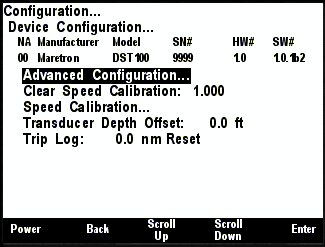

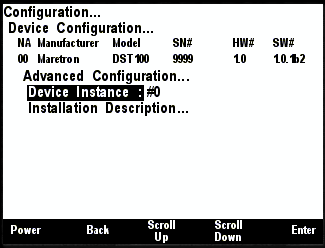

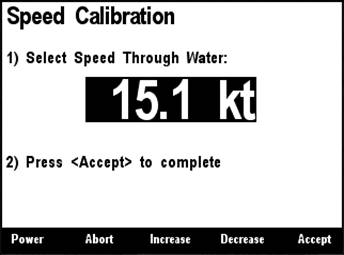

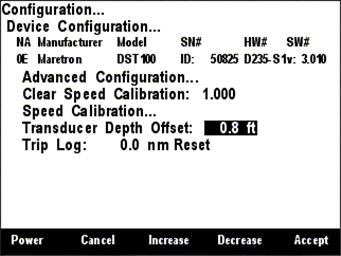

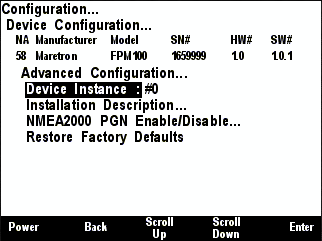

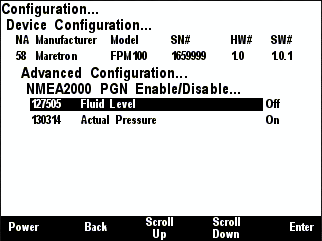

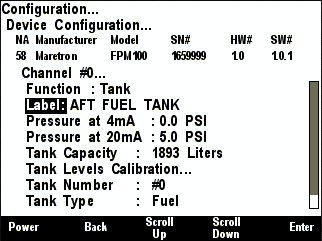

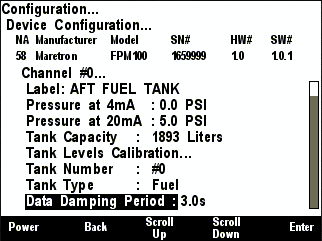

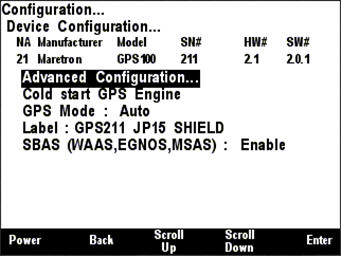

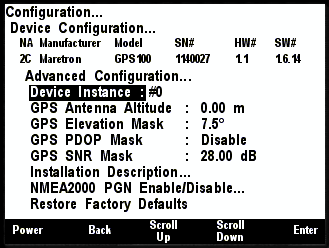

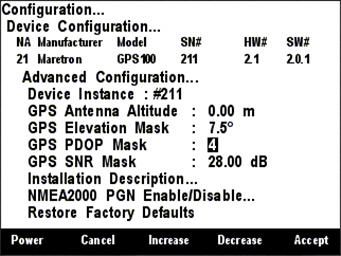

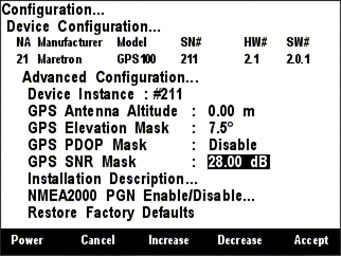

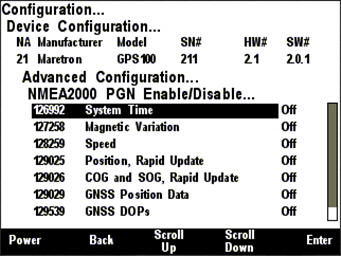

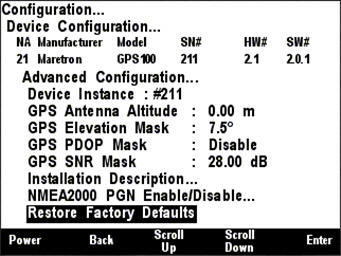

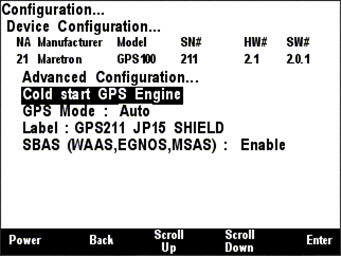

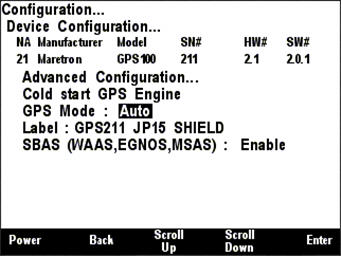

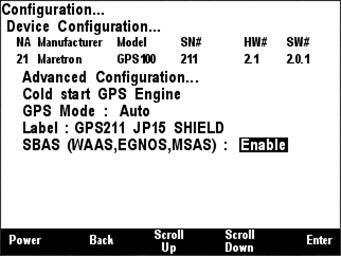

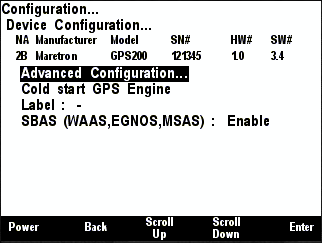

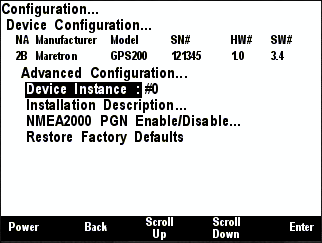

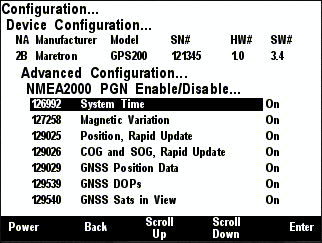

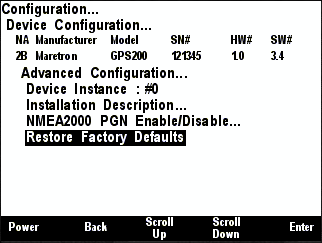

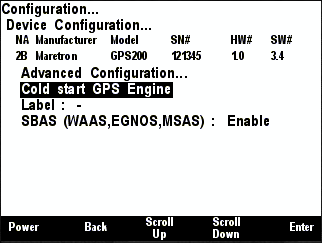

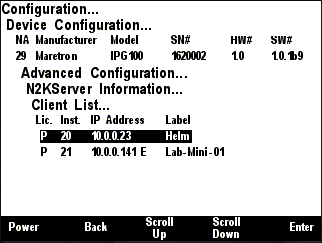

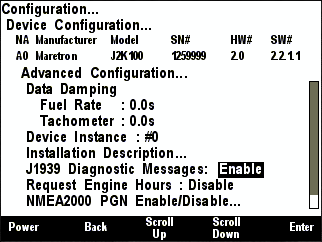

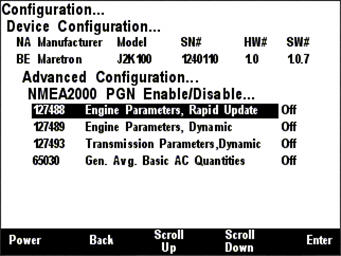

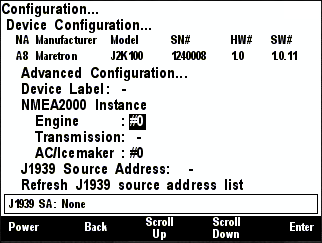

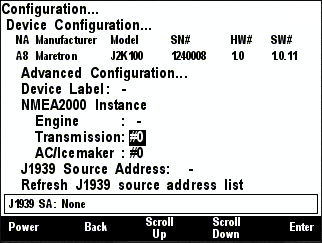

