This document outlines how to configure the CLMD16 using Maretron’s N2KAnalyzer® V3 software

in conjunction with either a Maretron USB100 or a Maretron IPG100 connected to

an active NMEA2000® network. For information on how to use Maretron’s N2KAnalyzer® V3 software or to download the latest

version of Maretron’s N2KAnalyzer® V3 software please

visit:

https://www.maretron.com/products/N2KAnalyzer.php

For N2KAnalyzer® V3 software to configure a CLMD16 unit the

CLMD16 unit must be powered and connected to an active NMEA2000® network.

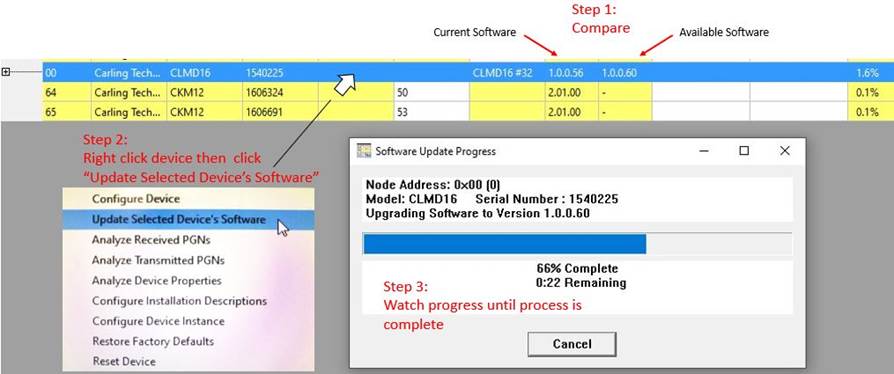

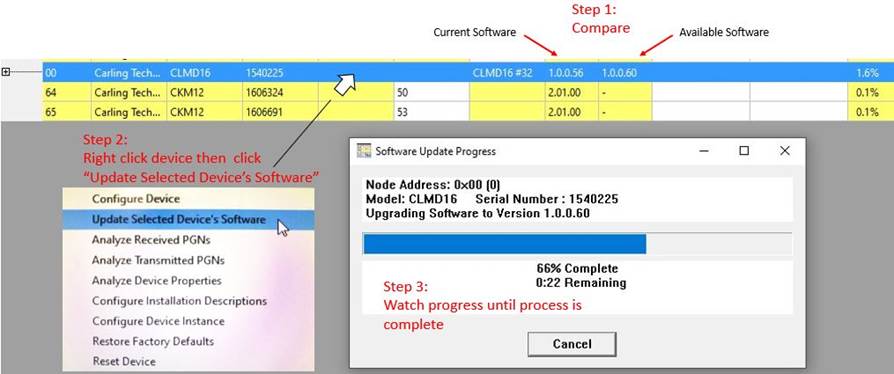

Before attempting to configure CLMD16, always ensure that

you are using the latest version of Maretron N2KAnalyzer® V3 and install the latest software / firmware to your

CLMD16 unit using N2KAnalyzer® V3. To update software for CLMD16 first compare

“Current Software” vs “Available Software”, right click CLMD16 inside

N2KAnalyzer® and click on “Update Selected Device’s Software”. A Dialog Box

will appear showing the software update progress.

·

Successful configuration of a CLMD16 unit consist of configuring

the unit’s various input channels and the unit’s output channels known as ECBs

(Electronic Circuit Breaker)

CLMD16’s Input Channels

could be any of the following:

1) Physical hardwired

inputs to the CLMD16’s input channels on the “J3” connector

(Referred to as

“Binary Events”)

2) NMEA 2000®

Binary Status Report PGN 127501 states

(Referred to as

“Discrete I/O Input”)

3) NMEA 2000® 127500 Load Controller PGN messages which could come

from a third party MFD (Multi-function Display) or any equipment running

Maretron’s N2KView® software. The name of the channels used to receive these

PGN messages are referred to as “Network Inputs 1-16” (One “Network Input”

corresponding with each ECB)

·

Next, “Switching Elements” placed in-between CLMD16’s input

channels and CLMD16’s ECB (Electronic Circuit Breaker) output

channels are “mapped”. CLMD16 Switching Application

Elements (referred to in the guide as “Switching Elements”) consists of any

of the following:

1) “Counter”

2) “Flash”

3) “Latch”

4) “Logic”

5) “Timer”

6) “Toggle”

7) “Toggle

Mode” & “Manual Mode”

·

Lastly, connecting or “mapping” the output of these “Switching

Elements” to the CLMD16’s ECB (Electronic Circuit Breaker) input signals

complete the configuration for each circuit. Note that “Switching Elements” can

be “mapped” to each other, for example the output of a “Toggle Element” can be

an input of a “Logic Element” and that “Logic Element” output can be the input

of a “Timer Element” giving the user ultimate flexibility to configure the

CLMD16. See the “Switching Elements Definition” segment of this guide to learn

the features of each.

·

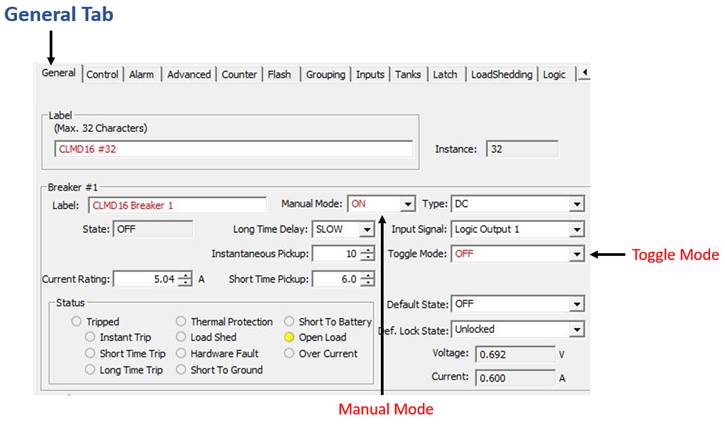

Some circuit configurations require the use of a mode called

“Manual Mode”. By default, when “Manual Mode” is not enabled the CLMD16’s ECBs

can be controlled by compatible third party MFDs. Also, when “Manual Mode” is

not enabled, the ECB control method from a compatible MFD may be limited to the

MFDs internal Switching Application software. Activate “Manual Mode” on any ECB

to sever this direct control allowing for the “Network Input” signal received

from the MFD to be directed into any CLMD16 “Switching Element(s)” then back

into the ECB control input. This feature gives the user the ability to take

advantage of the CLMD16’s “Switching Elements” even using a third party MFD or

multiple MFDs as the main point(s) of control.

In the following depictions you will see visual reference to

what “Toggle” and “Momentary Inputs” mean to the Switching Application. It is

important to understand that “Inputs” do not have to be a person pressing a

switch but could be a signal becoming present. This is also not to be confused

with physical switch types being sustained contact or momentary contact. This

definition is as it applies to the CLMD16 Switching Definition.

Momentary: As long as an Input is present the

Switching Application has an Input.

Toggle: Every

time an Input becomes present or “Turns On” the Switching Application changes

state.

There

is a list of input signals available to be used to activate the various

“Switching Elements” these “Input Signals” consist of the following:

|

Signal Name

|

Description

|

|

None Selected

|

This connects the

specified input to a constant Logic ‘0’ value

|

|

Binary Event 1 through 12 Low

|

The signal on binary event 1

through 12 is in the Low voltage range

|

|

Binary Event 1 through 12

Float

|

The signal on binary event 1

through 12 is in the Float voltage range

|

|

Binary Event 1 through 12

High

|

The signal on binary event

for the numbered channel is in the High voltage range

|

|

Network Input 1 through 16

|

The state of the signal on

Network Input for the numbered channel

|

|

Logic Output 1 through 48

|

The state of the output of

Logic Element for the numbered channel

|

|

Latch Output 1 through 16

|

The state of the output of

Latch Element for the numbered channel

|

|

Toggle Output 1 through 16

|

The state of the output of

Toggle Element for the numbered channel

|

|

Timer Output 1 through 16

|

The state of the output of

Delay Timer Element for the numbered channel

|

|

Flash Output 1 through 16

|

The state of the output of

Flash Element for the numbered channel

|

|

Counter Active 1 through 16

|

The state of the output of

Counter Element 1 through 16

|

|

Over Current Fault Ch 1

through 16

|

An Over Current Fault has

been detected on Channel 1 through 16

|

|

Ch 1 through 16 Tripped

|

The circuit breaker for the

numbered channel is tripped

|

|

Ch 1 through 16 Thermal Limit

Hit

|

The circuit breaker for the

numbered channel has reached its thermal limit

|

|

Discrete I/O 1 through 32

|

The discrete state I/O of the

signal the numbered channel

|

|

Breaker On 1 through 16

|

The state of an Output

Channel for the numbered channel

|

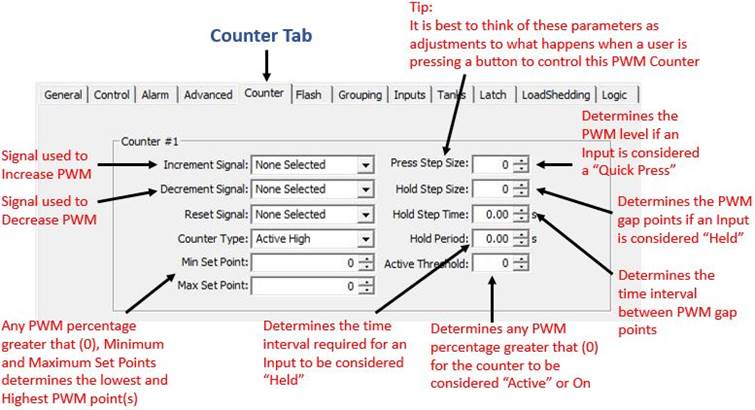

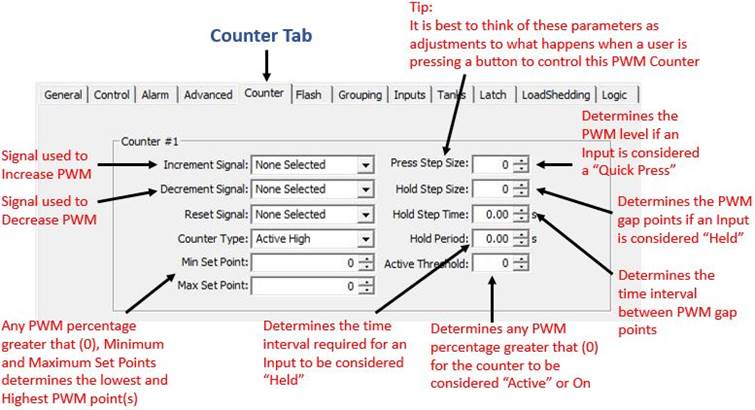

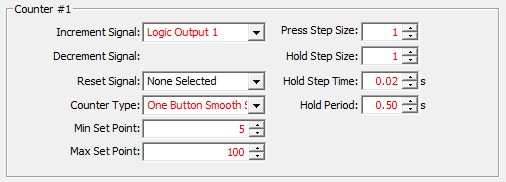

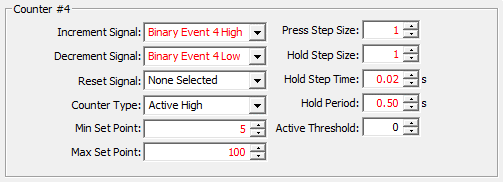

This function is used to adjust incremental and decremental

step points and gap sizes, Min. and Max set points, and user input signal delay

parameters for CLMD16 output channels set to drive PWM (Pulse-Width Modulation).

See following “Counter” dialog for a description of

the basic “Counter” features.

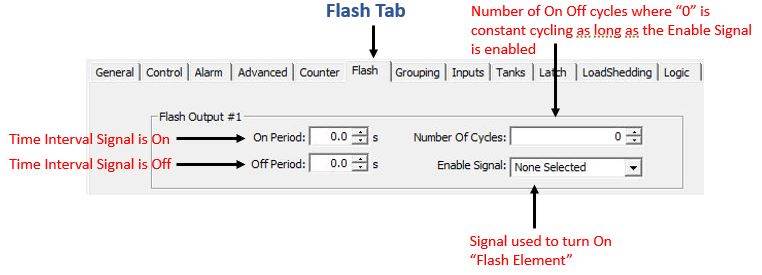

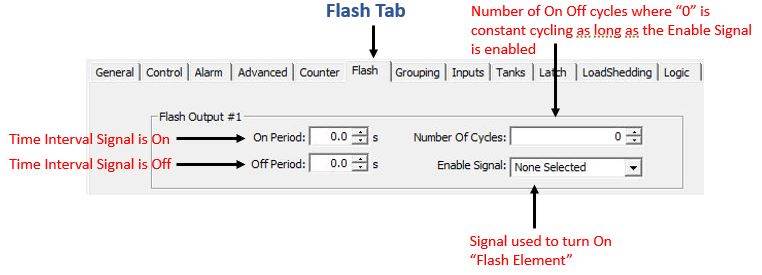

“Flash Element”

This function is used to turn On and Off signals at a user

configurable frequency. See following “Flash” dialog for a description of the

basic “Flash” features.

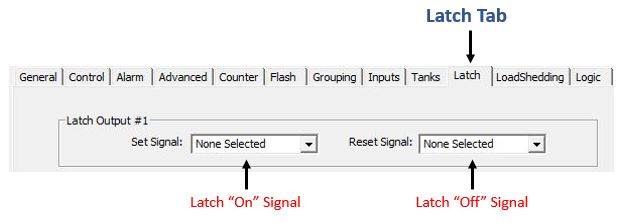

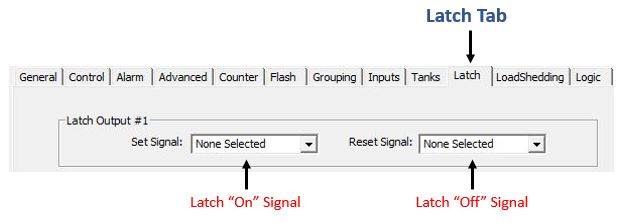

This function, unlike a “Toggle” signal where a single input can turn something

both

On and Off is exactly as it sounds, it “Latches” signals into an On state in

where it requires another signal to “Unlatch” or turn Off. See following “Latch”

dialog for a look at configuration input required for this feature.

