1 General

1.1 Introduction

Congratulations on your purchase of the Maretron DSM200 NMEA 2000® Multi-function Graphic Display. Maretron has designed and built your display to the highest standards for years of dependable and accurate service.

Maretron’s DSM200 is a high-resolution monochrome display that allows easy interpretation of NMEA 2000® instrument and navigation data through custom display configurations, with an easy-to-use five-key illuminated keypad.

The Maretron DSM200 is designed to operate within the harsh demands of the

marine environment. However, no piece of marine electronic equipment can

function properly unless installed, configured, and maintained in the correct

manner. Please read carefully and follow these instructions for installation,

configuration, and usage of the Maretron DSM200 in order to ensure optimal

performance.

1.2 Firmware Revision

This manual corresponds to DSM200 firmware revision 1.13.

1.3 DSM200 Features

The Maretron DSM200 has the following features.

- NMEA 2000® Interface

- Waterproof NMEA 2000® Connector

- Sealed Waterproof Enclosure

- Powered Directly from NMEA 2000® Port

- Surface, Flush, or Gimbal Mounting

- Adjustable Red Backlighting of Screen and Keys Preserves Night Vision

- Visual and Audible Alarms

- User Configurable Favorite Screens

1.4 Quick Install

Installing the Maretron DSM200 display involves the following four steps. Please refer to the individual sections for additional details.

1. Unpack the Box (Section 2.1)

2. Choose a Mounting Location (Section 2.2)

3. Mount the DSM200 (Section 2.3)

- Connect the DSM200 (Section 2.4)

2 Installation

2.1 Unpacking the Box

When unpacking the box containing the Maretron DSM200, you should find the following items:

1 – DSM200 NMEA 2000® Multi-function Graphic Display

4 – Mounting studs

4 – Mounting washers

4 – Mounting lock washers

4 – Mounting knurled nuts

1 – DSM200 User’s Manual

1 – Warranty Registration Card

If any of these items are missing or damaged, please contact Maretron.

2.2 Choosing a Mounting Location

The DSM200 is housed in a waterproof enclosure (IEC IP67 rating – protected against the effects of temporary immersion in water) and can be mounted in either an outdoor location or an indoor location.

2.3 Mounting the DSM200

The DSM200 has three mounting options, which includes surface mounting, flush mounting, or gimbal mounting. Maretron suggests a location at which the display can be viewed from a relatively straight angle, and at which the keys are easily pressed.

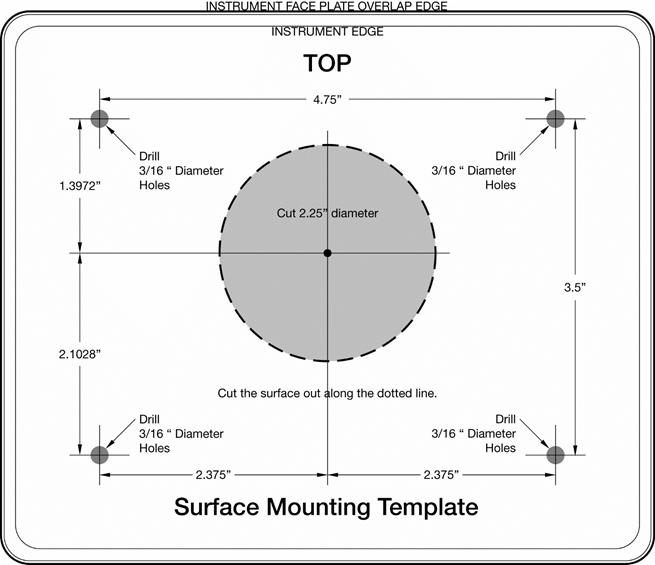

2.3.1 Surface Mounting the DSM200

The DSM200 can be directly mounted to any suitable surface as shown in Figure 1. The steps for this type of mounting are as follows:

1. Attach the Surface Mount Template (see Section 11) to the surface where the DSM200 is to be located.

a. Make sure the template is level by using one of the horizontal lines as a guide.

b. Scotch tape works well for securing the template.

c. The maximum thickness of the mounting material should not exceed 1¼” using the provided mounting studs, thicker surfaces can be accommodated but you will need to purchase longer studs.

2. Drill the four mounting holes all the way through the mounting surface at the locations indicated on the Surface Mount Template.

a. Use a 3/16” drill bit.

3. Drill or cut a single hole for the electrical connector.

a. Use a 2¼” hole saw.

b. You will probably want this hole to be large enough for your fingers so that you can connect or disconnect the cable without removing the DSM200.

4. Remove the template from the mounting surface.

5. Insert the 2” studs into the back of the DSM200.

a. Make sure the studs are fully inserted into the back of the DSM200 but don’t over tighten the studs.

6. Insert the studs protruding from the back of the DSM200 through the mounting holes and secure with the provided hardware.

a. Place the flat washer on the stud first followed by the lock washer followed by the knurled nut.

b. Hand tighten the knurled nut.

Figure 1 – Surface Mounting the DSM200

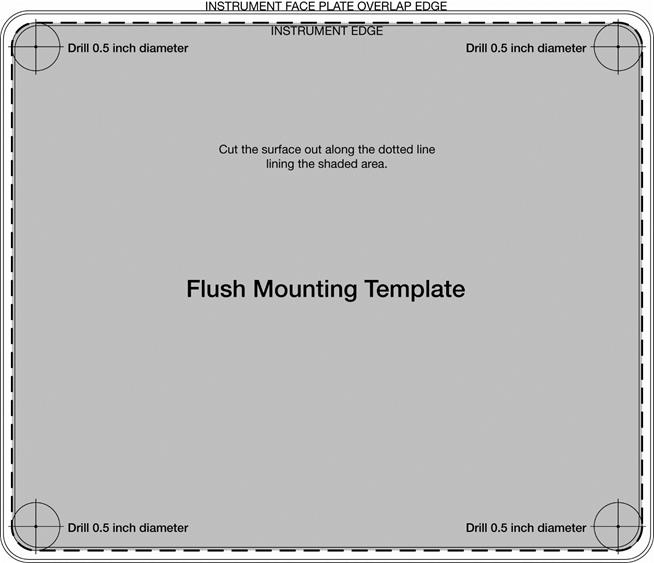

2.3.2 Flush Mounting the DSM200

The DSM200 can be flush mounted to any suitable surface as shown in Figure 2. The steps for this type of mounting are as follows:

1. Attach the Flush Mount Template (see Section 11) to the surface where the DSM200 is to be located.

a. Make sure the template is level by using one of the horizontal lines as a guide.

b. Scotch tape works well for securing the template.

c. The maximum thickness of the mounting material should not exceed 1¼” using the provided mounting studs, thicker surfaces can be accommodated but you will need to purchase longer studs.

2. Cut out an opening as indicated on the Flush Mount Template.

a. Sorry, we should have made the flange larger, but be very careful not to go outside the indicated cutout area. Be on the safe side and cut the hole a little small and rasp or file to fit.

3. Remove the template from the mounting surface.

4. Insert the 2” studs into the back of the DSM200.

a. Make sure the studs are fully inserted into the back of the DSM200 but don’t over tighten the studs.

5. Remove the back of the case from the DSM200.

a. Place your thumbs on top of the studs and your finger along the side of the case and squeeze the back cover off the DSM200.

6. Insert the back of the DSM200 through the front side of the cutout.

7. Place the back cover on the opposite side of the mounting surface with the mounting holes aligned with the mounting studs and secure with the supplied hardware.

a. Place the flat washer on the stud first followed by the lock washer followed by the knurled nut.

b. Hand tighten the knurled nut.

Figure 2 – Flush Mounting the DSM200

2.3.3 Gimbal Mounting the DSM200

The DSM200 can be gimbal mounted to any horizontal surface such a counter or ceiling as shown in Figure 3. The gimbal mounting bracket is an optional accessory that includes necessary hardware for fastening the DSM200 to the gimbal mount.

Figure 3 – Gimbal Mounting the DSM200

2.4 Connecting the DSM200

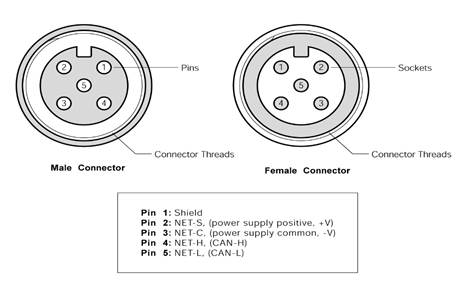

The Maretron DSM200 provides a connection to an NMEA 2000® interface through a connector that can be found on the back of the unit.

The NMEA 2000® connector is a five pin male connector (see Figure 4). You connect the DSM200 to an NMEA 2000® network using a Maretron NMEA 2000® cable (or compatible cable) by connecting the female end of the cable to the DSM200 (note the key on the male connector and keyway on the female connector). Be sure the cable is connected securely and that the collar on the cable connector is tightened firmly. Connect the other end of the cable (male) to the NMEA 2000® network in the same manner. The DSM200 is designed such that you can plug or unplug it from an NMEA 2000® network while the power to the network is connected or disconnected. Please follow recommended practices for installing NMEA 2000® network products.

Figure 4 – NMEA 2000® Connector Face View

2.4.1 Checking the Connection

Once the NMEA 2000® connection to the Maretron DSM200 has been completed, check to see that information is being properly received by observing the display. One way to verify connectivity is to enter the data selection menu, which is described in Section 5.2.2.2. Refer to Section 8, “Troubleshooting”, if no information appears.

3 Operating the DSM200

3.1 Turning the DSM200 On

To turn on the DSM200, press the

power key (the leftmost of the five keys on the keypad). The DSM200 will

display a warning and ask you to press the Accept key (![]() ) to acknowledge

the warning and continue operation of the DSM200 (see Figure 5 below).

Alternatively, you may power down the DSM200 by pressing and holding the power

key (see Section 3.2 below for details).

) to acknowledge

the warning and continue operation of the DSM200 (see Figure 5 below).

Alternatively, you may power down the DSM200 by pressing and holding the power

key (see Section 3.2 below for details).

Figure 5 – DSM200 Powerup Screen

3.2 Turning the DSM200 Off

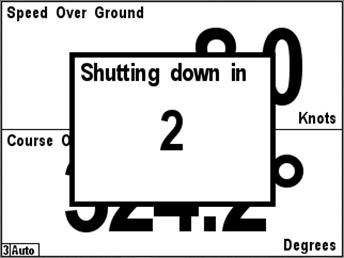

To turn the DSM200 off, press and hold the power key. The DSM200 will display a countdown screen, which can be seen in Figure 6. If you continue to hold the power key, the DSM200 will power down in approximately three seconds. If you release the power key before these three seconds have elapsed, the DSM200 will return to its current operational state.

Figure 6 – Powerdown Countdown Screen

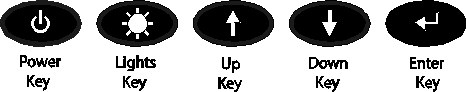

3.3 Keypad Essentials

The DSM200 has a five-key keypad located below the screen. Each key has slightly different functions depending on the operating mode. Figure 7 below shows the DSM200 keys and their names.

Figure 7 – Keypad and Key Names

In the normal viewing mode where your favorite screens are displayed, the keys on the DSM200 keypad have the following functions:

- Power

Key (![]() ) – turns the DSM200 off (see

Section 3.1 on page 7 for details).

) – turns the DSM200 off (see

Section 3.1 on page 7 for details).

- Lights

Key (![]() ) – cycles the backlight

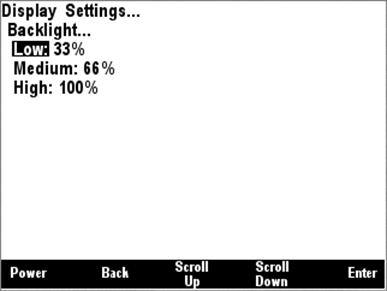

brightness between off and the three programmed brightness levels (see Section 5.2.3.1 on page 76 for details).

) – cycles the backlight

brightness between off and the three programmed brightness levels (see Section 5.2.3.1 on page 76 for details).

- Up

Key (![]() ) – switches the display from

the current favorite screen to the next highest numbered favorite screen that

is enabled for that particular mode.

) – switches the display from

the current favorite screen to the next highest numbered favorite screen that

is enabled for that particular mode.

- Down

Key (![]() ) – switches the display from

the current favorites screen to the next lowest numbered favorite screen that

is enabled for that particular mode

) – switches the display from

the current favorites screen to the next lowest numbered favorite screen that

is enabled for that particular mode

- Enter

Key (![]() ) – changes from favorite

screens mode to menu mode

) – changes from favorite

screens mode to menu mode

In menu mode, a legend appears along the bottom of the screen displaying the function of each of the keys. The functions differ slightly depending on whether a menu is being accessed, a selection is being made from a list of possible data values, or a numeric value is being increased or decreased.