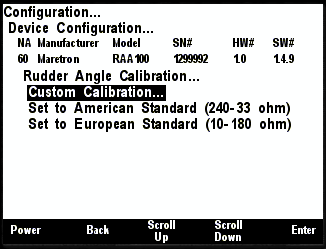

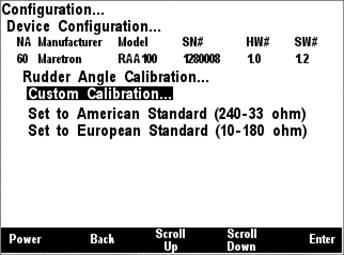

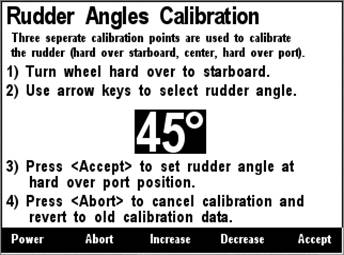

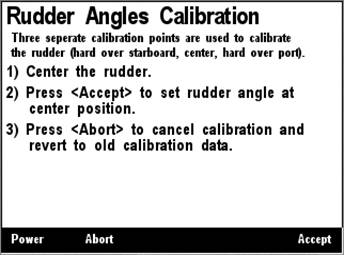

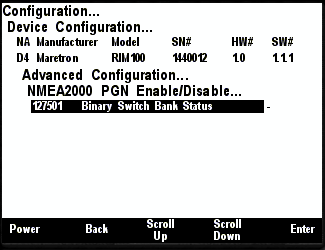

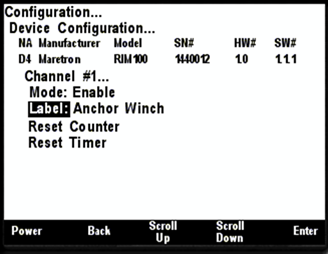

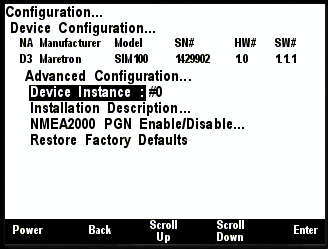

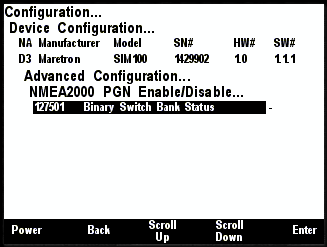

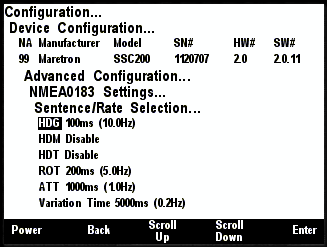

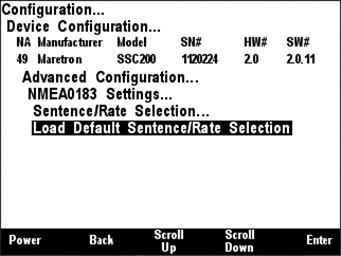

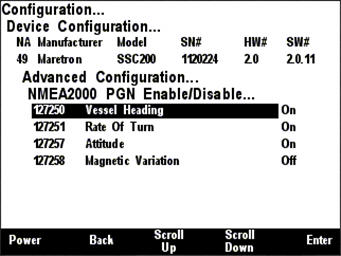

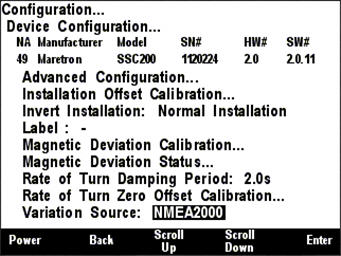

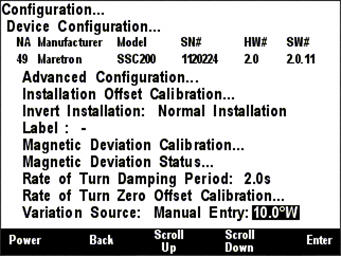

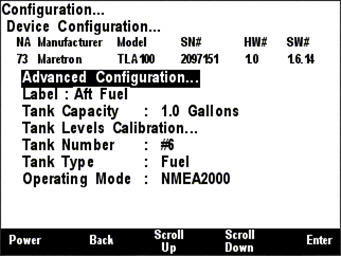

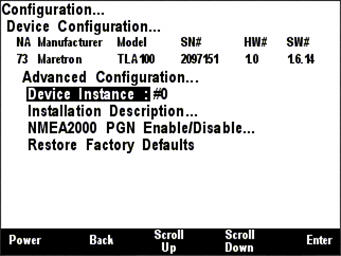

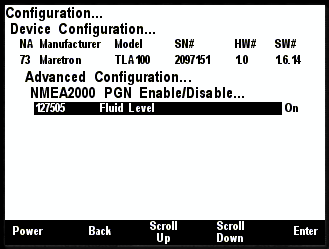

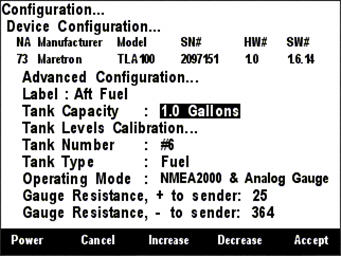

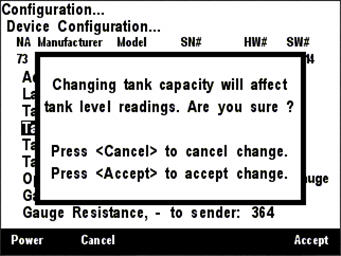

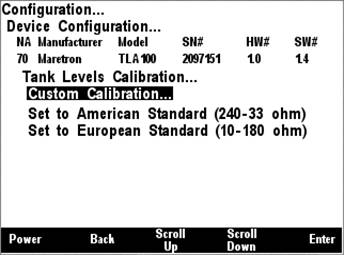

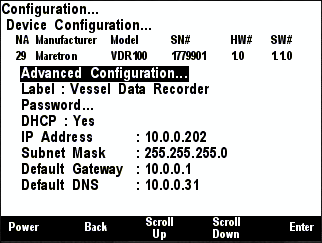

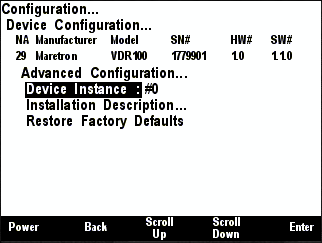

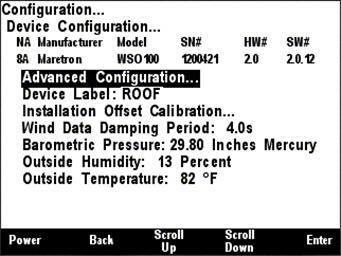

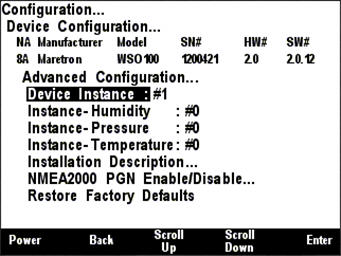

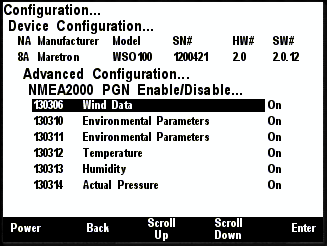

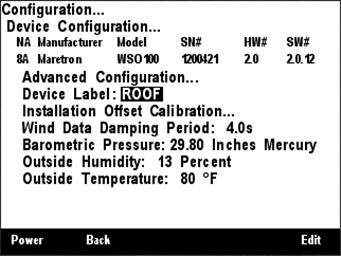

The available options within the Configuration screen are shown in Figure 8.