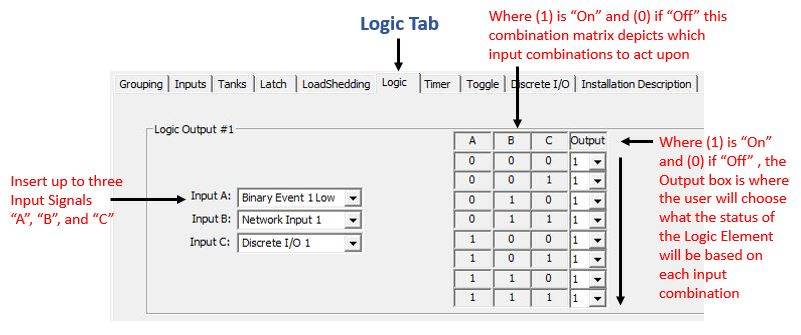

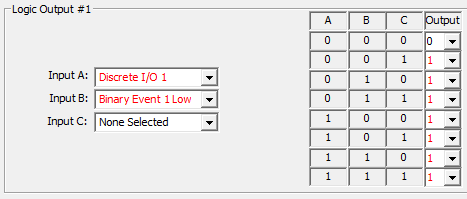

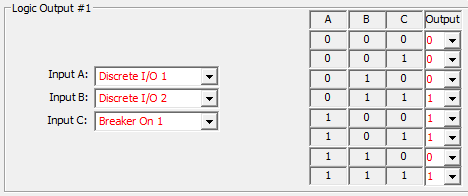

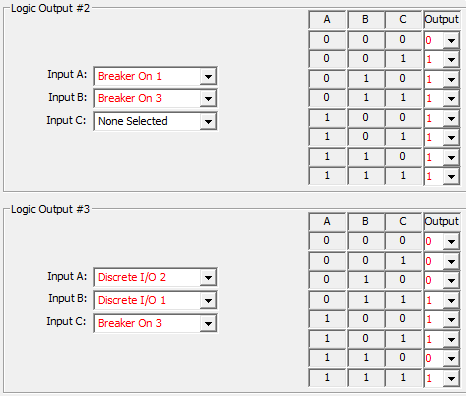

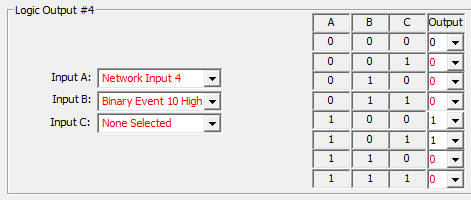

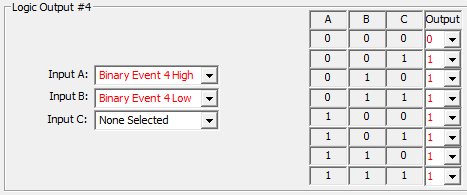

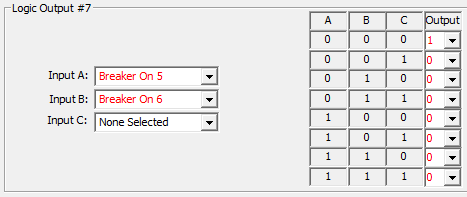

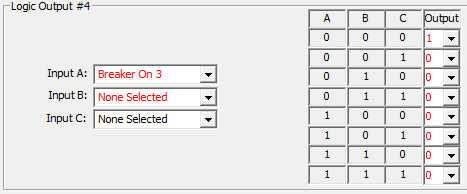

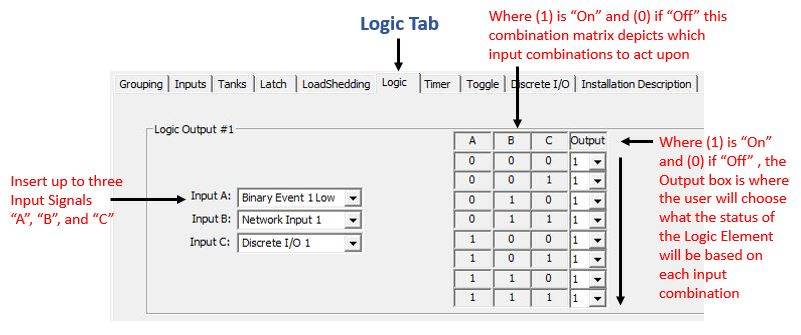

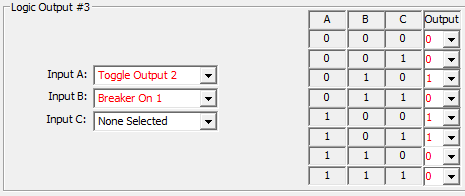

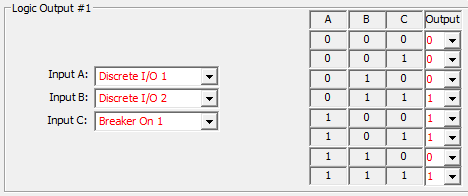

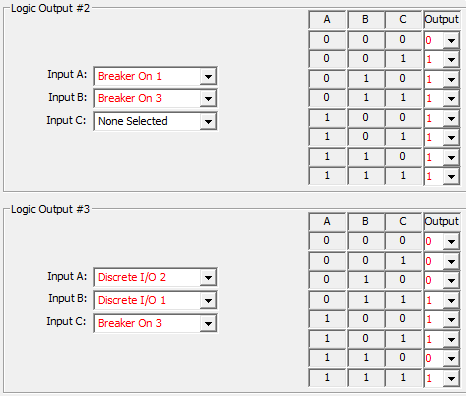

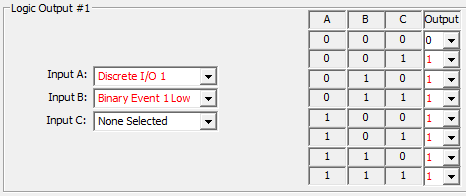

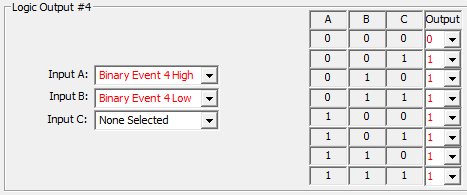

If an ECB breaker requires combinatory Logic rules applied to it a “Logic

Element” must be used. Applying “Logic Elements” will help you to achieve many

desirable results with countless potential solutions. This function is used to

combine up to three different input signals to create a single output using

Boolean Logic method where the user can choose the Logic Output state of On or

Off for any combination of 3 input signals. See

following “Logic” dialog for details on how to set-up a Logic Element.

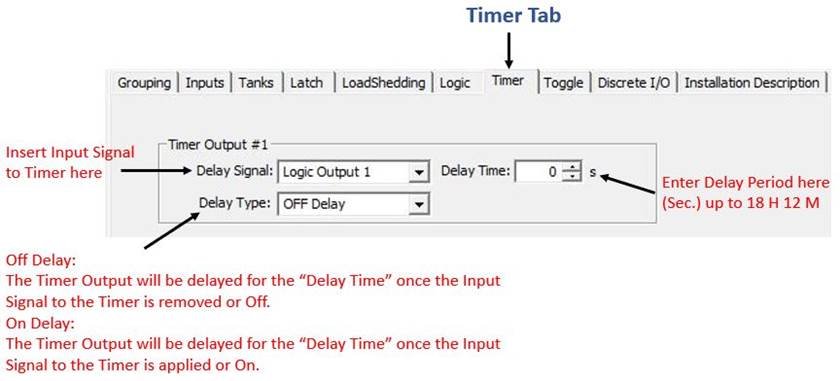

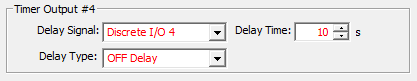

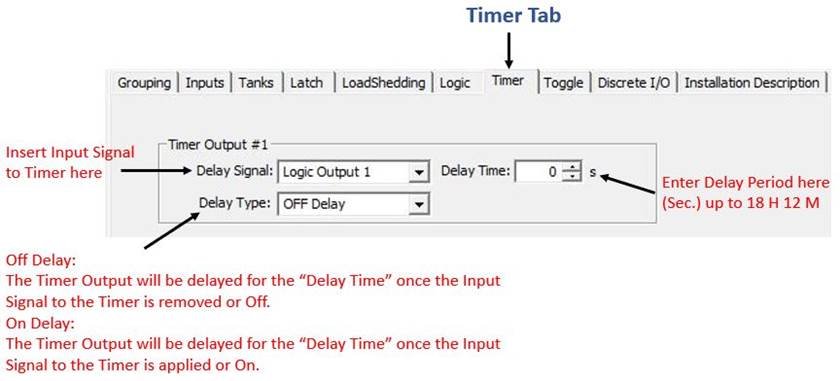

The “Timer” element is used to delay functions for any set time up to 18 hours

and 12 minutes per timer. See following “Timer” dialog for details on how to

set-up a Timer Element.

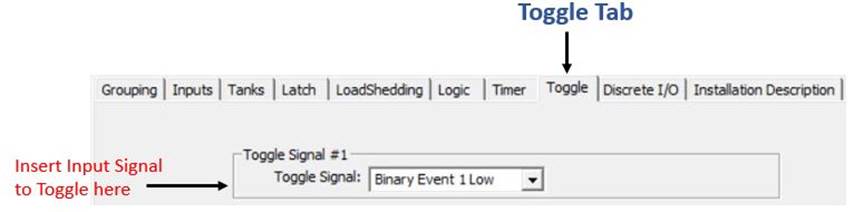

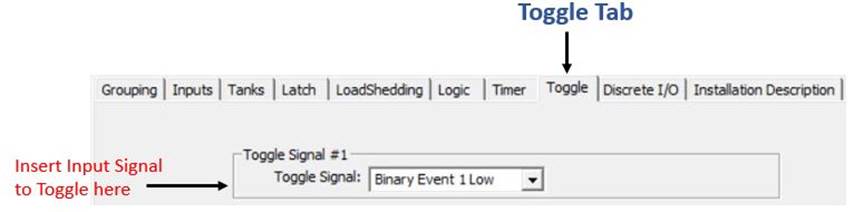

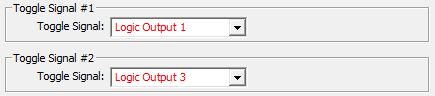

The “Toggle” element is a “Latch” element that does not require two separate

Inputs to change state but instead can turn its Output both On and Off using a

single input. The “Toggle” element will turn its output

On when it detects an Input Signal and when it detects it’s next Input Signal

it will turn its Output Off. See following dialog to familiarize the

“Toggle” set-up.

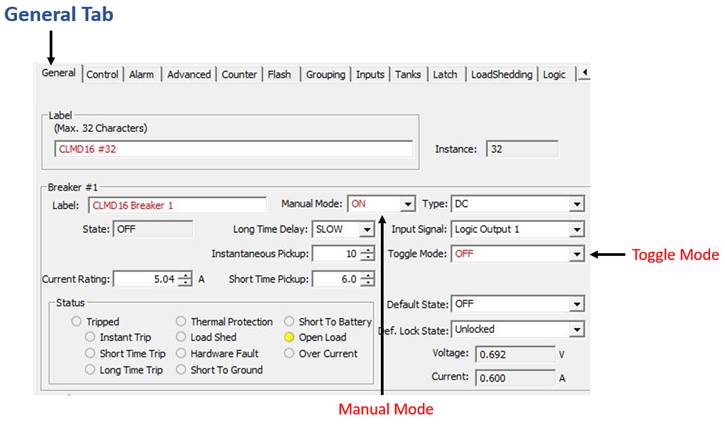

“Toggle Mode” is

part of the Switching Application that is not an independent “Switching Element”

but instead, a “Switching Element” added to the ECB directly. When this mode is

enabled, the state of the ECB will change to the opposite state whether On or

Off each time an Input Signal changes from Off to On, including ECB direct, “Network

Input” Toggle commands. This command could come from a Digital Switching

compatible MFD or any equipment running Maretron’s N2KView® software.

“Manual Mode” Manual

Mode is part of the Switching Application that is not an independent “Switching

Element” but instead, disallows the ability for devices using NMEA 2000® 127500

Load Controller PGN to have direct ECB control accessibility. This does not

mean the device using 127500 PGN will have no way to gain access to control an

ECB, but instead limits the accessibility to only “Network Inputs 1-16” from

the Available Signals to be used as inputs within the Switching Application.

This feature can be used to funnel commands from any device using 127500 PGN

into CLMD16 Switching Application Logic. By default, “Manual Mode” is not

enabled and the CLMD16’s ECBs can be controlled by compatible third party MFDs

and Maretron’s N2KView® software. Please note, the ECB control method from a

compatible MFD will be limited to the MFD’s internal Switching Application software.

The software used by third-party MFDs is usually limited to Toggle Operation

whereas Maretron’s N2KView® may be able to perform the desired action without

the use of “Manual Mode”. By activating “Manual Mode” on any ECB, direct ECB

control is not possible however, the “Network Input” signal received from the

MFD may be directed into any CLMD16 “Switching Element(s)” then back into the

ECB control input allowing for ultimate configurability such as sequencing,

special lighting control, modes, and group switching even with a third-party

MFD. “Manual Mode” can also be used to disallow access to ECBs that are

designated for Load Sequencing or Sub-Routines.

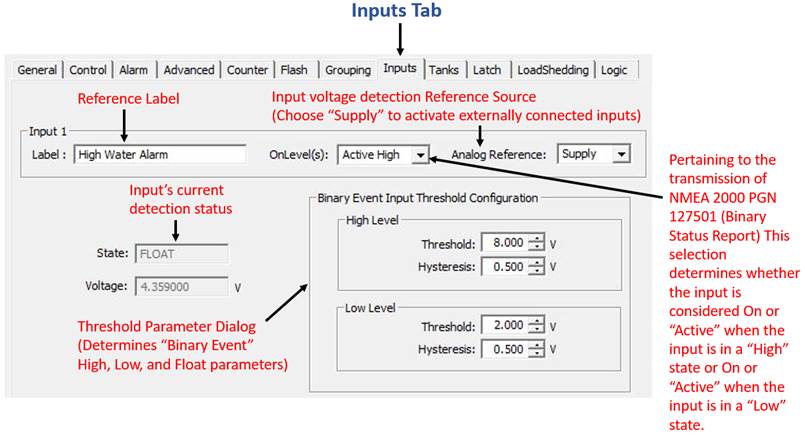

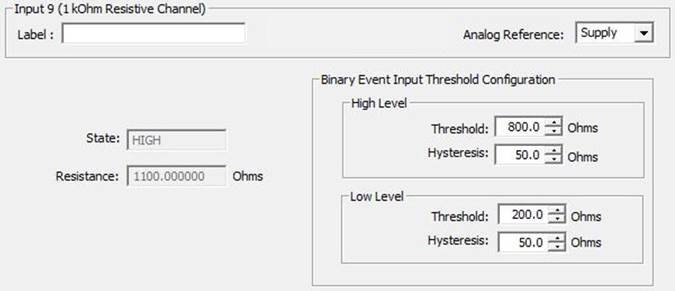

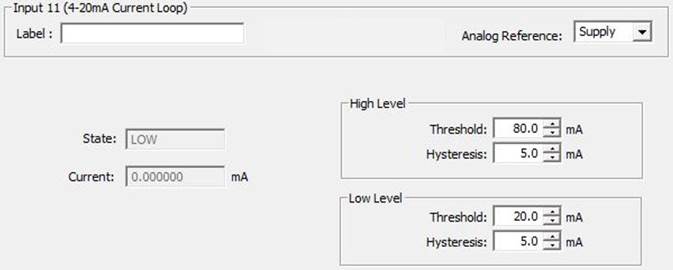

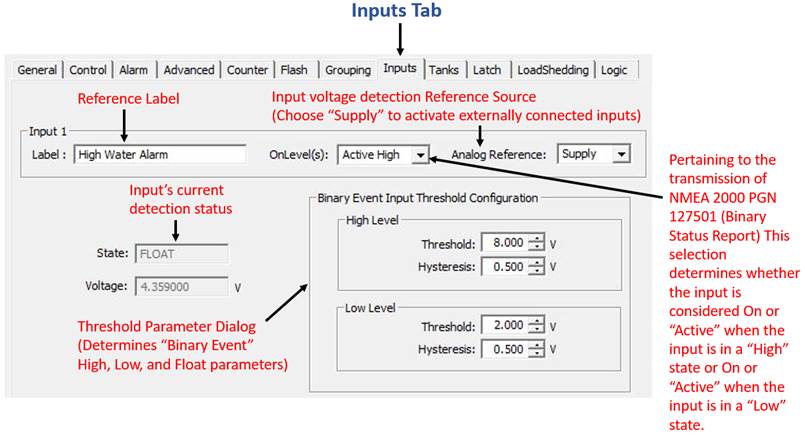

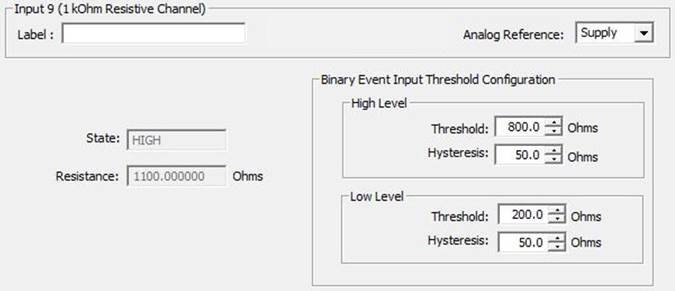

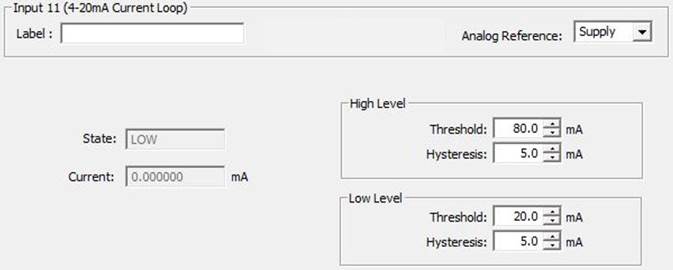

The CLMD16 has 11 hardwired input

channels. Eight of these channels monitor potential connections to supply DC

voltage, two monitor resistance to DC (-) and one is a current loop channel

that will measure 4-20 mA DC (-) current. Each Input has “High Level” and “Low

Level” thresholds as well as “Hysteresis” levels that are user adjustable to

determine what input statuses are. For example, a user can adjust these

thresholds such that a “High Level” threshold is 8v and “Low Level” threshold

is 2v. These settings will translate to; when a DC (+) input of 8v or greater

is detected the input channel is considered within the “High Level” category, when

a DC (+) input of 2v or lower or a DC (-) signal pulling the input channel

“Low” (0v) is detected the input channel is considered within the “Low Level”

category. Anything in-between the “High Level” and “Low Level” categories is

considered inside the “Float” category. The “Hysteresis”, in other words, can

be considered a buffer on both ends of the threshold setting. Hysteresis is

used to “dampen” the threshold mark disallowing the potential of nuisance or

rapid status switching. For example, using the

abovementioned “High Level” threshold of 8v, if an input voltage of “just

about” or “just below” 8v is detected where the input is fluctuating between

under 8v and over 8v the input status will change at the frequency of the

fluctuation. Hysteresis is designed to create a buffer on both ends of the

threshold setting to prevent the potential of rapid status changes. For example,

again using the abovementioned “High Level” threshold of 8v, when a hysteresis

of 0.5v is applied to this threshold value the input status does not change

until 7.5v or under and 8.5v or over. Application of hysteresis creates an

environment where status changes to the input are more affirmative.

Once Input types are entered into the Inputs Dialog, the

“High Level”, “Float” and “Low Level” detection of each input parameter can be plugged

directly into the control input of an ECB or used as inputs to “Switching Elements”

of:

1) “Counter”

2) “Flash”

3) “Latch”

4) “Logic”

5) “Timer”

6) “Toggle”

The names of these input detections are called “Binary Event

Low”,” Binary Event High”, and “Binary Event Float” numbers 1 – 11, (a number

correlating to each Input number) where each number has “Low”, “Float” and

“High” detection giving a total of 33 potential signals for the CLMD16 to act

upon related to these 11 inputs and their threshold states being met.

See

below the three different CLMD16 Dialogs used for

configuring these input types

(Voltage, Resistive, and Current Loop).