When accessing a menu, the keys on the DSM200 keypad have the following functions:

- Power

Key (![]() ) – turns the DSM200 off (see

Section 3.1 on page 7 for details).

) – turns the DSM200 off (see

Section 3.1 on page 7 for details).

- Back

Key (![]() ) – returns to the next

higher-level menu. If already at the top-level menu, returns to favorite

screens mode.

) – returns to the next

higher-level menu. If already at the top-level menu, returns to favorite

screens mode.

- Scroll

Up Key (![]() ) – changes the currently

selected (or highlighted) menu item from the presently selected one to the one

immediately above it. If the top menu item is already selected, the selection

wraps to the bottom menu item.

) – changes the currently

selected (or highlighted) menu item from the presently selected one to the one

immediately above it. If the top menu item is already selected, the selection

wraps to the bottom menu item.

- Scroll

Down Key (![]() ) – changes the currently

selected (or highlighted) menu item from the presently selected one to the one

immediately below it. If the bottom menu item is already selected, the

selection wraps to the top menu item.

) – changes the currently

selected (or highlighted) menu item from the presently selected one to the one

immediately below it. If the bottom menu item is already selected, the

selection wraps to the top menu item.

- Enter

Key (![]() ) – if the currently selected

menu item has a submenu, opens that submenu. If the currently selected menu

item has an editable value (indicated by a colon (:) followed by the data

value, moves the selection to the editable value and changes the keys to edit

mode.

) – if the currently selected

menu item has a submenu, opens that submenu. If the currently selected menu

item has an editable value (indicated by a colon (:) followed by the data

value, moves the selection to the editable value and changes the keys to edit

mode.

When editing a value chosen from a list, the keys on the DSM200 keypad have the following functions:

- Power

Key (![]() ) – turns the DSM200 off (see

Section 3.1 on page 7 for details).

) – turns the DSM200 off (see

Section 3.1 on page 7 for details).

- Back

Key (![]() ) – aborts the edit and

restores the editable value to its previous value

) – aborts the edit and

restores the editable value to its previous value

- Scroll

Up Key (![]() ) – changes the currently

selected editable value from the presently selected one to the one immediately

above it in the list of possibilities. If the top menu item is already

selected, the selection wraps to the bottom menu item.

) – changes the currently

selected editable value from the presently selected one to the one immediately

above it in the list of possibilities. If the top menu item is already

selected, the selection wraps to the bottom menu item.

- Scroll

Down Key (![]() ) – changes the currently

selected editable value from the presently selected one to the one immediately

below it in the list of possibilities. If the bottom menu item is already

selected, the selection wraps to the top menu item.

) – changes the currently

selected editable value from the presently selected one to the one immediately

below it in the list of possibilities. If the bottom menu item is already

selected, the selection wraps to the top menu item.

- Enter

Key (![]() ) – Accepts the currently

displayed value and stores it.

) – Accepts the currently

displayed value and stores it.

When editing a numeric value, the keys on the DSM200 keypad have the following functions:

- Power

Key (![]() ) – turns the DSM200 off (see

Section 3.1 on page 7 for details).

) – turns the DSM200 off (see

Section 3.1 on page 7 for details).

- Cancel

Key (![]() ) – aborts the edit and

restores the editable value to its previous value

) – aborts the edit and

restores the editable value to its previous value

- Increase

Key (![]() ) – increases the editable

value

) – increases the editable

value

- Decrease

Key (![]() ) – decreases the editable

value

) – decreases the editable

value

- Accept

Key (![]() ) – Accepts the currently

displayed value and stores it,

) – Accepts the currently

displayed value and stores it,

4 Important Concepts

4.1 Favorite Screens

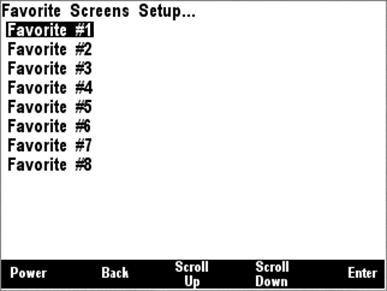

The DSM200 can display many different types of information in many different configurations. It is capable of displaying up to four distinct measurements on its screen at one time. Rather than making you select from among the many types of available information any time you want to change the displayed data, the DSM200 has the concept of “Favorite Screens”. A “Favorite Screen” is a combination of display settings, data to display, and formats in which to display the data. The DSM200 supports up to 8 different favorite screens.

4.2 Categories and Data Types

The DSM200 is capable of displaying many types of information. In order to make it easier to locate a specific type of information to display, the different types of information are organized into general categories:

1. AC Power

2. Battery

3. Depth

4. Engine

5. Environment

6. Fuel Management

7. GPS

8. Heading

9. Navigation

10. Rudder

11. Speed

12. Tank

13. Time

14. Transmission

15. Vessel

16. Wind

The following sections explore each category in detail and spell out all of the data types that are available for display, if the appropriate sensors are installed in the network.

4.2.1 AC Power

- Gen. AC Current – displays the electrical current being sourced from a generator

- Gen. AC Frequency – displays the frequency of the AC power from a generator

- Gen. AC Voltage – displays the RMS voltage of the AC power from a generator

4.2.2 Battery

The DSM200 supports the display of information for up to sixteen batteries.

- Current – displays the electrical current being sourced to/from the battery

- Voltage – displays the voltage measured at the battery

- Temp. – displays the battery case temperature

4.2.3 Depth

- Transducer Offset – displays the offset being used by a depth transducer

- Water – displays the current reading from a depth transducer

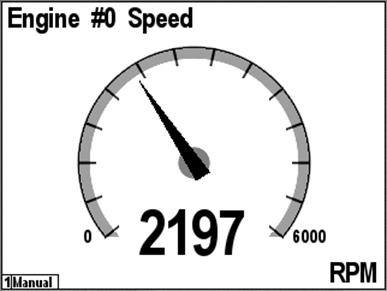

4.2.4 Engine

The DSM200 supports the display of information for up to four engines.

- Boost Pressure – displays the boost pressure of a supercharger or turbocharger

- Engine Hours – displays the number of hours of operation reported by the engine

- Fuel Pressure – displays the pressure of the fuel for the engine

- Fuel Rate – displays the rate of fuel consumption for the engine

- Oil Pressure – displays the engine’s oil pressure

- Oil Temp – displays the engine’s oil temperature

- Tachometer – displays the rotational speed of the engine

- Tilt/Trim – displays the tilt or trim of the drive

- Voltage – displays the electrical power supply voltage measured at the engine

- Water Pressure – displays the engine’s water pressure

- Water Temp – displays the engine’s water temperature

4.2.5 Environment

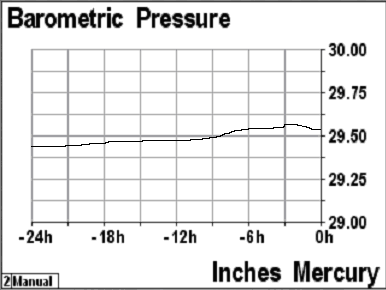

- Barometer – displays the current atmospheric (barometric) pressure

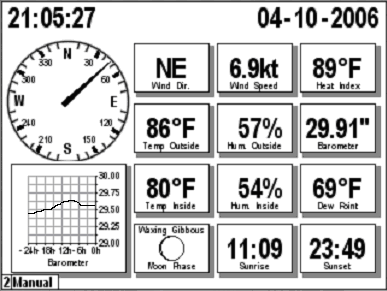

- Heat Index – displays the current heat index based on air temperature and humidity

- Humidity Inside – displays the relative humidity from an indoor humidity sensor

- Humidity Outside – displays the relative humidity for an outdoor humidity sensor

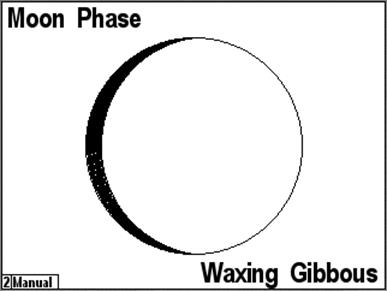

- Moon Phase – displays the phase of the moon at the current time and position

- Sunrise – displays the local time of sunrise for the current day and position

- Sunset – displays the local time of sunset for the current day and position

- Temp. Dew Point – displays the current dew point based on air temperature and humidity

- Temp. Engine Room – displays the air temperature from a sensor mounted in an engine room

- Temp. Inside – displays the air temperature from a sensor mounted inside the vessel

- Temp. Main Cabin – displays the air temperature from a sensor mounted inside the main cabin

- Temp. Outside – displays the air temperature from a sensor mounted outside

- Temp. Sea – displays the current temperature of the water

- Twilight AM – displays the time of nautical twilight before sunrise for the current day and position

- Twilight PM – displays the time of nautical twilight after sunset for the current day and position

- Weather – displays a screen with a wide variety of weather-related data (See Section 6.7 for details)

- Wind Chill – displays the current wind chill based on air temperature and wind speed

4.2.6 Fuel Management

- Total Fuel Economy – displays the distance traveled per unit fuel used (for example, miles per gallon or kilometers per liter) for all engines whose data has been enabled in the Configuration->Data Enable menu (see Section 5.2.2.1.1 for details)

- Total Fuel Rate – displays the rate of fuel usage per unit time (for example, gallons or liters per hour) for all engines whose data has been enabled in the Configuration->Data Enable menu

- Total Fuel Remaining – displays the total fuel remaining in all fuel tanks whose data has been enabled in the Configuration->Data Enable/Disable menu

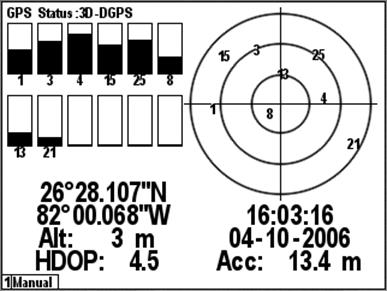

4.2.7 GPS

- Course Over Ground – displays the current Course Over Ground (always referenced to true north)

- Lat/Lon – displays the current latitude and longitude of the vessel

- Speed Over Ground – displays the current speed over ground

- Status – displays the current operating mode and status of the currently selected GPS receiver (please see Section 6.3, “GPS Status Display”, on page 89 for more details)

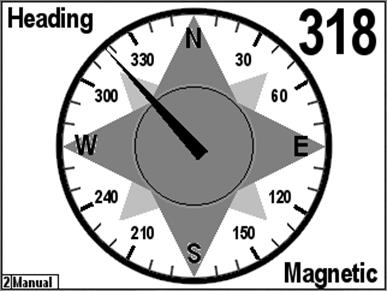

4.2.8 Heading

- Magnetic/True (depending on Heading Units Setting) – displays the current heading of the vessel (the direction the vessel is pointing)

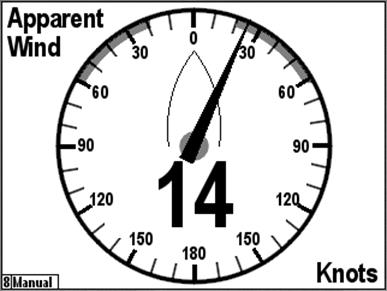

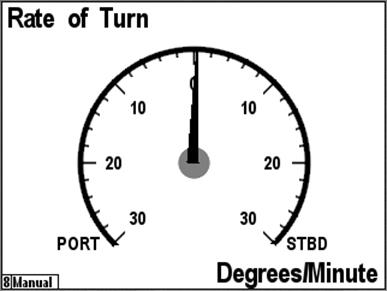

- Rate of Turn – displays the angular rate of rotation of the vessel about the vertical axis

- Variation – displays the magnetic variation used to convert between true and magnetic headings

4.2.9 Navigation

The DSM200 is not a primary navigation device; that is, it does not provide means for entering and storing waypoint and route data. The DSM200 can receive information on the current leg of the voyage from a primary navigation device (such as a chart plotter or PC with navigation software and NMEA 2000® interface) and display this information.

- Bearing Origin to Destination – displays the direction from the origin waypoint to the destination waypoint

- Bearing To Waypoint – displays the bearing to the destination waypoint

- Course Over Ground – displays the current Course Over Ground (always referenced to true north)

- Cross Track Error – displays the cross-track error (minimum distance from the boat to the programmed route)

- Distance To Waypoint – displays the distance to the destination waypoint

- Est. Time of Arrival – displays the Estimated Time of Arrival at the waypoint

- Lat/Lon – displays the current latitude and longitude of the vessel

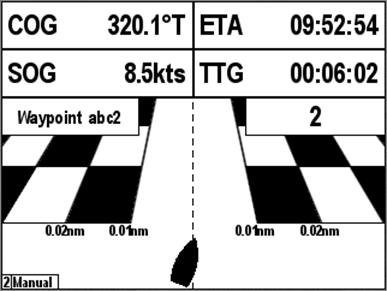

- Rolling Road – displays navigation information for the current leg of the route (see Section 6.5, ”Rolling Road”, on page 91 for details)

- Set/Drift – displays the direction (set) and speed (drift) of the water current

- Speed Over Ground – displays current Speed over Ground (relative to the earth, not the water)

- Time To Go – displays the estimated Time To Go until arrival at the waypoint

- VMG to Waypoint – displays the Velocity Made Good; that is, the speed at which the distance to the waypoint is decreasing

- Waypoint Number – this displays the number of the destination waypoint

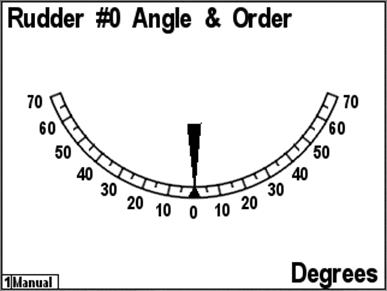

4.2.10 Rudder

- Rudder Angle – displays the angle of the vessel’s rudder as indicated by the rudder sensor

4.2.11 Speed

- Through Water – displays the speed of the boat relative to the water

- Over Ground - displays Speed over Ground (relative to the earth, not the water)

- Total Log – displays the total distance traveled by the vessel since the log indicator was installed

- Trip Log – displays the distance traveled by the vessel since the trip indication of the log indicator was last reset

4.2.12 Tank

The DSM200 supports the display of information for up to sixteen tanks.