Figure 8 – Configuration Screen

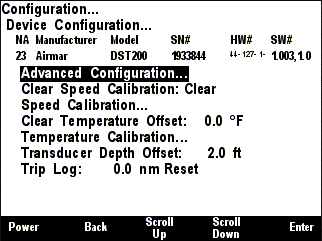

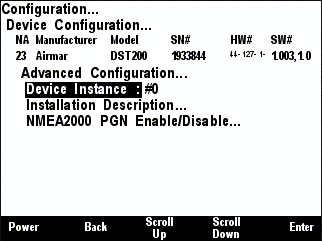

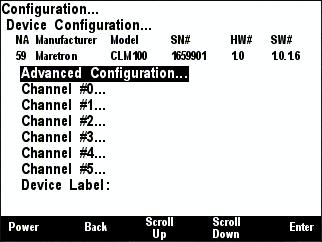

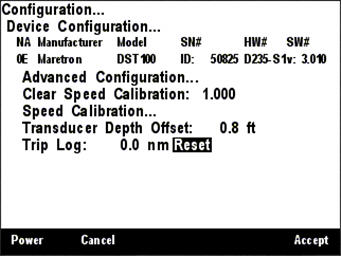

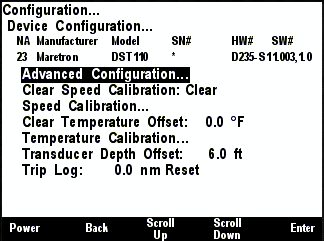

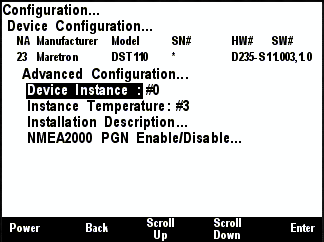

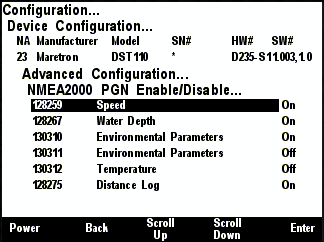

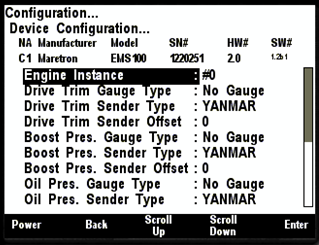

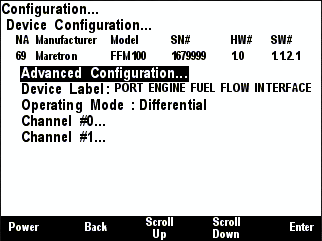

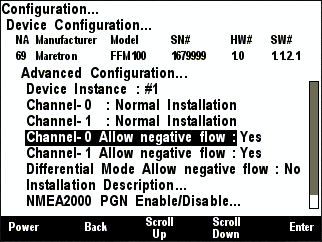

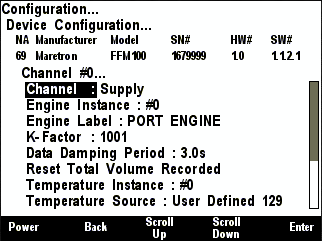

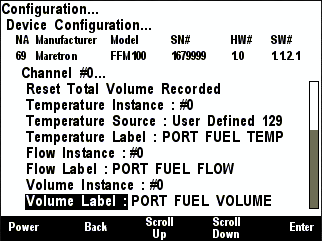

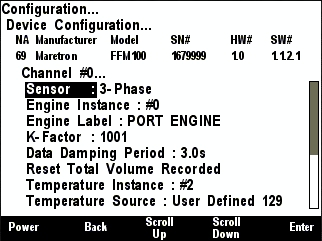

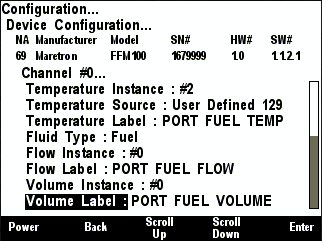

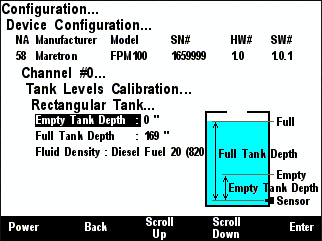

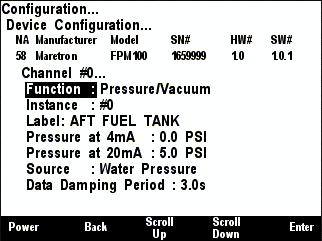

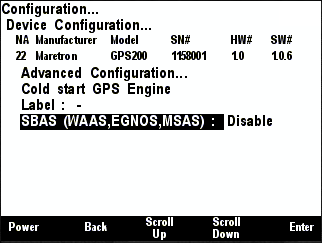

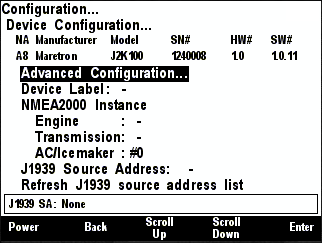

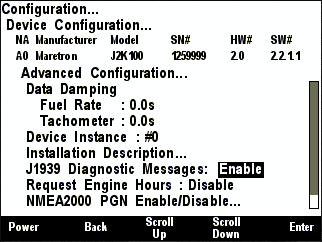

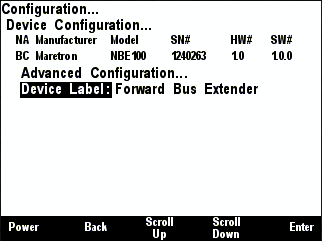

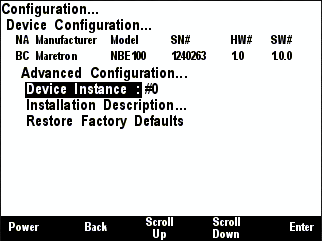

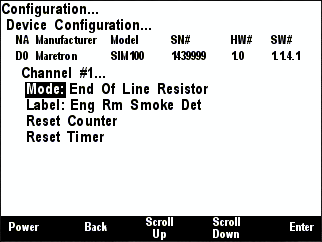

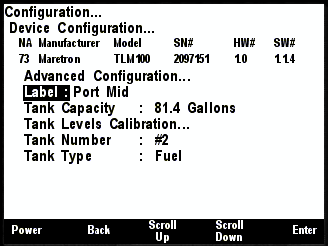