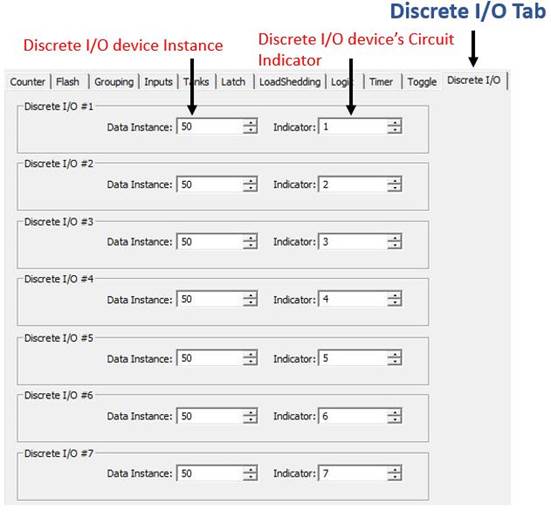

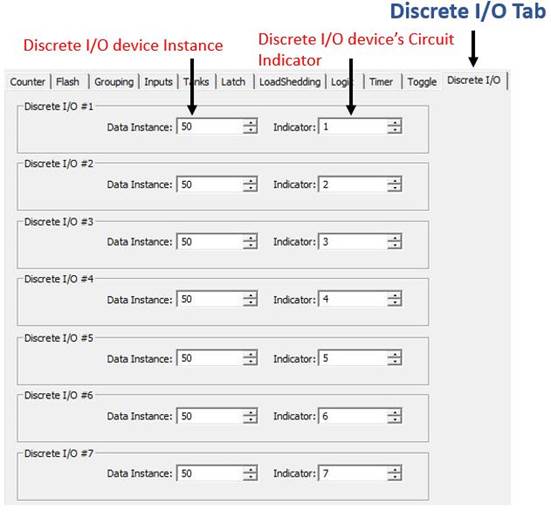

The CLMD16 supports “Discrete I/O” inputs such as signals

from Maretron’s CKM12 and VMM6 units. Configuring the CLMD16 to act upon

“Discrete I/O” inputs starts first with choosing which “Discrete I/O’s” you

want the CLMD16 to “watch for” or be assigned to act upon. Every “Discrete I/O”

device has a unique “Data Instance” for the device as a whole and “Indicator”

numbers corelating with the “Discrete I/O’s” every switch. Apply the “Discrete

I/O” device’s “Data Instance” and “Indicator” number to the CLMD16’s “Discrete

I/O” input channels to then enable these CLMD16 input channels to be used to

plug directly into an ECB control input or used as inputs to “Switching Elements”

of:

1) “Counter”

2) “Flash”

3) “Latch”

4) “Logic”

5) “Timer”

6) “Toggle”

Please note that if the “Discrete I/O” device is to report

the CLMD16’s ECB status, the “Discrete I/O” device itself needs to have each of

its “Indicators” to be assigned to the CLMD16’s “Data Instance” and particular

ECB it is “watching”. See below the CLMD16’s dialog for “Discrete I/O” input

configuration.

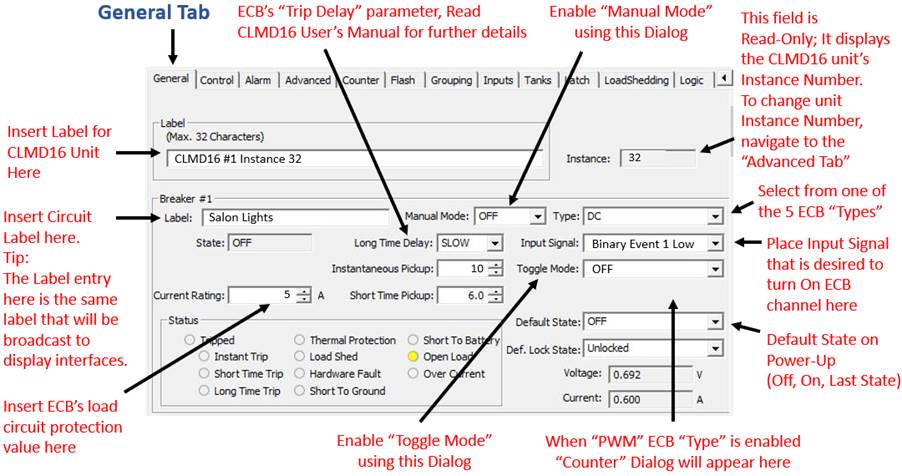

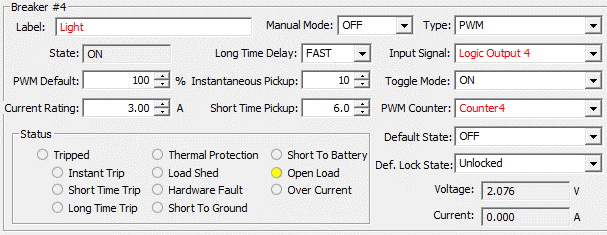

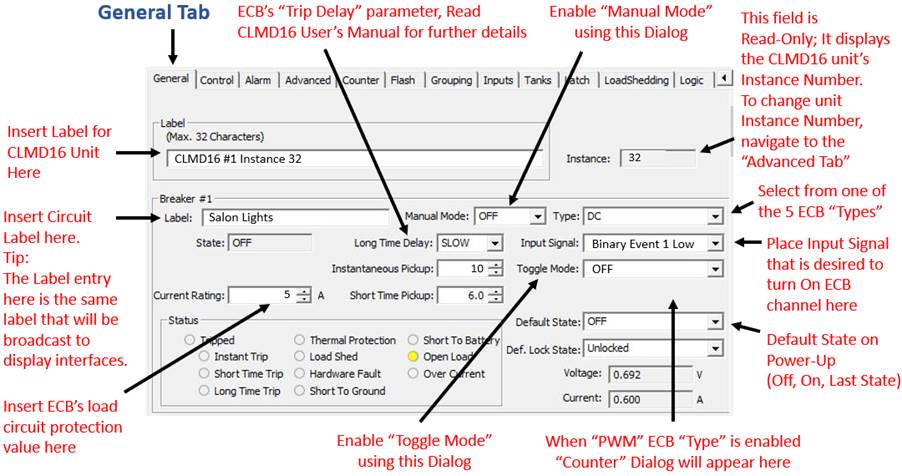

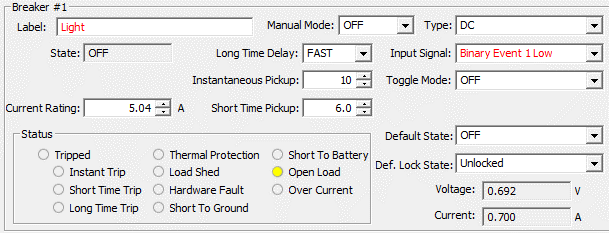

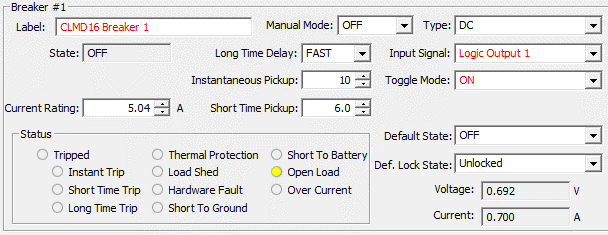

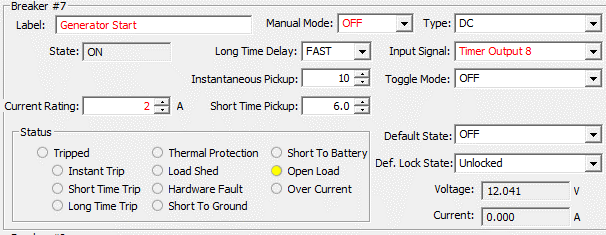

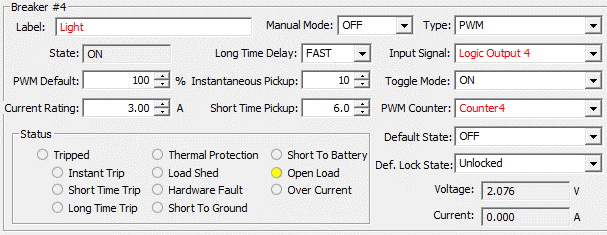

Where the CLMD16’s ECB profiles are configured, the “General

Tab” should be the second if not first configuration point when configuring

CLMD16 then visited again as the last stop to finalize the configuration. This

method is recommended because the “General Tab” is where the ECB circuit names,

and ECB “Type” is configured. By configuring the CLMD16’s ECB or Output

Channels into the configuration first you then know where the final destination

of the Inputs or abovementioned “Switching Elements” will go as Input Signals

to the ECB channel.

There are 5 ECB “Types” to choose from:

1) DC

(Standard On / Off Channel)

2) PWM / PWM W/Counter

(Pulse-Width Modulation Enabled)

3) Soft Start DC

(Standard On / Off Channel with Soft Start Enabled)

4) Full-Bridge

(Reversing Polarity / H-Bridge Enabled)

5) Soft Start Full-Bridge

(Reversing Polarity / H-Bridge with Soft Start Enabled)

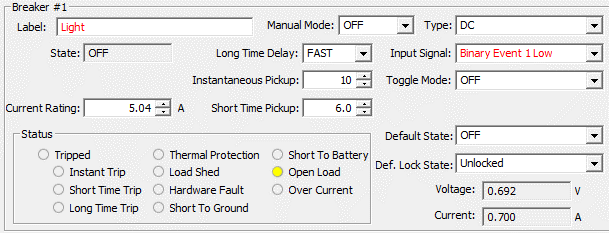

See following dialog to acquaint yourself with ECB

configuration.

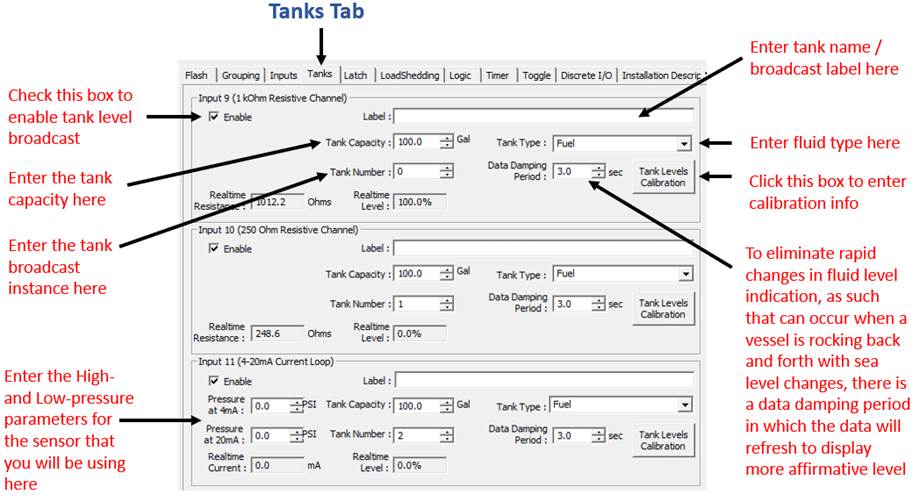

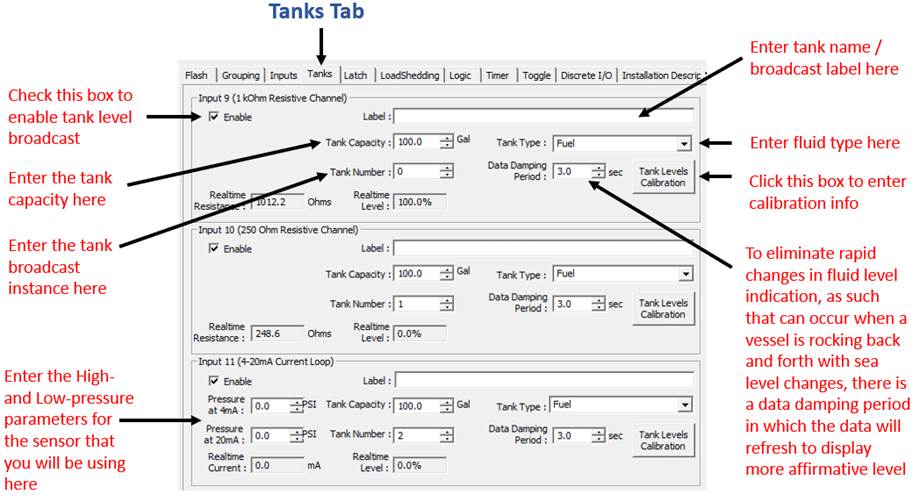

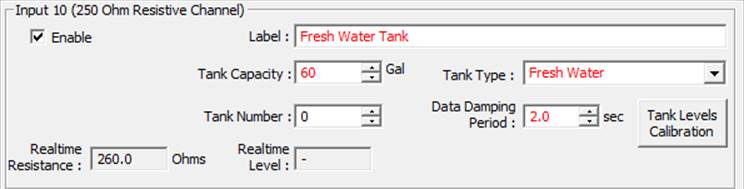

The CLMD16 is able to broadcast up to three instances of

tank level data via NMEA 2000® 127505 PGN. The following dialog(s) explain the parameters

that will need to be configured for the tank level broadcast.

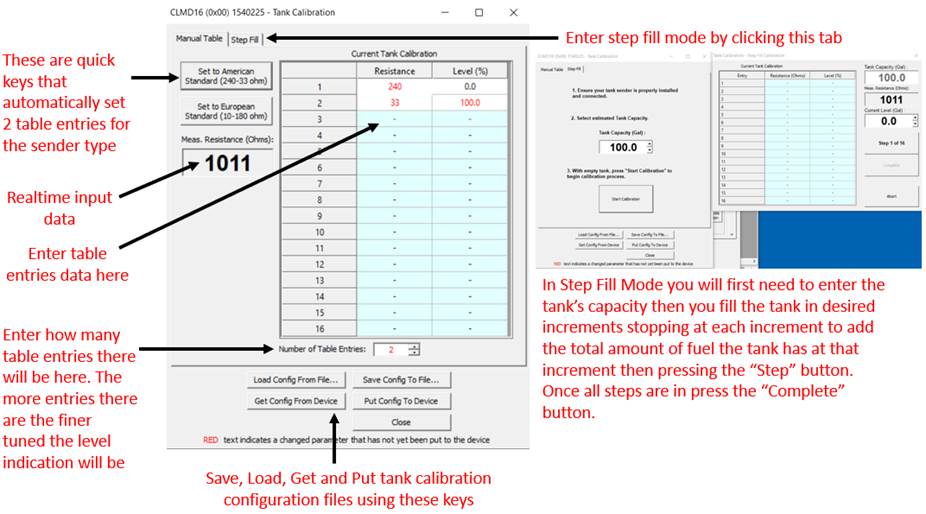

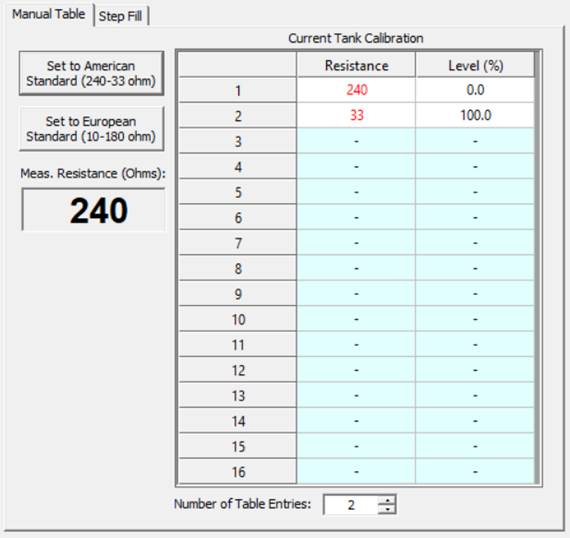

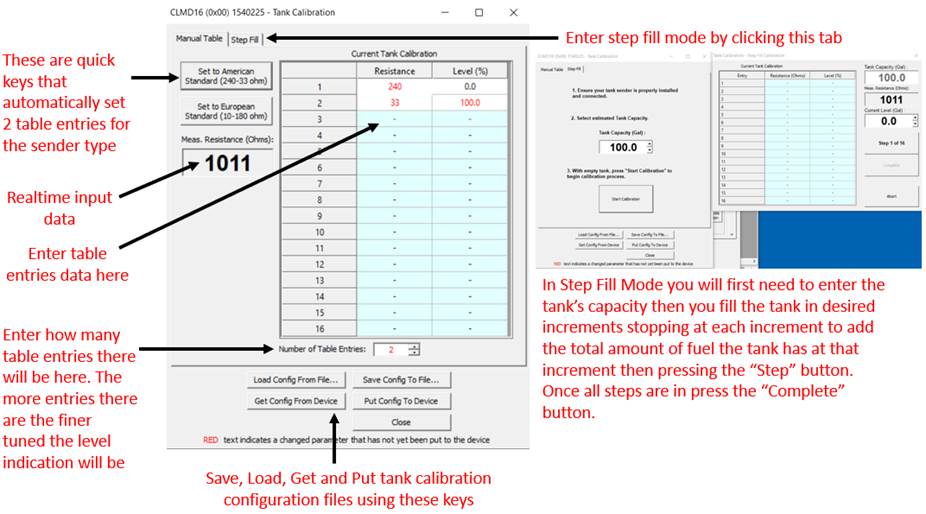

By clicking on “Tank Levels Calibration” another dialog box

will appear. See the following dialog depiction to understand how to enter the

calibration data. Please note the tank level calibrations are not saved with

the CLMD16 device’s overall configuration file but instead, the CLMD16 has the

ability to save each tank level channel’s calibration to individual files. This

is not done automatically when the CLMD16’s configuration is saved as the

configurator will need to save tank calibration data files separately.

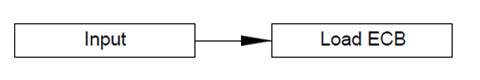

Applying a single momentary or sustained contact input

signal to CLMD16 in order for the ECB output to replicate the input signal of

“On” or “Off” is a one-step procedure. See following process to apply inputs to

the CLMD16 ECBs.

Step 1:

Apply “Input signal” to desired breaker / load output control or

“ECB”. In this example the Input Signal is “Binary Event Low”

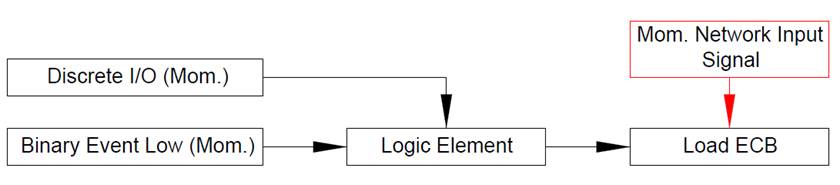

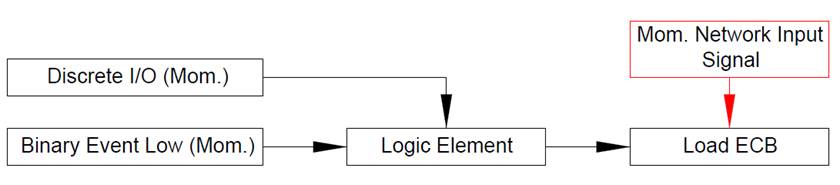

The most efficient configuration for momentary operation of

a CLMD16 ECB load from multiple input sources requires the input sources to be

physically momentary in nature such as a momentary “Discrete I/O” input or an

input from a hardwired switch that has a physical momentary operation. (known

as: “Binary Event”). When adding multiple momentary inputs together to control

an ECB load in a momentary fashion a “Logic Element” will need to be used to

combine the inputs to achieve a single output in which the output of the “Logic

Element” will be applied to the breaker’s “Input Signal”. In the following

example there will be two input signals combined inside a “Logic Element”. One

input is from a hardwired switch that has a momentary DC (-) signal called

“Binary Event Low” and one input is a momentary Discrete I/O input called

“Discrete I/O 1”. Both will switch the desired load in a momentary fashion. See

following steps to configure this circuit type.