- Capacity – displays the fluid capacity of the tank

- Level – displays the level of fluid in the tank as a percentage of its capacity

- Remaining – displays the amount of fluid in the tank

4.2.13 Time

- Date Local – displays the current date referenced to the local time offset

- Date UTC – displays the current date referenced to Universal Time Coordinated

- Moon Phase – displays the phase of the moon at the current time and position

- Sunrise – displays the local time of sunrise for the current day and position

- Sunset – displays the local time of sunset for the current day and position

- Time Local – displays the current time referenced to the local time offset (see Section 5.2.6.11 on page 87 for details on how to set the local time offset.

- Time UTC – displays the current time referenced to Universal Time Coordinated (also known as Greenwich Mean Time, or GMT)

- Twilight AM – displays the time of nautical twilight before sunrise for the current day and position

- Twilight PM – displays the time of nautical twilight after sunset for the current day and position

-

4.2.14 Transmission

The DSM200 supports the display of information for up to four transmissions,

- Gear – displays the current gear of the transmission (forward, neutral, or reverse)

- Oil Pressure – displays the pressure of the oil in the transmission

- Oil Temp. – displays the temperature of the oil in the transmission

4.2.15 Vessel

- Pitch – displays the pitch of the vessel (rotation about the horizontal axis perpendicular to the ship’s keel)

- Roll – displays the roll of the vessel (rotation about the horizontal axis parallel to the ship’s keel)

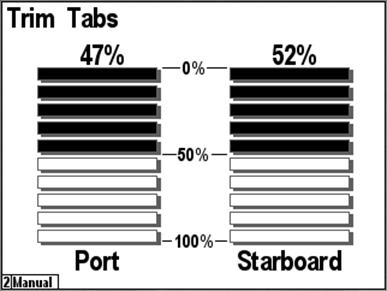

- Trim Tabs – displays the position of the vessel’s trim tabs

4.2.16 Wind

- Dir. Apparent – displays the angle of the wind relative to the vessel center line as it appears to an observer on the deck of a moving or stationary vessel (does not subtract out the speed of the vessel)

- Dir. Ground Ref. – displays the angle of the wind relative to true or magnetic north (depending on the unit setting of the heading parameter, see Section 5.2.6.1) measured relative to a stationary observer, calculated using heading, course over ground (COG), and speed over ground (SOG)

- Dir. True Ves. Ref – displays the angle of the wind relative to the vessel center line (vessel’s speed is subtracted from Apparent wind direction), calculated using speed through water (STW) or speed over ground (SOG) (depending on the unit setting of the “Wind True Ves. Ref.” Parameter, see Section 5.2.6.4)

- Speed Apparent – displays the speed of the wind as it appears to an observer on the deck of a moving or stationary vessel (does not subtract out the speed of the vessel)

- Speed Ground Ref. – displays the speed of the wind relative to a stationary observer, calculated using heading, course over ground (COG), and speed over ground (SOG)

- Speed True Ves. Ref – displays the speed of the wind as it would appear to an observer if the vessel was stopped in the water, calculated using speed through water (STW) or speed over ground (SOG) (depending on the unit setting of the “Wind True Ves. Ref.” Parameter, see Section 5.2.6.5)

5 Operating Modes

The DSM200 has two main operating modes including normal viewing of information in the favorite screens mode (Section 5.1) and the menu mode (Section 5.2).

5.1 Favorite screens modes

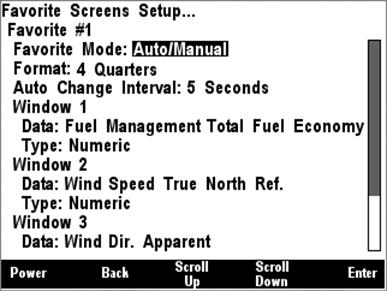

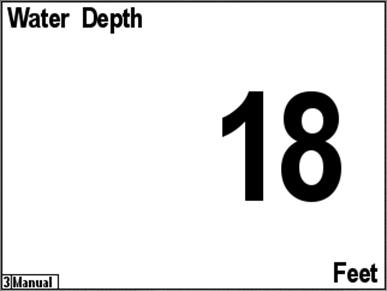

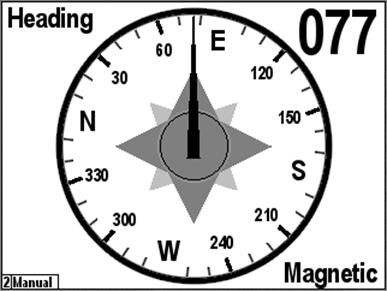

On power up, the DSM200 always enters the favorite screens mode. In the favorite screens modes, the DSM200 displays one of up to eight “favorite” screens. Each “favorite” screen can display one, two, three, or four information displays. Each information display can show any displayable data in any display type supported by that data. In favorite screens mode, the DSM200 can operate in one of two ways:

1) in Manual mode, in which a particular “favorite” screen remains on the display until you selects another one, or

2) in Auto mode, where the DSM200 automatically cycles between “favorite” screens, at time intervals which are individually programmable for each “favorite” screen.

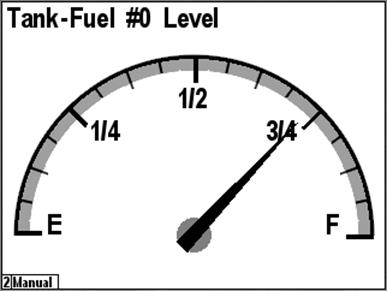

An example screen of the DSM200 running in favorite screens mode can be seen in Figure 8 below.

Figure 8 – DSM200 Running in Favorite Screens Mode

The very bottom left hand corner of the screen shows two important parameters: 1) it indicates which favorite screen is being displayed (in this case Favorite #5), and 2) it indicates that the DSM200 is currently operating in the Manual mode. Auto would appear in place of Manual if the DSM200 was operating in Auto mode.

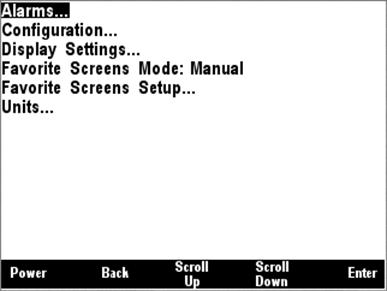

5.2 Menu Mode

The menu mode is entered while

viewing favorite screens by pressing the Enter key (![]() ). In menu

mode, the DSM200 may be configured by scrolling up and down the menu and

selecting one of the submenus found there. The DSM200 main menu can be seen in Figure 9 below.

). In menu

mode, the DSM200 may be configured by scrolling up and down the menu and

selecting one of the submenus found there. The DSM200 main menu can be seen in Figure 9 below.

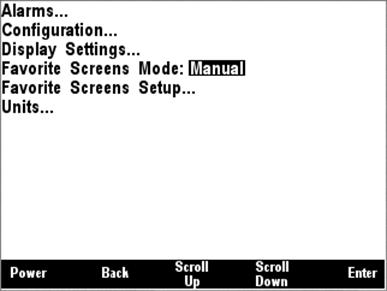

Figure 9 – Main Menu

5.2.1 Alarms Menu

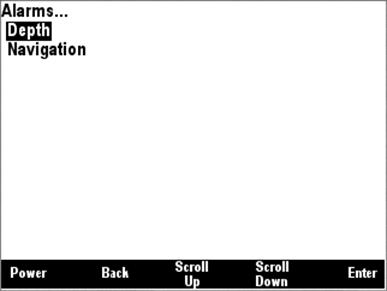

Selecting Alarms from the main menu takes you to the Alarms menu shown below in Figure 10.

Figure 10 – Alarms Menu

The alarms menu allows you to configure the DSM200 to notify you if parameter values are outside of a range you specify. The following alarms are available in the DSM200:

Depth

Min Depth (minimum water depth)

Max Depth (maximum water depth)

Navigation

Max XTE (maximum cross-track error – this also sets the cross-track error limit used in the rolling road display – See Section 6.5, ”Rolling Road”, on page 91 for details)

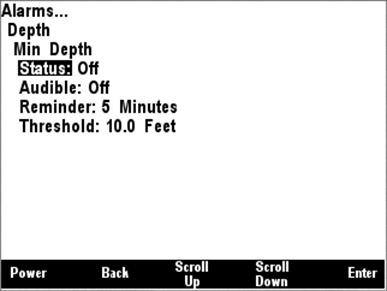

You can enable or disable an alarm, select whether it is audible, program a reminder time for the alarm, and set the parameter value limits for the alarm as shown in Figure 11.

Figure 11 – Alarms Settings Menu

If the “Status” setting for the

alarm is “Off”, then that alarm is disabled. If the “Status” setting is “On”,

then the DSM200 display will monitor the value of the parameter and will

indicate an alarm condition if the parameter is less than (for “Min” alarms) or

greater than (for “Max” alarms) the value specified into the “Threshold”

field. You can adjust the “Status” setting by moving the highlight to the

“Status:” field by pressing the Scroll Up (![]() ) or Scroll

Down (

) or Scroll

Down (![]() ) keys, and then pressing the

Enter Key (

) keys, and then pressing the

Enter Key (![]() ). Once you have done this,

the highlight moves from the “Status:” title to the “On” or “Off” indication.

Press the Increase (

). Once you have done this,

the highlight moves from the “Status:” title to the “On” or “Off” indication.

Press the Increase (![]() ) or Decrease (

) or Decrease (![]() ) keys to cause the indication to change to the desired value, and

then press the Accept key (

) keys to cause the indication to change to the desired value, and

then press the Accept key (![]() ) to cause the current value

to be stored.

) to cause the current value

to be stored.

If the “Audible” setting for an

alarm is “On” and the “Status” is also set to “On”, then the DSM200 will beep

continuously from the time the alarm condition is triggered until the user

acknowledges the alarm. You may adjust this setting by scrolling to the

“Audible:” title, pressing the Enter key (![]() ), pressing

the Increase (

), pressing

the Increase (![]() ) and Decrease (

) and Decrease (![]() ) keys to adjust the setting to the desired value, and then pressing

the Accept key (

) keys to adjust the setting to the desired value, and then pressing

the Accept key (![]() ) to cause the current value

to be stored.

) to cause the current value

to be stored.

Once you acknowledge an alarm by

pressing the “Dismiss” key, the DSM200 will stop checking the alarm condition

for the time specified by the “Reminder” setting to allow you time to address

and correct the alarm condition. If the “Reminder” field is set to “0

Minutes”, then the DSM200 will always check the alarm, which means that the

alarm might be re-triggered immediately after it is acknowledged by the user.

The range of values for the “Reminder” setting is between 0 minutes and 60

minutes. You may adjust this setting by scrolling to the “Reminder:” title,

pressing the Enter key (![]() ), pressing the Increase (

), pressing the Increase (![]() ) and Decrease (

) and Decrease (![]() ) keys to adjust the setting

to the desired value, and then pressing the Accept key to cause the current

value to be stored.

) keys to adjust the setting

to the desired value, and then pressing the Accept key to cause the current

value to be stored.

The “Threshold” field determines

the alarm value that is used as the point at which the alarm is triggered. For

“Min” alarms, if the monitored parameter value is less than the value of the

“Threshold” setting, then the alarm will be triggered. For “Max” alarms, if the

monitored parameter value is greater than the value of the “Threshold” setting,

then the alarm will be triggered. The range of acceptable parameters for this

setting depends on the parameter being monitored. You may adjust this setting

by scrolling to the “Threshold:” title, pressing the Enter key (![]() ), pressing the Increase (

), pressing the Increase (![]() ) and Decrease (

) and Decrease (![]() ) keys to adjust the setting to the desired value, and then pressing

the Accept key (

) keys to adjust the setting to the desired value, and then pressing

the Accept key (![]() ) to cause the current value

to be stored.

) to cause the current value

to be stored.