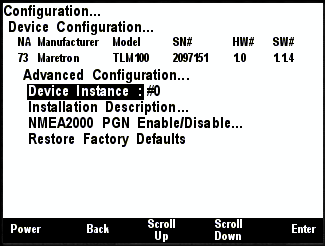

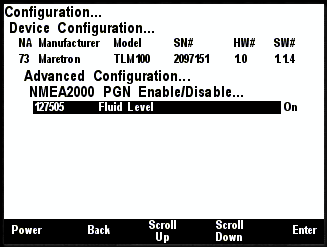

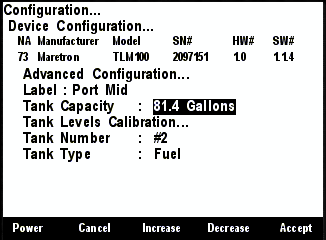

5.2.3.1 Device Configuration

The ability to calibrate and configure other devices on the bus is a major portion of this manual. For this reason it has been given an entire section. See section 6 for details.

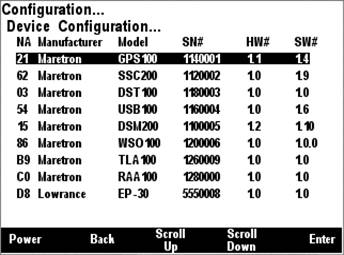

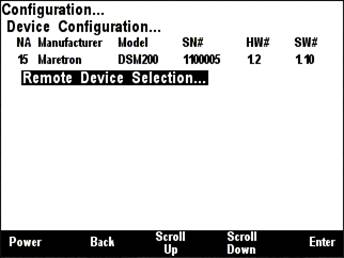

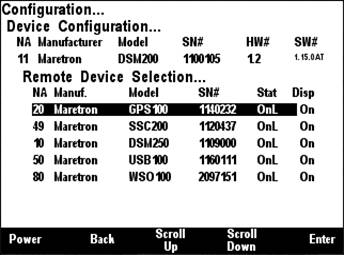

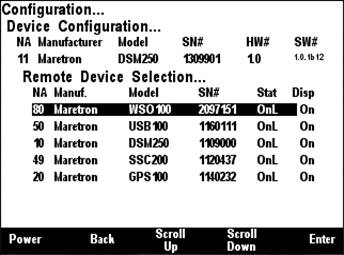

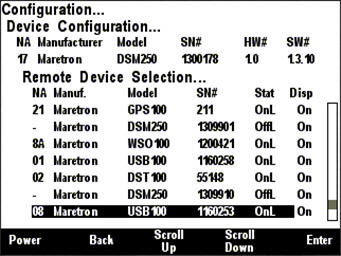

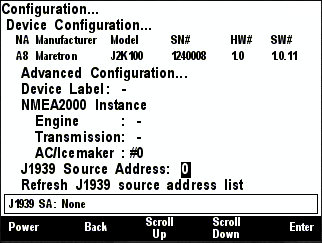

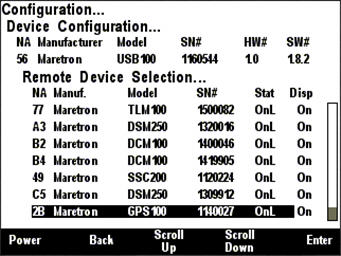

5.2.3.2 Device Selection

The “Device Selection…” menu allows you to enable and disable the display of data from individual NMEA 2000® devices. In this manner, multiple devices of the same type may be used in redundant and fail-safe configurations. A typical “Device Selection…” menu for a network configuration can be seen in Figure 9 below.