Note: a “Momentary Network Input” which could come from a third party MFD using

127500 Load Controller PGN or any equipment running Maretron’s N2KView®

software could be externally applied to control the ECB directly (Shown in

Red).

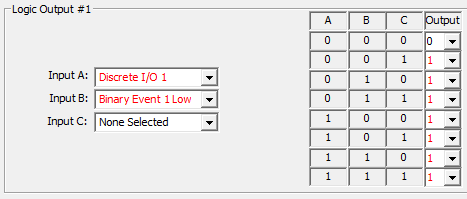

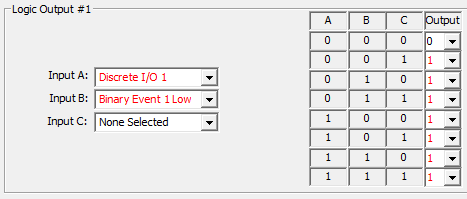

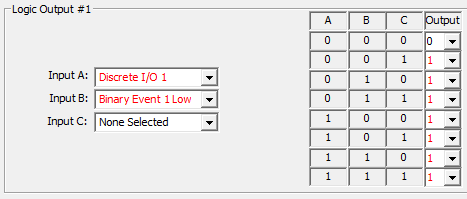

Step 1:

Assign inputs to a “Logic Element”. Where “0” is Off and “1” is On, configure

the “Logic Output” in a manner to where if any input source is On, the “Logic

Element’s Output” becomes active.

Step 2:

Place “Logic Output” signal into desired ECB control “Input Signal”.

When toggling a circuit On / Off, not all input sources are

treated equally. For example, a “Discrete I/O” input could be a momentary input

requiring a “Toggle Element” added to it. A “Binary Event” (Item hardwired to

an Input to the CLMD16) is subject to be whichever physical switch style the

installer chooses; therefore, the input could be a sustained contact and no

“Toggle Element” will be needed. Multi-Function Displays (MFDs) using 127500 Load Controller PGN or any equipment running

Maretron’s N2KView® software could have direct access to the CLMD16’s ECB

channels and the CLMD16 configuration will not be able to change the Digital

Switching origination command for this type of equipment. Most MFDs Digital

Switching commands are “Toggle style Network Input” by default. For these

reasons, it is vitally important that the configurator understands the

characteristics of each input type used for CLMD16 load switching for proper

configuration.

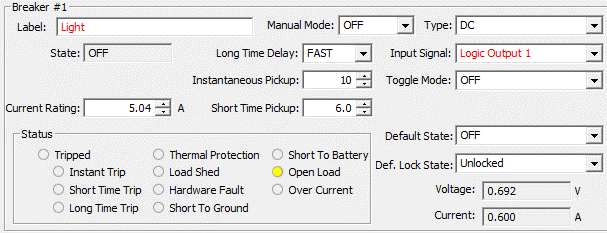

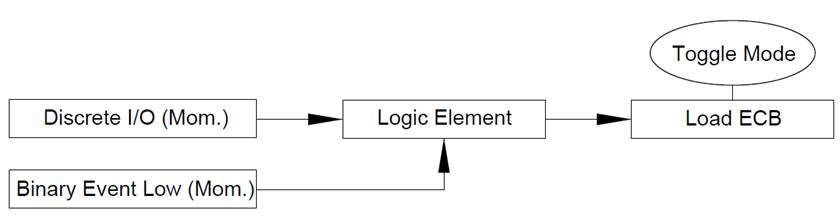

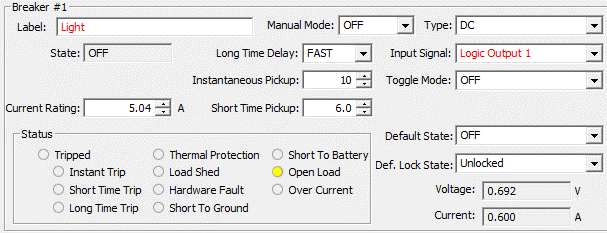

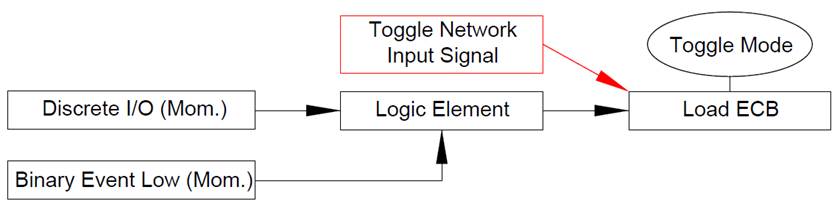

In the following circuit configuration example, there will be two momentary input sources used to switch a

single CLMD16 load in a toggle fashion. One input is from a hardwired switch that has a momentary DC

(-) signal called “Binary Event Low” and one input is a momentary Discrete I/O

input called “Discrete I/O 1”, both will be used to toggle the single CLMD16

load. The following steps shows how to accurately configure this circuit type.

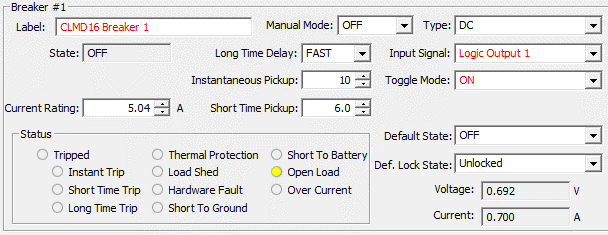

Step 1:

Assign inputs to a “Logic Element”. Where “0” is Off and “1” is On,

configure the “Logic Output” in a manner to where if any input source is On,

the “Logic Element’s Output” becomes active.

Step 2:

Place “Logic Output” signal into desired ECB control “Input Signal” and

turn on “Toggle Mode”.

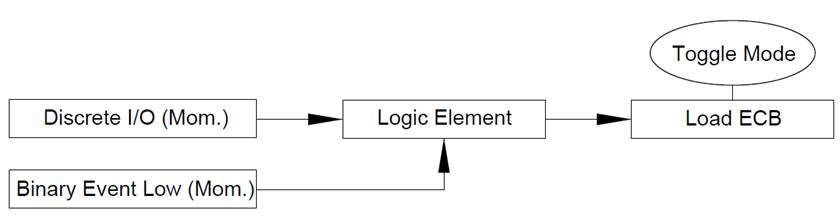

Similar to toggling a load On / Off from multiple momentary input

sources, this circuit type adds a “Toggling Network Input” signal into the

circuit. When a CLMD16 ECB is in “Toggle Mode” the ECB will toggle the state

from its current state of “On” or “Off” to the opposite state when the

following occurs: The Rising Edge or “On” detection of an ECB “Toggle Network

Input” or the Rising Edge or “On” detection of a direct ECB “Input Signal”.

This operational mode will allow for a “Toggle Network Input” which could come

from a third party MFD using 127500 Load Controller PGN or any equipment

running Maretron’s N2KView® software plus any applied direct ECB “Input Signal”

to toggle the ECB in harmony with each other. Tip: When an ECB is in “Toggle

Mode” a “Momentary Network Input” signal becomes unaffected by the “Toggle

Mode”.

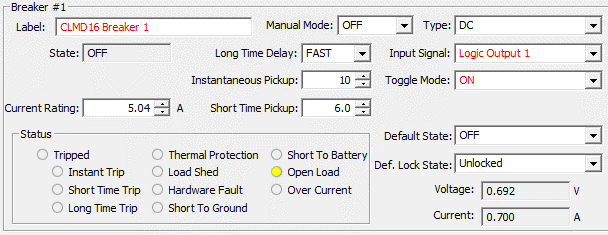

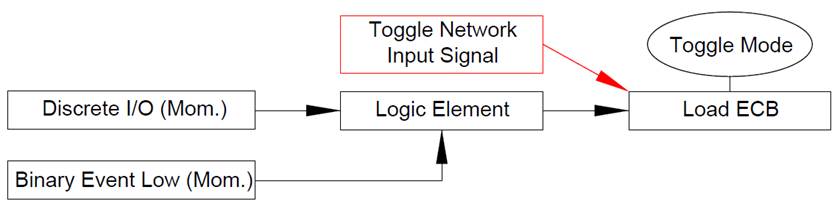

In the following example, there will be two momentary input

sources and one “Toggle Network Input” signal used to switch a single CLMD16

load in a Toggle fashion. One input is from a hardwired switch that has a

momentary DC (-) signal called “Binary Event Low” and one input is a momentary

Discrete I/O input called “Discrete I/O 1”. There is the additional influence on

the ECB of one externally set (Direct access through 127500 PGN) “Toggle

Network Input” signal. Take note that no different action is required to setup

this circuit type than the “Toggle a Load On / Off

from Multiple Momentary Input Sources” circuit

above. The only difference is the “Toggle Network Input” (shown in red) has

access to the ECB setup by the message’s origination equipment, may it be a third party MFD using 127500 Load Controller PGN or any

equipment running Maretron’s N2KView® software. Because the ECB is in

“Toggle Mode” the ECB’s “Input Signal” and “Toggle Network Input” will work in

harmony with each other toggling the ECB On / Off.

Step 1:

Assign inputs to a “Logic Element”. Where “0” is Off and “1” is On,

configure the “Logic Output” in a manner to where if any input source is On,

the “Logic Element’s Output” becomes active.

Step 2:

Place “Logic Output” signal into desired ECB control “Input Signal” and

turn on “Toggle Mode”.

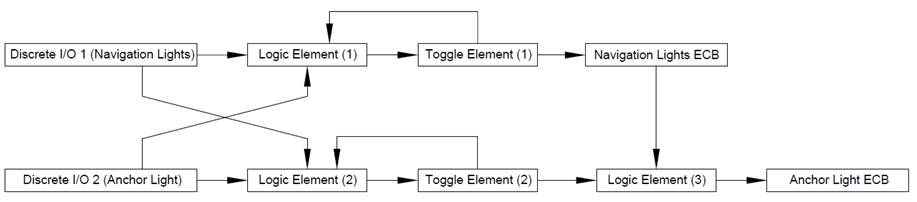

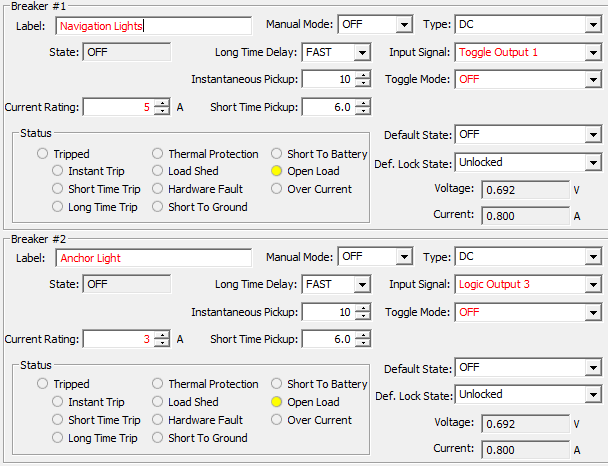

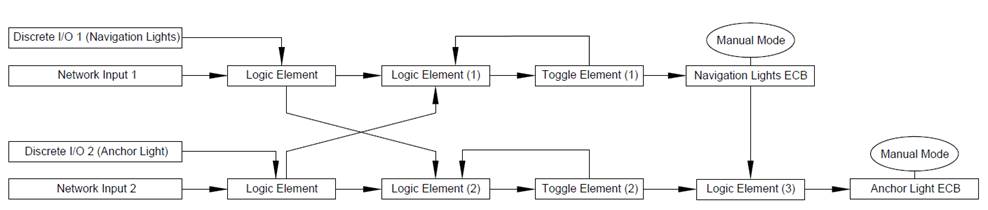

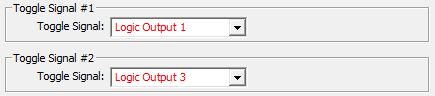

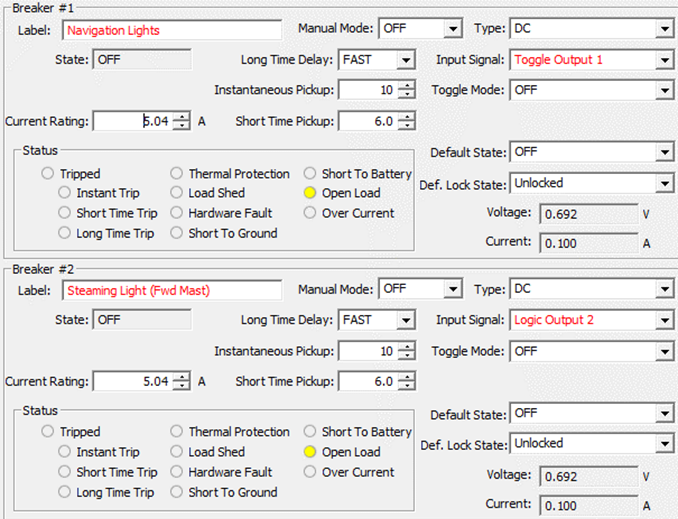

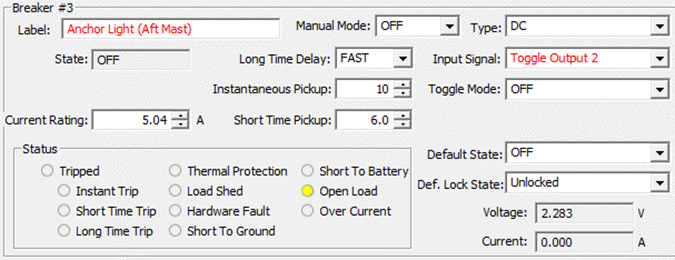

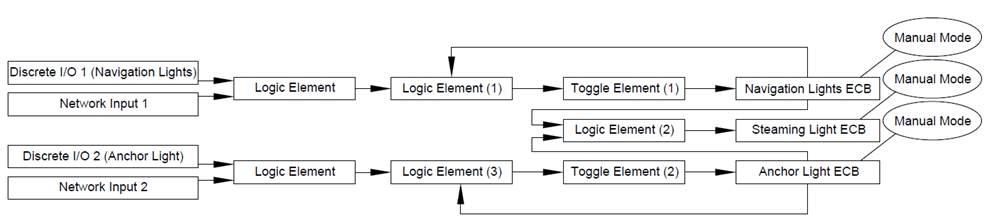

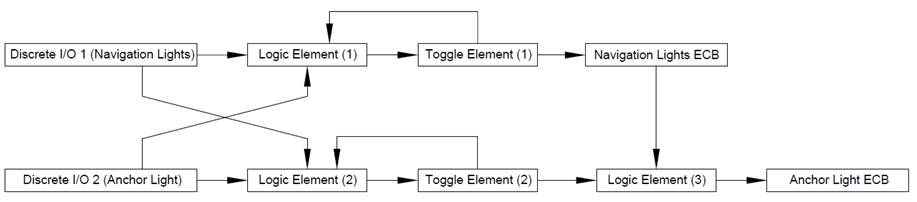

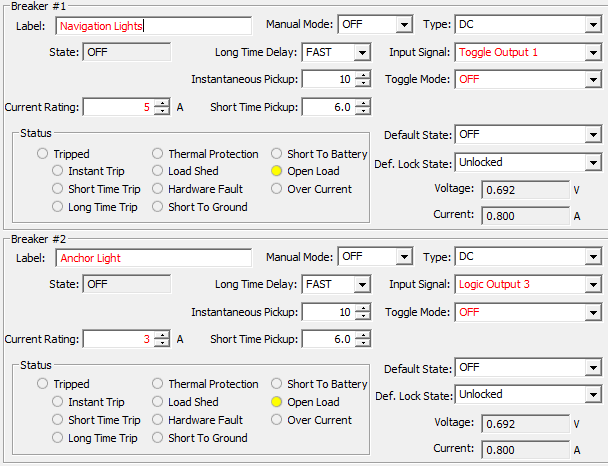

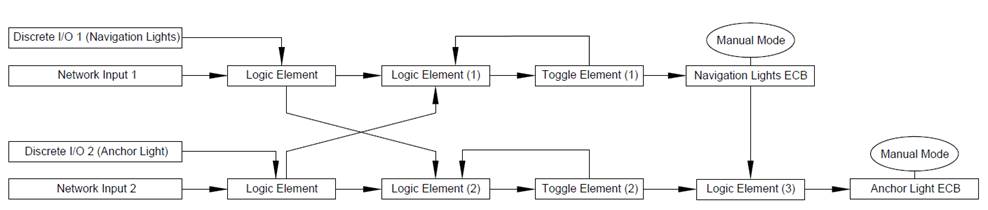

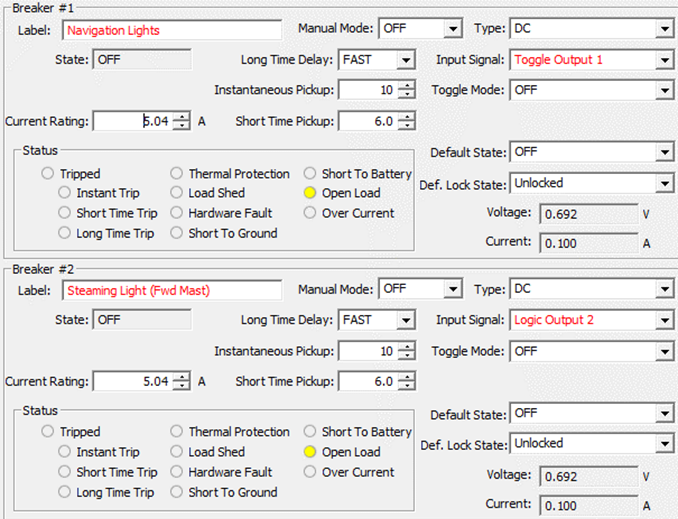

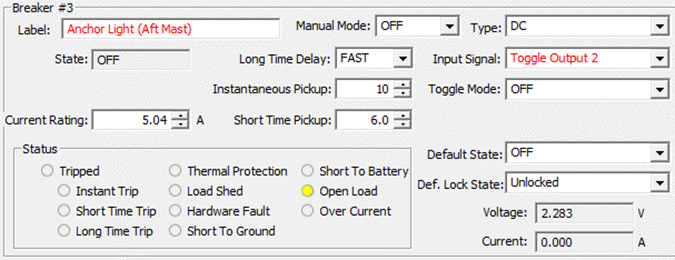

This circuit configuration type operates Navigation lights and

Anchor light loads using two separate “Discrete I/O” (Momentary) inputs. One input

for “Navigation Lights” and one for “Anchor Light”. When “Navigation Lights”

input is commanded both “Navigation Lights” and “Anchor Light” ECBs turn On.