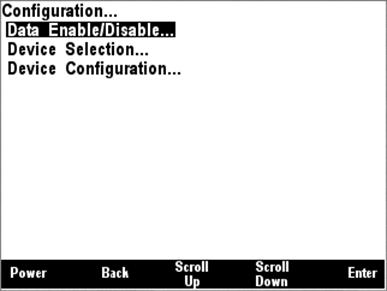

5.2.2 Configuration Menu

The configuration menu allows you to change the types of data that are displayed, as well as which NMEA 2000® nodes are displayed. The configuration menu also allows you to configure certain types of Maretron NMEA 2000® devices. The available options within the Configuration screen are shown in Figure 12.

Figure 12 – Configuration Menu

5.2.2.1 Data Enable/Disable

The Data Enable/Disable allows you to configure whether or not certain categories of information appear in other menus. This allows you to configure the DSM200 so that information that is not available on the network does not clutter the operating menus. For example, in a vessel without a wind sensor, it is often desirable to disable display of the “Wind” data types when configuring favorite screens. Figure 13 shows the Data Enable/Disable menu.

Figure 13 – Data Enable/Disable Menu

5.2.2.1.1 Fuel Management Considerations

In order to use the fuel management features of the DSM200, it is important to understand how total fuel rate, total fuel economy and total fuel remaining are calculated.

The total fuel rate is calculated by adding together the fuel rates of all engines that have been enabled in the Data Enable/Disable menu. If any engine has been enabled in the Data Enable/Disable menu and it is not present or is not transmitting any data, then the DSM200 will not calculate the total fuel rate. If you notice that the DSM200 is not displaying a figure for the total fuel rate, check that all engines which have been enabled in the Data Enable/Disable menu are present and powered on.

The fuel economy is calculated by dividing the speed of the vessel, obtained from the GPS speed over ground, by the total fuel rate.

The total fuel remaining is calculated by adding the fuel remaining readings from all tanks of type “fuel” that have been enabled in the Data Enable/Disable menu. If any fuel tank that has been enabled in the Data Enable/Disable menu is not present or is not transmitting any data, then the DSM200 will not calculate the total fuel remaining. If you notice that the DSM200 is not displaying a figure for the total fuel remaining, check that all fuel tanks which have been enabled in the Data Enable/Disable menu are present and powered on.

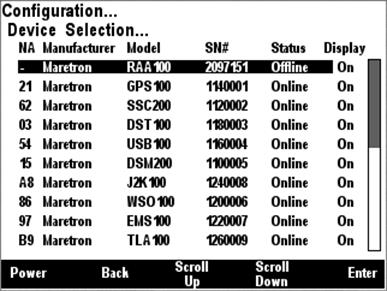

5.2.2.2 Device Selection

The Device Selection menu allows you to select which NMEA 2000® devices are displayed on the DSM200. In this manner, multiple devices of the same type may be used in redundant and fail-safe configurations. The DSM200 Device Selection Menu for an example network configuration can be seen in Figure 14 below.

WARNING: Do not select multiple devices of the same type for display. This will result in multiple and possibly conflicting readings.

Figure 14 – Device Selection Menu

The “NA” column of the menu displays the node address the device is using.

The “Manufacturer” column of the menu displays the manufacturer of the device.

The “Model” column displays the model number of the device.

The “SN#” column displays the serial number of the device, so that any of two or more devices of the same manufacturer and model number may be distinguished from one another.

The “Status” column indicates whether the device is currently connected to the bus and is responding to queries (“Online”), or has been disconnected from the bus, has lost power, or for some other reason is not responding to queries (“Offline”).

The “Display” column

indicates whether data from that particular device is accepted for display by

the DSM200 (“On”) or that the DSM200 ignores data transmitted by this device

(“Off”). By scrolling to the device and pressing the Enter key (![]() ), you may then use the Scroll Up (

), you may then use the Scroll Up (![]() ) and Scroll

Down (

) and Scroll

Down (![]() ) keys to toggle the “Display”

status for this particular device. Once you are satisfied with the state of the

“Display” setting, press the Enter key (

) keys to toggle the “Display”

status for this particular device. Once you are satisfied with the state of the

“Display” setting, press the Enter key (![]() ) to accept

the setting.

) to accept

the setting.

The DSM200 will retain information on devices that have been removed from the bus or powered down (“Offline”) so that when they are placed back on the bus, they will assume their prior “Display” setting.

The DSM200 will automatically select (turn “On”) any new devices that it detects transmitting on the network. Therefore, if you add a new device to the network that transmits the same data as an existing network device, for example, a second GPS, then you must enter the Device Selection Menu and deselect one of the two devices.

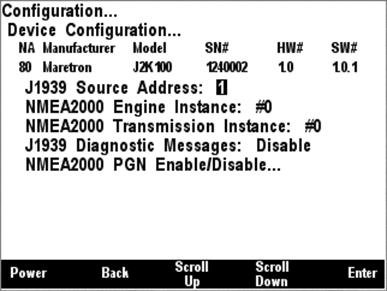

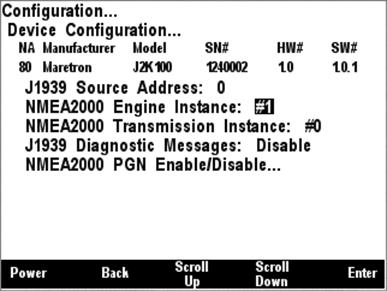

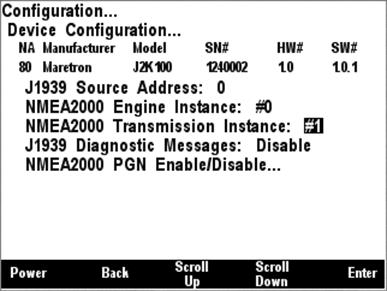

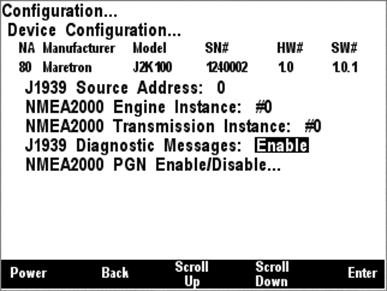

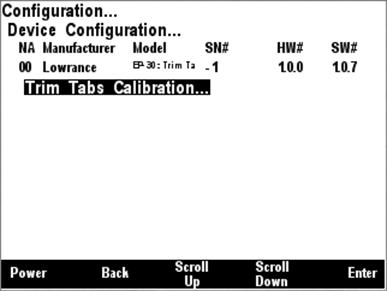

5.2.2.3 Device Configuration

The Device Configuration menu enables you to configure certain types of devices on the NMEA 2000® network. Devices that may be configured using the DSM200 include the following:

1. Maretron SSC200 – set installation offset, perform magnetic deviation calibration, check magnetic deviation calibration status, invert installation, configure magnetic variation settings, setup NMEA0183 interface, program rate of turn damping, zero the rate-of-turn offset, and enable/disable individual NMEA 2000® PGN transmissions.

- Maretron DST100 – set transducer offset, zero trip distance log

- Maretron GPS100 – enable and disable WAAS functionality, set the GPS mode, program the elevation, PDOP and SNR masks, set the antenna altitude, force a cold start, enable/disable individual PGN transmission, and reset the unit back to its factory defaults.

- Maretron DSM200 – allows configuration of other DSM200s on network

5. Maretron USB100 – allows configuration of USB100s on network

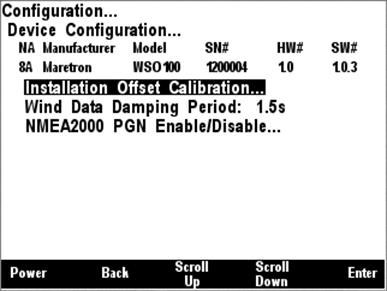

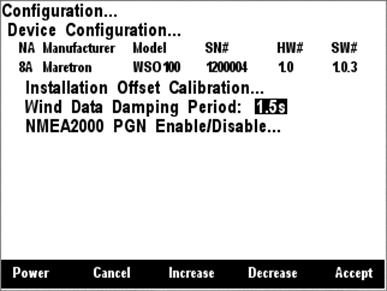

6. Maretron WSO100 – set installation offset, set wind damping rates, and enable/disable individual NMEA 2000® PGN transmissions.

7. Maretron J2K100 – set J1939 node address, set NMEA 2000 engine/transmission instance, enable pass-through of J1939 diagnostic messages, and enable/disable individual NMEA 2000® PGN transmissions.

8. Maretron TLA100 – Set tank type and tank number, set operating mode, set tank capacity, and calibrate for irregular shaped tanks.

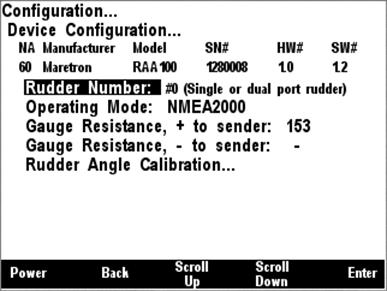

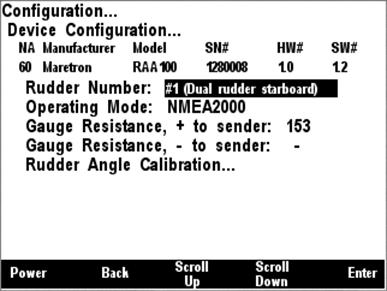

9. Maretron RAA100 – Set rudder number, operating mode, and calibrate rudder position.

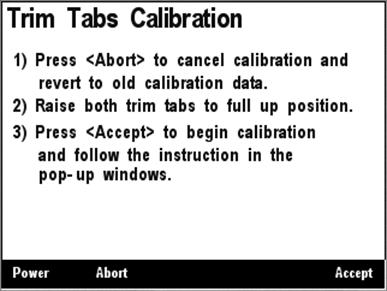

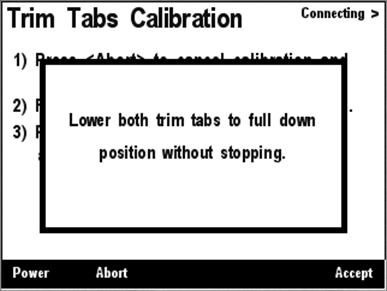

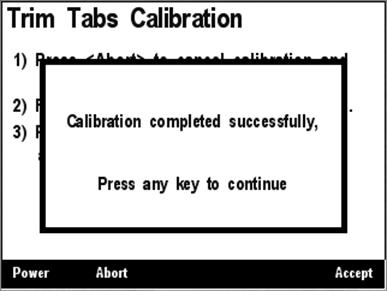

10. Bennett EP-30 – Calibrate trim tabs.

More device types will be included in future firmware releases.

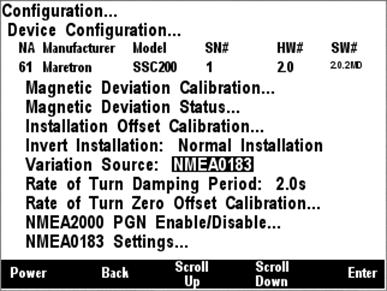

The Device Configuration menu is shown in Figure 15.

Figure 15 – Device Configuration Menu

The “HW” column shows the device hardware version.

The “SW” column shows the device software version.

5.2.2.3.1 Maretron SSC200 Configuration

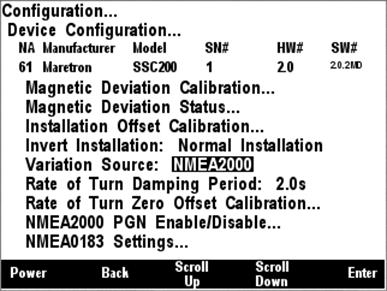

Nine configurable parameters for the Maretron SSC200 solid state compass may be configured using the Maretron DSM200 display. The Maretron SSC200 configuration menu can be seen in Figure 16 below.

Figure 16 – Maretron SSC200 Configuration Menu

5.2.2.3.1.1 Magnetic Deviation Calibration

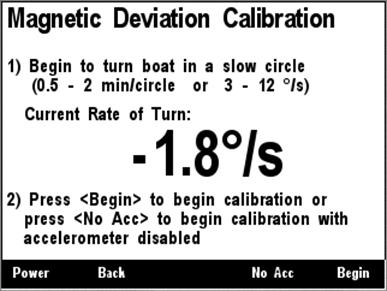

The DSM200 is capable of performing magnetic deviation calibration on a Maretron SSC200 solid state compass. The first screen (Figure 17) gives instructions for performing the procedure. First, begin to turn the boat in a slow circle (either clockwise or counter-clockwise) at about 3 to 12 degrees per second.

Figure 17 – Maretron SSC200 Magnetic Deviation Calibration Start Screen

Once you have begun the turn, press

Begin (![]() ) to start the calibration

procedure. If you do not wish to perform magnetic deviation calibration at this

time, press Abort (

) to start the calibration

procedure. If you do not wish to perform magnetic deviation calibration at this

time, press Abort (![]() ), and the currently stored

deviation tables will be retained.