NOTE: Now that you can select instances for each displayed parameter, you do not need to configure this menu. This menu entry is retained for backward compatibility.

Figure 9 – Device Selection Screen

The “NA” column of the menu displays the node address the device is using.

The “Manufacturer” column of the menu displays the manufacturer of the device.

The “Model” column displays the model number of the device.

The “SN#” column displays the serial number of the device, so that any of two or more devices of the same manufacturer and model number may be distinguished from one another.

The “Status” column indicates whether the device is currently connected to the bus and is responding to queries (“Online”), or has been disconnected from the bus, has lost power, or for some other reason is not responding to queries (“Offline”).

The “Display” column indicates whether data from that

particular device is accepted for display by the DSM410

(“On”) or that the DSM410 ignores data transmitted by this device (“Off”). By

scrolling to the device and pressing the Enter key (![]() ), you may then use the Scroll

Up (

), you may then use the Scroll

Up (![]() )

and Scroll Down (

)

and Scroll Down (![]() ) keys to toggle the “Display”

status for this particular device. Once you are satisfied with the state of the

“Display” setting, press the Enter key (

) keys to toggle the “Display”

status for this particular device. Once you are satisfied with the state of the

“Display” setting, press the Enter key (![]() ) to accept the setting.

) to accept the setting.

The DSM410 will retain information on devices that have been removed from the bus or powered down (“Offline”) so that when they are placed back on the bus, they will assume their prior “Display” setting.

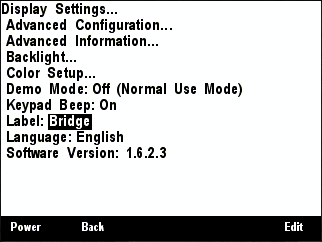

5.2.4 Display Settings Menu

The display settings menu allows you to change parameters related to display operation.

Figure 10 – DSM410 Display Settings Screen

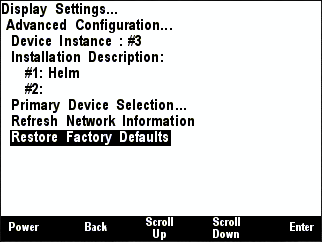

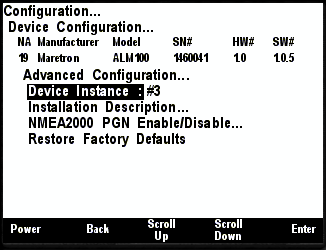

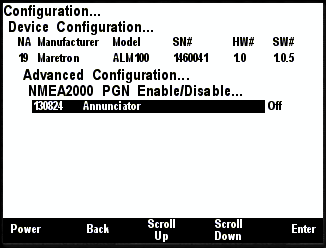

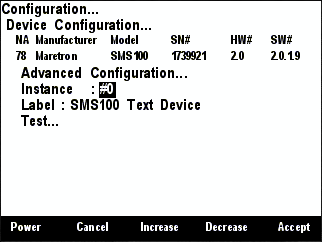

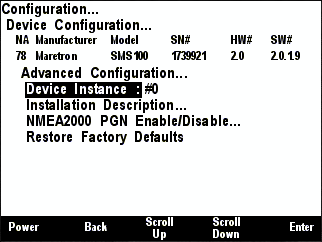

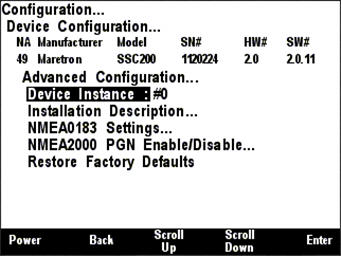

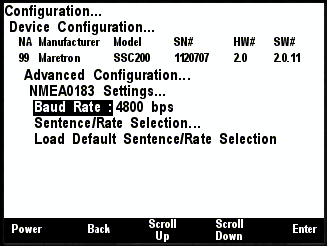

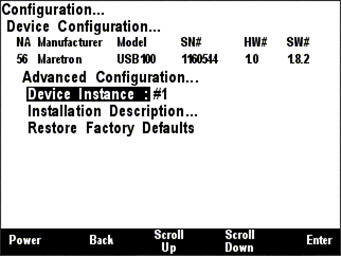

5.2.4.1 Advanced Configuration

Advanced Configuration changes some complex parameters within the device, and should only be performed by an advanced user. Typically advanced configuration is only done at installation and should not need to be done while at sea.

Figure 11 – DSM410 Advanced Configuration

5.2.4.1.1 Installation Description

This entry allows you to modify the NMEA 2000 installation description text strings. You can enter any information you like here, such as the date the unit was installed, or the location in which it was installed, for later reference. Tools such as Maretron N2KAnalyzer allow you to view these values later. See section 3.3.4 for details on how to enter a textual value.

5.2.4.1.2 Primary Device Selection

Not all the data displayed by the DSM410 can be taken directly off the NMEA 2000 bus. Some require calculations with other parameters before the desired value can be displayed. An example would be the display of ground relative wind. In this case, the wind measured by the weather station needs to be combined with the vessel heading, course over ground, and speed over ground.

The instance number of the weather station is specified for each control.

This table provides the instance numbers of the other parameters used in the calculations.

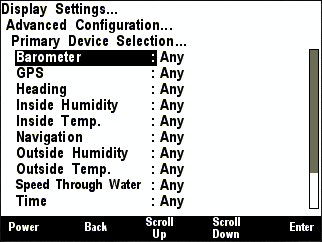

Figure 12 – DSM410 Primary Device Selection

5.2.4.1.3 Refresh Network Information

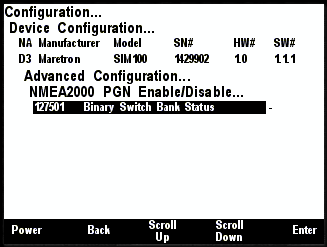

The Device Configuration (5.2.3.1) and Device Selection (5.2.3.2) menus display a list of devices that have been detected on the NMEA2000 bus. This list is kept in memory permanently to reduce the overhead of requesting device information each time one of these pages is requested.

Pressing the Enter key while this selection is highlighted will clear the list of devices. It will be necessary to perform this action to remove traces of devices that have been removed from the bus.

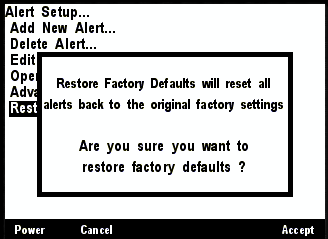

5.2.4.1.4 Restore Factory Defaults

This option restores all settings on the DSM410 device to their factory default state.