When “Anchor Light” input is commanded “Anchor Light” ECB turns On. When

“Anchor Light” input is commanded while “Navigation Lights” ECB is On, the

“Navigation Lights” ECB is turned Off and “Anchor Light” ECB remains On. In

this example, “Discrete I/O 1” is used for “Navigation Lights” and “Discrete

I/O 2” is used for “Anchor Light”.

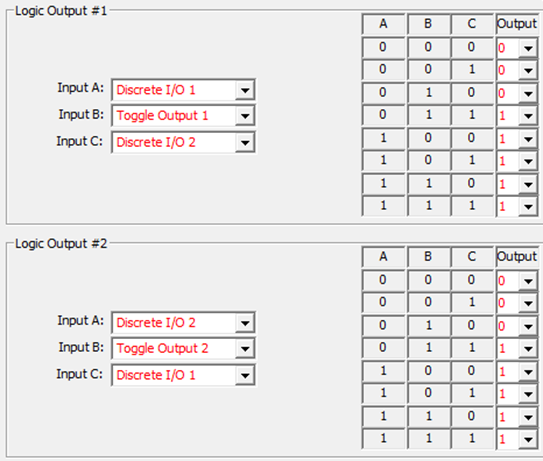

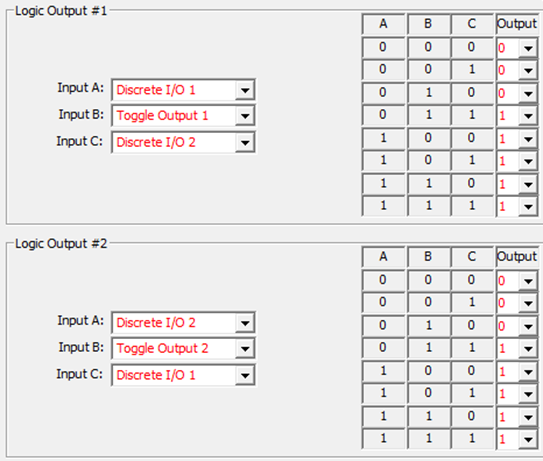

Step 1:

Choose appropriate output rules for the “Logic Elements” that will make

this circuit possible. Where 0 is Off and 1 is On, attention to the logic

output correlation to the input combination must be paid for proper operation. Notice

that the output for the “Logic Element” #1 (Used for Navigation Lights) will

turn On therefor Toggling the ECB in two states, first, with “Discrete I/O 1”

and also with “Discrete I/O 2” if the “Toggle Output 1” is already in the On

state, therefore toggling the ECB Off. The same occurs for “Logic Element #2”

(Used for Anchor Lights). In this manner each opposite input or “Discrete I/O”

cancels the other.

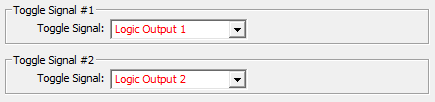

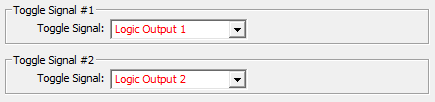

Step 2:

Place “Logic Output” signals into “Toggle Elements”.

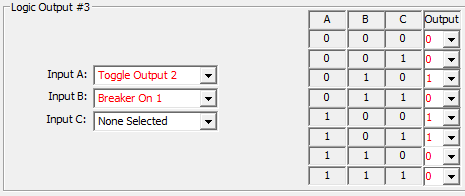

Step 3:

Create an intervening “Logic Element” for the “Anchor Light” circuit. This

“Logic Element” is used to ensure each time the “Navigation Lights” ECB

(Breaker 1) is On the “Anchor Light” ECB (Breaker 2) will turn On as well.

Select the “Logic Output” in where if either “Logic Inputs” turn On so does the

Output.

Step 4:

Place “Toggle Output” signal into “Navigation Lights” ECB and the

intervening “Logic Output” signal into “Anchor Light” breaker inputs. Ensure

“Toggle Mode” is Off.

Note:

Because a third party MFD using 127500 Load Controller PGN or any equipment

running Maretron’s N2KView® software, by default, will have direct access to

control the above-mentioned ECBs (#1 & 2) the “Navigation Lights Logic”

circuit shown here will only operate via “Discrete I/O 1 & 2”. The same

“Navigation Lights Logic” behavior may be able to be replicated inside the

internal logic of the equipment having direct control accessibility (N2KView®)

or if this logic needs to be accessed by third party MFD, “Manual Mode” can be

enabled severing this direct control access. Combinatory “Logic Elements” can

be inserted before the “Logic Element 1” and “Logic Element 2” to add “Network

Inputs 1 & 2” to the scheme enabling the same “Navigation Lights Logic”

behavior via “Network Inputs 1 & 2” as long as the signal is a momentary

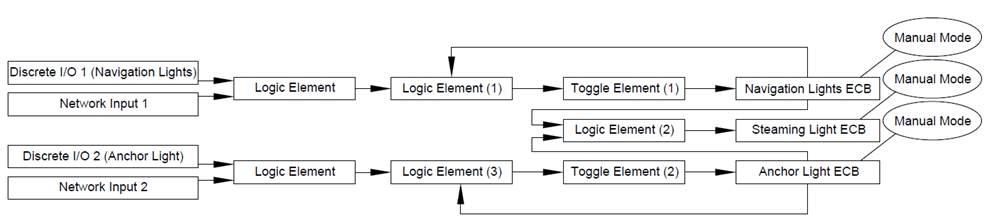

type Input Signal. The mapping for this exact circuit would look as shown below:

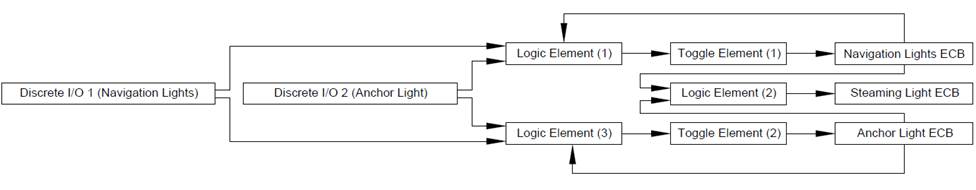

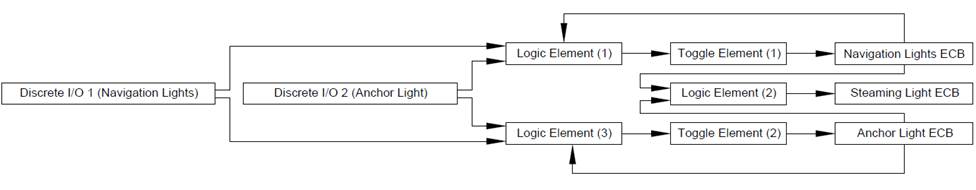

This circuit configuration type operates Navigation lights

and Steaming Light (Fwd Mast) using one “Discrete I/O” input then Steaming

Light (Fwd Mast) and Anchor light (Aft Mast) using a second “Discrete I/O” input.

When “Navigation Lights” “Discrete I/O” input is commanded both “Navigation

Lights” and “Steaming Light” (Fwd Mast) ECBs turn On. When “Anchor Light” “Discrete

I/O” input is commanded “Anchor Light” (Aft Mast) + “Steaming Light” (Fwd Mast)

ECBs turn On. When “Anchor Light” “Discrete I/O” input is commanded while

“Navigation Lights” ECB is On, the “Navigation Lights” ECB Output is turned Off

and “Anchor Light” (Aft Mast) ECB output turns On while “Steaming Light” (Fwd

Mast) ECB stays On.

Step 1:

Choose appropriate output rules for the “Logic Elements”:

In this example Discrete I/O 1 is “Navigation Lights” and Discrete I/O 2 is

“Anchor Light”. Where 0 is Off and 1 is On, attention to the logic output

correlation to the input combination must be paid for proper operation. Just as

the previous circuit above (“Navigation / Anchor

Lights Toggle Logic using two Momentary Input Signals”), there will be

rulesets that allow for Logic Output operation to occur only when the status of

a breaker is already On for the “Logic Elements” associated with “Navigation

Lights” ECB and “Anchor Light” (Aft Mast) ECBs. Notice the “Logic Element”

associated with the “Steaming Light” ECB allows for the ECB to turn On when

either ECB 1 (Navigation) or ECB 2 (Anchor) is in the On state.

Step 2:

Place “Logic Output” signals 1 and 3 into “Toggle Elements”.

Step 3:

Place “Toggle and Logic Output” signals into ECB “Input Signal” locations.

Ensure “Toggle Mode” is Off.

Note:

Because a third party MFD using 127500 Load Controller PGN or any equipment

running Maretron’s N2KView® software, by default, will have direct access to

control the above-mentioned ECBs (#1-3) the “Navigation Lights Logic” circuit

shown here will only operate via “Discrete I/O 1 & 2”. The same “Navigation

Lights Logic” behavior may be able to be replicated inside the internal logic

of the equipment having direct control accessibility (N2KView®) or if this

logic needs to be accessed by third party MFD, “Manual Mode” can be enabled

severing this direct control access. Two combinatory “Logic Elements” can be

inserted before the “Logic Elements 1 & 3” to enable the same “Navigation

Lights Logic” behavior via “Network Inputs 1 & 2” as long as the signal is

a momentary type of Input Signal. The mapping for this exact circuit would look

as shown below:

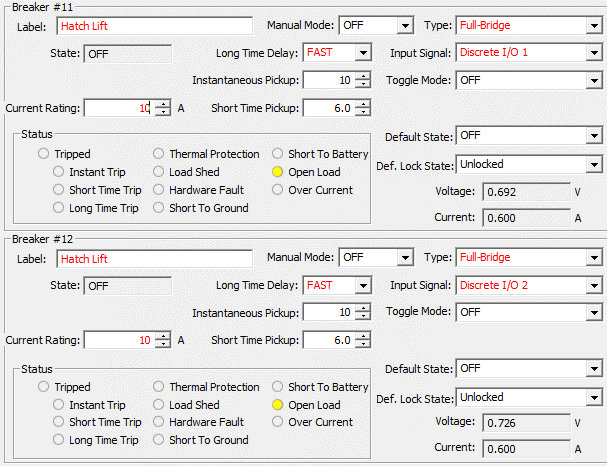

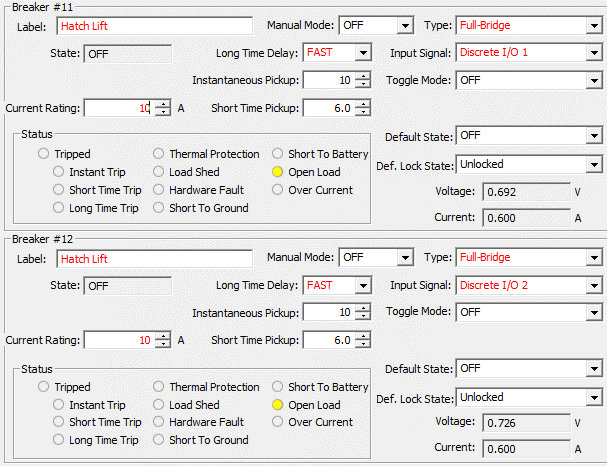

Use this circuit type to control any load requiring

reversing polarity up to 12A. Apply this circuit to a motor or some electric

actuators to reverse directionality. Setting up this circuit type requires a

one step process unless adding multiple control points. To add control points,

apply the control points to a “Logic Element” then plug the “Logic Output” into

the ECBs “Input Signal”. Breakers 1,2 and 11,12 are capable of reverse polarity

drive. The step required to setup this circuit type is to change EBC “Type” to

“Full-Bridge” or “Soft Start Full-Bridge” See following Dialog to see configuration

example.

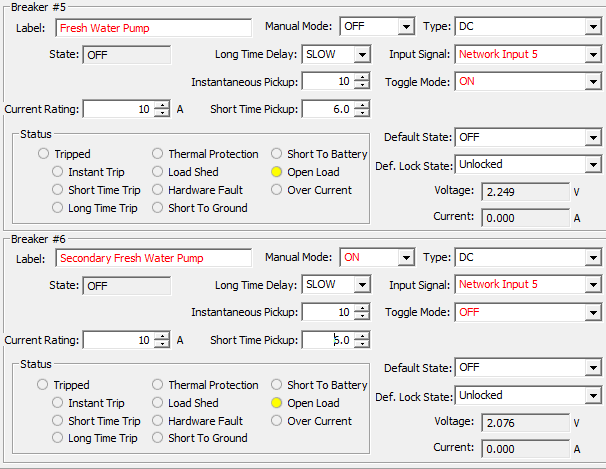

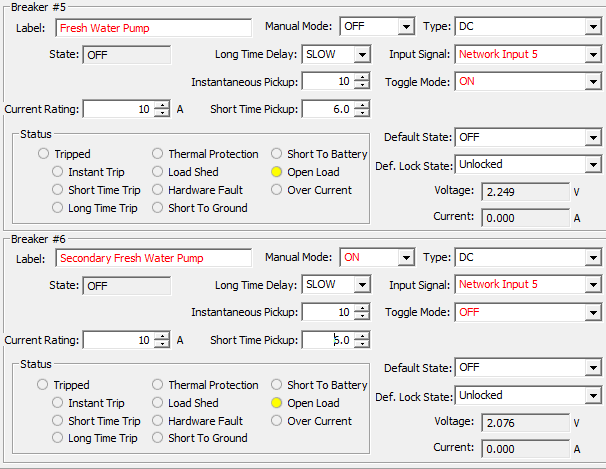

In the following example there is a single freshwater pump

controlled by “Network Input” in a vessel however the end user desires to add

another pump but wishes to continue to use only one switch to control both

pumps. The first pump already has a control circuit. See the following step to

configure the second pump.

Step 1:

Find the original freshwater pump’s control source, in this example it is “Network

Input 5”. Replicate the “Input Signal” of the original pump’s “Input Signal” to

the new secondary pump’s “Input Signal”. The secondary pump is only desired to

be controlled by the original Pump’s ECB control, for this reason, the

secondary pump ECB’s “Manual Mode” will need to be enabled. This dis-allows Breaker

#6’s direct control of the secondary pump by “Network Input 6”, but instead

will allow for only control of Breaker #6 by the “Input Signal” selected

(“Network Input 5”). Turn “Toggle Mode” for Breaker #6 Off to ensure Breaker #6

will follow the state of the original freshwater pump’s control.

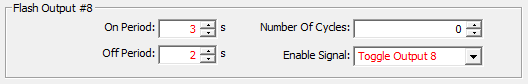

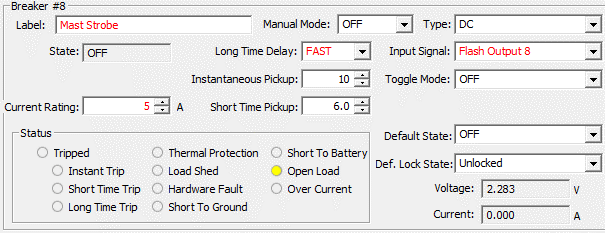

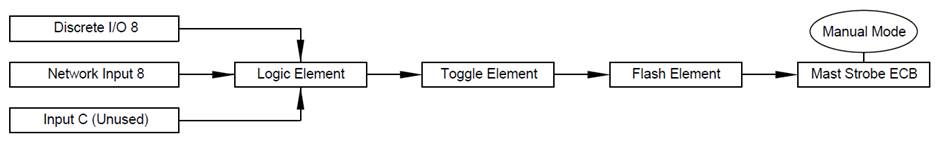

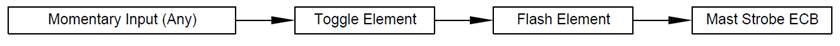

This circuit example utilizes a “Flash Element” to operate a

load called “Mast Strobe”. The following steps will outline how to configure this

load to automatically turn On / Off with the frequency of On for 3 Sec. and Off

for 2 Sec. triggered by a momentary input.

Step 1:

Assign Momentary Input to Toggle Element:

In this example “Discrete I/O 8” is the input signal to enable the mast

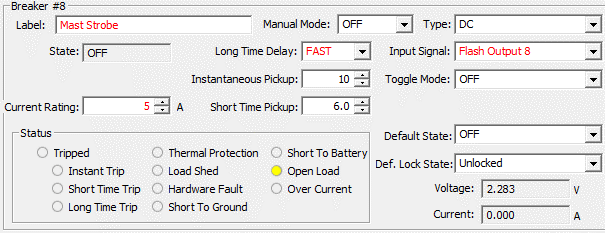

strobe circuit.

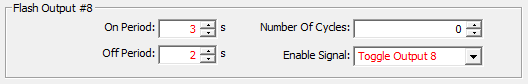

Step 2:

Where “0” is infinite cycles, set-up “Flash Element” details.