), and the currently stored

deviation tables will be retained.

If you are in a large vessel, it

may be difficult to turn the vessel in a small enough circle to avoid

significant centrifugal force applied to the compass during magnetic deviation

calibration. This can cause the built-in tilt sensors inside the compass to

mistakenly believe that the compass is tilted during the magnetic deviation

calibration, which can adversely affect the quality of the magnetic deviation

calibration, especially in northerly latitudes where magnetic inclination

(magnetic dip) is higher. If this is the case, instead of pressing the Begin (![]() ) key, press the No Acc(

) key, press the No Acc(![]() ) key. This will cause the

compass to ignore its tilt sensors and assume that the compass is level to the

earth’s surface during the calibration. You must keep the boat level during

calibration if you choose this option.

) key. This will cause the

compass to ignore its tilt sensors and assume that the compass is level to the

earth’s surface during the calibration. You must keep the boat level during

calibration if you choose this option.

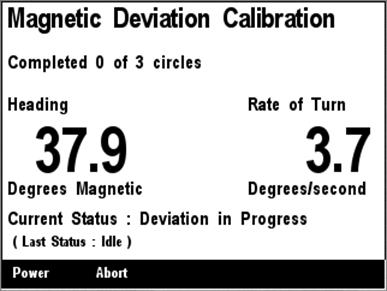

After you press the Begin (![]() ) key or the No Acc(

) key or the No Acc(![]() ) key, a status screen will

appear (Figure 18).

) key, a status screen will

appear (Figure 18).

Figure 18 – Maretron SSC200 Magnetic Deviation Calibration Progress Screen

This progress screen shows the

number of circles completed, the current heading, the current rate of turn, and

the current status of compass calibration. If you do not wish to continue magnetic

deviation calibration at this time, press Abort (![]() ), and the

currently stored deviation tables will be retained. Once calibration is

successful, a completion screen will appear. If calibration is unsuccessful, a

screen will appear indicating this, and you should repeat the calibration

procedure.

), and the

currently stored deviation tables will be retained. Once calibration is

successful, a completion screen will appear. If calibration is unsuccessful, a

screen will appear indicating this, and you should repeat the calibration

procedure.

5.2.2.3.1.2 Magnetic Deviation Status

Pressing the Enter key (![]() ) with the

“Magnetic Variation Status” menu item selected causes the screen shown in Figure 19 to be displayed.

) with the

“Magnetic Variation Status” menu item selected causes the screen shown in Figure 19 to be displayed.

Figure 19 – Maretron SSC200 Magnetic Deviation Status Screen

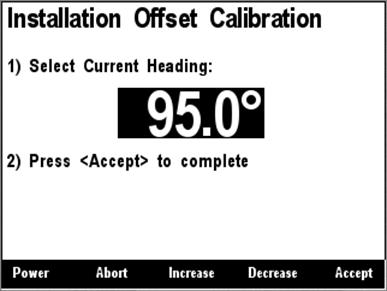

5.2.2.3.1.3 Installation Offset Calibration

The installation offset (i.e., misalignment of installed

SSC200 with vessels center line) may be calibrated using the Maretron DSM200

display. Once the compass is installed, point the vessel at a known heading,

and then select the compass from the Device Configuration menu. Scroll down (![]() ) the menu items to the line entitled “Installation Offset Calibration”

and press enter (

) the menu items to the line entitled “Installation Offset Calibration”

and press enter (![]() ) which takes you to the screen

shown in Figure 20.

) which takes you to the screen

shown in Figure 20.

Figure 20 – Maretron SSC200 Installation Offset Calibration Screen

Use the Increase (![]() ) and

Decrease (

) and

Decrease (![]() ) keys to adjust the display value

until it matches the known heading to which the boat is pointed. Press the

Accept (

) keys to adjust the display value

until it matches the known heading to which the boat is pointed. Press the

Accept (![]() ) key to accept the value when you

are satisfied. If you do not wish to perform installation offset calibration

at this time, press the Abort (

) key to accept the value when you

are satisfied. If you do not wish to perform installation offset calibration

at this time, press the Abort (![]() ) key and the installation offset

will not be altered.

) key and the installation offset

will not be altered.

5.2.2.3.1.4 Inverted Installation Entry

Normally, the SSC200 is mounted so that the label on the compass is facing up and the NMEA 2000 and NMEA 0183 connectors are facing towards the bow of the vessel. Recent version of SSC200 firmware support mounting the compass upside-down (for instance, to a ceiling), or backwards (with connectors facing towards the stern of the vessel, so that the SSC200 can be mounted to the aft side of a bulkhead). If either of these mounting options is used, the DSM200 can be used to inform the SSC200 of this fact so that it can adjust heading, rate or turn, pitch, and roll readings to be corrected accordingly.

Figure 21 - Setting the Installation Orientation

The choices that are offered are “Normal Installation” (default), “Backward Installation”, “Upside-Down Installation”, or “Upside Down and Backward”.

5.2.2.3.1.5 Variation Source Entry

The SSC200, being a magnetic compass, transmits heading information referenced to the magnetic north pole (magnetic heading). The SSC200 is capable of transmitting heading information referenced to the earth’s geographic North Pole (true heading). In order to produce true heading, information regarding the magnetic variation at the current location is required. Please see the SSC200 User’s Manual for more details on the use of magnetic variation by the SSC200 compass.

By default, the SSC200 is capable of receiving variation information on either its NMEA 0183 or NMEA 2000® interfaces (please see Figure 22). This causes the SSC200 to use variation data from either the NMEA 0183 interface or the NMEA 2000® interface.

Figure 22 – Setting Variation Source to NMEA 0183 or NMEA 2000® (factory default)

You should need to alter this setting only if:

1) There are variation sources available on both the NMEA 2000® and NMEA 0183 interfaces, or

2) There is no magnetic variation source available.

If variation sources are available on both the NMEA 2000® and NMEA 0183 interfaces, you must tell the SSC200 which source to use. Figure 23 below shows the NMEA 0183 source selected. This causes the SSC200 to use variation data from the NMEA 0183 interface and ignore all other variation sources (i.e., NMEA 2000® interface and manual entries).

Figure 23 – Setting Variation Source to NMEA 0183 Only

Figure 24 below shows the NMEA 2000® source selected.

Figure 24 – Setting Variation Source to NMEA 2000® Only

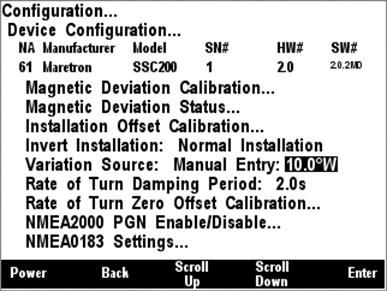

If there is no magnetic variation

source available on either the NMEA 2000® or the NMEA 0183

interface, and you wish to display true heading information, you may manually

enter a magnetic variation. To set a manual variation value, you must change

the variation source by pushing the Enter key (![]() ) with the

“Variation Source” menu item selected. This highlights the next field where you

select “Manual Entry” by scrolling (

) with the

“Variation Source” menu item selected. This highlights the next field where you

select “Manual Entry” by scrolling (![]() or

or ![]() ) through the

options until you reach “Manual Entry”. Pressing the Enter key (

) through the

options until you reach “Manual Entry”. Pressing the Enter key (![]() ) with the “Manual Entry” menu item selected takes you to the screen

shown in Figure 25.

) with the “Manual Entry” menu item selected takes you to the screen

shown in Figure 25.

Figure 25 – Entering Manual Variation

Press the Scroll Up (![]() ) or Scroll Down (

) or Scroll Down (![]() ) key to change the amount of

East or West variation. Press the Accept Key (

) key to change the amount of

East or West variation. Press the Accept Key (![]() ) when the

desired number is shown. You may also disable manual variation by setting the

value to “Disable”; this option appears between the values 0.0°E and 0.1°W when

scrolling through the values. When manual variation is disabled, the SSC200

will not transmit any variation information and heading information will be

available only in magnetic heading format.

) when the

desired number is shown. You may also disable manual variation by setting the

value to “Disable”; this option appears between the values 0.0°E and 0.1°W when

scrolling through the values. When manual variation is disabled, the SSC200

will not transmit any variation information and heading information will be

available only in magnetic heading format.

WARNING: Magnetic variation changes as your location on the earth changes; therefore magnetic variation should be adjusted with changes in position. Neither the DSM200 nor the SSC200 will make these changes automatically; they are the responsibility of the user.

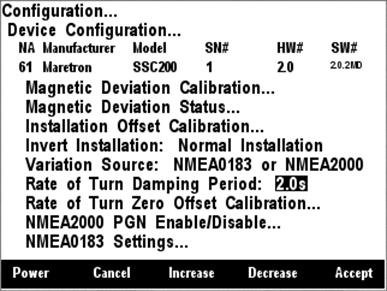

5.2.2.3.1.6 Rate of Turn Damping Period

The SSC200 is capable of transmitting the rate of turn of a vessel. Different applications may require different damping for the rate of turn measurement. The DSM200 may be used to set the damping period for the rate of turn measurement to anywhere between 0.1 seconds and 60 seconds. Figure 26 shows an example of the damping period set to 2 seconds.

Figure 26 – Programming SSC200 Rate of Turn Damping Period

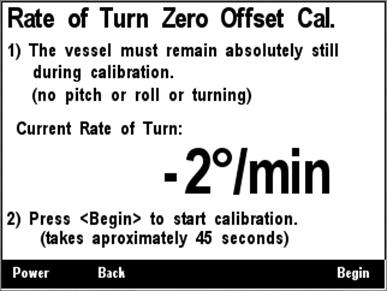

5.2.2.3.1.7 Rate of Turn Zero Offset Calibration

The DSM200 is capable of displaying rate of turn

information from a Maretron SSC200 compass. Although the compass provides very

accurate rate of turn information, it can drift off of zero even though the

vessel is not turning. Fortunately, the SSC200 can learn the zero offset for

different conditions found on the vessel. You teach the compass these zero offset

values by pressing the Enter key (![]() ) with the “Rate of Turn Zero

Offset Calibration” menu item selected which causes the DSM200 to display the

screen shown in Figure 27.

) with the “Rate of Turn Zero

Offset Calibration” menu item selected which causes the DSM200 to display the

screen shown in Figure 27.

Figure 27 – Maretron SSC200 Rate of Turn Zero Offset Calibration Screen

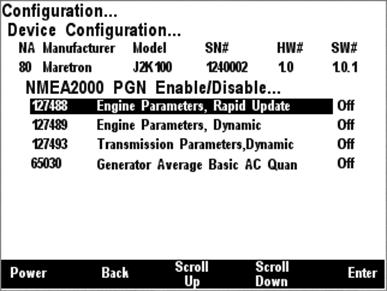

5.2.2.3.1.8 NMEA 2000® PGN Enable/Disable

The SSC200 compass transmits several different messages,

which can be turned on or turned off by the DSM200 display. Pressing the Enter

key (![]() ) with NMEA2000®

PGN Enable/Disable” menu item selected causes the DSM200 to display the screen

shown in Figure 28.

) with NMEA2000®

PGN Enable/Disable” menu item selected causes the DSM200 to display the screen

shown in Figure 28.

Figure 28 – Maretron SSC200 NMEA 2000® PGN Enable/Disable Menu

You can enable or disable specific transmissions by scrolling (![]() or

or

![]() )

through the different transmitted messages and pressing the Enter key (

)

through the different transmitted messages and pressing the Enter key (![]() ) on the message to be configured. Select whether you want the

message to be transmitted (“On”) or disabled (“Off”) using the Scroll Up (

) on the message to be configured. Select whether you want the

message to be transmitted (“On”) or disabled (“Off”) using the Scroll Up (![]() ) or Scroll Down (

) or Scroll Down (![]() ) keys followed by the Enter

key (

) keys followed by the Enter

key (![]() ).

).

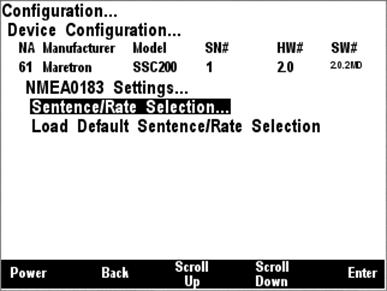

5.2.2.3.1.9 NMEA0183 Settings

Several characteristics of the NMEA 0183 interface of the SSC200 may be programmed using the DSM200 display. This can be used for initial programming of a SSC200 compass even if only the NMEA 0183 interface is to be used after installation is complete. Figure 29 below shows the possible programming options for the NMEA 0183 interface.

Figure 29 – SSC200 NMEA 0183 Setting options

The NMEA 0183 interface is a very low bandwidth interface. The SSC200 is capable of transmitting a wide variety of NMEA 0183 sentences, and can exceed the bandwidth of the NMEA 0183 interface if all sentences are transmitted at maximum rates, causing lost data in NMEA 0183 multiplexers or on the SSC200 interface itself.