5.2.4.2 Advanced Information

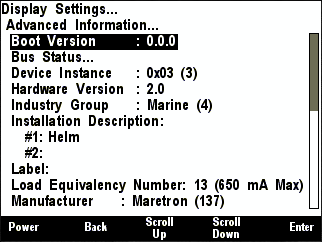

The Advanced Information Page displays information pertaining to the permanent setup and configuration of the DSM410.

Figure 13 – DSM410 Advanced Information Screen

Most of the items within the Advanced Information… menu are obvious and not described here, although a less obvious menu item (Bus Status…) is described below.

5.2.4.2.1 Bus Status

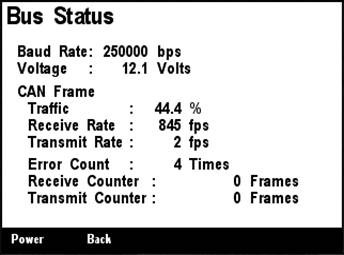

The DSM410 is capable of monitoring the NMEA 2000® network and displaying certain statistics.

Baud Rate: the speed capability of the connected network given in bits per second (bps),

Voltage: the network voltage as measured by the DSM410 in Volts,

Traffic: the percent usage of the total available bandwidth measured by the DSM410,

Receive Rate: the DSM410 measured received rate in frames per second (fps),

Transmit Rate: the DSM410 measured transmit rate in frames per second (fps),

Error Count: the DSM410 measured error frames since entering the Bus Status screen,

Receive Counter: the number of DSM410 measured received frames, and

Transmit Counter: the number of DSM410 measured transmitted frames.

Figure 14 – Bus Status Display

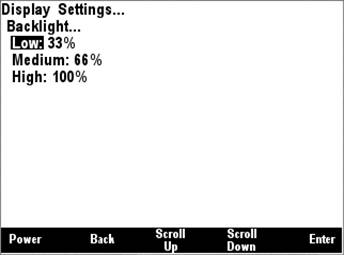

5.2.4.3 Backlight

The DSM410 has three user-programmable lighting levels which

may be cycled through using the Lights key (![]() ) on the keypad while the DSM410

is operating in favorite screens mode. Each time you quick press the Lights key

(

) on the keypad while the DSM410

is operating in favorite screens mode. Each time you quick press the Lights key

(![]() ) in favorite screens mode, the DSM410 backlight will transition between the “Low” setting, the “Medium” setting, and the

“High” setting Note that a quick press of the Lights key (

) in favorite screens mode, the DSM410 backlight will transition between the “Low” setting, the “Medium” setting, and the

“High” setting Note that a quick press of the Lights key (![]() ) changes the screen

intensity or backlight while a long press changes the color palette as

described in Section 5.2.4.4. The Backlight menu allows you to program the

“Low”, “Medium”, and “High” brightness levels. The value that appears next to

the appropriate setting is measured in percent of full brightness. The

Backlight menu can be seen in Figure 15 below.

) changes the screen

intensity or backlight while a long press changes the color palette as

described in Section 5.2.4.4. The Backlight menu allows you to program the

“Low”, “Medium”, and “High” brightness levels. The value that appears next to

the appropriate setting is measured in percent of full brightness. The

Backlight menu can be seen in Figure 15 below.

Figure 15 – Backlight Menu

5.2.4.4 Color Setup

The DSM410 has eight user-programmable color palettes. The default color palettes are as follows:

· Color Set #1 – White Back Ground, Black Foreground

· Color Set #2 – Red Back Ground, Black Foreground

· Color Set #3 – Blue Back Ground, Black Foreground

· Color Set #4 – Green Back Ground, Black Foreground

· Color Set #5 – Black Background, White Foreground

· Color Set #6 – Black Background, Red Foreground

· Color Set #7 – Black Background, Blue Foreground

· Color Set #8 – Black Background, Green Foreground

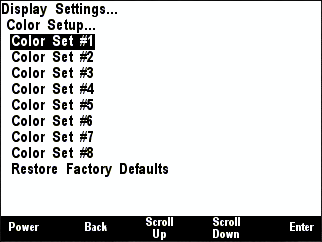

Choosing the “Color Setup…” menu item from the main “Display Settings…” menu takes you to the screen shown in Figure 16.

Figure 16 – Color Palette Selection Screen

Use the Scroll Up (![]() ) or Scroll Down (

) or Scroll Down (![]() )

keys to move the highlight to the color set that you want to change, and then

press the Enter key (

)

keys to move the highlight to the color set that you want to change, and then

press the Enter key (![]() ). Selecting “Color Set #1”

takes you to the screen shown in Figure 17.

). Selecting “Color Set #1”

takes you to the screen shown in Figure 17.

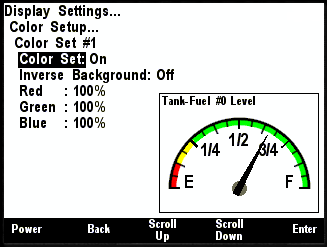

Figure 17 – Color Palette Configuration Screen

You can enable or disable Color Set #1 by changing the

“Color Set:” to “Off”. This will disable Color Set #1 while changing between

color palettes when using a long press of the Lights key (![]() )

when the DSM410 is operating in favorite screens mode. Change the “Color Set:”

back to “On” to enable this color palette.

)

when the DSM410 is operating in favorite screens mode. Change the “Color Set:”

back to “On” to enable this color palette.

Notice that Color Set #1 has a white background (100% Red,

100% Green, and 100% Blue equals white) and that the foreground color is black.

You can adjust the three different colors to achieve different color

backgrounds. Use the Scroll Up (![]() ) or Scroll Down (

) or Scroll Down (![]() )

keys to move the highlight to the color you want to change, and then press the

Enter key (

)

keys to move the highlight to the color you want to change, and then press the

Enter key (![]() ). Use the Scroll Up (

). Use the Scroll Up (![]() ) or Scroll Down (

) or Scroll Down (![]() ) keys with the percentage

number selected to change that particular color’s intensity. You can also

switch the background color to the foreground color by changing the Inverse

Background to “On”. The background will switch to black and the percentage

color settings are now used to define the foreground color.

) keys with the percentage

number selected to change that particular color’s intensity. You can also

switch the background color to the foreground color by changing the Inverse

Background to “On”. The background will switch to black and the percentage

color settings are now used to define the foreground color.