Step 3:

Apply “Flash Output” to Mast Strobe ECB. Ensure Toggle Mode is Off.

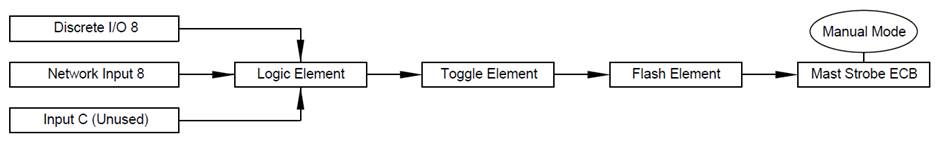

Note:

Because a third party MFD using 127500 Load Controller PGN or any equipment

running Maretron’s N2KView® software, by default, will have direct access to

control ECB #8 (Breaker #8), the “Flash Element” shown here will only operate

via “Discrete I/O 8”. The same “Flash” behavior may be able to be replicated

inside the internal logic of the equipment having direct control accessibility (N2KView®)

or if this logic needs to be accessed by third party MFD, “Manual Mode” can be

enabled severing this direct control access. A combinatory “Logic Element” can

be inserted before the “Toggle Element” to enable the same “Flash” behavior via

“Network Input 8” as long as the signal is a momentary type

of Input Signal. The mapping for this exact circuit would look as shown

below:

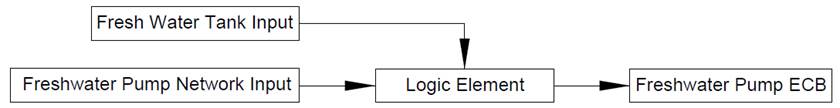

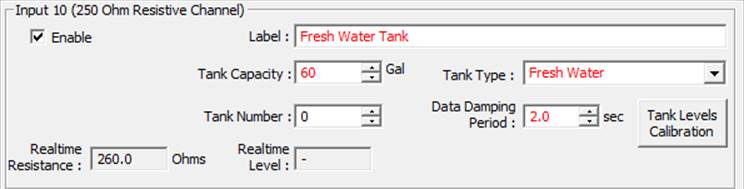

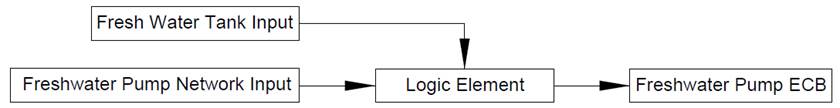

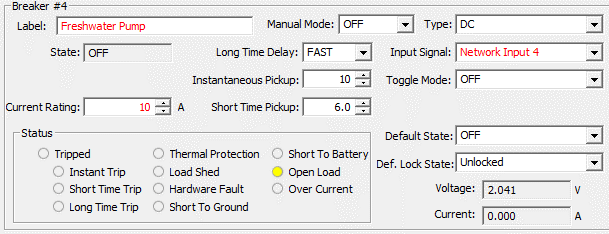

In the following example there will be a freshwater pump

load that turns Off based on tank level becoming low and restores functionality

when filled back up. The freshwater pump in this example is connected to “ECB /

Breaker 4” and the “Freshwater Tank” we are monitoring is connected to “Input

10”. The intent of this is so the freshwater pump does not run dry potentially

damaging the pump. Using this circuit type can prevent unwanted damage to pumps

as well as a way to keep fluid systems primed. See the following example to

setup this circuit type.

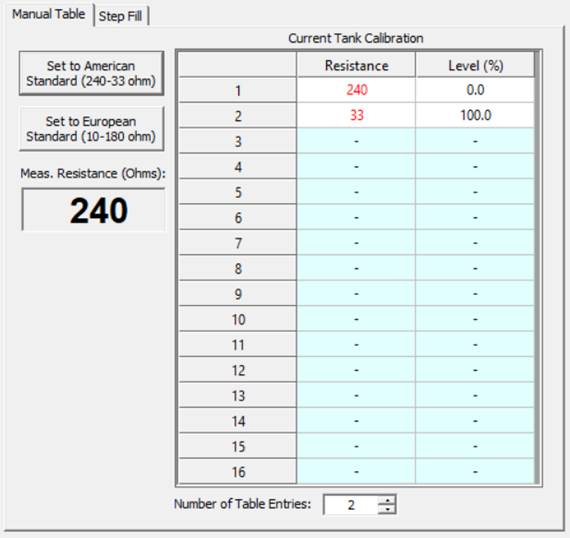

Step 1:

Understand what resistance readings equate to “Full” and “Empty” to the CLMD16.

Press “Tank Levels Calibration” on the particular input used for the freshwater

tank sender. Understanding that 240 Ohms = “Tank Empty” / 0%, We will use “230

Ohms” as our “Marker” for when we want the freshwater pump connected to breaker

4 to switch Off. It is recommended that this “Marker” is determined by judging

“Measured Resistance” ohm reading when calibrating for accuracy in determining

the best “Marker Point”.

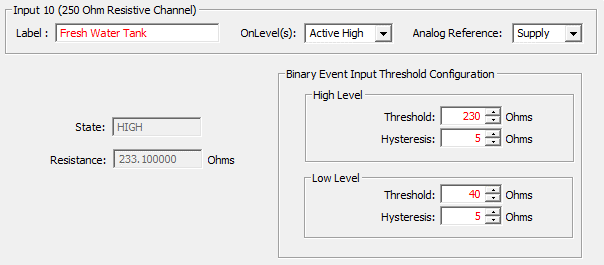

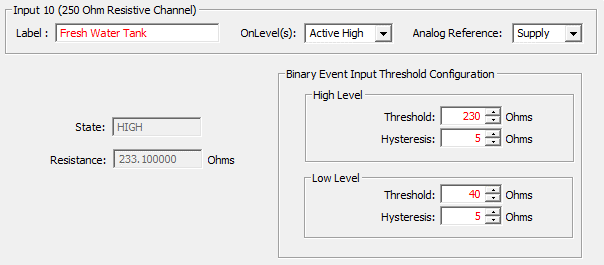

Step 2:

Remembering our “Marker Point” of: “230 Ohms” the next step will be to navigate

to the “Inputs Tab” and create a “Binary Event High Level” based on this

“Marker Point”. The reason this is going to be a “High Level” indication is

because the variable resistive sender Ohm level continuously goes higher as to

tank level gets lower in fluid level.

Step 3:

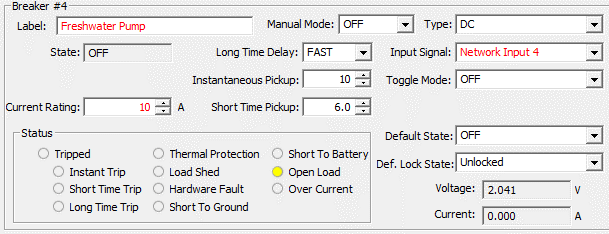

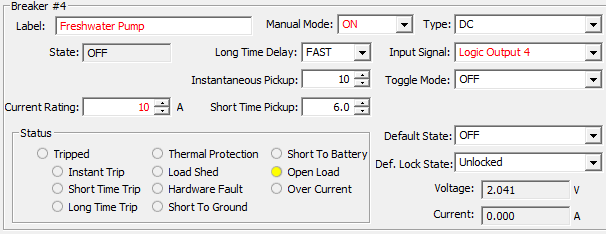

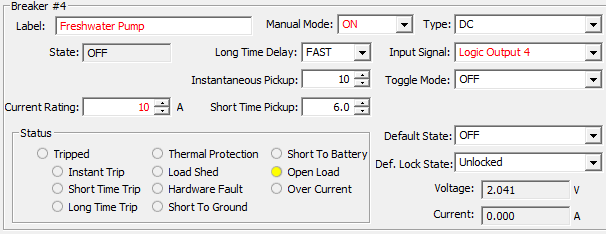

Next, an interjection of a “Logic Element” needs to be inserted into the

freshwater pump circuit control. Find out what type of “Input Signal” is

currently being used for the freshwater pump load. In this case it is “Network

Input 4”. Remove “Network Input 4” and add an available “Logic Element”. In

this example we are going to use “Logic Output 4”. Ensure “Toggle Mode” is Off

as “Toggle Mode” changes the state of the breaker every time and “Input Signal”

is detected therefore this will cause the pump not to restore its state when

the tank is re-filled. Also because we do not want to allow for direct ECB control

accessibility, turn “Manual Mode” on.

From:

To:

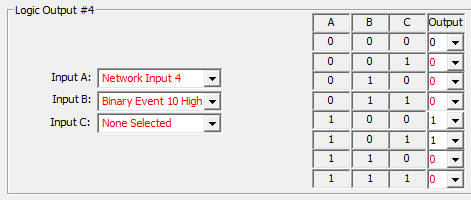

Step 4:

Now, Using the newly created “Binary Event High” signal, add this signal to the

interjected “Logic Element” and place the original freshwater control “Input

Signal” that was “Network Input 4” into the “Logic Element” as well. Select the

logic element’s output parameters such that when the “Binary Event High” signal

is met the “Logic Output” turns off consequently turning off the freshwater

pump.

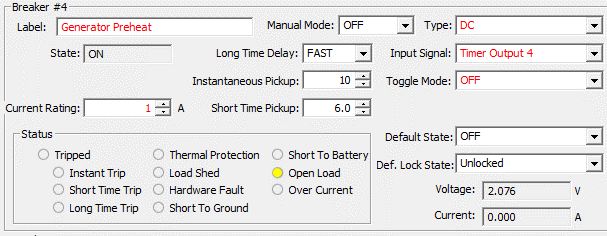

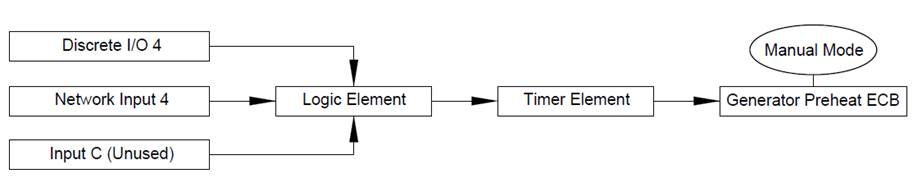

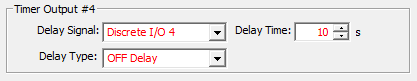

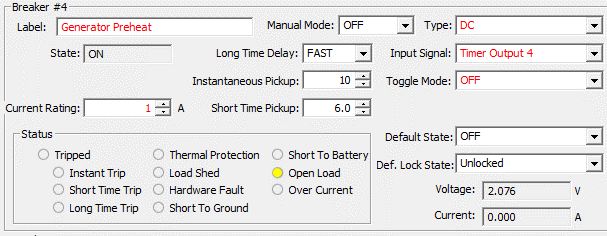

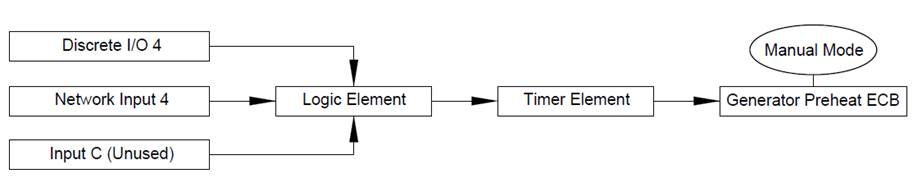

This Circuit uses a “Timer Element”. In this example there

will be a “Delay Off” signal used to “Time” a load named “Generator Preheat”

that needs to be triggered by “Discrete I/O 4” (Momentary Input). The generator

requires a 10s timed signal to preheat the generator. See following steps to

setup a circuit of this type.

Step 1:

Place the Input Signal used to trigger the “Generator Preheat” Circuit into the

“Timer Element” “Delay Signal”. Set up the “Timer Element” parameter for “Off

Delay” and apply the needed 10s. This will make for when the “Delay Signal” is

enabled (after releasing the momentary “Network Input 4” or turning it “OFF”) the

circuit will stay On for 10s.

Step 2:

Apply “Timer Output” into the “Input Signal” of the breaker used for the

Generator Preheat.

Note:

Because a third party MFD using 127500 Load Controller PGN or any equipment

running Maretron’s N2KView® software, by default, will have direct access to

control ECB #4 (Breaker #4), the “Timer Element” shown here will only operate

via “Discrete I/O 4”. The same “Timer” behavior may be able to be replicated

inside the internal logic of the equipment having direct control accessibility (N2KView®) or if this logic needs to be accessed by third

party MFD, “Manual Mode” can be enabled severing this direct control access.

A combinatory “Logic Element” can be inserted before the “Timer Element” to

enable the same “Timer” behavior via “Network Input 4” as long as the signal is

a momentary type of Input Signal. The mapping for this exact circuit would look

as shown below:

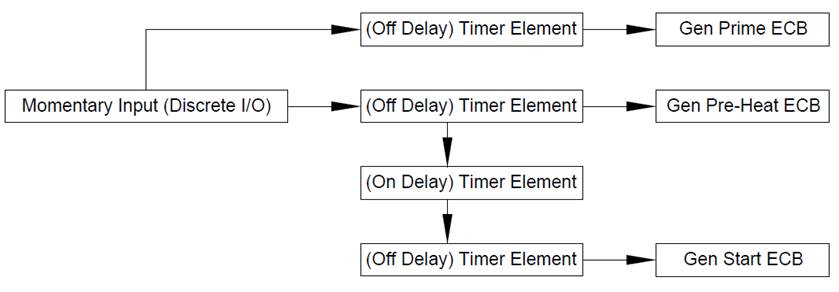

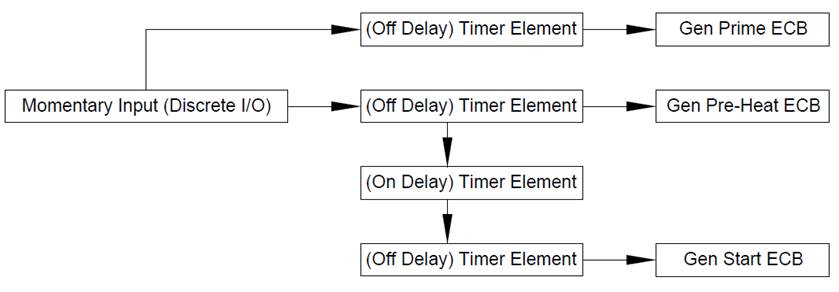

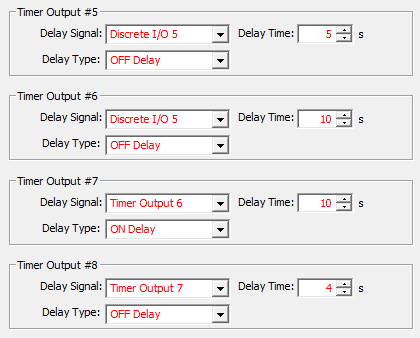

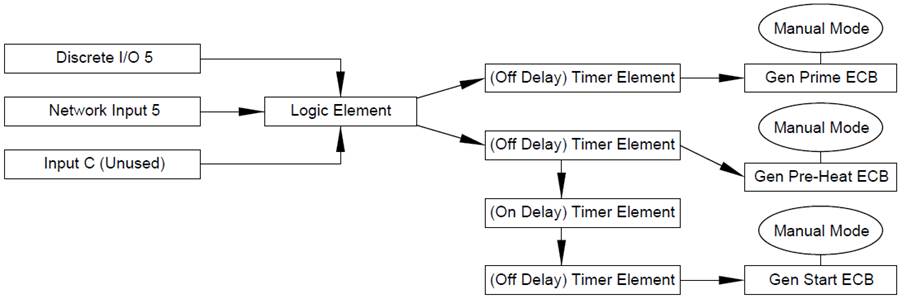

In this example there will be a sequence of 2 timed events

using “Timer Elements” to start the process of Priming, Pre-heating, and

starting a Generator where these items must be handled in a manner of sequence.

First sequence being to “Prime” and “Pre-Heat” and last sequence to “Start”.

The input used to start this sequence is “Discrete I/O 5” (Momentary Input) and

called “Gen Start”. Each “Timer Element” will trigger an ECB / breaker output

for each of the three actions the Generator will need to start (Prime, Preheat,

Start). The generator requires 5s to “Prime”, 10s to “Pre-Heat” and 4s to

“Start”.

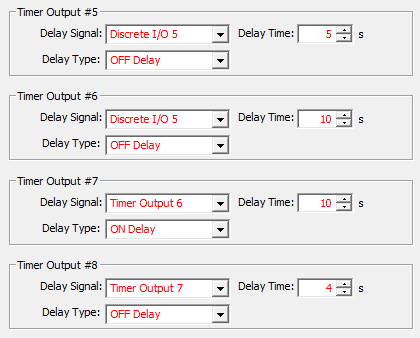

Step 1:

Place desired Momentary Input (Discrete I/O 5) to start the “Timer Elements”

for “Prime” and “Pre-Heat”. Add the output of the Pre-Heat “Timer Output” to

another “Timer Element” where the “Timer Element” has an “On Delay” equivalent

to the time the “Pre-Heat” “Timer Element” is set to (10s). Add the output of

the “On Delay” “Timer Element” to the “Timer Element” that will be used for the

4s “Start” signal.

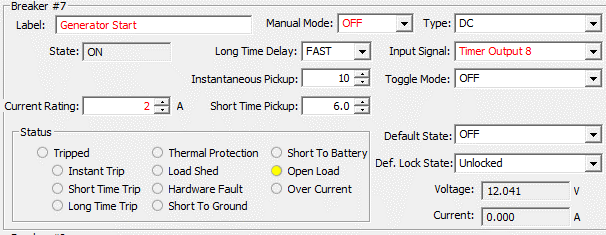

Step 2:

Apply “Timer Outputs” to appropriate Breaker “Input Signals” for each sequence

function

( Prime, Preheat, Start). Ensure “Toggle Mode” is off on each ECB.