It is important, therefore, to limit the types of NMEA 0183 sentences transmitted only to those that are necessary for other products which are connected to the NMEA 0183 interface. Figure 30 below shows the SSC200 NMEA 0183 Settings Periodic Rate Setup menu. In this menu, you can selectively enable and disable the different NMEA 0183 sentences that the SSC200 can transmit, and you can program the transmission interval for the enabled sentences. In the figure, you can see that the HDG and ROT sentences will be transmitted every 0.1 second (10 times/second), the ATT sentence will be transmitted once per second, and the HDM and HDT sentences are disabled.

The last line in the menu enables you to program the lifetime of the variation data received by the SSC200. In the figure, you can see that the “Variation Time” has been programmed to 5.0 seconds. This means that if the compass has not received magnetic variation for five seconds, it will no longer transmit true heading data, as the variation data it has received is now expired. The default value of 5.0 seconds should be adequate for the majority of applications, but it may need to be increased for variation sources that transmit less frequently.

Figure 30 – SSC200 NMEA 0183 Periodic Rate Menu

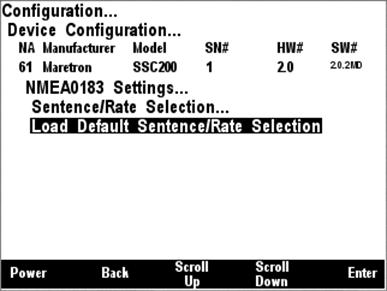

Figure 31 below shows the last menu option, which will reset the NMEA 0183 sentence enable/disable status, along with transmission intervals and variation time, to their factory default settings.

Figure 31 – SSC200 Load Default Periodic Rate Menu Selection

5.2.2.3.2 Maretron DST100 Configuration

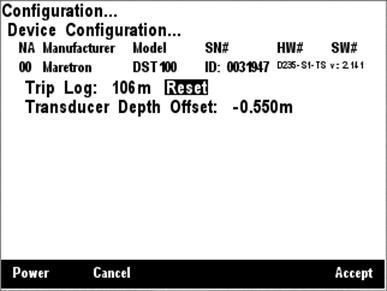

5.2.2.3.2.1 Trip Log Resetting

The DSM200 is capable of clearing the trip log counter

within a DST100 depth/speed/temperature transducer. You zero the trip log by

pressing the Enter key (![]() ) with the “Trip Log” menu

item selected which result in the screen shown Figure 32. Pressing the accept (

) with the “Trip Log” menu

item selected which result in the screen shown Figure 32. Pressing the accept (![]() ) key while the “Reset” menu item is selected will complete the

operation

) key while the “Reset” menu item is selected will complete the

operation

Figure 32 – Resetting the DST100 Trip Distance Log

5.2.2.3.2.2 Transducer Depth Offset Calibration

The DSM200 can set the transducer depth offset parameter in a DST100 depth/speed/temperature transducer. If you are interested in the actual water depth (as opposed to the depth beneath the keel), then you should program a positive value equal to the distance from the waterline to the depth of the DST100. The DSM200 will then add the measured depth of the water (as seen by the DST100) to the programmed offset value to produce the total water depth. If you are interested in the depth of water beneath the keel, then you should program a negative value equal to the distance between the DST100 and the bottom of the keel. The DSM will then subtract the programmed offset from the measured depth of the water (as seen by the DST100) showing you the depth of water beneath the keel.

You program the transducer depth offset by pressing the

Enter key (![]() ) with the “Transducer Depth

Offset” menu item selected which results in the screen shown in Figure 33.

) with the “Transducer Depth

Offset” menu item selected which results in the screen shown in Figure 33.

Figure 33 – Setting the Transducer Depth Offset in a DST100

With the offset value

highlighted, you can change the offset by using the Increase and Decrease keys (![]() or

or

![]() ).

Once you have selected the desired offset, push the Enter key (

).

Once you have selected the desired offset, push the Enter key (![]() ) to complete the transducer depth offset calibration. This

procedure actually programs the offset value into the DST100 such that all

displays subsequently receive the offset information. This means you don’t have

to program multiple displays each with the corresponding offset information as

the information is stored at a single place (at the source).

) to complete the transducer depth offset calibration. This

procedure actually programs the offset value into the DST100 such that all

displays subsequently receive the offset information. This means you don’t have

to program multiple displays each with the corresponding offset information as

the information is stored at a single place (at the source).

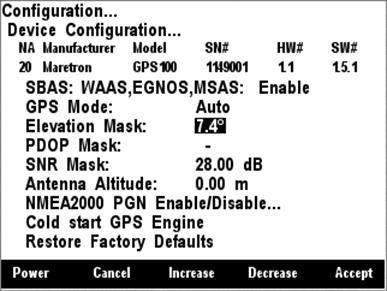

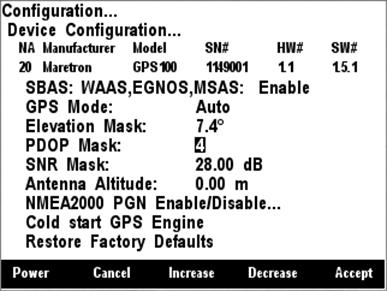

5.2.2.3.3 Maretron GPS100 Configuration

The GPS100 has several different programmable parameters that are configurable by the DSM200 display. Normally, it is not necessary to configure the GPS100 although there may be some circumstances where configuration is desirable. The following sections describe the different configuration modes including the “Restore Factory Defaults” configuration, which allows you to return the GPS100 to the factory settings.

5.2.2.3.3.1 SBAS (WAAS) Enable/Disable

The DSM200 is capable of enabling or disabling the SBAS

(WAAS) function on a Maretron GPS100 GPS Antenna/Receiver. You can change this

setting by pressing the Enter key (![]() ) with the “SBAS:

WAAS,EGNOS,MSAS” menu item selected which causes the screen shown in Figure 34 to be displayed.

) with the “SBAS:

WAAS,EGNOS,MSAS” menu item selected which causes the screen shown in Figure 34 to be displayed.

Figure 34 – Configuring SBAS on a GPS100

The allowable option for SBAS configuration are either “Disable” which causes the GPS100 not to use SBAS satellites, or “Enable” which causes the GPS100 to use SBAS satellites for developing a position fix.

5.2.2.3.3.2 GPS Mode Setting

The DSM200 is capable of setting the minimum operating

mode on a Maretron GPS100 GPS Antenna/Receiver. You can choose this setting by

pressing the Enter key (![]() ) with the “GPS Mode” menu

item selected which causes the screen shown in Figure 35 to be displayed.

) with the “GPS Mode” menu

item selected which causes the screen shown in Figure 35 to be displayed.

Figure 35 – Configuring GPS Operating Mode on a GPS100

The allowable options for GPS Mode are “1D” which allows the GPS to report data when only a one-dimensional fix (time only) or better is obtained; “2D”, which allows the GPS to report data only when a two-dimensional fix or better is obtained; “3D”, which allows the GPS to report data only when a three-dimensional fix or better is obtained, or “Auto” (default), which allows the GPS to report any available data, regardless of the quality of the fix.

5.2.2.3.3.3 Elevation Mask

The DSM200 is capable of setting the Elevation Mask on a

Maretron GPS100 GPS Antenna/Receiver. You can choose this setting by pressing

the Enter key (![]() ) with the “Elevation Mask”

menu item selected which causes the screen shown in Figure 36 to be displayed.

) with the “Elevation Mask”

menu item selected which causes the screen shown in Figure 36 to be displayed.

Figure 36 – Configuring Satellite Elevation Mask on a GPS100

The allowable values for Elevation Mask are between -90° and 90°. This number represents the elevation of a satellite above the horizon. Satellites with 0° elevation are at the horizon, while satellites with 90° elevation are directly overhead. The GPS will exclude satellites with an elevation lower than the value of this parameter from the position solution.

5.2.2.3.3.4 PDOP Mask

The DSM200 is capable of setting the PDOP Mask on a

Maretron GPS100 GPS Antenna/Receiver. You can choose this setting by pressing

the Enter key (![]() ) with the “PDOP Mask” menu

item selected which causes the screen shown in Figure 37 to be displayed.

) with the “PDOP Mask” menu

item selected which causes the screen shown in Figure 37 to be displayed.

Figure 37 – Configuring PDOP Mask on a GPS100

The allowable values for PDOP Mask are between 1 and 20. This number represents the Position Dilution of Precision, which indicates the accuracy of the computed position and is a function of the positions of the received satellites. If the PDOP of a given position solution is above the value of this parameter, then the GPS100 will report that no fix is obtained. Disabling the PDOP Mask by setting the value to “-“) will cause the GPS100 to report any position fixes obtained, regardless of the accuracy of the fix.

5.2.2.3.3.5 SNR Mask

The DSM200 is capable of setting the SNR (Signal to Noise

Ratio) Mask on a Maretron GPS100 GPS Antenna/Receiver. You choose this setting

by pressing the Enter key (![]() ) with the “SNR Mask” menu

item selected which results in the screen shown in Figure 38.

) with the “SNR Mask” menu

item selected which results in the screen shown in Figure 38.

Figure 38 – Configuring SNR Mask on a GPS100

The allowable values for the SNR Mask are between 1 dB and 60 dB. This number represents the signal to noise ratio of a satellite’s signal as received by the GPS100. Higher numbers indicate a better quality signal. The GPS will exclude satellites with signal to noise ratios lower than the value of this parameter from the position solution.

5.2.2.3.3.6 Antenna Altitude

The DSM200 is capable of setting the antenna altitude on

a Maretron GPS100 GPS Antenna/Receiver. You can choose this setting by pressing

the Enter key (![]() ) with the “Antenna Altitude”

menu item selected which causes the screen shown in Figure 39 to be displayed.

) with the “Antenna Altitude”

menu item selected which causes the screen shown in Figure 39 to be displayed.

Figure 39 – Configuring Antenna Altitude on a GPS100

The allowable values for the Antenna Altitude are between -100m and 100m. This number represents the altitude or the GPS100, and is used to improve the quality of the position fix if only a two-dimensional fix is obtainable. If a three-dimensional position fix is obtainable, this value is not used.

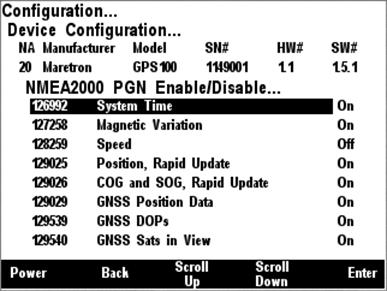

5.2.2.3.3.7 NMEA 2000® PGN Enable/Disable

The GPS100 GPS Antenna/Receiver

transmits several different messages, which can be turned on or turned off by

the DSM200 display. Pressing the Enter key (![]() ) with

NMEA2000® PGN Enable/Disable” menu item selected causes the DSM200

to display the screen shown in Figure 40.

) with

NMEA2000® PGN Enable/Disable” menu item selected causes the DSM200

to display the screen shown in Figure 40.

Figure 40 – Maretron GPS100 NMEA 2000® PGN Enable/Disable Screen

You can enable or disable specific transmissions by scrolling (![]() or

or

![]() )

through the different transmitted messages and pressing the Enter key (

)

through the different transmitted messages and pressing the Enter key (![]() ) on the message to be configured. Select whether you want the

message to be transmitted (“On”) or disabled (“Off”) using the Scroll Up (

) on the message to be configured. Select whether you want the

message to be transmitted (“On”) or disabled (“Off”) using the Scroll Up (![]() ) or Scroll Down (

) or Scroll Down (![]() ) keys followed by the Enter

key (

) keys followed by the Enter

key (![]() ).

).

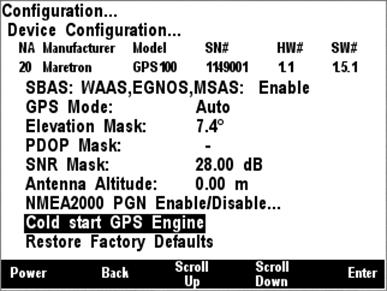

5.2.2.3.3.8 Cold Start GPS

The DSM200 is capable of restarting the GPS algorithm on

a Maretron GPS100 GPS Antenna/Receiver. You can choose this setting by pressing

the Enter key (![]() ) with the “Cold Start” menu

item selected which causes the screen shown in Figure 41 to be displayed. This

will cause the GPS100 to discard all position and satellite data and compute a

position fix.

) with the “Cold Start” menu

item selected which causes the screen shown in Figure 41 to be displayed. This

will cause the GPS100 to discard all position and satellite data and compute a

position fix.

Figure 41 – Performing a Cold Start of the GPS100

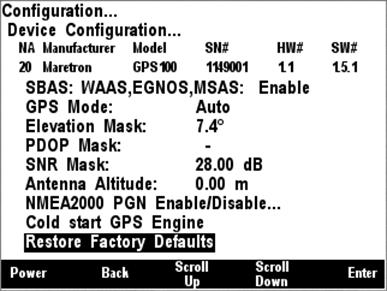

5.2.2.3.3.9 Restore Factory Defaults

The DSM200 is capable of restoring all programmable

settings on a Maretron GPS100 GPS Antenna/Receiver to the factory default

condition. You can choose this setting by pressing the Enter key (![]() ) with the “Restore Factory Defaults” menu item selected which

causes the screen shown in Figure 42 to be displayed. This will cause the

GPS100 to set all programmable settings to the factory default condition.