The “Restore Factory Defaults” menu selection will restore all of the color sets to their factory default states.

5.2.4.5 Demo Mode

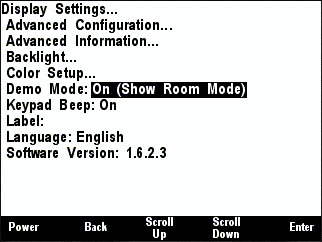

The DSM410 has a demo mode suited for displaying the capabilities of the unit. It causes the DSM410 to operate in a “simulated data” mode, where the DSM410 will install a set of pre-defined favorite screens and other configuration and will then display only the internally generated simulated data and will ignore any data arriving over the NMEA 2000® bus. While in demo mode, the DSM410 will display a “Demo” indicator in the upper right hand corner of the screen. Programming this option to “On (Show Room Mode)” or “On (Boat Show Mode, No Auto Reset)” will cause the DSM410 to enter the demo mode while programming this option for “Off (Normal Use Mode)” will cause the DSM410 to return to using data from the NMEA 2000® bus.

In order to be able to demonstrate all of the DSM410’s capabilities, the unit allows the user to setup and configure different screens while in demo mode. However, in a show room environment and five minutes after the last button push (i.e., the customer has walked away the demo unit), the DSM410 will reset itself to the default screens. There are others times where it is important that the DSM410 doesn’t automatically reset after five minutes to the default screens, for example at a boat show where it is desired to show specific screens while running in the demo mode and thus the “Boat Show Mode”.

WARNING: All data displayed in demo mode is simulated. Do not use this data for vessel monitoring or navigation purposes.

Figure 18 – Setting the Demo Mode

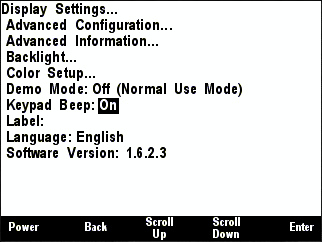

5.2.4.6 Keyboard Beep

The DSM410 has an annunciator that can be programmed to beep every time a key is pressed. Conversely, the keypad beep may be disabled if desired.

Figure 19 – Setting the Keyboard Beep Option

5.2.4.7 Label

Each DSM410 can be given a software label. Normally this label will indicate the position of the DSM410 and is used by the Alert System to identify one DSM410 from another.

Figure 20 – Editing the DSM410 Label

5.2.4.8 Language

The DSM410 currently supports two languages: English and

Dutch (Nederlands). Support for other languages is planned for future firmware

releases. To change the currently used language, use the Scroll Up (![]() ) or Scroll Down (

) or Scroll Down (![]() ) keys to move the highlight to

the “Language:” menu item, and then press the Enter key (

) keys to move the highlight to

the “Language:” menu item, and then press the Enter key (![]() ) to

move the highlight to the language selection on the right. Use the Scroll Up (

) to

move the highlight to the language selection on the right. Use the Scroll Up (![]() ) or Scroll Down (

) or Scroll Down (![]() ) keys to change the selection

to the desired value, and then press the Enter key (

) keys to change the selection

to the desired value, and then press the Enter key (![]() ) to confirm

your selection. The DSM410 will then reset itself, after which the selected

language will be used for menus and titles.

) to confirm

your selection. The DSM410 will then reset itself, after which the selected

language will be used for menus and titles.

5.2.4.9 Software Version

This field displays the version of the Firmware running in the DSM410.

5.2.5 Favorite Screens Mode

The DSM410 supports two methods of operation in favorites

mode: “Auto”, in which the DSM410 automatically cycles through all favorite

screens that have been enabled for Auto mode, and “Manual”, in which the DSM410 continues to display the currently displayed favorite screen until you press the Scroll

Up (![]() ) or Scroll Down (

) or Scroll Down (![]() )

keys, in which the DSM410 will display the next higher or lower numbered

favorite screen, respectively, that is enabled for Manual mode.

)

keys, in which the DSM410 will display the next higher or lower numbered

favorite screen, respectively, that is enabled for Manual mode.

Figure 21 – Setting the Favorite Screens Mode

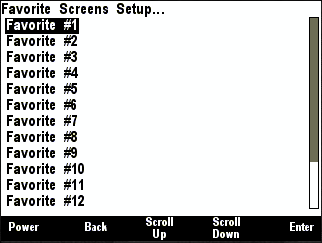

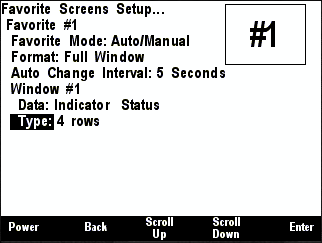

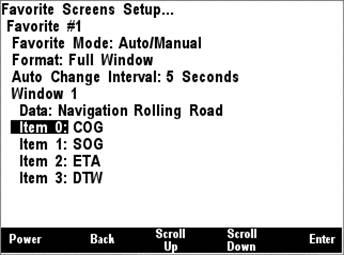

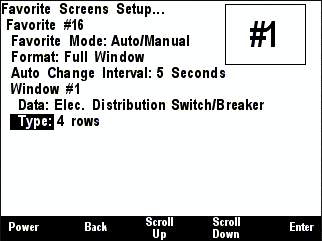

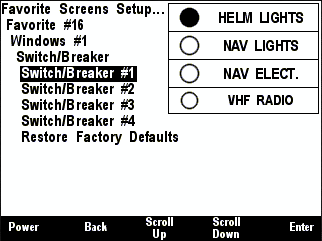

5.2.6 Favorite Screens Setup Menu

The DSM410 supports the configuration of sixteen favorite screens. The favorite setup screen allows you to select which of the sixteen favorite screens you wish to configure.