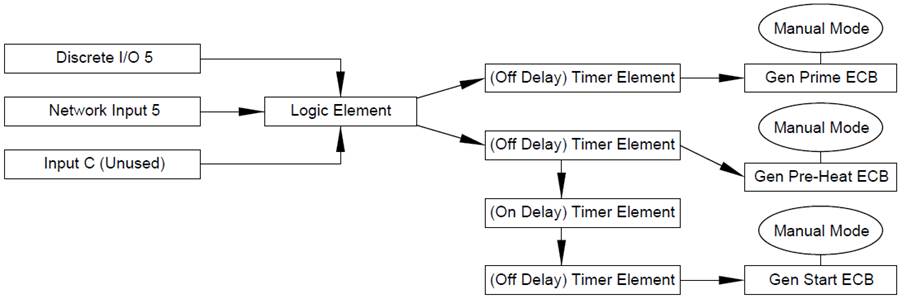

Note:

Because a third party MFD using 127500 Load Controller PGN or any equipment

running Maretron’s N2KView® software, by default, will have direct access to

control all three ECBs shown in this example, the “Circuit Sequence” shown in

this example will only operate via “Discrete I/O 5”. The same “Circuit

Sequence” behavior may be able to be replicated inside the internal logic of

the equipment having direct control accessibility (N2KView®) or if this logic

needs to be accessed by third party MFD, “Manual Mode” can be enabled to each

ECB severing this direct control access. A combinatory “Logic Element” can

be the “Input Signal” of each “Timer Element” to enable the same “Circuit

Sequence” behavior via “Network Input 5” as long as the signal is a momentary type

of Input Signal. The mapping for this exact circuit would look as shown below:

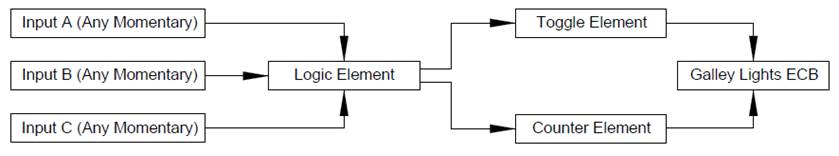

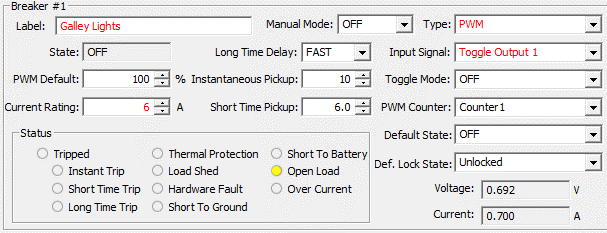

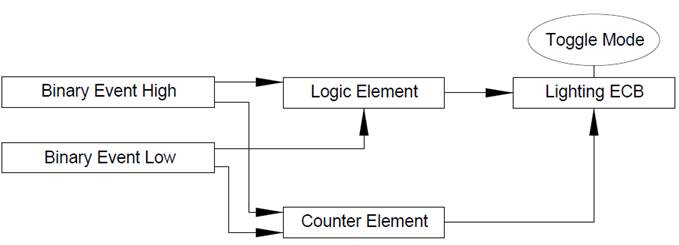

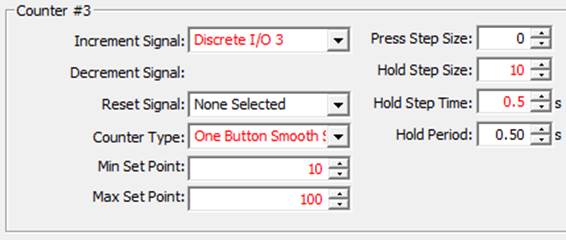

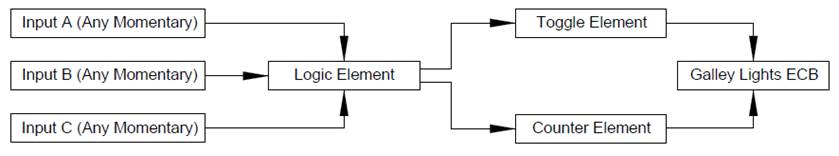

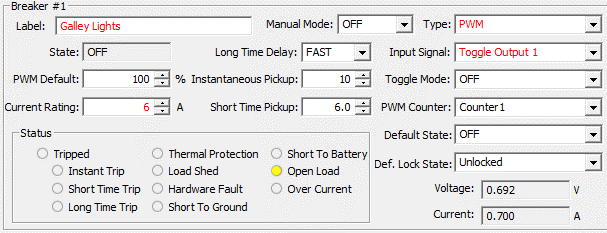

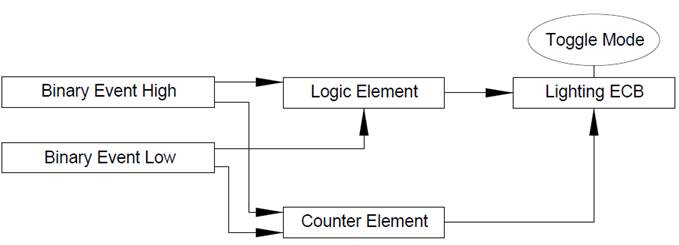

In this example there is a load called “Galley Lights” that

can have one or more momentary inputs to toggle the lights On / Off if the

momentary input is turned On with a “Quick Press”. If the momentary input is

“Held”, the lights will dim up/ dim down (PWM up / down) as long as the input

is On or “Held”. If the input is “Held” and then released at the desired dim

level (PWM level) the dim level is retained for each time the load is toggled

On using a “Quick Press” until the next time the input is “Held”. This feature is

obtained by the use of PWM “Counter” also known as a “Counter Element”. See

following steps to setup this circuit type for one or more control points.

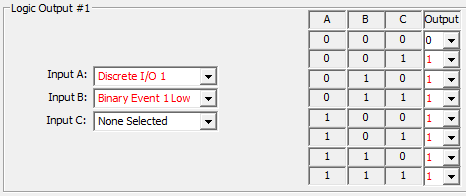

Step 1:

Apply the desired momentary inputs to control this circuit to a “Logic

Element”. Where “0” is Off and “1” is On, configure the

“Logic Output” in a manner to where if any input source is On the “Logic

Element’s Output” becomes active. This step is not necessary if only one

control point is necessary for the circuit. If only one control point is being

used for this circuit place that control input in the stead of “Logic Output

1”.

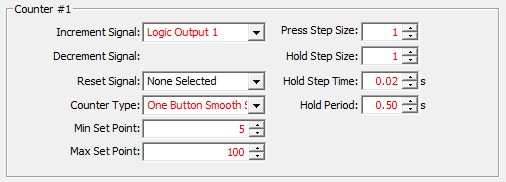

Step 2:

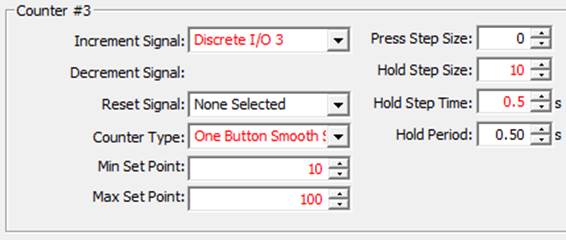

Apply “Logic Output” to the “Counter Element”, Select “One Button Smooth

Scroll” for the “Counter Type” Set “Counter” parameters. The parameters

depicted in this example are a good choice for this circuit type however can be

adjusted as desired.

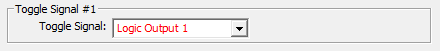

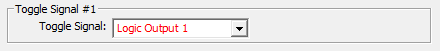

Step 3:

Apply “Logic Output” to a “Toggle Element”

Step 4:

After setting the ECB “Type” to “PWM”, Apply both the “Toggle Output” and the

“Counter Element” to the ECB parameters. Ensure “Toggle Mode” is Off.

Note:

The “One Button Smooth Scroll” shown in this example will only operate via

“Discrete I/O 1” and “Binary event 1 Low”. When a “Counter” is selected the

“One Button Smooth Scroll” behavior cannot be replicated by any equipment

having direct control accessibility to the ECB via 127500 Load Controller PGN

including N2KView® but instead the load will only

Toggle On / Off. If this behavior is desired by MFD, the use of “Toggle Mode”

and elimination of the “Toggle Element” show in this example is acceptable. If

this logic needs to be accessed by third party MFD or N2KView®, “Manual Mode”

can be enabled to the ECB and “Network Input” for breaker 1 (Network Input 1)

can be added to “Input C” of “Logic Element 1” therefor allowing “One Button

Smooth Scroll” behavior to occur via “Network Input” such as control from Third

Party MFD or N2KView®. Keep in mind, “One Button

Smooth Scroll” operates via momentary Input only. If dimming a circuit from

N2KView® only is desired, select “None” in the “PWM Counter” Dialog and enable

PWM control from N2KView®.

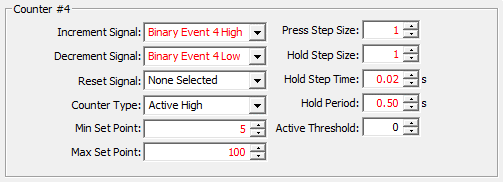

In this example there is a hardwired input to CLMD16 wired

to “Input 4”. This hardwired input is connected directly to the center position

of the SPDT switch one side of the switch is wired to DC (+) and the other to

DC (-). If the ECB output is off and the switch is

activated one direction and held, the CLMD16 hardwired input will receive DC

(-) and the ECB output will PWM down or dim. If the ECB output is off and the

switch is activated and held the other direction, the hardwired input will

receive DC (+) and the ECB output will PWM up or brighten. When the switch is

activated in either direction in a quick manner, the ECB will toggle On if Off

and Off if On while recalling the last PWM state.

Step 1:

Populate a “Logic Element” that contains both “Binary Event High” (Connected to

DC+) and “Binary Event Low” (Connected to DC-) for the appropriate DC Input (In

this example it is “Input 4”). Where “0” is Off and “1” is On, configure the

“Logic Output” in a manner to where if any input source is On the “Logic

Element’s Output” becomes active.

Step 2:

Setup “Counter” where the “Increment Signal” is the “Binary Event High” signal,

and the “Decrement Signal” is “Binary Event Low”. Because it is not desired to

Dim down below 5% set the “Minimum Set Point” to 5. Set the Maximum to 100. See

other parameters for a generic setting used for lighting where the “Hold Period”

(Correlating to the amount of time the input must be held before dimming) is

set to 0.5s and the time in between PWM steps is 0.02s with a PWM “Step Size”

set in 1% PWM gap.

Step 3:

Setup ECB parameters. Ensure “Toggle Mode” is On. Place the “Logic Output” into

the “Input Signal” and be sure to select “PWM” as the ECB “Type” this will

allow for the entry of the “Counter”.

Note:

If this circuit does not operate, please ensure parameter settings defining

“Binary Event Low” and “Binary Event High” are set in accordance with the

defining voltages that the CLMD16 will be receiving from your input source.

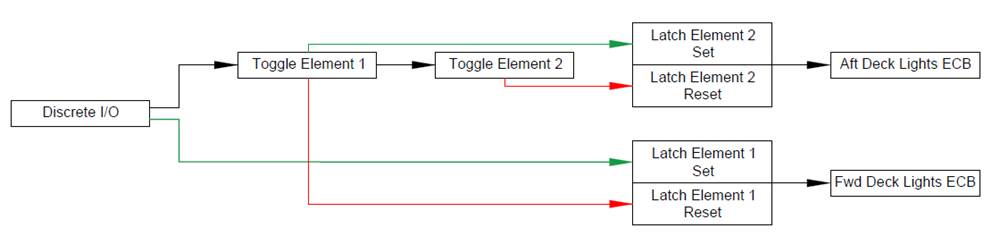

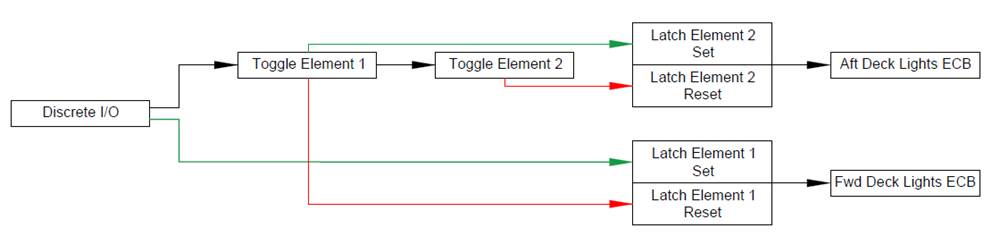

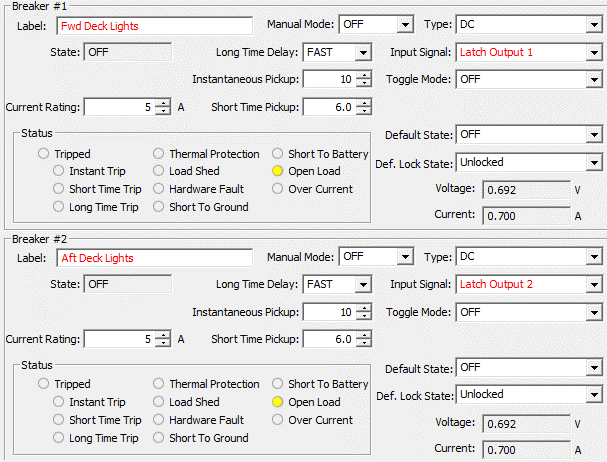

In the following example there is a circuit that has two

loads, one load is called “Fwd. Deck Lights” and one load is called “Aft Deck

Lights”. It is the desire for this circuit to operate from a single input

(Discrete I/O 1) where “Press 1” turns On “Fwd Deck Lights”, “Press 2” turns On

“Aft Deck Lights”, “Press 3” turns On both, “Press 4” turns both Off. See the

following example steps to setup a circuit of this type.

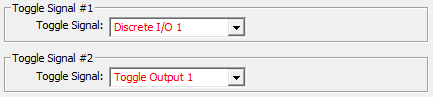

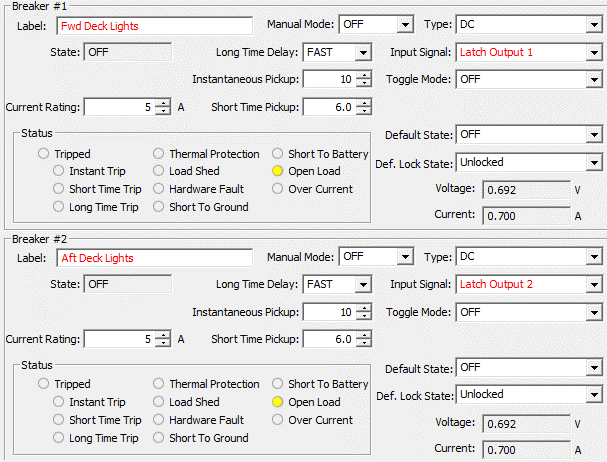

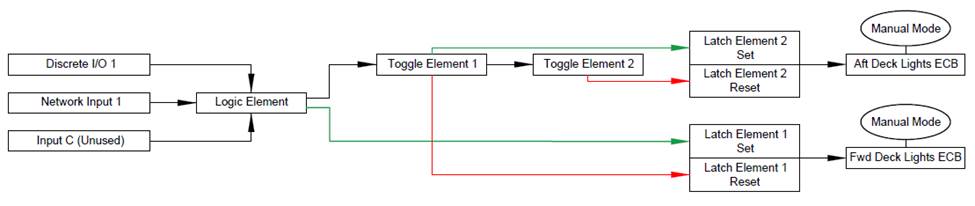

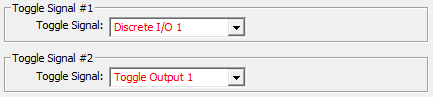

Step 1:

Place circuit control input (Discrete I/O 1) into a “Toggle Element”, then add

the output of the first “Toggle Element” into a second “Toggle Element”

Step 2:

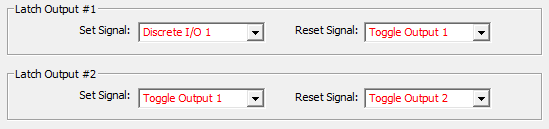

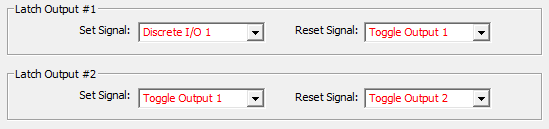

Place the circuit control input into a “Latch Element”, “Set Signal”. The

output of the first “Toggle Element” goes into the “Reset Signal”. Creating

another “Latch Element” place the output of the first “Toggle Element” into the

“Set Signal” field. In the “Reset Signal” field place the output of the second

“Toggle Element”.

Step 3:

Apply the outputs of the “Latch Elements” into the “Input Signal” field of the

two load ECB parameter dialogs. Ensure “Toggle Mode” is Off.