) with the “Restore Factory Defaults” menu item selected which

causes the screen shown in Figure 42 to be displayed. This will cause the

GPS100 to set all programmable settings to the factory default condition.

Figure 42 – Restoring Factory Defaults on the GPS100

5.2.2.3.4 Maretron USB100 Configuration

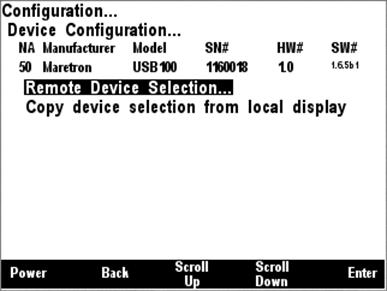

Maretron USB100 gateways on the network may be configured using the DSM200. The USB100 configuration menu is shown in Figure 43 below. There are two configurable items for the USB100: “Remote Device Selection”, and “Copy device selection from local display”.

Figure 43 – USB100 Configuration Menu

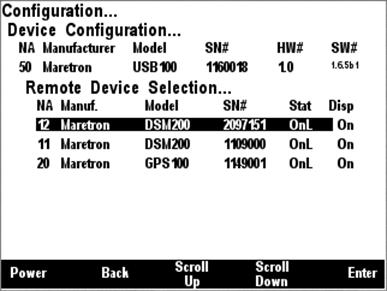

5.2.2.3.4.1 Remote Device Selection

Like the DSM200, the Maretron USB100 NMEA 2000® to NMEA 0183 gateway can be configured to select which NMEA 2000® devices are selected for display on the computer attached to the USB interface of the USB100. In this manner, multiple devices of the same type may be used on a NMEA 2000® network in a fail-safe configuration. The USB100 Device Selection Menu for an example network configuration can be seen in Figure 44.

WARNING: Do not select multiple devices of the same type for display. This will result in multiple and possibly conflicting readings.

Figure 44 – USB100 Device Selection Menu

The “NA” column of the menu displays the node address the device is using.

The “Manuf” column of the menu displays the manufacturer of the device.

The “Model” column displays the model number of the device.

The “SN#” column displays the serial number of the device, so that any of two or more devices of the same manufacturer and model number may be distinguished from one another.

The “Stat” column indicates whether the device is currently connected to the bus and is responding to queries (“Online”), or has been disconnected from the bus, has lost power, or for some other reason is not responding to queries (“Offline”).

The “Disp” column

indicates whether data from that particular device is accepted for display by

the USB100 (“On”) or that the USB100 ignores data transmitted by this device

(“Off”). By scrolling to the device and pressing the Enter key (![]() ), you may then use the Scroll Up (

), you may then use the Scroll Up (![]() ) and Scroll

Down (

) and Scroll

Down (![]() ) keys to toggle the “Display”

status for this particular device. Once you are satisfied with the state of the

“Display” setting, press the Enter key (

) keys to toggle the “Display”

status for this particular device. Once you are satisfied with the state of the

“Display” setting, press the Enter key (![]() ) to accept

the setting.

) to accept

the setting.

The USB100 will retain information on devices that have been removed from the bus or powered down (“Offline”) so that when they are placed back on the bus, they will assume their prior “Display” setting.

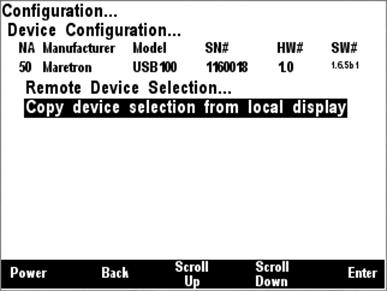

5.2.2.3.4.2 Copy device selection from local display

Since it is normally desirable for an attached computer to display the same sensors as a DSM200, it is possible to copy the device selection settings from a DSM200 unit to a USB100. In this way, it is possible to make all device selection changes on a single DSM200 unit and then quickly and conveniently duplicate these new device selection settings on USB100 units attached to the network. Figure 45 below shows this menu item highlighted.

Figure 45 – USB100 Copy Device Selection Menu Item

After you select this menu item and press Enter, the device selection settings from this DSM200 unit will be copied to the selected USB100 unit.

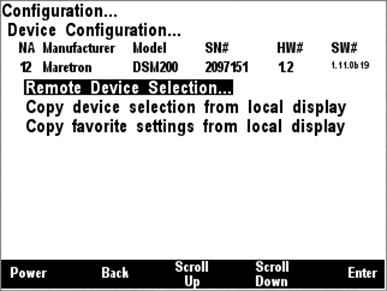

5.2.2.3.5 Maretron DSM200 Configuration

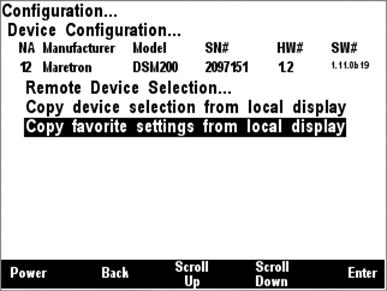

Many configuration settings on remotely-located DSM200 units may be configured from a DSM200. The Remote DSM200 configuration menu is shown in Figure 46 below. There are three configurable items on the DSM200: “Remote Device Selection”, “Copy device selection from local display”, and “Copy favorite settings from local display”.

Figure 46 – Remote DSM200 Configuration Menu

5.2.2.3.5.1 Remote Device Selection

A DSM200 unit can be used to configure other DSM200 units on the network to select which NMEA 2000® devices are selected for display on those DSM200 units. In this manner, multiple devices of the same type may be used on a NMEA 2000® network in a fail-safe configuration. For example, a certain compass unit may be selected for display on the remote DSM200. The Remote DSM200 Device Selection Menu for an example network configuration can be seen in Figure 47 below.

WARNING: Do not select multiple devices of the same type for display. This will result in multiple and possibly conflicting readings.

Figure 47 – Remote DSM200 Device Selection Menu

The “NA” column of the menu displays the node address the device is using.

The “Manuf.” column of the menu displays the manufacturer of the device.

The “Model” column displays the model number of the device.

The “SN#” column displays the serial number of the device, so that any of two or more devices of the same manufacturer and model number may be distinguished from one another.

The “Stat” column indicates whether the device is currently connected to the bus and is responding to queries (“Online”), or has been disconnected from the bus, has lost power, or for some other reason is not responding to queries (“Offline”).

The “Disp” column

indicates whether data from that particular device is accepted for display by

the remote DSM200 (“On”) or that the remote DSM200 ignores data transmitted by

this device (“Off”). By scrolling to the device and pressing the Enter key (![]() ), you may then use the Scroll Up (

), you may then use the Scroll Up (![]() ) and Scroll

Down (

) and Scroll

Down (![]() ) keys to toggle the “Display”

status for this particular device. Once you are satisfied with the state of the

“Display” setting, press the Enter key (

) keys to toggle the “Display”

status for this particular device. Once you are satisfied with the state of the

“Display” setting, press the Enter key (![]() ) to accept

the setting.

) to accept

the setting.

The remote DSM200 will retain information on devices that have been removed from the bus or powered down (“Offline”) so that when they are placed back on the bus, they will assume their prior “Display” setting.

5.2.2.3.5.2 Copy device selection from local display

Since it is normally desirable for all DSM200 units on a network to display the same sensors, it is possible to copy the device selection settings from a DSM200 unit to a remotely located DSM200. In this way, it is possible to make all device selection changes on a single DSM200 unit and then quickly and conveniently duplicate these new device selection settings on other DSM200 units attached to the network. Figure 48 below shows this menu item highlighted.

Figure 48 – Remote DSM200 Copy Device Selection Menu Item

After you select this menu item and press Enter, the device selection settings from this DSM200 unit will be copied to the selected remote DSM200 unit.

5.2.2.3.5.3 Copy favorite settings from local display

It is also possible to copy the favorite screen settings from one DSM200 to a remote DSM200 unit. This menu item can be seen selected in Figure 49 below.

Figure 49 – Copy favorite settings from local display Menu Item

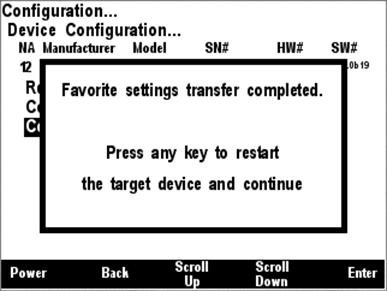

By selecting this menu item and pressing Enter, all of the favorite screen settings will be copied from the local DSM200 to the selected remote DSM200 unit. After copying favorite screen settings, it is necessary to restart the remote unit. A screen, which can be seen in Figure 50 below will appear indicating that favorite settings have been successfully transferred to the remote DSM200 and that the remote DSM200 must be restarted to complete the operation. Press Enter to restart the remote DSM200 unit, complete the favorite settings transfer operation, and return to the previous menu selection.

Figure 50 – Favorite Settings Transfer Completion Screen

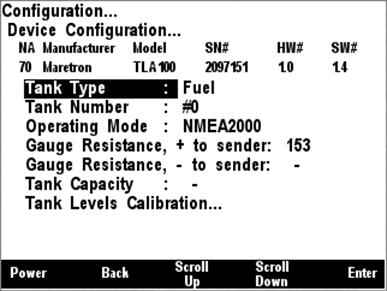

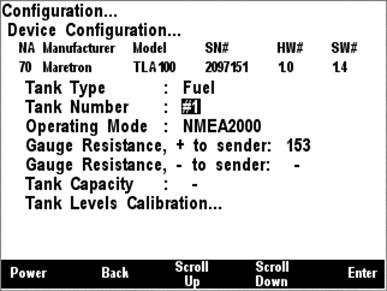

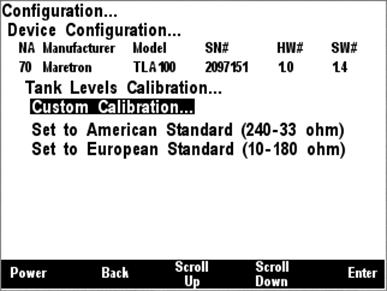

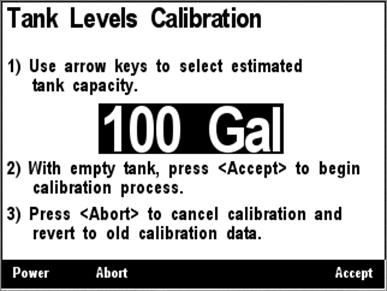

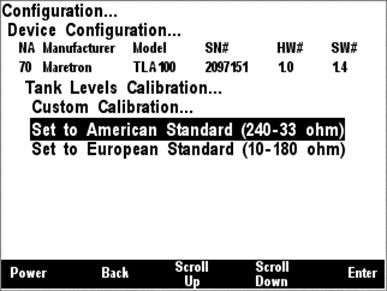

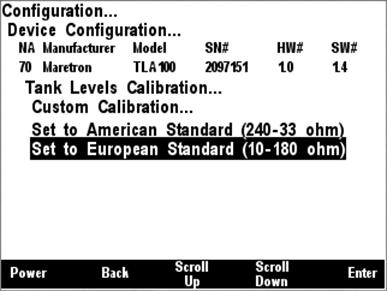

5.2.2.3.6 Maretron TLA100 Configuration

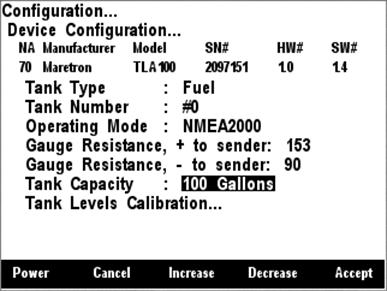

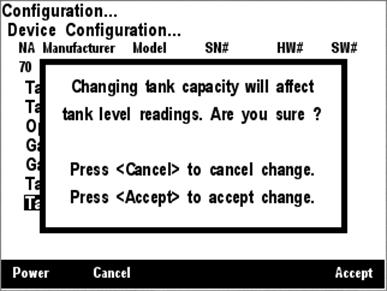

Maretron TLA100 tank level adapters on the network may be configured using the DSM200. The TLA100 configuration menu is shown in Figure 51 below.