Figure 22 – Favorite Screens Setup Screen

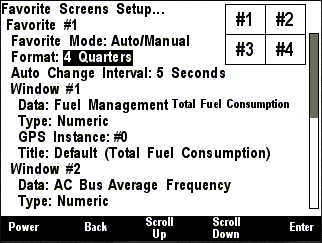

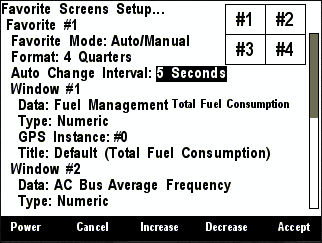

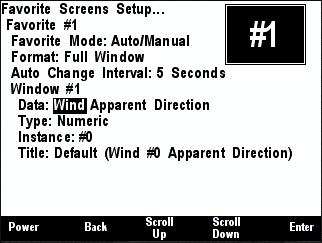

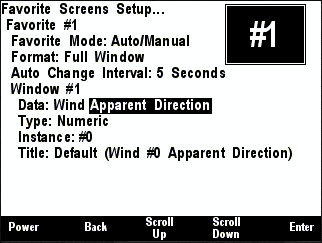

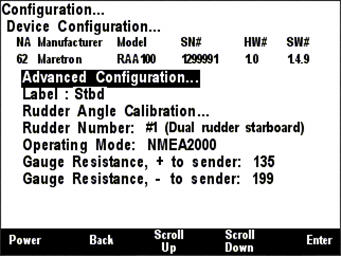

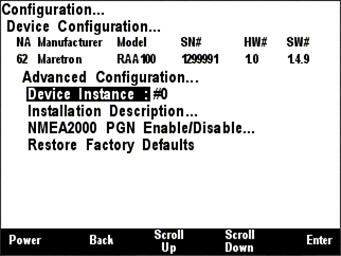

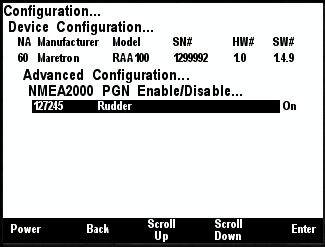

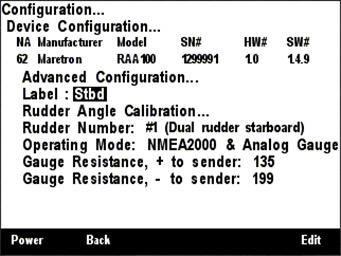

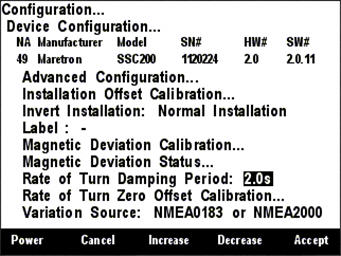

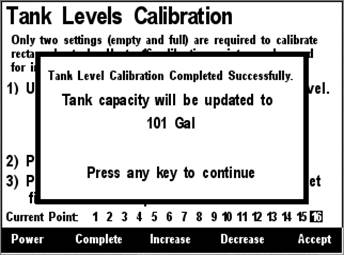

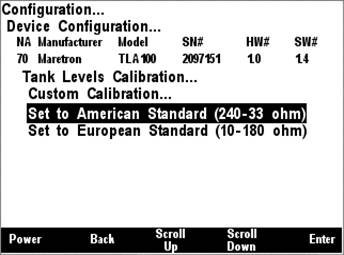

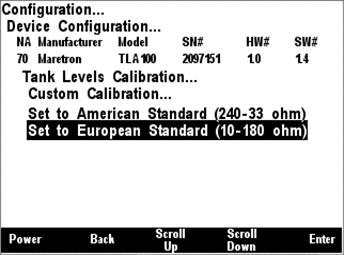

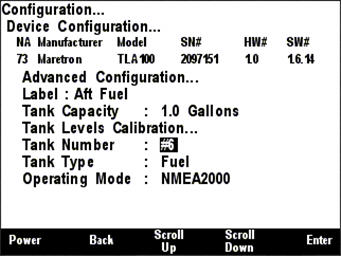

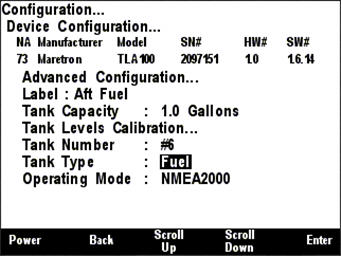

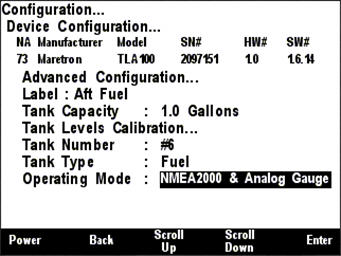

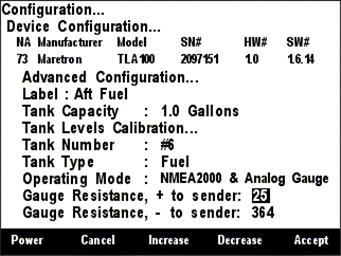

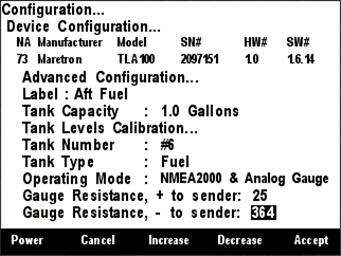

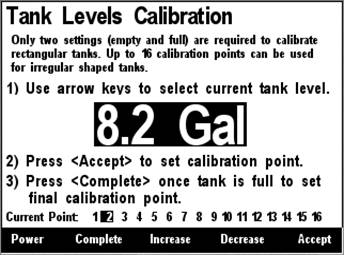

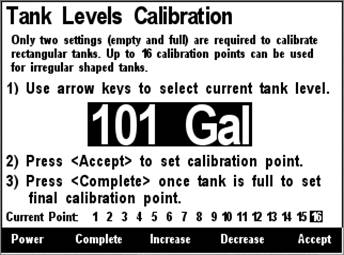

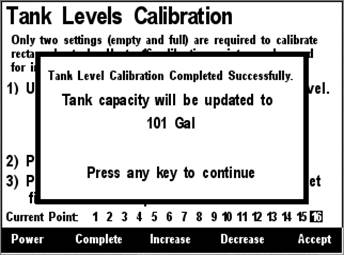

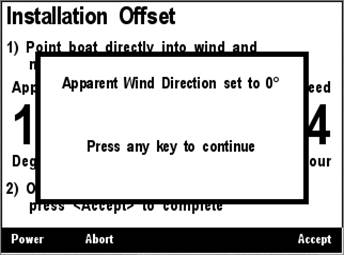

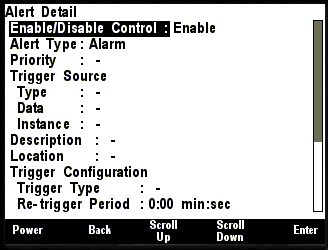

Once you have selected a favorite screen to configure, you will see the screen shown in Figure 23 . The exact format of the setup screen will depend on the format chosen.