Note:

Because a third party MFD using 127500 Load Controller PGN or any equipment

running Maretron’s N2KView® software, by default, will have direct access to

control ECB #s 1 & 2 Separately (Breakers #1 & 2), the “Toggle

Sequence” shown here will only operate via “Discrete I/O 1”. The same “Toggle

Sequence” behavior may be able to be replicated inside the internal logic of

the equipment having direct control accessibility (N2KView®) or if this logic

needs to be accessed by third party MFD, “Manual Mode” can be enabled to both

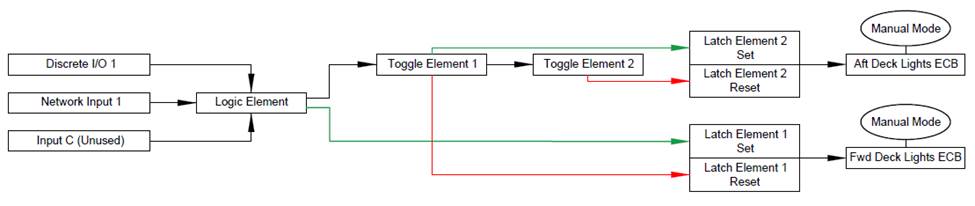

ECBs severing this direct control access. A combinatory “Logic Element” can be

inserted before “Toggle Element 1” and “Latch Element 1” to enable the same “Toggle

Sequence” behavior via “Network Input 1” as long as the signal is a momentary type

of Input Signal. The mapping for this exact circuit would look as shown below:

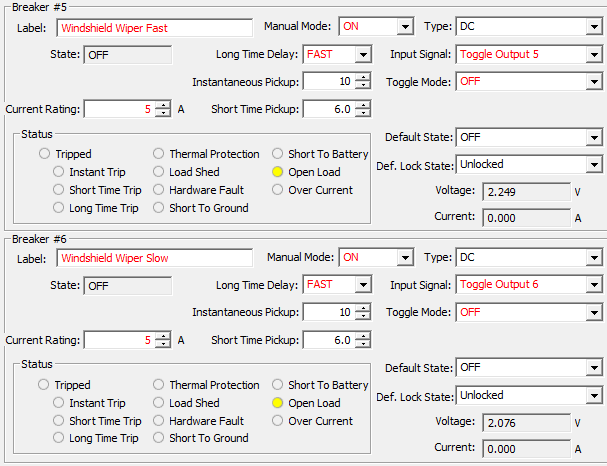

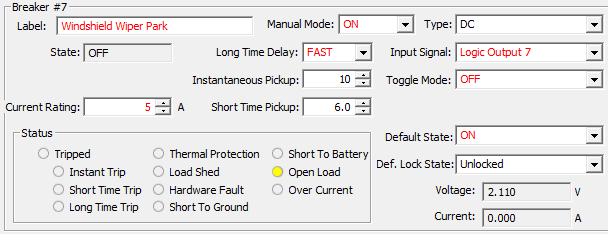

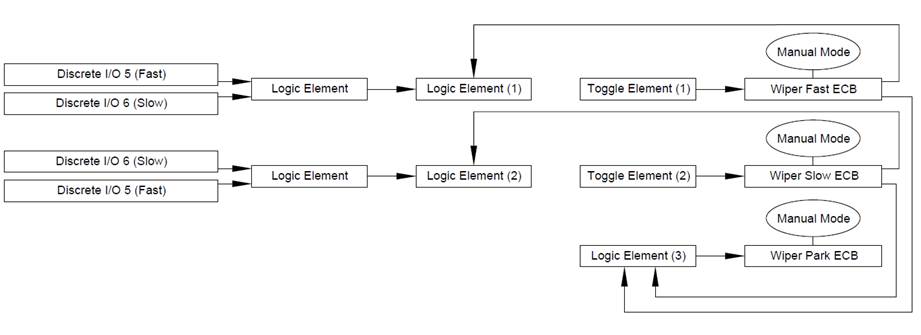

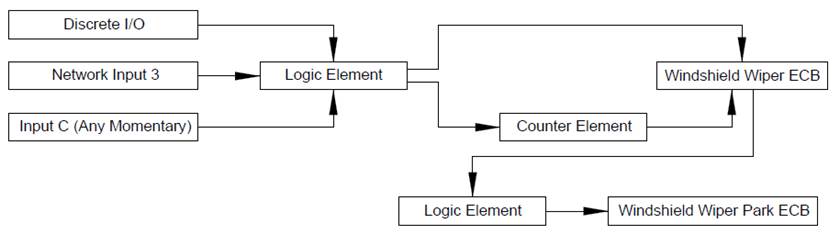

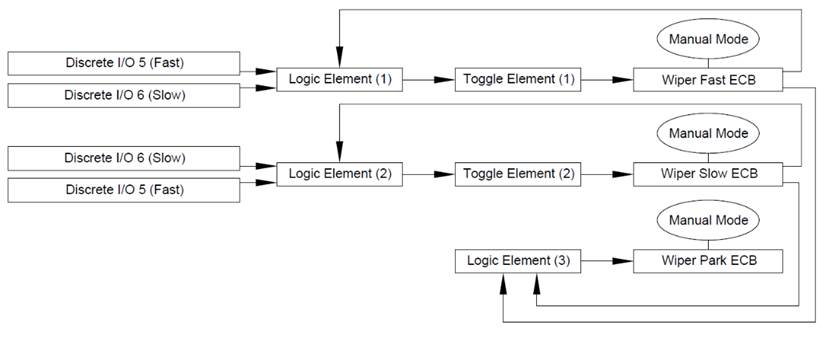

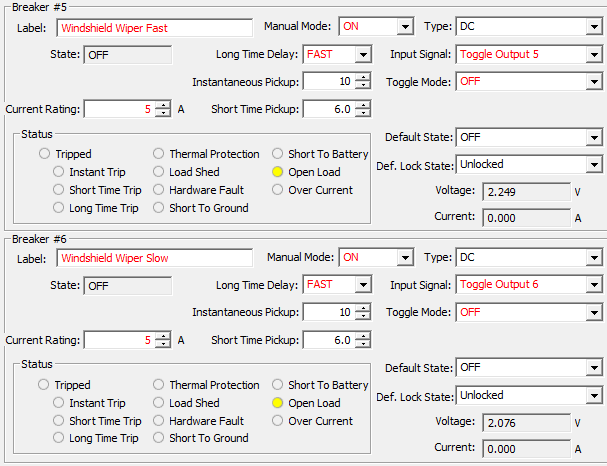

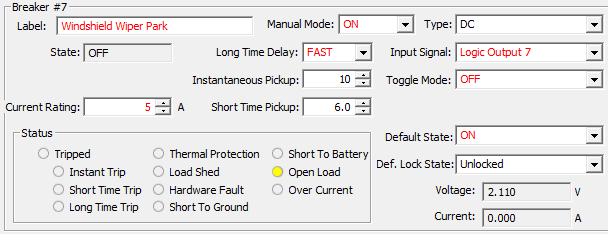

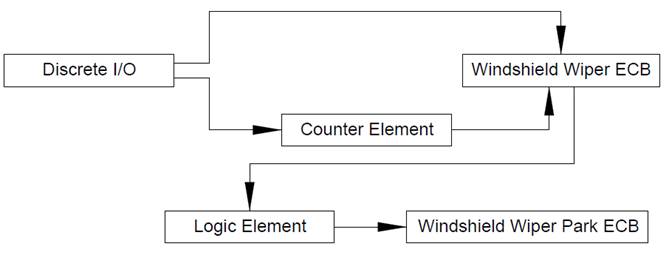

In the following example there is a windshield wiper motor

that accepts a DC (+) output for each speed. One for “Fast” and one for “Slow”.

The windshield wiper system will need a “Park” signal (DC +) that will need to

be applied when the wiper is not in “Slow” or “Fast” operation. The circuit

will take a total of 3 outputs from CLMD16. The “Fast” operation will have to

disable the “Slow” operation and vise-versa as the wiper motor cannot accept

both signals at once. The “Park” signal must be On by default, turn Off when

the “High” or “Low” operations are On and restore to the On state when “Fast”

and “Slow” are Off. The control for this circuit will be “Discrete I/O 5” for

“Fast” and “Discrete I/O 6” for “Slow” See the following example steps to setup

a circuit of this type.

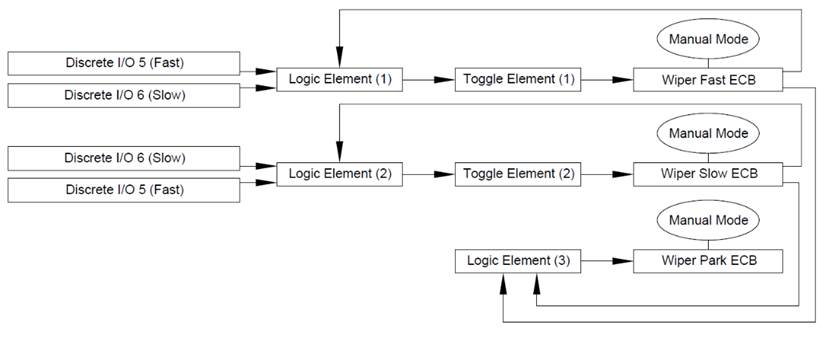

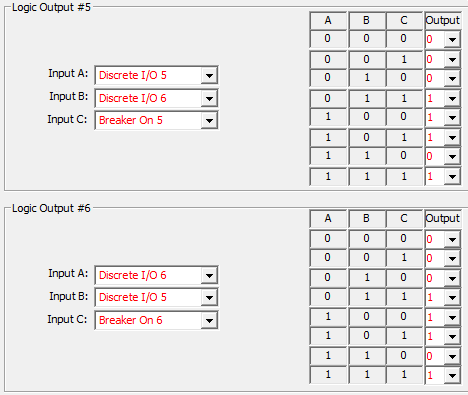

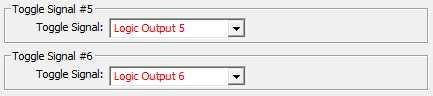

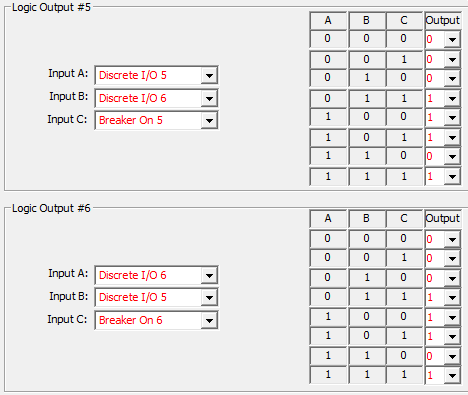

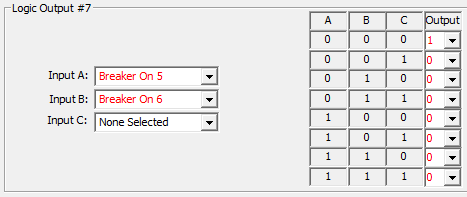

Step 1:

Because this circuit is mostly done within the “Logic Element” Switching Logic,

It is best to start with the “Logic Elements”. In this example, “Logic Elements

5-7” will correspond with ECBs 5-7 respectively. Where “0” is Off and “1” is

On, configure the “Logic Output” in a manner where each “Discrete I/O” used for

control will cancel the other, yet the opposing Discrete I/O will not allow for

the Output to do so unless the ECB is On. Do this by using the “Breaker On”

signal. Notice the arrangement for the “Logic Output 7” where the output will

not turn On unless both ECBs 5 and 6 are Off.

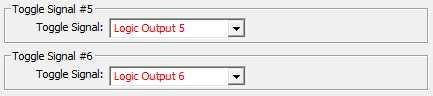

Step 2:

Place the “Logic Outputs” of the “Fast and Slow” speed ECBs into “Toggle

Elements”

Step 3:

Map the “Toggle Elements” and the single “Logic Element” into the ECBs “Input

Signals”. ensure “Toggle Mode” is Off. Because damage to the motor can occur if

operated incorrectly, it is best this circuit has “Manual Mode” enabled on its

ECBs. This will prevent an MFD using 127500 Load Controller PGN to have direct

access to control the ECBs.

Note:

The same Windshield Wiper Control behavior may be able to be replicated

inside the internal logic of equipment having direct control accessibility

(N2KView®) or any third party MFD using 1275000 Load Controller PGN. If this

logical circuit needs to be accessed by third party MFD, two combinatory “Logic

Elements” can be inserted into the circuit allowing “Network Input” control of

this circuit as long as the signal is a momentary type of Input Signal. The

mapping for this exact circuit would look as shown below:

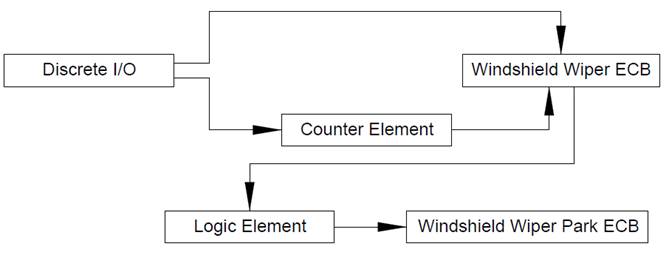

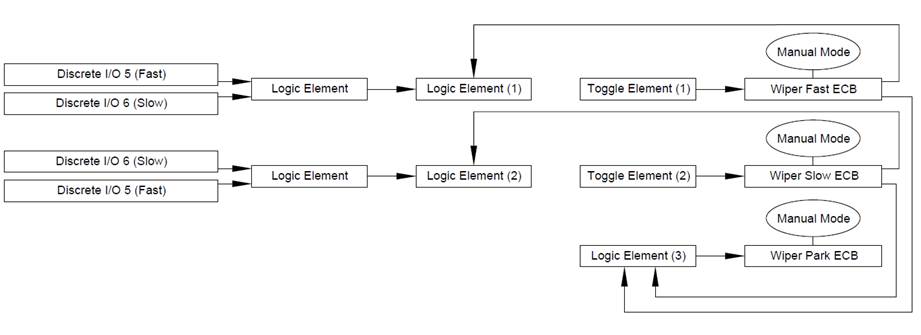

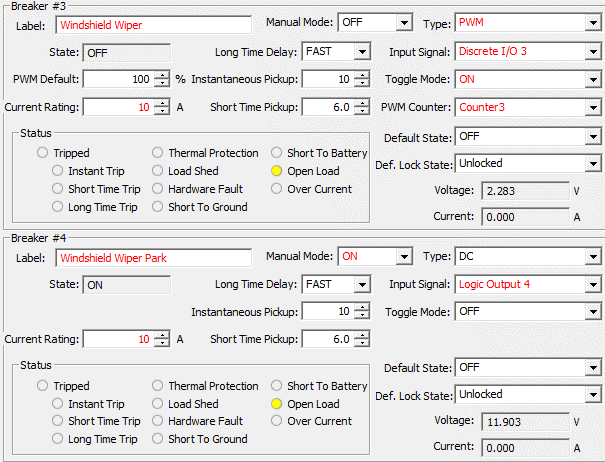

In the following example there is a windshield wiper motor

that is PWM compatible for speed control. The customer wants to have one

Discrete I/O key that will turn the wiper motor On and Off and use the same key

to adjust the speed at start-up. One ECB output will be used as a PWM type ECB

to make this speed control happen however there is the need for a second ECB to

be used to enable the “Park” signal for the wiper motor. The “Park” signal

needs to be On whenever the wiper motor power / speed control ECB is Off. The

following example shows how this circuit type will be arranged using “Discrete

I/O 3” as the circuit control.

Step 1:

Place desired parameters into the “Counter Element” that will be used for the

speed control. This example will use “One Button Smooth Scroll” as the “Counter

Type” allowing for a loop of steps in PWM from PWM “Min Set Point” to “Max set

point” then back down to “Min set point” in a continuous loop. The PWM counter

does not start until the “Hold Step Time” is reached. The “Hold Step Size” is

10% therefore giving the wiper motor a total of 9 speeds between 10% PWM and

100% PWM.

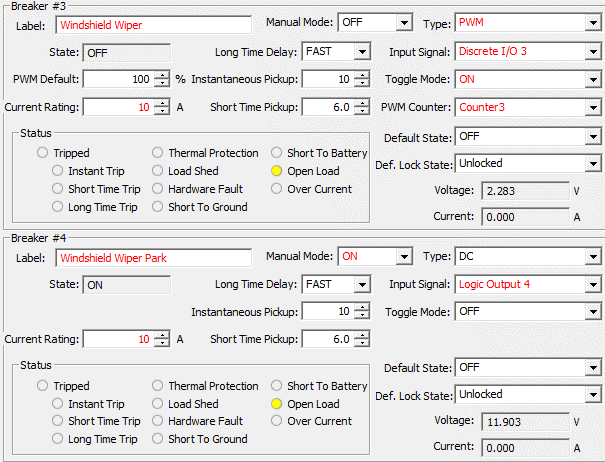

Step 2:

Arrange the ECB parameters. For the ECB used as the speed control output to the

motor, set the ECB to “PWM” type with the appropriate “Counter Element”

assigned to the ECB. Ensure “Toggle Mode” is On for this ECB. Set the ECB

parameters for the windshield wiper “Park” signal choosing an available “Logic

Element” as the “Input Signal”. Ensure “Toggle Mode” is Off for this ECB.

Because the ECB used for the “Park” signal should not be influenced by any

outside signals turn “Manual Mode” on for this ECB.

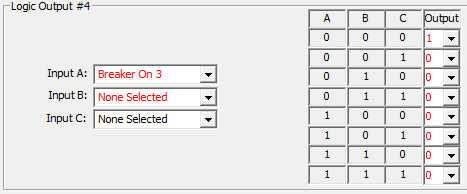

Step 3:

Add the “Park” signal Logic. Where “0” is Off and “1” is On, configure the “Logic

Output” in a manner where the “Logic Output” will always be On when the ECB

used for the speed control is Off.

Note:

Because of the use of a “Counter Element” the same Windshield Wiper Control

behavior will not be able to be replicated inside the internal logic of any equipment

having direct control accessibility to the ECBs including N2KView® or any third

party MFD using 1275000 Load Controller PGN. If this logical circuit needs to be

accessed by third party MFD, a single combinatory “Logic Element” can be

inserted into the circuit allowing “Network Input” control of this circuit as

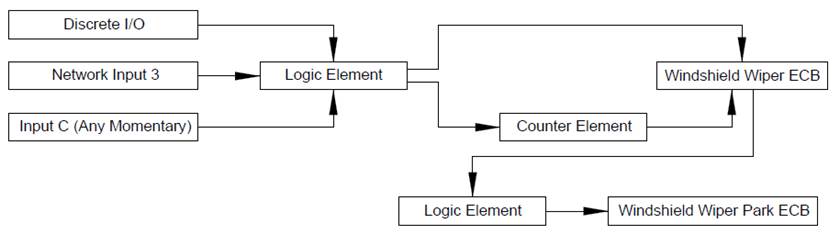

long as the signal is a momentary type of Input Signal. The mapping for this

exact circuit would look as shown below:

For

further information about Maretron’s MPower Digital Switching solutions, please

visit,

https://www.maretron.com/