Figure 51 - TLA100 Configuration Menu

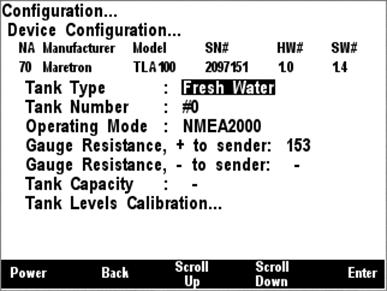

5.2.2.3.6.1 Tank Type

The TLA100 can be used in tanks

containing any of a number of different types of fluids. So that

network-connected monitoring devices can determine easily what sort of fluid is

in the monitored tank, the TLA100 must be programmed to indicate the fluid type

it is monitoring. Figure 52 below shows a screen shot of the tank type being

configured. First, use the Scroll Up (![]() ) or Scroll

Down (

) or Scroll

Down (![]() ) keys to position the

highlighted cursor over “Tank Type”, then press the Enter key (

) keys to position the

highlighted cursor over “Tank Type”, then press the Enter key (![]() ) to move the highlight to the tank type data itself. Now, use the

Scroll Up (

) to move the highlight to the tank type data itself. Now, use the

Scroll Up (![]() ) or Scroll Down (

) or Scroll Down (![]() ) keys to change the tank type data to the type desired. Finally,

press the Enter key (

) keys to change the tank type data to the type desired. Finally,

press the Enter key (![]() ) to confirm the selection and

store the value within the TLA100.

) to confirm the selection and

store the value within the TLA100.

Available tank types are as follows:

- Fuel

- Fresh Water

- Waste Water

- Live Well

- Oil

- Black Water

There are also a number of reserved tank types to accommodate possible future undefined tank types.

Figure 52 - Configuring the Tank Type

5.2.2.3.6.2 Tank Number

Next, the tank number must be configured. A tank number can have a value between 0 and 15. Each tank of a particular type must have a tank number that is different from all other tanks of the same type. For instance, only one TLA100 on a fuel tank may have tank number equal to “0”. A screenshot of tank number configuration is shown in Figure 53 below.

In order to configure the tank number, use the Scroll Up (![]() ) or Scroll Down (

) or Scroll Down (![]() ) keys to move the highlighted

cursor to “Tank Number”, then press the Enter key (

) keys to move the highlighted

cursor to “Tank Number”, then press the Enter key (![]() ) to move the

cursor over to the tank number value. Use the Scroll Up (

) to move the

cursor over to the tank number value. Use the Scroll Up (![]() ) or

Scroll Down (

) or

Scroll Down (![]() ) keys to select the desired

tank number. Finally, press the Enter key (

) keys to select the desired

tank number. Finally, press the Enter key (![]() ) to confirm

your selection and store the new tank number within the TLA100.

) to confirm

your selection and store the new tank number within the TLA100.

Figure 53 - Configuring the Tank Number

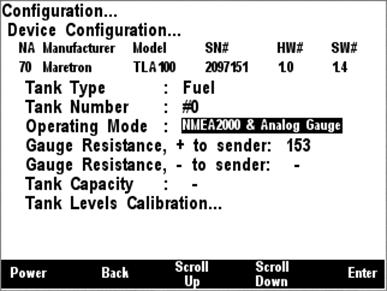

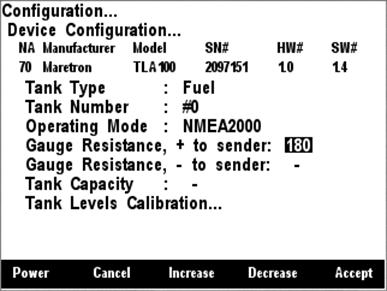

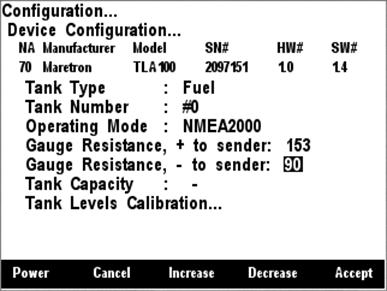

5.2.2.3.6.3 Operating Mode

The TLA100 can be operated in one of two operating modes, depending on the installation.

1) NMEA 2000 (the only thing that is connected to the resistive sender is the TLA100)

2) NMEA 2000 & Analog Gauge (in addition to the TLA100, the resistive sender is also connected to a dual-coil analog gauge).

It is important that this setting be performed correctly in order for the TLA100 to produce correct level measurements. A screenshot showing configuration of the operating mode appears in Figure 54 below.

To configure the operating

mode, use the Scroll Up (![]() ) or Scroll Down (

) or Scroll Down (![]() ) keys to move the highlighted cursor over the “Operating Mode” menu

item, then press the Enter key (

) keys to move the highlighted cursor over the “Operating Mode” menu

item, then press the Enter key (![]() ) to move the highlight over

the operating mode value. Use the Scroll Up (

) to move the highlight over

the operating mode value. Use the Scroll Up (![]() ) or Scroll

Down (

) or Scroll

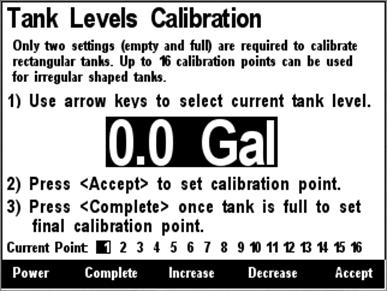

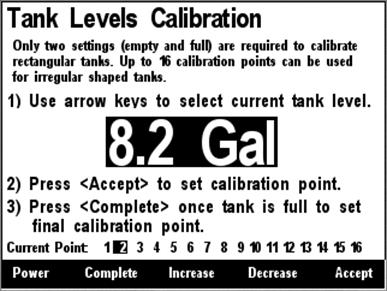

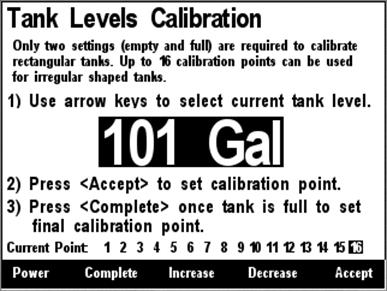

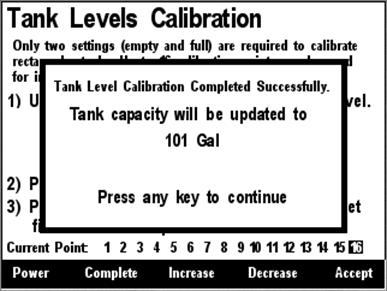

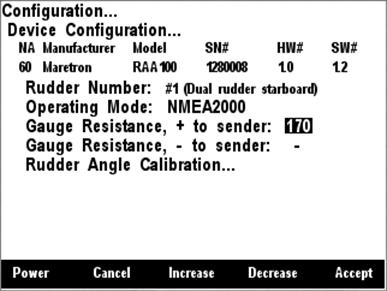

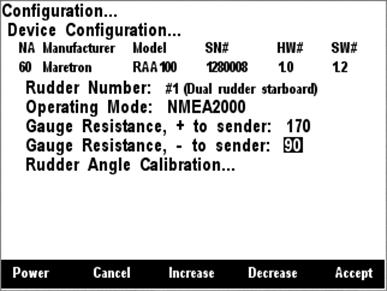

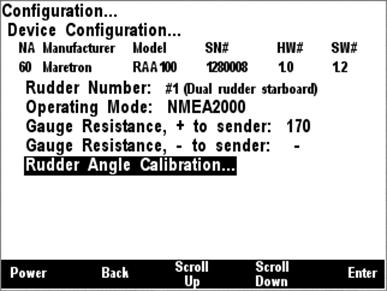

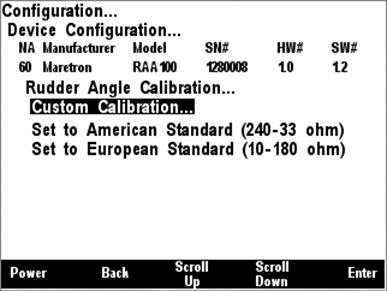

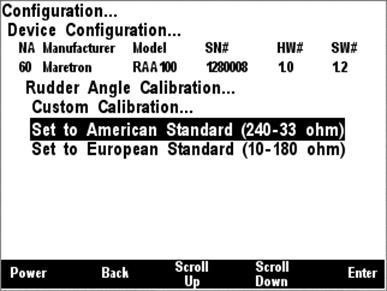

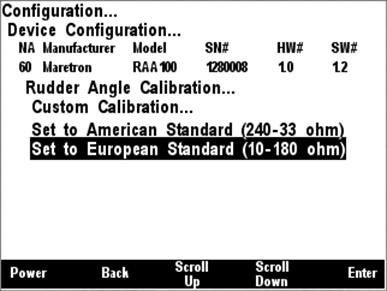

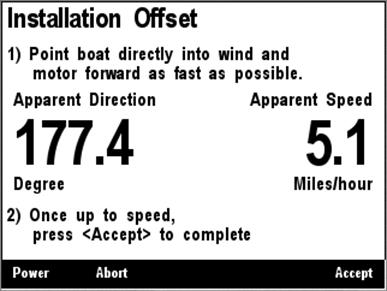

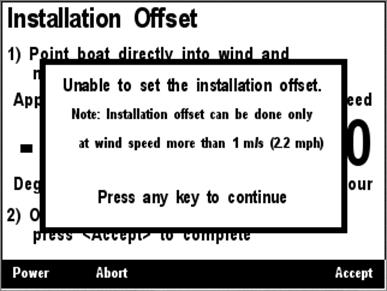

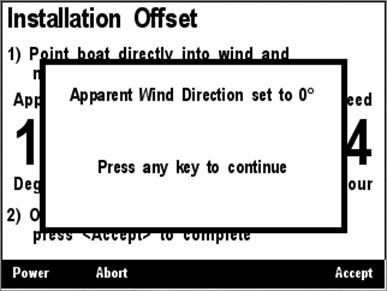

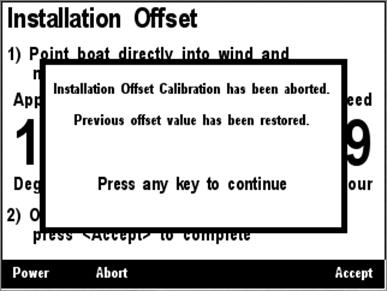

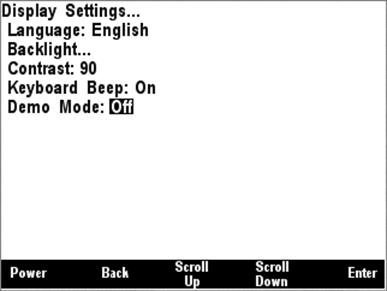

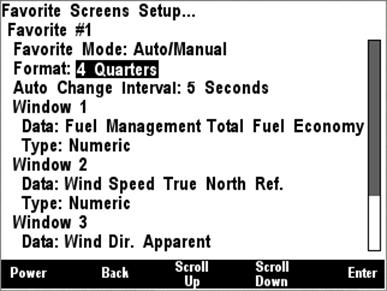

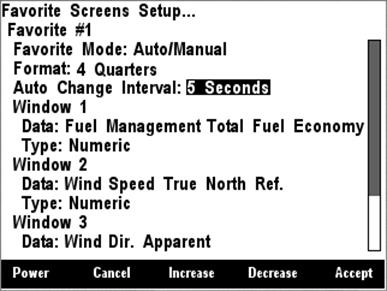

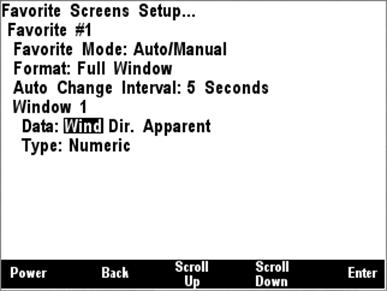

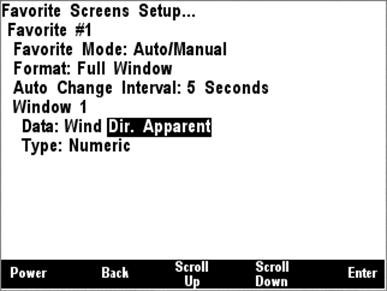

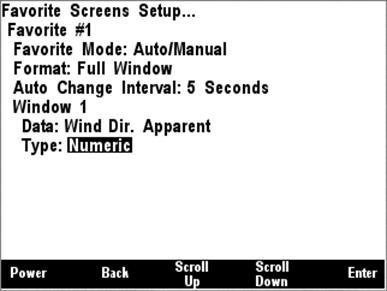

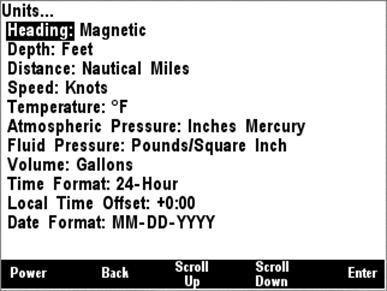

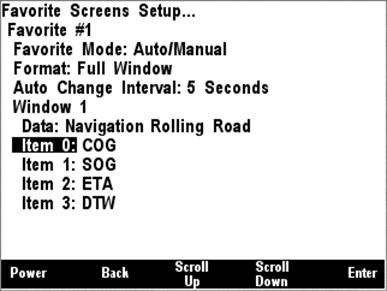

Down (![]() ) keys to change the operating